Page 1

Modular

powerchair control system

DX SYSTEM MANUAL

MT

Page 2

About this Manual

This manual can help you understand and install the Dynamic Controls DX System.

It describes the general principle, but it gives no guidelines for specific applications. If there is a

specific requirement for your application, please contact Dynamic Controls or one of the sales

and service agents, to assist you.

This manual must be read together with all other relevant DX Module or DX component

manuals, as well as all applicable Dynamic TSBs, application notes and service instructions.

In this manual there are a few symbols that will help you quickly identify the purpose of the

paragraph that follows:

Notes & Precautions:

Notes provide supporting information for the previous paragraph or section

that should be followed in order to install, configure, and use the product

safely and efficiently.

Warnings:

Warnings provide important information for the previous paragraph or

section that must be followed in order to install, configure, and use the

product safely and efficiently.

The term ‘programming’ used in this manual refers to adjusting parameters and configuring

options to suit an application. ‘Programming’ does not change or alter any software within the

controller and is performed using a controlled programming tool available only to authorised

personnel.

The term ‘accessory’ used in this manual refers to equipment that is ancillary to the main

functioning of the DX system. It does not refer to an accessory of the powerchair. The

DX System is a component of the powerchair.

DX is not user serviceable. Specialised tools are necessary for the repair of any component.

Do not install, maintain or operate this equipment without reading, understanding and

following this manual – including the Safety and Misuse Warnings – otherwise injury or damage

may result. This manual contains integration, set-up, operating environment, test and

maintenance information needed in order to ensure reliable and safe use of the DX System.

Due to continuous product improvement Dynamic reserves the right to update this manual. This

manual supersedes all previous issues, which must no longer be used.

Dynamic reserves the right to change the product without notification.

Any attempt to gain access to or in any way abuse the electronic components and

associated assemblies that make up the powerchair system renders the manufacturer’s

warranty void and the manufacturer free from liability.

Dynamic, the Dynamic logo and the DX logo are trademarks of Dynamic Controls. All other

brand and product names, fonts, and company names and logos are trademarks or registered

trademarks of their respective companies.

Dynamic owns and will retain all trademark rights and Dynamic or its licensors own and will

retain all copyright, trade secret and other proprietary rights, in and to the documentation.

All materials contained within this manual, in hard-copy or electronic format, are protected by

copyright laws and other intellectual property laws.

© Copyright 2007 Dynamic Controls. All rights reserved

Page 3

MT

3

Contents

1 Introduction to the DX System .................................9

The heart of the DX System..................................................................... 9

DX System extensions............................................................................... 9

DX System connections ........................................................................... 9

One system fits all ..................................................................................... 9

2 A typical DX powerchair setup..............................10

2.1 Installation procedure................................................................... 11

2.1.1 General wiring recommendations.............................12

2.2 The batteries...................................................................................13

2.2.1 Battery type ................................................................... 13

2.2.2 Battery capacity ........................................................... 13

2.2.3 Battery charging ........................................................... 15

2.2.4 Battery protection......................................................... 16

2.2.4.1 Thermal circuit breakers................................................. 16

2.2.4.2 Battery Saver.................................................................... 16

2.2.4.3 High Voltage Rollback.................................................... 16

2.3 The motors....................................................................................... 17

2.3.1 Motor types....................................................................17

2.3.2 Motor connections ....................................................... 18

2.3.3 Motor resistance............................................................ 18

2.4 The parkbrakes............................................................................... 19

2.4.1 Parkbrake types............................................................. 19

2.4.2 Parkbrake configurations............................................. 19

2.4.2.1 Two 24V parkbrakes – Dual, M1 and M2..................... 19

2.4.2.2 One 24V parkbrake – Single, M1 only.......................... 20

2.4.2.3 Two 12V parkbrakes........................................................ 21

2.4.3 Manual parkbrake release switch.............................. 22

2.4.4 Mechanical parkbrake release..................................22

2.4.5 Parkbrake operation and programming...................22

2.4.5.1 Electrical delay................................................................ 23

2.4.5.2 Mechanical delay........................................................... 23

3 The DX BUS ...............................................................25

3.1 The DX BUS cable........................................................................... 26

3.2 DX BUS Module connection layout............................................. 28

Page 4

GBK60348

: Issue 1 – October 2007

4

4 The DX Power Module.............................................29

4.1 General Power Module features................................................. 29

4.2 Available Power Modules............................................................. 30

4.3 Power Module programmable parameters.............................. 31

4.3.1 List of parameters.......................................................... 31

4.3.2 Motors............................................................................. 33

4.3.2.1 Current Limit.....................................................................33

4.3.2.2 Hardware Current Limit Scaler......................................33

4.3.2.3 Load Compensation....................................................... 34

Determining the motor resistance................................35

4.3.2.4 Temp Dependent Load Comp..................................... 40

4.3.2.5 Veer Compensation.......................................................40

Adjusting Veer compensation with the HHP............... 41

4.3.2.6 Emergency Deceleration............................................... 41

4.3.2.7 Left/Right Motor Swap.................................................... 42

4.3.2.8 Motor Invert......................................................................42

4.3.2.9 Motor Stall......................................................................... 43

4.3.2.11 Motor Continuity Test...................................................... 43

4.3.2.12 Maximum Motor Volts..................................................... 44

4.3.2.13 Input Demand Scaler ..................................................... 44

4.3.3 Park Brakes..................................................................... 45

4.3.3.1 Park Brake......................................................................... 45

4.3.3.2 Brake / Bridge Off Delay ................................................ 45

4.3.3.3 Test Park Brake Driving.................................................... 45

4.3.4 Battery............................................................................. 46

4.3.4.1 Battery Guess...................................................................46

4.3.4.2 Voltmeter Battery Gauge .............................................. 46

4.3.4.3 Slow Batt Time Scale Driving.......................................... 46

4.3.4.4 Batt Gauge Ramp Rate.................................................47

4.3.4.5 Batt Gauge Threshold..................................................... 47

4.3.4.6 High Voltage parameters..............................................47

4.3.4.7 Temperature Rollback.................................................... 48

4.3.4.8 Halve Turning Gain.......................................................... 48

5 The DX Master Remote ...........................................49

5.1 Introduction.................................................................................... 49

5.1.1 The User Control Module (UCM).................................50

5.1.2 The physical user interface.......................................... 50

5.2 Available Master Remotes........................................................... 51

5.2.1 Master Remotes with joystick ...................................... 51

5.2.2 Master Remotes without joystick ................................52

5.3 Programmable parameters......................................................... 53

5.3.1 Speed and acceleration principles........................... 53

5.3.1.1 Speed Demand............................................................... 53

5.3.1.2 Speed limiting options.................................................... 54

5.3.1.3 Acceleration and deceleration.................................... 56

Damping Point................................................................. 57

Soft-Start Acceleration ................................................... 57

Page 5

MT

5

5.3.2 Drive Profiles...................................................................58

5.3.2.1 The principle..................................................................... 58

5.3.2.2 Drive Profile 0.................................................................... 59

5.3.2.3 Speed setting recommendations................................. 59

Programming Drive Profiles as a digital Speed Pot.... 59

Programming Drive Profiles for different environments

............................................................................................ 60

5.3.2.4 Single Drive Profile mode...............................................60

5.3.3 Two or more joysticks: choosing the joystick source 61

5.3.4 Reducing the movement to operate the joystick...61

5.3.5 Chair stability ................................................................. 61

5.3.6 List of parameters.......................................................... 62

5.3.7 Drive Profiles parameters............................................. 65

5.3.7.1 Forward Speed @ Maximum ......................................... 66

5.3.7.2 Forward Speed @ Minimum........................................... 66

5.3.7.3 Forward Acceleration..................................................... 66

5.3.7.4 Forward Deceleration..................................................... 66

5.3.7.5 Reverse Speed @ Maximum.......................................... 67

5.3.7.6 Reverse Speed @ Minimum...........................................67

5.3.7.7 Reverse Acceleration..................................................... 67

5.3.7.8 Reverse Deceleration..................................................... 67

5.3.7.9 Turning Speed @ Maximum...........................................68

5.3.7.10 Turning Speed @ Minimum............................................. 68

5.3.7.11 Turning Acceleration ...................................................... 68

5.3.7.12 Turning Deceleration ...................................................... 68

5.3.7.13 Non-Linear Turn................................................................ 69

5.3.7.14 Short Throw Travel / Short Throw Shape....................... 70

5.3.7.15 Grip.................................................................................... 72

5.3.7.16 Damping Point / Turn Damping / Speed Damping... 73

5.3.7.17 Min To Max Decel Ratio ................................................. 73

5.3.7.18 Chair Stability Parameters.............................................. 74

5.3.7.19 Steering stability parameters......................................... 78

5.3.8 Drive Profile Options parameters................................ 80

5.3.8.1 Maximum Profile Number............................................... 80

5.3.8.2 Wrap Profiles..................................................................... 81

5.3.8.3 Change Profile While Driving......................................... 81

5.3.8.4 Allow Non-Driving Profile ................................................ 82

5.3.8.5 Sleep Timeout .................................................................. 82

5.3.8.6 Soft-Start Time .................................................................. 82

5.3.8.7 Joystick Source................................................................83

5.3.8.8 Joystick Swap Forward / Reverse ................................. 84

5.3.9 General User Options parameters.............................. 85

5.3.9.1 Chair Speed.....................................................................85

5.3.9.2 Soft-Start Acceleration ................................................... 85

5.3.9.3 Neutral Maximum............................................................ 85

5.3.9.4 Disable OONAPU Faults.................................................. 86

5.3.9.5 Speed Pot Scaler............................................................. 86

5.3.9.6 Drive Delay After Power-up........................................... 87

5.3.9.7 Lock Enable...................................................................... 87

5.3.9.8 Sleep Mode Enable ........................................................ 87

5.3.9.9 Power-up Profile Number............................................... 88

5.3.9.10 Enable Joystick Wakeup................................................ 88

Page 6

GBK60348

: Issue 1 – October 2007

6

5.3.10 System Settings parameters........................................ 89

5.3.10.1 CLAM Slowdown............................................................. 89

5.3.10.2 Neutral to PB Delay......................................................... 90

5.3.10.3 Chair Speed Enable........................................................ 90

5.3.10.4 Single Profile Mode ......................................................... 91

5.3.10.5 CANH Power Switch........................................................ 91

5.3.10.6 CAN Terminator...............................................................91

5.3.10.7 UCM Joystick Swap Left/Right....................................... 92

5.3.10.8 Rotate UCM Joystick....................................................... 92

5.3.10.9 ACU Enable...................................................................... 92

5.3.10.10 ACU Joystick Swap Left/Right ....................................... 93

5.3.10.11 ACU has Momentary Switch.......................................... 93

5.3.10.12 ACU Momentary Switch Timeout.................................. 93

5.3.10.13 RJM Enable....................................................................... 94

5.3.10.14 RJM Joystick Swap Left/Right........................................94

5.3.10.15 RJM has Analog Joystick................................................ 94

5.3.10.16 Joystick Switch Threshold ............................................... 96

6 DX Modules .............................................................97

6.1 Introduction.................................................................................... 97

6.1.1 The GPSB/SLIO ............................................................... 97

6.2 Secondary Remotes...................................................................... 98

6.2.1 Available Secondary Remotes................................... 98

6.3 DX Steering/Actuator/Lighting Modules.................................... 99

6.4 DX Environmental Control Modules..........................................100

6.5 DX Auxiliary Modules...................................................................100

6.6 Programmable parameters.......................................................101

6.6.1 Actuator Settings (CLAM/TAM)................................. 103

6.6.1.1 CLAM Enable.................................................................103

6.6.1.2 CLAM is Critical.............................................................. 103

6.6.1.3 Actuator While Driving.................................................. 103

6.6.1.4 Actuator 1 - 5 Enable.................................................... 104

6.6.1.5 Actuator 1 - 5 Current Limit.......................................... 104

6.6.1.6 Actuator Timeout .......................................................... 105

6.6.1.7 Actuator Open Circuit Test.......................................... 105

6.6.1.8 Joystick Actuators ......................................................... 105

6.6.1.9 Actuator buttons are bi-directional ........................... 106

6.6.2 Lighting Settings (CLAM/LM/LMZ).............................106

6.6.2.1 CLAM Lighting Enable..................................................107

6.6.2.2 Lighting Module Enable ............................................... 107

6.6.2.3 Lighting Module is Critical............................................107

6.6.2.4 Side Lights Enable.......................................................... 108

6.6.2.5 Indicators Enable........................................................... 108

6.6.2.6 Hazard Lights Enable .................................................... 108

6.6.2.7 Remember Hazard State ............................................. 108

6.6.3 Remote Control Settings (ARC/RSM)....................... 109

6.6.3.1 ARC Enable....................................................................109

6.6.3.2 ARC Always Drives Actuators 1&2.............................. 109

6.6.3.3 ARC Drives Actuators 1&2 in Profile 0......................... 109

6.6.3.4 ARC Drives Actuator 3, 4, 5.......................................... 110

6.6.4 Environment Control Settings (ECU1/ECU2)............ 111

6.6.4.1 ECU Enable..................................................................... 111

6.6.4.2 ECU Channel ENABLE ................................................... 111

Page 7

MT

7

7 DX programming...................................................113

7.1 Programming tools ...................................................................... 114

7.1.1 The Hand Held Programmer (HHP)........................... 114

7.1.1.1 HHP Technician Mode.................................................. 114

7.1.2 The PC-based Wizard program ................................115

7.1.2.1 Dongle versions.............................................................. 115

7.1.3 Programming accessories ordering information.... 116

7.2 Localised parameter storage....................................................117

7.3 Auto Download............................................................................ 118

7.4 Programming and testing a DX chair for stability................... 119

7.5 Retain the settings with a Master Remote replacement ...... 125

7.5.1 Replacement with the same type Master Remote125

7.5.2 Replacement with another type Master Remote .128

8 Testing ....................................................................130

8.1 Before testing................................................................................ 130

8.2 The testing procedure................................................................. 130

9 Diagnostics ............................................................133

9.1 Limp Mode.................................................................................... 133

9.2 Stuck Power Button...................................................................... 133

9.3 Out Of Neutral At Power Up (OONAPU).................................. 134

9.4 Diagnostic tools............................................................................ 134

9.5 Battery warning conditions ........................................................135

9.6 Flash codes...................................................................................136

10 Appendices ...........................................................139

10.1 Intended Use and Regulatory Statement................................ 139

10.2 Maintenance................................................................................ 140

10.3 Warranty........................................................................................ 140

10.4 Safety and Misuse warnings....................................................... 141

10.5 Electromagnetic Compatibility (EMC).....................................143

10.6 Minimising emissions .................................................................... 143

10.7 Environmental statement........................................................... 143

Contact Details ...........................................................144

Page 8

GBK60348

: Issue 1 – October 2007

8

Page 9

MT

1 Introduction to the DX System

The DX-system is a modular powerchair control system. This modularity makes it

possible to design a powerchair that can meet the requirements of any user requirements that can range from simple drive-only control to full environmental

control. Just add additional modules when requirements grow.

The heart of the DX System

The most basic DX control system consists of two parts:

A DX Power Module, connects to the battery and to the motors

A DX Master Remote

The Master Remote is the brain of the DX System. Every DX System must have one,

and only one. There are several different Master Remotes available to choose from:

with joystick, without joystick, ch in remote, attendant remote, etc.

DX System extensions

In addition to the Power Module and the Master Remote, many other remotes and

modules are available to extend the DX System, like:

• Secondary Remotes, for example: attendant remotes, sip ‘n puff, finger steering

• Switch input modules

• Lighting and Seating control modules

• Environmental control modules

The DX System can be extended to a maximum of 16 modules.

DX System connections

All modules are connected to each other by a DX BUS cable.

Most DX Modules have two DX BUS connector sockets. That way

you can connect another DX part easily.

DX BUS is an interface (the way the modules "talk" to each other) based on the CAN

interface, which is widely used in the automotive industry. CAN is well known for its

reliability and its fault detection. DX BUS inherits this reliability, and even improves on it.

One system fits all

Start out with a simp le system and add the modules you need at the time they

become available, or when the application requirements grow. See the Dynamic

Controls pr oduct catalogue for the latest a dditions to the product range.

9

Page 10

2 A typical DX powerchair setup

A standard powerchair installation with the DX System consists of the following

electrical parts:

The Batteries (section 2.2)

The Motors (section 2.3)

The Parkbrakes (section

2.4)

A DX Power Module (chapter

4)

A DX Master Remote (chapter

5)

The DX BUS cables (section

3.1)

Optional: Actuator or Lighting Modules (chapter

6)

P

PB1

M1

P

PB2

M2

P

To HHP

or Wizard

24V Batter

y

DX Master Remote

To Battery

Charger

DX Power Module

DX BUS

GBK60348

: Issue 1 – October 2007

10

Page 11

MT

2.1 Installation procedure

To install the DX System safely:

• First read and understand the DX System manual and the manuals of all the

used DX components.

• Mount all the electrical parts o f the powerchair setup (motors, parkbrakes,

batteries, DX Modules and remotes) on the powerchair. See the manuals of

the used DX Modules for the physical dimensions and mounting

recommendations.

• Do not connect any cables before all the parts of the DX System are

mounted.

• Connect the DX Power Module to the rest of the DX System with the DX BUS

cables (see section

2.1.1 for general wiring recommendations).

• Cover any unused DX BUS sockets with a GME64909 DX BUS Connector Cover.

• Conn ec t the DX Power Mo dul e to the mo tors ( see secti on

2.3.2) and the park

brakes (see section

2.4.2).

• Connect the DX Power Module to the batter ies (see section

2.2.4.1).

Do not turn on the DX System yet.

• Lift the powerchair off the ground and check the installation thoroughly

(see section

8.1)

• Program the system to the requirements of a particular powerchair or user

(see chapter

7).

• Test the system for functionality and safe ty (see chapter

8).

Warning:

Do not connect the '+' terminal of the battery to the DX System until

the powerchair is completely wired and ready for testing as

described in the

Testing section (chapter 8).

11

Page 12

2.1.1 General wiring recommendations

• Keep all cables as short as possible.

• Try to run wires in pairs or bunches.

• Do not route the motor cables near the motor case, where possible.

• Avoid wire loops, especially loops of single wires instead of wire pairs.

• Fasten cables to the powerchair frame to prevent strain on the connectors.

• Do not leave electrical connections unnecessarily exposed.

• Make sure that all vehicle sub-frames are electrically connected.

• To minimise electromagnetic emissions by the motor brushes, it may be necessary

to fit capacitors between the brush hold ers and the motor case. Make sure that

the leads are kept as short as possible. A suitable capacitor is 4n7, 250V

Polypropylene.

• For low-current signals, do not use wire sizes smaller than 0.5 mm

2

/AWG20, because

smaller wires are physically not strong enough for this application.

• For best electrical performance, the wire size must be as large as possible.

Maximum Wire

Current

Recommended

Minimum Wire Size

Power Module

60A 3 mm2 / AWG 12

80A 4 mm2 / AWG 11

100A 6 mm2 / AWG 9

The Power Module wire sizes above are appropriate for cable lengths up to

400 mm / 15". For longer cables, increase the wire si ze by 0.5 mm

2

for every

additional 200 mm / 7.5" in length. G enerally, the larger the wire size, the better the

powerchair performance will be.

• Do not use damaged or abused cables. A damaged cable can potentially

produce localised heat, sparks or arcing and as such it can cause a fire.

• Protect all cables against possible contact with flammable material.

• Where possible, the installation must prevent and/or discourage the user to

disconnect the DX BUS cable.

Warning:

1. Route the cables and fasten all DX components in a position so

that the cables, the connectors and the connector sockets do not

allow water entry or suffer from physical strain, abuse or damage,

like cutting or crushing. Take particular care on powerchairs with

movable structures like seat raise/tilt or swing-away arms. Make

sure that the cables do not extend from the powerchair so that

they can not be caught or damaged by external objects.

2. The DX BUS cable distributes 24V power to the DX modules, even

when the system is switched off. Avoid short circuit between the

DX BUS cable pins whenever a DX BUS connector is removed from

its socket. Make sure that the DX BUS connector can not reach

potential shorting points. If any protruding, bare metal screws or

pins are within reach of a DX BUS cable end, cover or plastic-coat

them to make sure that they do not cause short circuits between

DX BUS cable pins. Disconnect all the cables of the powerchair at

the powered end whenever units are replaced or moved.

3. The user maintenance schedule and the service instructions of the

powerchair must include the appropriate inspection and

maintenance requirements for the connectors and the cables.

GBK60348

: Issue 1 – October 2007

12

Page 13

MT

2.2 The batteries

The batteries provide the energy for the powerchair to drive. The batteries

are connected to the DX Power Module. The DX Power Module sends the

energy of the batteries to the motors and to the other modules.

The batteries must be operated and maintained according to the instructions of the

battery manufacturer.

2.2.1 Battery type

• 24V (commonly 2 x 12V)

• Lead -Acid / Deep Cycle Gel Cell

• Rated capacity: 20 – 120 Ah (dependent on application and Power Module)

2.2.2 Battery capacity

Choose a battery capacity that is compatible with the intended use. This ensures that

the required chair range and/or operating time is achieved.

The rated capacity in Ampere-hours (Ah) of a battery is usually specified for a 20 hour

discharge rate (or 0.05 CA, a current of 5% of the rated capacity). A higher

continuous discharge current dramatically reduces the available battery capacity.

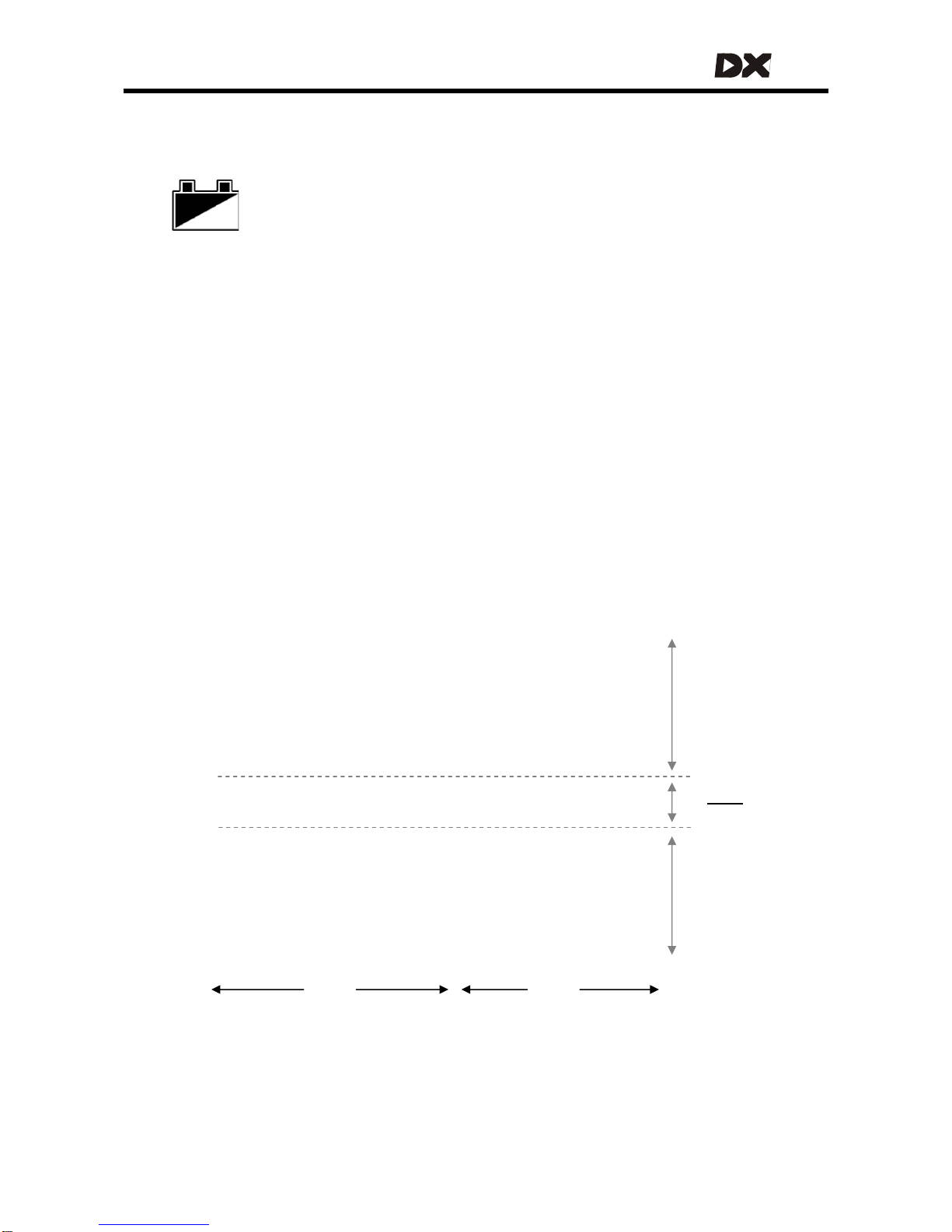

As the graph shows, when the discharge current equals the rated capacity (1 CA),

DX Saver

active (2.2.4.2)

1 2 4 6 8 10 20 40 60 2 4 6 8 10 20

Typical discharge times for lead acid batteries

Hours Minutes

Discharge time

26

22

20

18

16

24

Normal

operation

Battery

fault

Battery voltage (V)

13

Page 14

the battery does not last the expected one complete hour, but only 30 minutes,

giving an actual available capacity of only 50%.

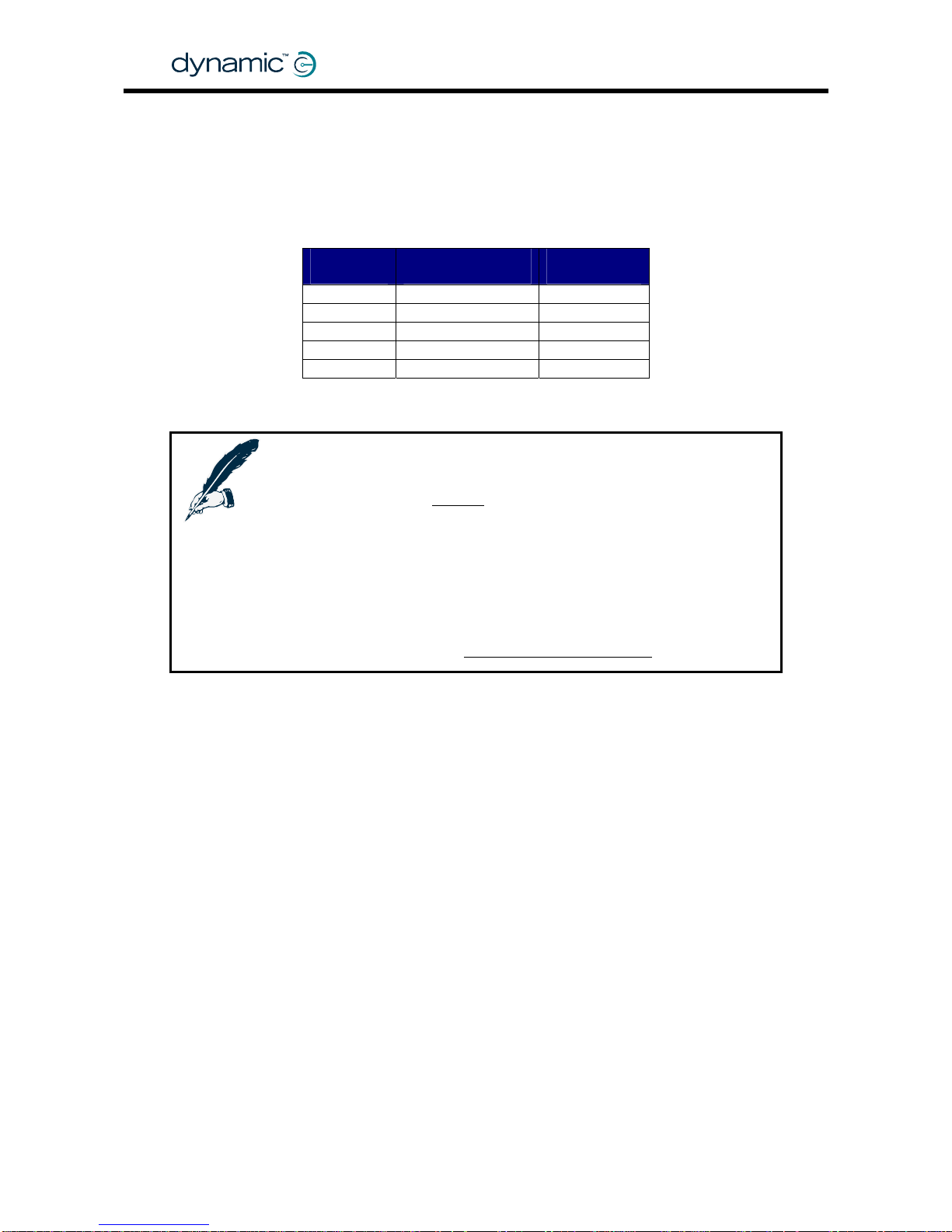

Rated

capacity

Average

discharge current

Actual

capacity

20 Ah 40 A (2 CA) 5 Ah (25%)

20 Ah 20 A (1 CA) 10 Ah (50%)

20 Ah 12 A (0.6 CA) 12 Ah (60%)

20 Ah 8 A (0.4 CA) 15 Ah (75%)

20 Ah 1 A (0.05 CA) 20 Ah (100%)

Notes:

1. Dynamic Controls recommends to use batteries with a

capacity that is

at least twice as high as the average

discharge current.

2. New batteries often start with only 80% of their rated capacity.

After a few charging cycles the capacity will increase to 100%.

3. Deep discharging or overcharging dramatically decreases the

capacity of the battery. This damage is permanent, the battery

will never return to its original capacity.

See also section

9.5: Battery warning conditions.

GBK60348

: Issue 1 – October 2007

14

Page 15

MT

2.2.3 Battery charging

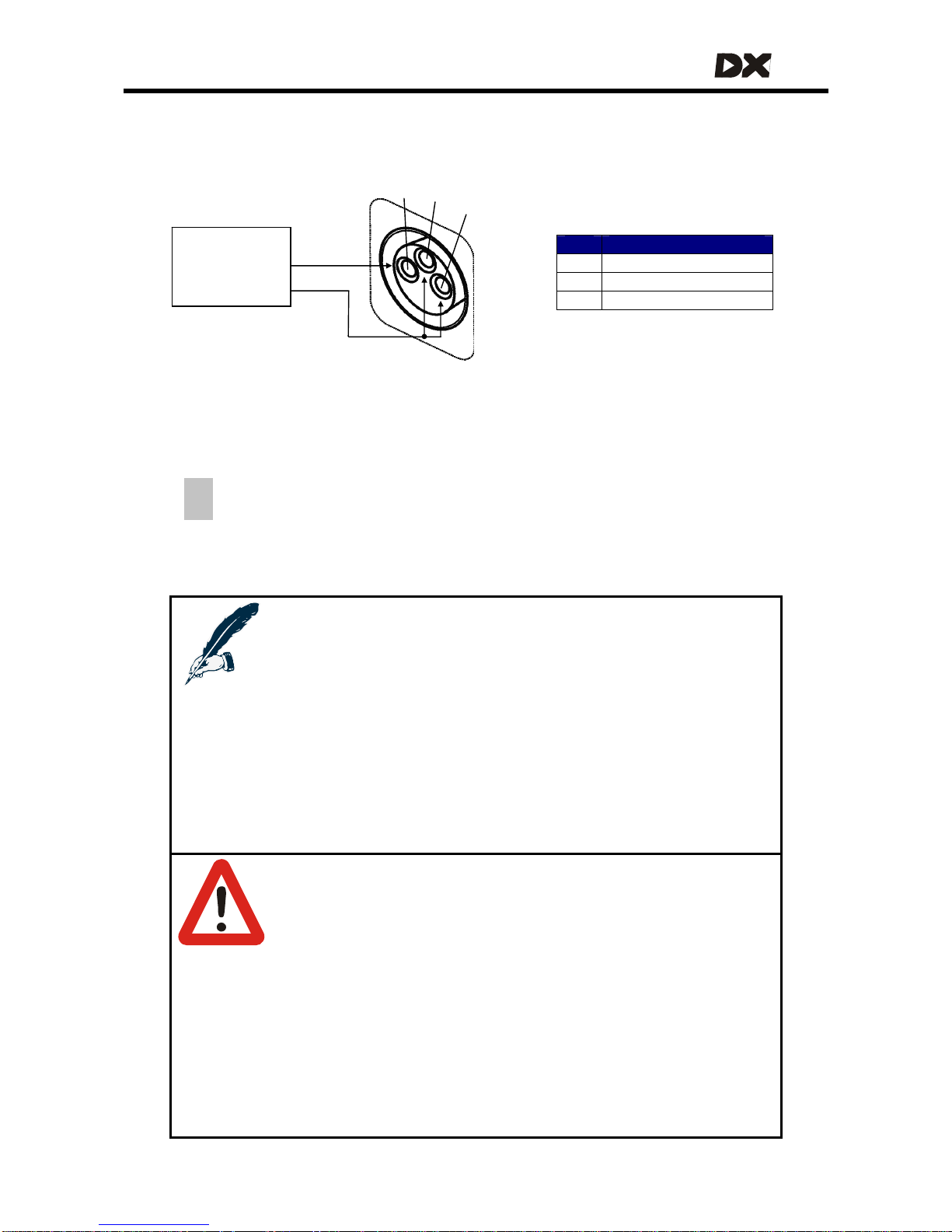

The battery charging socket of the DX System is a 3-pin XLR type normally located on

the DX Master Remote.

1

3

2

Battery

charger

Pin Signal

1 Battery Positive (B+)

2 Battery Negative (B-)

3 Drive Inhibit

B+

B-

The Drive Inhibit signal makes sure that the powerchair does not drive when the

batteries are being charged. This signal must be provided within the battery charger

plug as a connection between pin 2 and pin 3. Ensure that the battery charger is

compatible with this configuration before connecting it to the charging socket.

When turned on during charge, DX Master Remotes that have a 7-segmen t

display will show a dash to indicate that the powerchair is inhibited to drive. It

is still possible to use accessory functions like actuators.

Once the Battery Charger displays a ‘full’ battery charge, the battery charger plug

may be removed.

Notes:

1. For the exact location of the battery charging socket, see the

manual of the Master Remote that is used.

2. It is recommended to leave the system off while charging when

possible. A load during charging – especially a large load like

the use of actuators - can cause some battery chargers to think

that the battery is more empty than that it actually is.

Dependent on the specifications of the battery charger, this

can result in overcharging and possible battery damage. Read

the manual of the used battery charger for more information.

3. Overcharging dramatically decreases the lifespan of a battery.

Warnings:

1. Do not disconnect the batteries or open the circuit breaker

during charging. See the manual of the battery charger for

more information.

2. If during charging the battery gauge starts to flash to indicate

an overvoltage condition, immediately turn off either the

battery charger or the DX System.

3. To remove the charger plug, pull in the direction of the cable.

Do not try to turn the plug.

4. The battery charger used must be correctly selected and

adjusted according to the instructions of the battery

manufacturer. Failure to do so can damage or destroy the

batteries, give poor range, or be potentially dangerous.

15

Page 16

2.2.4 Battery protection

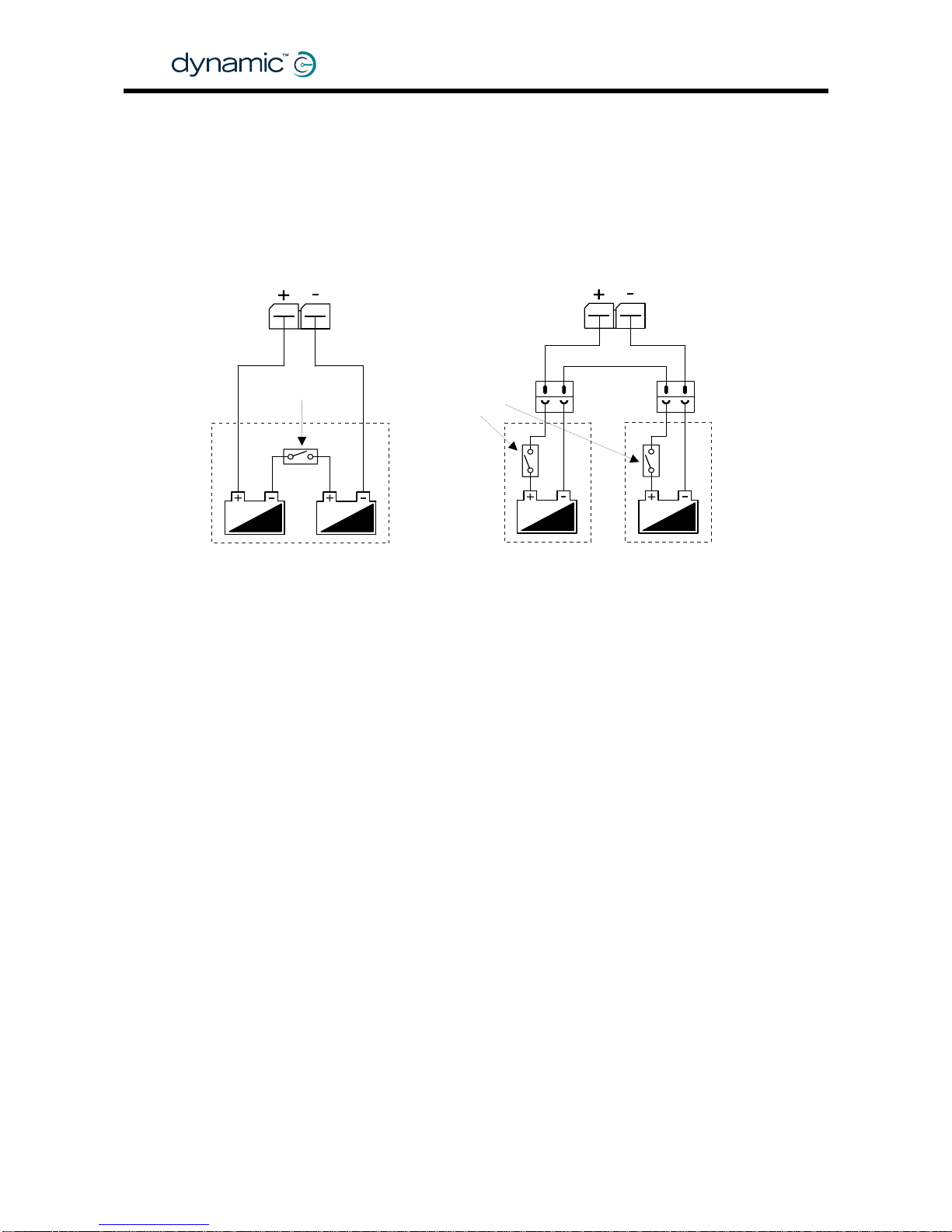

2.2.4.1 Thermal circuit breakers

To protect the batteries and the system cables f rom external short circuits, a therma l

circuit breaker or fuse must be installed between the batteries and the rest of the

system - as close as possible to the batteries. If the two batteries are permanently

wired together in a single battery box, the best position for the circuit breaker is

between the two batteries. If the batteries are separated in individual battery boxes,

each battery requires its own circuit breaker.

The circuit breaker or fuse must be of the slow acting type. The rating of the circuit

breaker must be appropriate for the power requirement, inclu ding the total weight of

the chair, the battery capacity and the wiring.

GBK60348

: Issue 1 – October 2007

16

2.2.4.2 Battery Saver

If the battery Voltage falls below 21V, the DX System reduces the performance of the

powerchair. This

• pro tects th e battery

• gives the powerchair a longer range before the battery is completely empty

• gives the user a physical warning that the battery is almost empty before

the battery is damaged.

2.2.4.3 High Voltage Rollback

High Voltage Rollback is a battery protection feature that is especially useful for users

who have to drive downhill often.

When a powerchair drives downhill, the Power Module sends the generated motor

current to the battery. However, if the battery is fully charged already, it can not

accept the generated current anymore. This causes the battery voltage to become

too high, which can cause damage to the battery or the controller.

High Voltage Rollback gradually decreases the speed of the powerchair until the

battery can accept more current. The deceleration of the powerchair gives a timely

physical wa rning to the us er to take corrective acti o n , like turni ng on the lights or

slowing down.

High Voltage Rollback can be enabled wi th the Wizard (see

4.3.4.6).

Single Battery Box

Thermal Circuit

Breake

r

Separate Battery Boxes

Thermal Circuit

Breake

r

s

Page 17

MT

2.3 The motors

The wheel motors control the powerchair speed and direction. The motors are

connected to the DX Power Module.

Note:

If one of the motors is not connected to the DX Power Module, the

DX System detects a Motor Fault (see

9.6) and prevents driving.

2.3.1 Motor types

Drive motor

type

Motor

resistance

Current Power

Module

Min. wire size

2 x 60A DX-PMB 3 mm

2

2 x 75A DX2-PMA75L 4 mm

2

2 x 80A DX-PMB2 4 mm

2

24V DC* 0 – 0.5 Ω

1 x 120A

(2x 60A

parallel)

DX-PMB-S 3 mm

2

(two wires in parallel,

each carrying 60A)

24V AC

Gearless

Brushless

N/A 2 x 100A DX-GB 6 mm

2

*12V DC motors can be used if the controller is programmed to half speed.

Notes:

1. The motor wire sizes above are appropriate for motor loom

lengths up to 400 mm. For longer looms, increase the wire size

by 0.5 mm

2

for every additional 200 mm length. Generally, the

larger the wire size, the better the powerchair performance.

2. The chosen size and length of the motor wires can affect the

optimum setting of the Load Compensation parameter (see

section

4.3.2.3).

3. Gearless Brushless motors and the DX-GB Power Module are

not covered in this manual. Any reference to motors or motor

connectors in this manual is referring to DC motors and the

applicable Power Modules. Read the DX-GB manual for more

information about the Gearless Brushless system.

Warning:

The Power Module must be correctly configured for the

applicable motor resistance with the Load Compensation

parameter, see section

4.3.2.3. Failure to set this parameter

correctly can be dangerous for the powerchair user, because

the chair can become uncontrollable.

17

Page 18

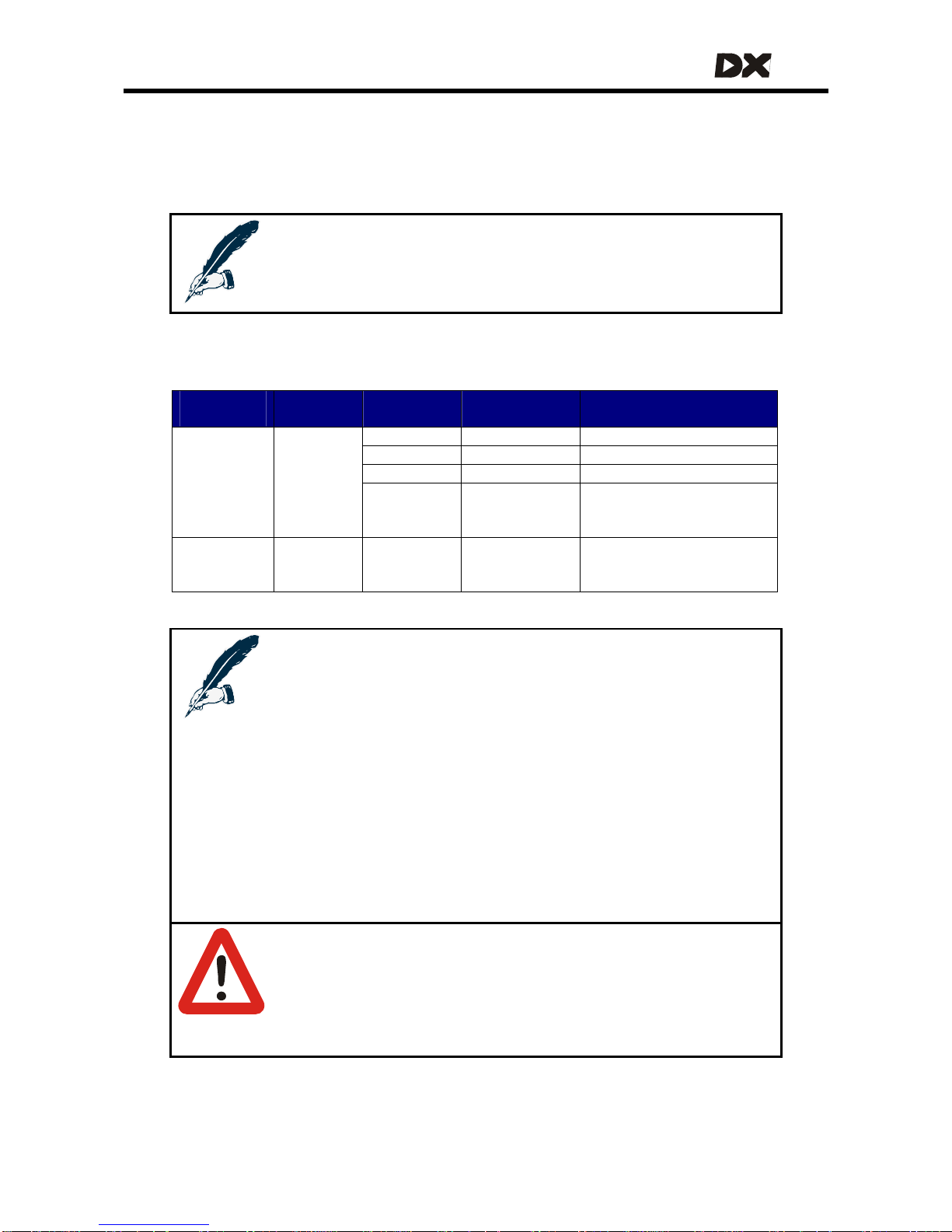

2.3.2 Motor connections

The DC motor cables must be connected to the Motor/Parkbrake connectors of the

DX Power Module.

M2 / Right M1 / Left

+

-

+

-

Notes:

1. Keep the motor cables as short as practical to minimise

voltage drops in the cable.

2. If the

Left/Right Motor Swap parameter (see section 4.3.2.7) is

set to

Swap instead of Normal, the Power Module will assign

M1 to the Right motor and M2 to the Left motor.

3. If the

Motor Invert parameter (see section 4.3.2.8) is set to Yes

instead of

No, the polarity of the + and - terminals will be

swapped.

2.3.3 Motor resistance

The resistance of different motor types varies typically between 20 and 350 mΩ.

The DX Power Module must know what the motor resistance is because the motor

resistance determines the internal voltage drop in the motor when the motor is under

high load (when the motor needs a lot of current to do a task).

If the voltage inside the motor drops too much, the performance of the powerchair

will be decreased:

• It will feel unresponsive

• It will slow down or stop when it tries to go up a slope or up a sidewalk edge.

The DX

Load Compensation feature compensates for the voltage drop in the motor.

If the motor has a high resistance, the Power Module applies a higher voltage to the

motor terminals in high load conditions. This prevents a loss of performance.

To find o ut how to determine the motor resistance and how to progr am Load

Compensation, see section

4.3.2.3.

GBK60348

: Issue 1 – October 2007

18

Page 19

MT

2.4 The parkbrakes

The parkbrakes make sure that the powerchair does not move when it is

not actively driven or when the power is turned off.

For safety, parkbrakes are always applied unless they are actively

released, either by the Power Module or manually with a parkbrake

release switch.

P

Note:

If the parkbrakes are not connected to the DX Power Module, the DX

System detects a Parkbrake Fault (see

9.6) and prevents driving.

2.4.1 Parkbrake types

• Fail-saf e ele c tro-magne tic parkbrak es attached to each motor

• 24V or 12V

• 1A – 2A maximum current per parkbrake (dependent on the Power Module used,

see the PM manual for the correct specification)

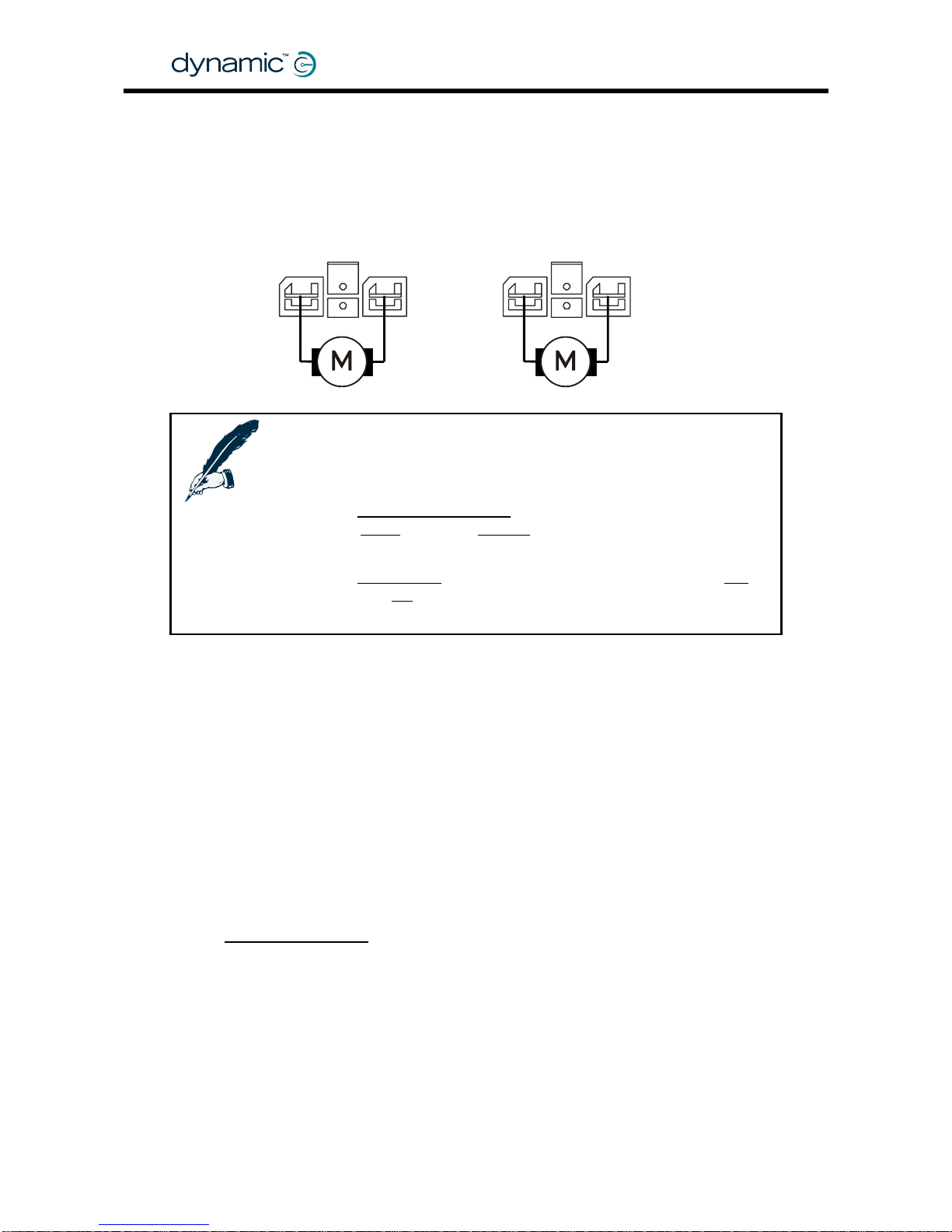

2.4.2 Parkbrake configurations

The parkbrake connection pins are located in the mo tor connectors of the DX Power

Modules.

PB+

PB-

2.4.2.1 Two 24V parkbrakes – Dual, M1 and M2

In the dual configuration each parkbrake is driven from a separate output.

For this configuration the DX Power Module

Park Brake parameter (see section

4.3.3.1) must be set to Dual.

P

P

24V

Park

Brake

24V

Park

Brake

M2

M1

19

Page 20

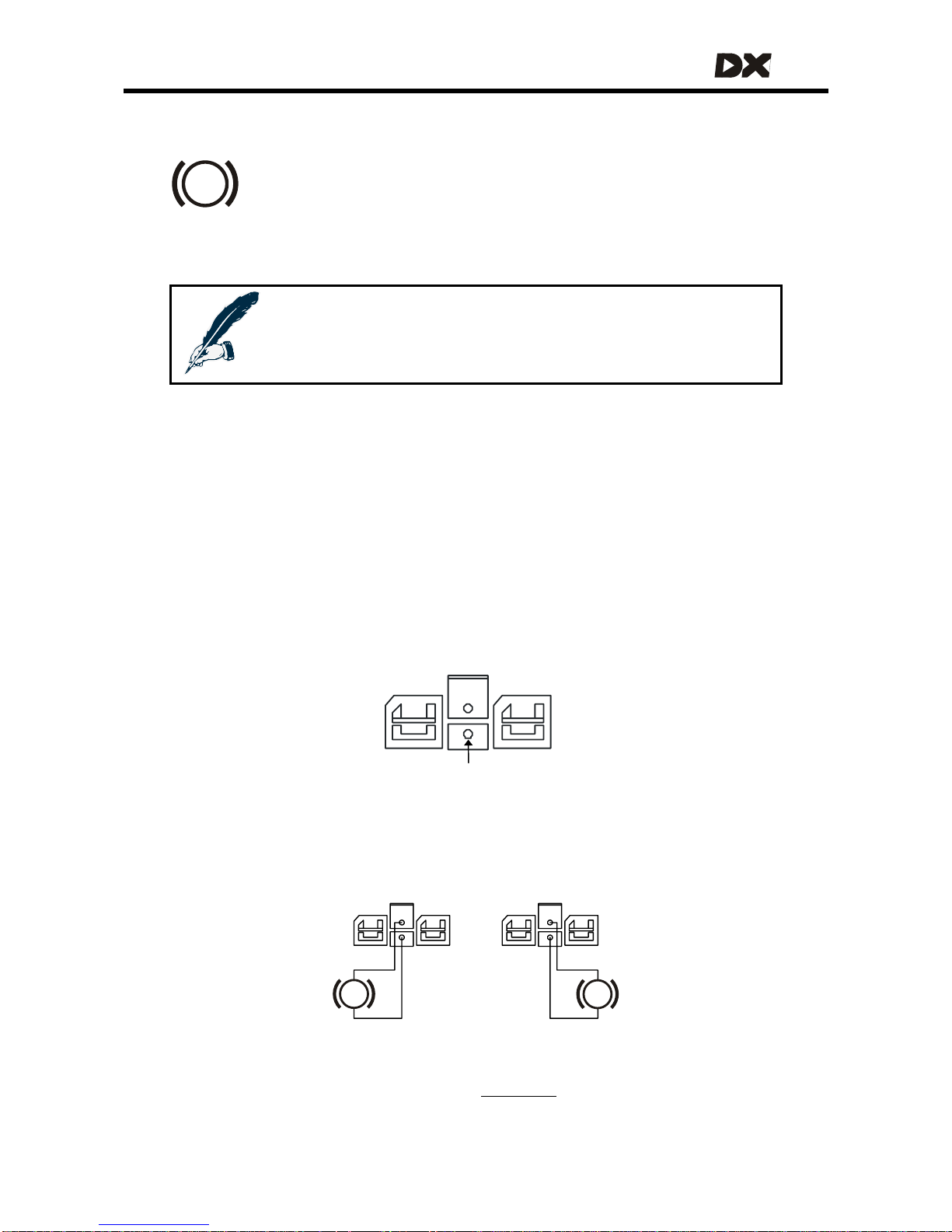

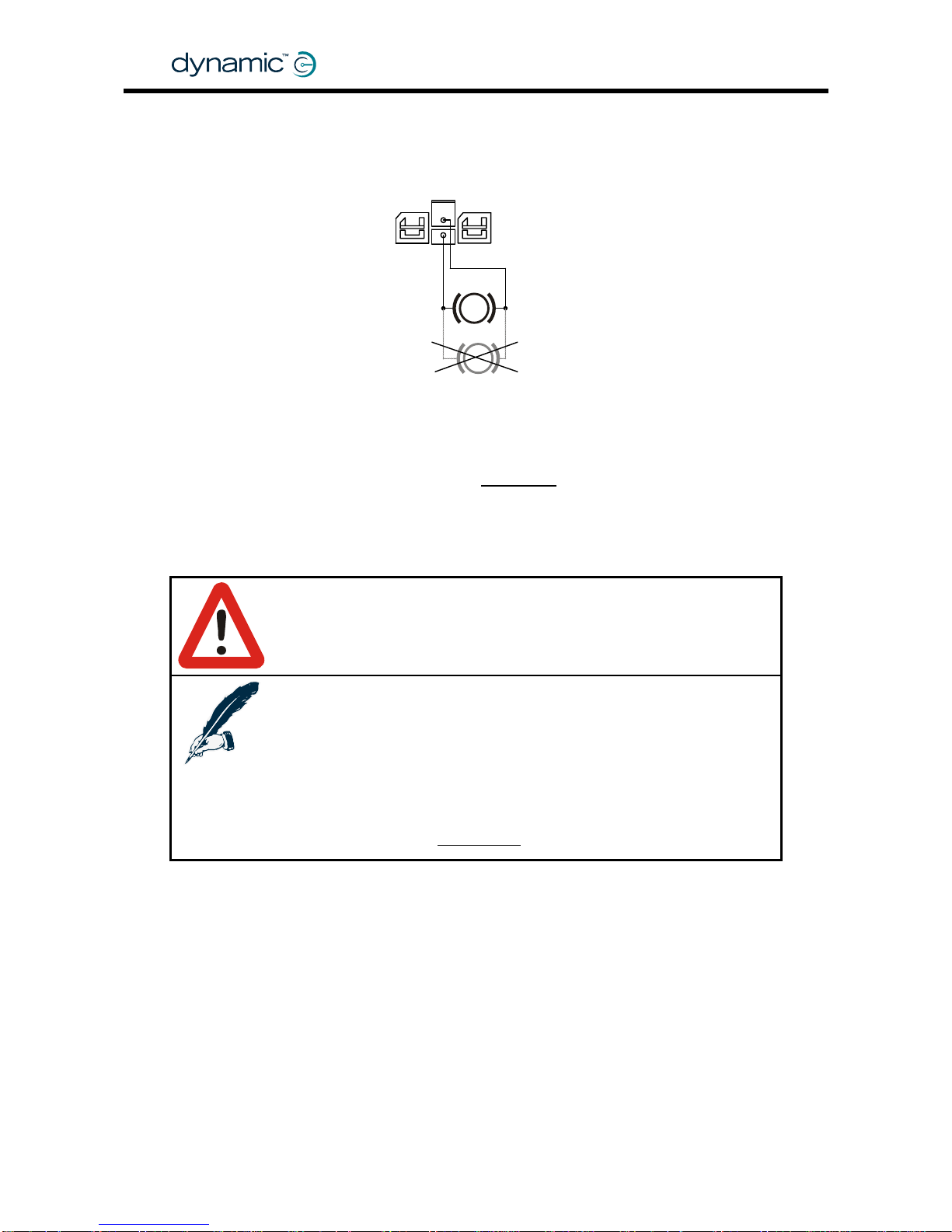

2.4.2.2 One 24V parkbrake – Single, M1 only

In the single configuration the parkbrake is driven from the M1 output only.

For this configuration the DX Power Module

Park Brake parameter (see section

4.3.3.1) must be set to Single.

Do not connect

a 2

nd

24V park-

brake like this

24V

Park

Brake

M1

P

P

Warning:

Do not connect a second 24V parkbrake in parallel to M1, because

an open circuit fault in only one of the two parkbrakes can not be

detected. Always use the dual configuration for two 24V parkbrakes.

Note:

1. If in this configuration the parkbrake is connected to M2

instead of M1, a Left Parkbrake Fault (flash code 5) will occur.

2. If the Park Brake parameter is set to Dual in this configuration

(with no parkbrake connected to M2), a Right Parkbrake Fault

(flash code 6) will occur.

See also section

9.6: Flash codes

GBK60348

: Issue 1 – October 2007

20

Page 21

MT

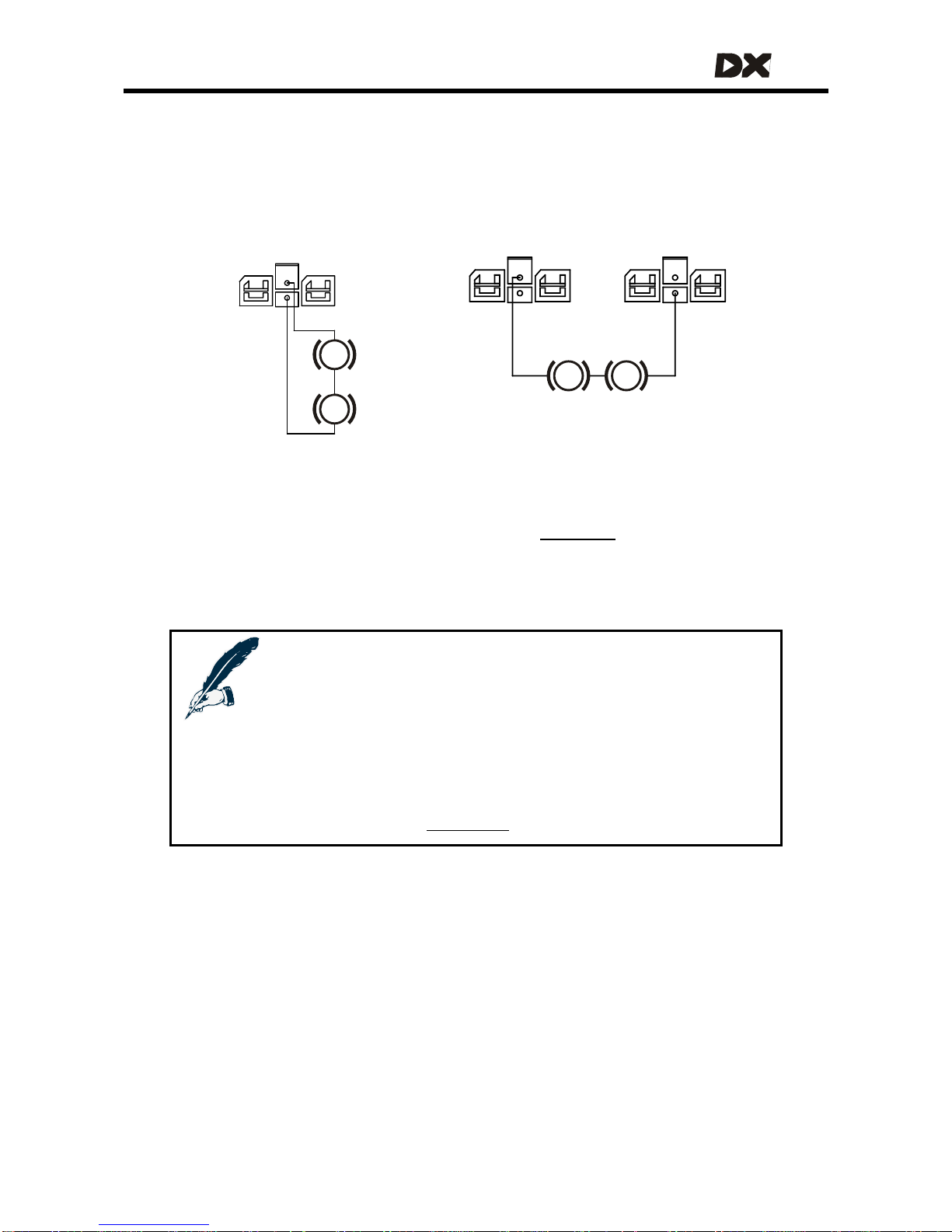

2.4.2.3 Two 12V parkbrakes

If the powerchair has two 12V parkbrakes, both can be driven from a single 24V

output by connecting the 12V parkbrakes in series. Alternatively, the 12V parkbrakes

can be connected to both parkbrake outputs. In the latter case the parkbrakes will

be driven from the PB+ output of M1.

For both these configurations the DX Power Module

Park Brake parameter (see

section

4.3.3.1) must be set to Single.

12V

Park

Brake

M1

12V

Park

Brake

M1

12V

Park

Brake

12V

Park

Brake

PB+ PB-

P

P

P P

M2

12V parkbrakes configuration 2 12V parkbrakes configuration 1

Notes:

Configuration 1: if the park brakes are connected to M2 instead of

M1, a Left Parkbrake Fault (flash code 5) will occur.

Configuration 2: if PB+ is connected to M2 instead of M1, a Left

Parkbrake Fault (flash code 5) will occur.

Both configurations: if the Park Brake parameter is set to Dual, a Right

Parkbrake Fault (flash code 6) will occur.

See also section

9.6: Flash codes

21

Page 22

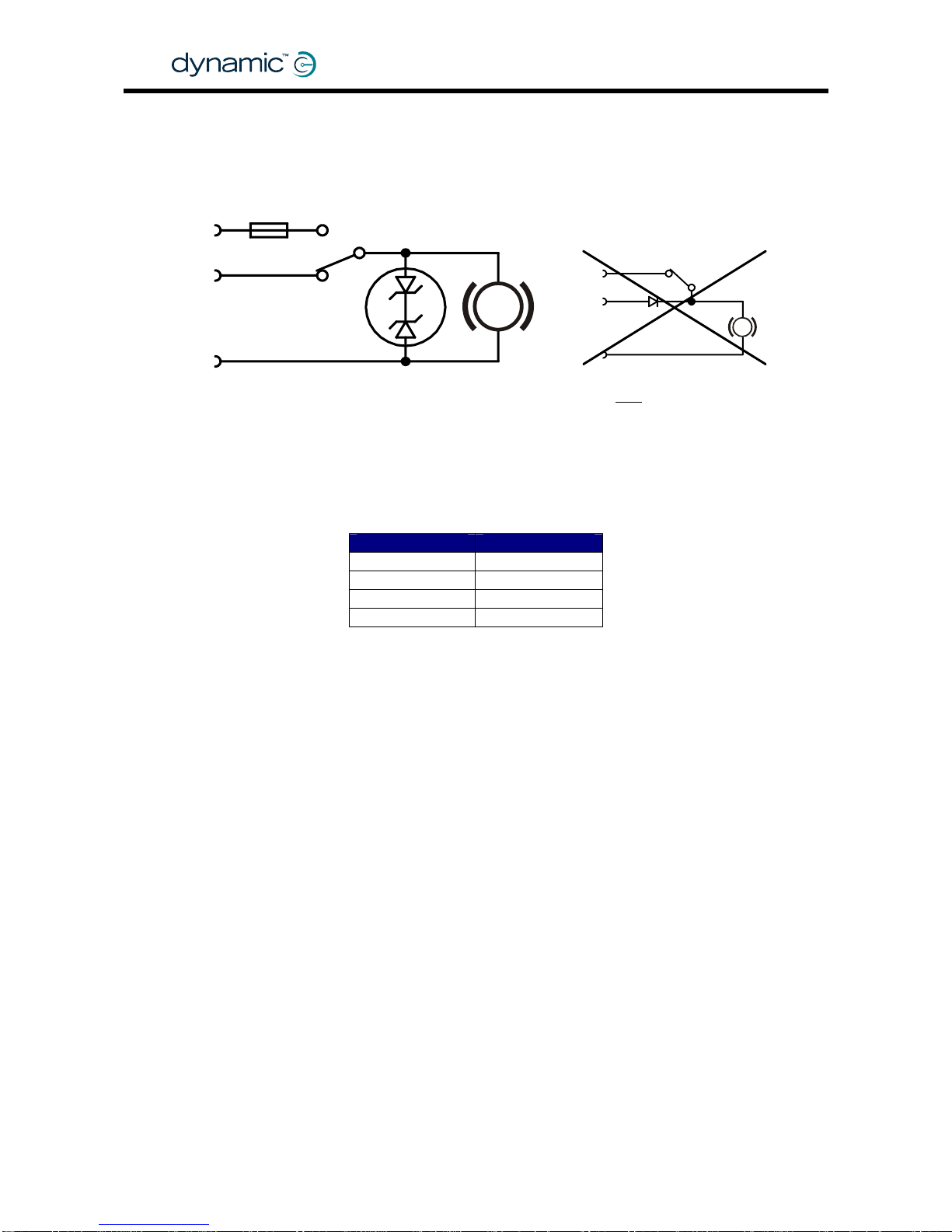

2.4.3 Manual parkbrake release switch

Manually operated parkbrake release switch es must be fitted together with a suitable

suppression device across each parkbrake.

The suppression device prevents the genera tion of high voltage transients causing

possible damage to the Power Module or to the parkbrake release switch itself.

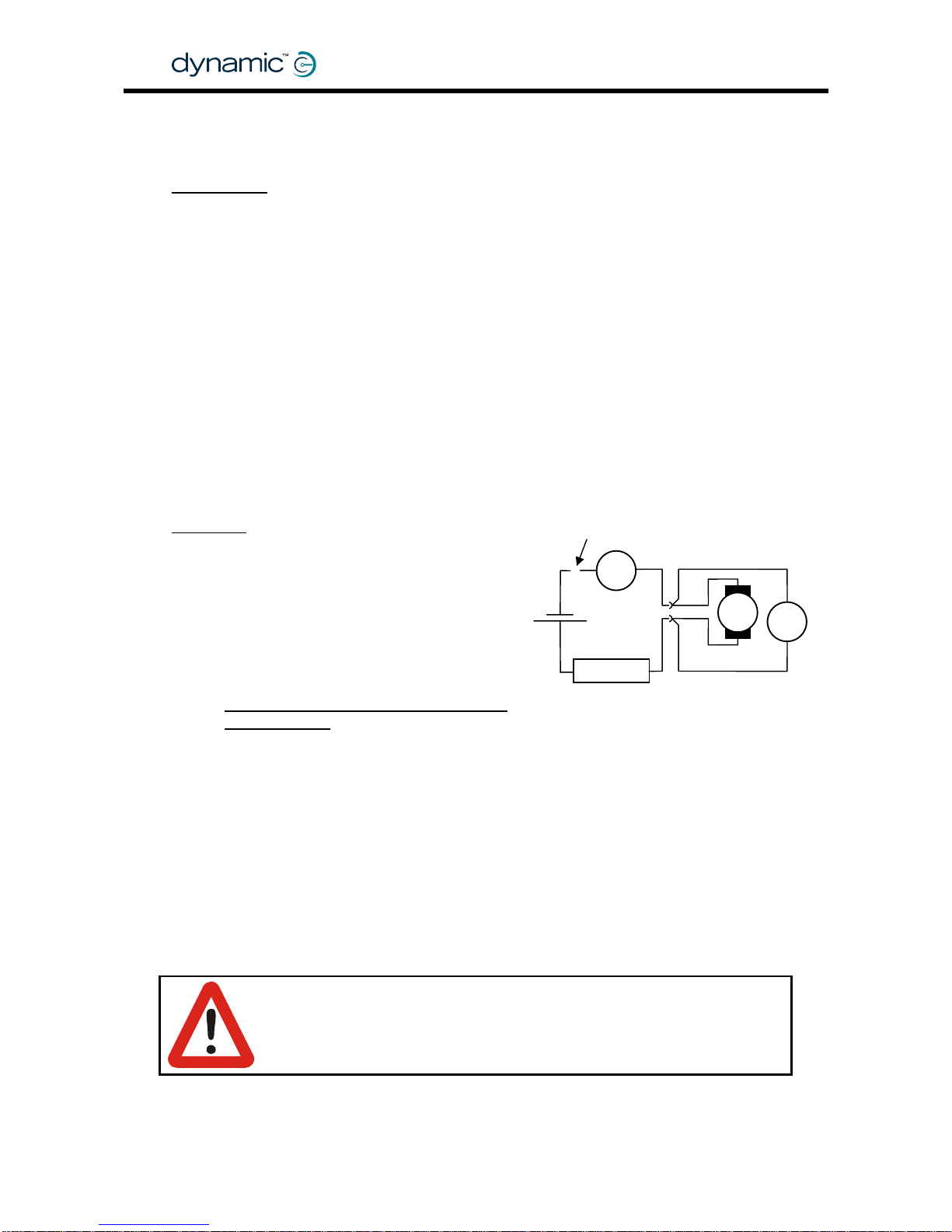

Some suitable suppression devices are:

Always fit a suppression device

2x zener diode

39V, min 2W

Surge: min 50W, 2ms

Parkbrake

PB+

Battery+

Fuse

Release

switch

PB-

Do NOT

connect like this

P

P

Motorola Philips

3EZ39D5 BZX70C36

3EZ36D5 BZX70C39

1N5365A BZT03C36

1N5366A BZT03C39

2.4.4 Mechanical parkbrake release

To make it possible to manually push the chair if the battery is empty, some form of

mechanical clutch or parkbrake release is required. For safety, if the parkbrake is

mechanically released the chair must not be able to drive.

One way to achieve this is to put a switch that disconnects the parkbrake from the

Power Module in the mechanical parkbrake release. When the parkbrake is

disconnected from the Power Module a Parkbrake Fault will occur and the

powerchair will not be able to drive.

2.4.5 Parkbrake operation and programming

For safety, parkbrakes are always mechanically applied in their electrical "off"-state.

This makes sure that the parkbrakes do not consume energy when the powerchair is

turned off. It also makes sure that the powerchair does not roll away if the battery

becomes empty on a slope.

To release the parkbrake, it must be "energised" (switched on), either by the Power

Module or manually with a parkbrake release switch.

• Energise a parkbrake to release it

• De-energise a parkbrake to apply the brake.

GBK60348

: Issue 1 – October 2007

22

Page 23

MT

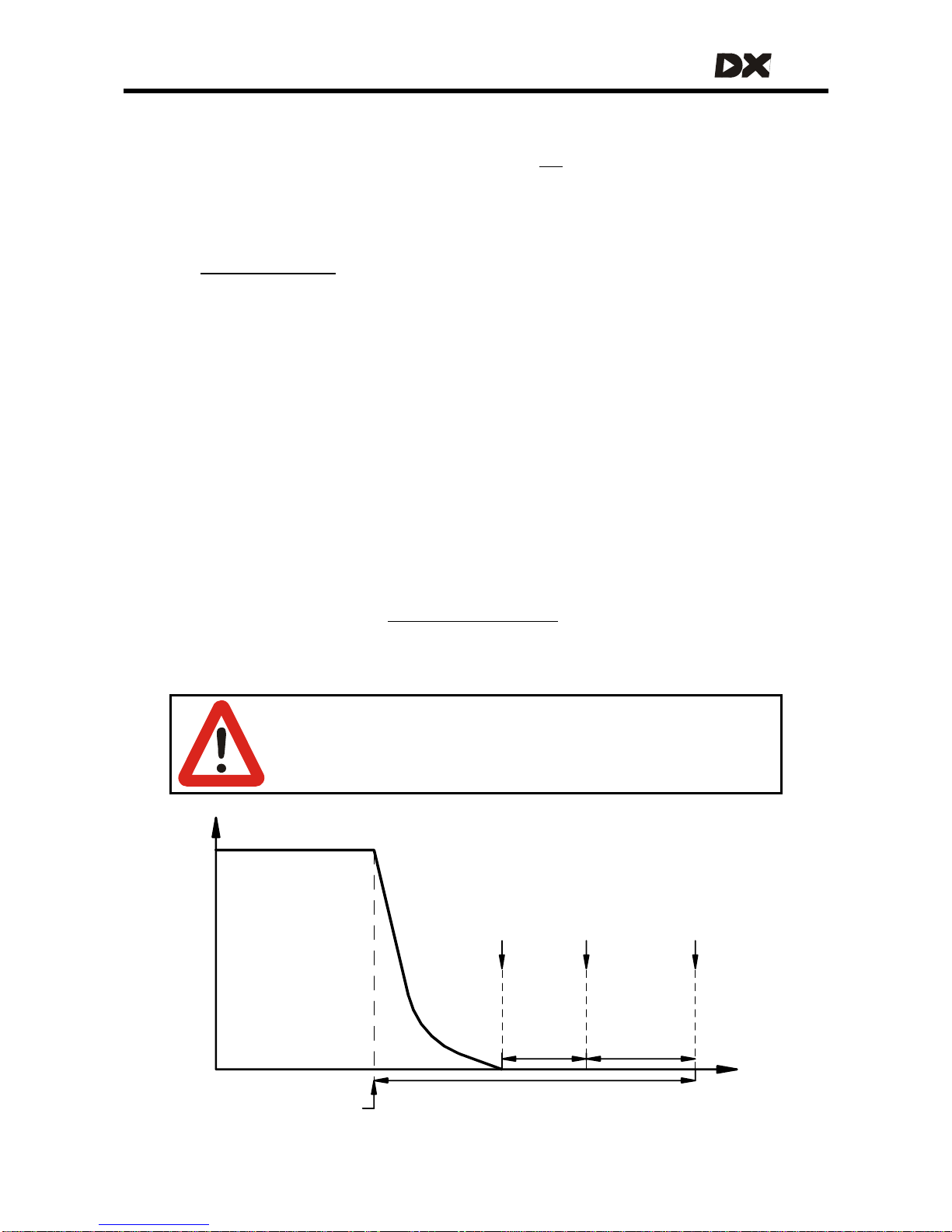

2.4.5.1 Electrical delay

When the powerchair stops, the parkbrakes will be applied. However, the parkbrakes

must not be applied too early. The parkbrakes must

not engage

• if the powerchair stops to change direction (for example forward to reverse)

• before the powerchair has come to a halt after high deceleration

• before the powerchair has come to a halt when parking on a slope

The

Neutral to PB Delay parameter (see section 5.3.10.2) is the delay between zero

speed demand and the moment that the parkbrakes are de-energised.

The correct value of this parameter is dependent o n the mechani c s o f the parkbrake

that is used on the chair. The delay must be longer for fast acting parkbrakes.

This parameter is set by the powerchair manufacturer for specific powerchair types. It

cannot be adjusted by dealers.

2.4.5.2 Mechanical delay

There is a significant delay between the moment that the parkbrake is de-energised

and the moment that the parkbrake actually engages mechanically. This delay

becomes important when the powerchair decelerates and stops. When the

powerchair has stopped, it will take some time before the parkbrakes are actually

engaged.

The Power Module uses the motors to brake and hold the powerchair during the time

that the parkbrakes are not engaged (active motor braking). The motor braking time

can be programmed with the

Brake / Bridge Off Delay parameter (section 4.3.3.2).

After the time defined in the Brake / Brid ge Off Delay parameter the Power Module

will switch off the motors.

Warning:

Make sure that the Brake / Bridge Off Delay time is greater than the

mechanical delay of the parkbrakes used. The parkbrakes must

engage before the motors turn off, or the chair will roll away.

Brake / Bridge

Off Delay

Speed

Demand

Active Motor Braking

Parkbrakes engaged

Motors switched off

Neutral to

Parkbrake

Delay

Parkbrake

de-energised

Zero

Speed

demand

decreases

according to

deceleration

parameter

Joystick returned

to the center

23

Page 24

GBK60348

: Issue 1 – October 2007

24

Page 25

MT

3 The DX BUS

DX BUS is the interface (the way the modules "talk" to each other) that connects all

the DX components together.

The DX BUS interface is based on CAN-Bus tech nology, which is commonly used in

safety critical applications like automotive and industrial control networks. CAN

provides extremely robust data reliability wi th excellent error detection and correction

capabilities. This makes the DX BUS a safe and fault tolerant data network.

The DX BUS also distributes power to the DX Modules and can safely carry up to 12

Ampere continuously.

DX BUS Connector Pinout

Pin Function

1 Communications – CANL

2 Communications – CANH

3 DXB+ (24 V, fused)

4 DXB- (0 V)

CAN-H and CAN-L are used for communication between the modules.

DXB+ and DXB- supply power to the modules and to the loads connected to them.

The maximum continuous current over the DX BUS DXB+ and DXB- wires is 12A.

Most DX devices have two DX BUS connectors

Notes:

Dynamic recommends to fit unused DX BUS connectors with a

GME64909 DX BUS Connector Cover. This also complies with

ISO 7176 requirements.

25

Page 26

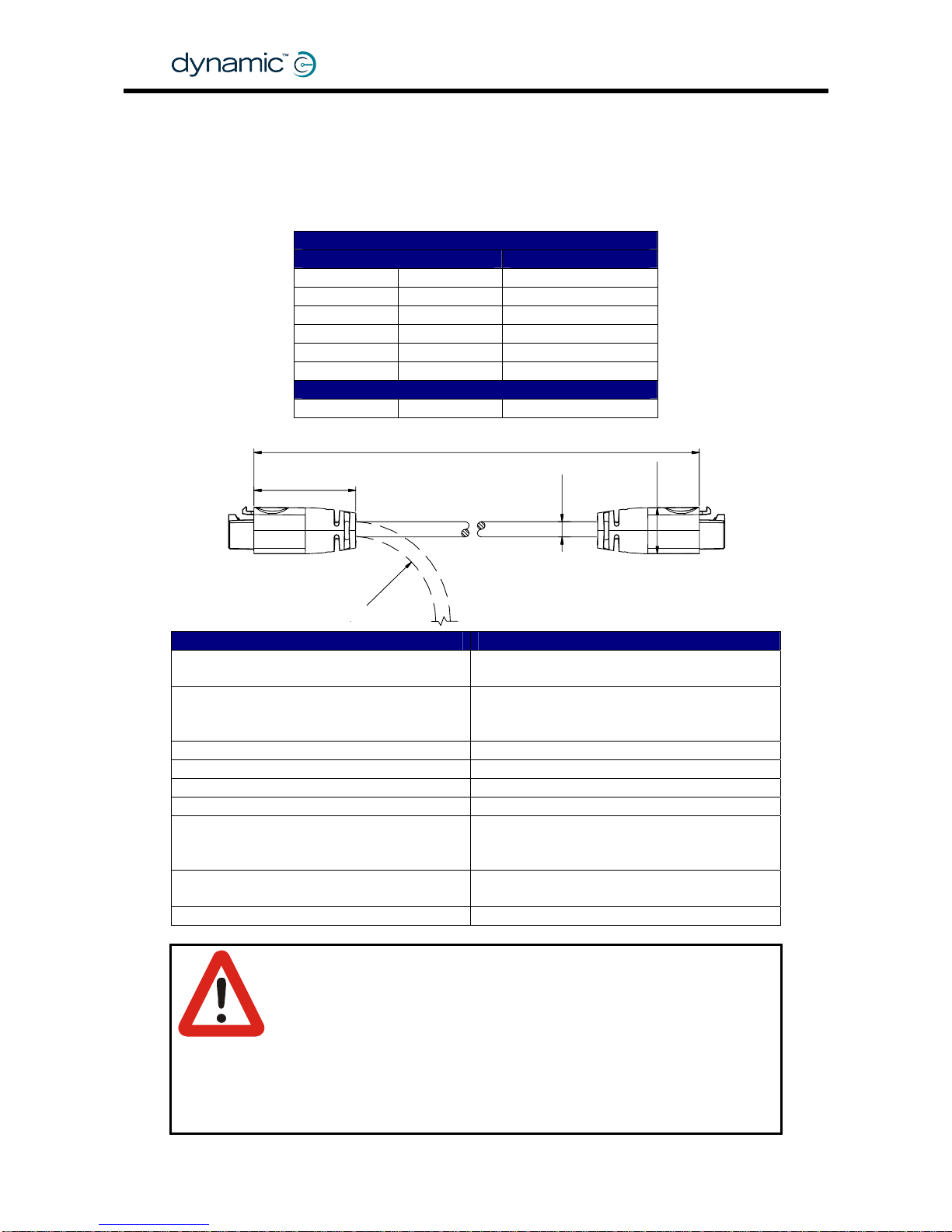

3.1 The DX BUS cable

Cable specifications - straight cable

The part number of the straight cable is GSM630YY, where YY = the length in 100 mm.

DX BUS cable straight

Length Part/Order number

300 mm 1 ft GSM63003

500 mm 1' 8" GSM63005

1.0 m 3' 3" GSM63010

1.5 m 4' 11" GSM63015

2.0 m 6' 7" GSM63020

2.5 m 8' 2" GSM63025

DX BUS cable with Ferrite bead to improve EMC

2.0 m 6' 7" GSM63020F

GBK60348

: Issue 1 – October 2007

26

Parameter Value

Contact Resistance (per contact)

As per IEC 512-2, Positronic

3 mΩ nom, 7 mΩ max

Wire resistance @ 20°C

DXB+

DXB-

15.1 mΩ/m, 4.6 mΩ/ft

8.5 mΩ/m, 2.6 mΩ/ft

Operating Current (DXB+/DXB-) 12 A nom, 20 A RMS max

Connector Latch Holding Force 40 N min

Cable Strain 100 N max (accidental, non-repetitive)

Cable Flex Force 10 N max

Minimum Cable Bend Radius

Flexing values for (T > –10°C/14°F)

10 mm / 0.39 inch - fixed installation

25 mm / 1 inch - occasional flexing

50 mm / 2 inch - frequent flexing

Operating Temperature

(ambient, fixed installation)

–25°C to +50°C

–13°F to +12 2°F

Cable Temperature Rating 80°C / 176°F (internal operating temp)

Warning:

The specified bend/flex radiuses are minimum values and must be

considered as a guideline only. Where frequent flexing is part of the

intended application, the installer must ensure an appropriate

bend/flex radius for the intended and foreseeable environmental

conditions. Extreme cold temperatures considerably reduce cable

flexibility. Appropriate life testing must be carried out to

determine/confirm the expected service life and inspection and

maintenance schedule.

35

YY x 100 ± 10

Ø7.0

13 x 16

R

-

B

E

N

D

Page 27

MT

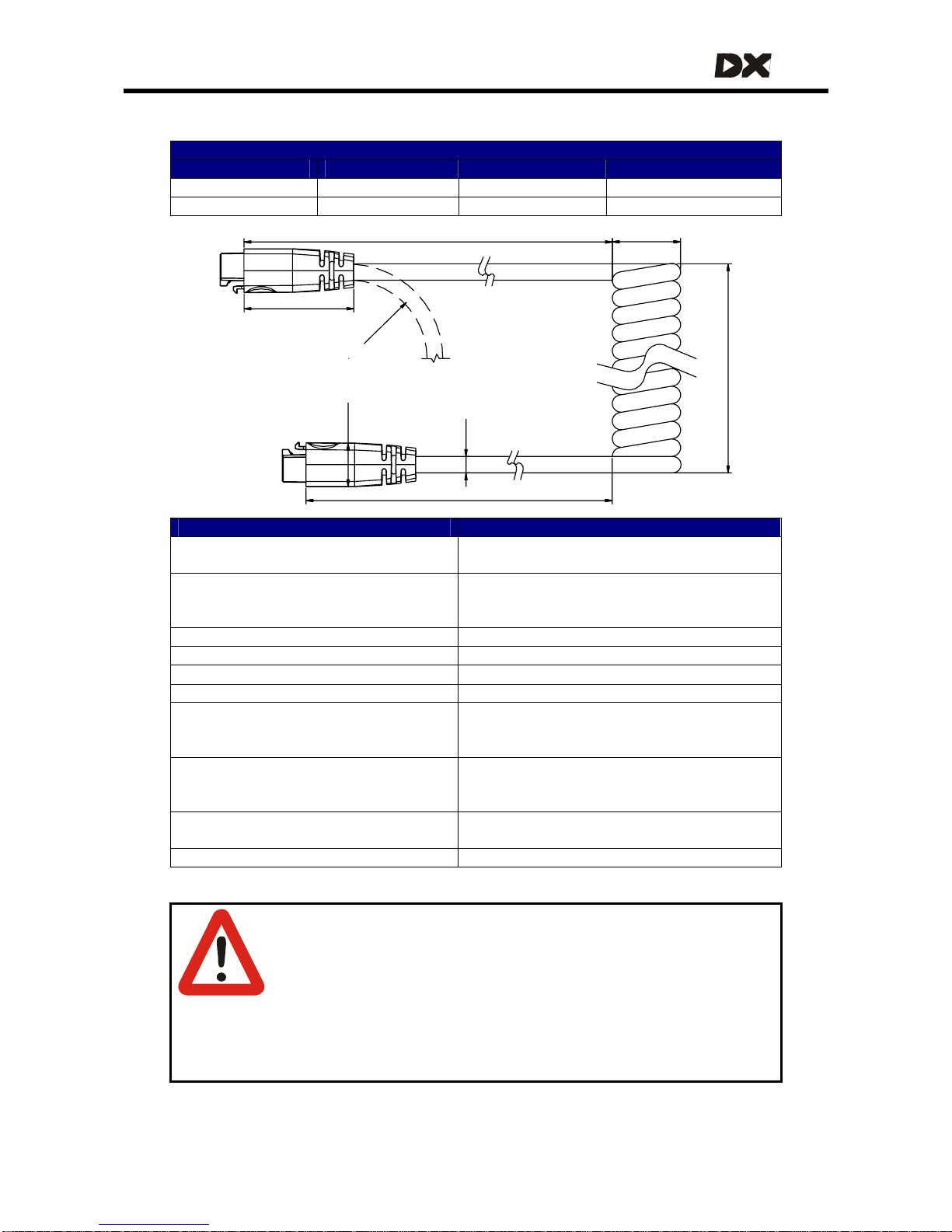

Cable specifications – curly cable

DX BUS Curly Cable

Tail Length La Coil Length Tail Length Lb Part/Order number

200 mm / 8 inch 300 mm / 1 ft 200 mm / 8 inch GSM63051

500 mm / 1'8" 300 mm / 1 ft 200 mm / 8 inch GSM63052

R

-

B

E

N

D

La ± 20

Ø26 ± 2

300 ± 30 approx. 40 coils

compressed coil length

Lb ± 20

Ø7.5

13 x 16

40

Parameter Value

Contact Resistance (per contact)

As per IEC 512-2, Positronic

3 mΩ nom, 7 mΩ max

Wire resistance @ 20°C

DXB+

DXB-

15.1 mΩ/m, 4.6 mΩ/ft

8.5 mΩ/m, 2.6 mΩ/ft

Curly Cable electrical length 2.3 m / 7'6" nom for the coiled section

Operating Current (DXB+/DXB-) 12 A nom, 20 A RMS max

Connector Latch Holding Force 40 N min

Cable Strain 100 N max (accidental, non-repetitive)

Spring Force - extension refers to the

coiled section

< 20N @ 2x extension (T > 10°C/50°F)

< 50N @ 2x extension (T > –10°C/14°F)

< 30N @ 3x extension (T > 10°C/50°F)

Minimum Cable Bend Radius

Flexing values for (T > –10°C/14°F)

20 mm / 0.8 inch - fixed installation

30 mm / 1.2 inch - occasional flexing

50 mm / 2 inch - frequent flexing

Operating Temperature

(ambient, fixed installation)

–25°C to +50°C

–13°F to +12 2°F

Cable Temperature Rating 80°C / 176°F (internal operating temp)

Warnings:

1. Do not extend the spring coils below 0°C. Do not extend the coils

farther than 2x compressed length below 10°C, or 3x compressed

length above 10°C. Avoid extension above 3x compressed length

because this can cause a permanent stretching of the coil.

2. Make sure that no spring force is applied to the DX BUS connector;

fasten a strain relief or cable tie on or near to the coiled section of

the cable.

27

Page 28

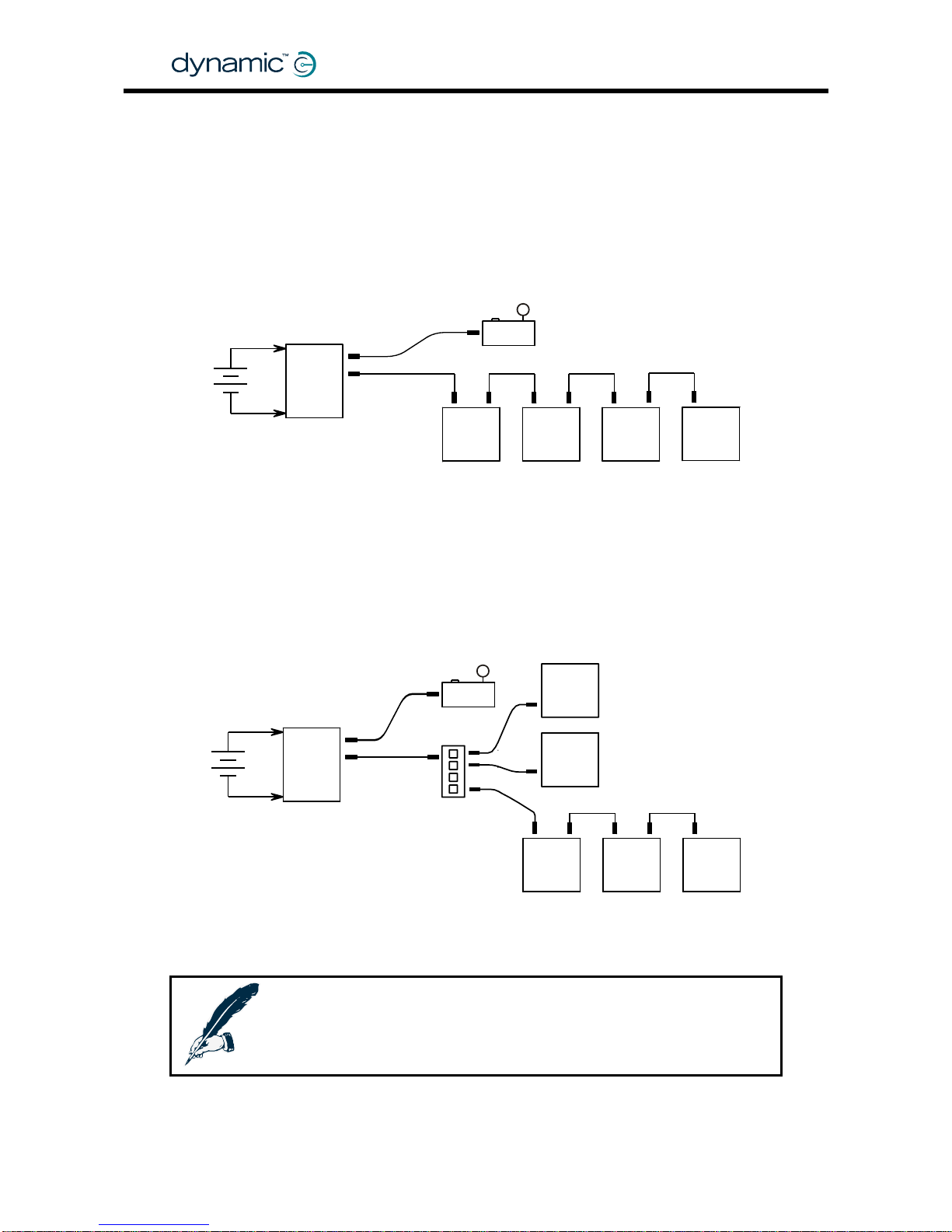

3.2 DX BUS Module connection layout

DX Modules normally have one or two DX BUS sockets for system interconnections.

Smaller DX Modules can have a permanently mounted cable ending in a DX BUS

plug, instead of DX sockets.

The optimu m connectio n lay out is depend ent on the type of module s th at are

present in the DX System. Low-current modules can be co nnected in series. This

provides a low-cost and simple solution.

ause a voltage drop on the DX BUS when they are connec ted far away from the

Because of the internal resistance of the DX BUS cable, high-current modules can

c

Power Module. For this reason all high-current DX Modules (for example actuators

and lights) must be connected as close to the Po wer Module as possible, preferably

in parallel.

DX modules connected in series

DX Master Remote

DX

Power

Module

DX

module

DX

module

DX

module

DX

module

24V

DX BUS

DX BUS

High-current DX modules connected in parallel

24V

DX

power

module

DX BUS

DX BUS

DX

module

HIGH I

DX

module

HIGH I

DX

module

HIGH I

DX

module

LOW I

DX

module

LOW I

DX Remote

DX splitter box

DX-SKT-X4

Note:

l length of all DX BUS cables together must not exceed 15 m.

The tota

GBK60348

: Issue 1 – October 2007

28

Page 29

MT

4 The DX Power Module

The DX Power Module converts the speed and direction signals generated by a DX

Remote into high current outputs. These outputs drive the motors and activate the

parkbrakes.

The Power Module must be connected to:

• The DX BUS (see chapter

3)

• The battery (see section

2.2)

• The mo tors (see section

2.3)

• The parkbrakes (see section

2.4).

The Power Module is fully programmable for a wide range of powerchair types and

user needs.

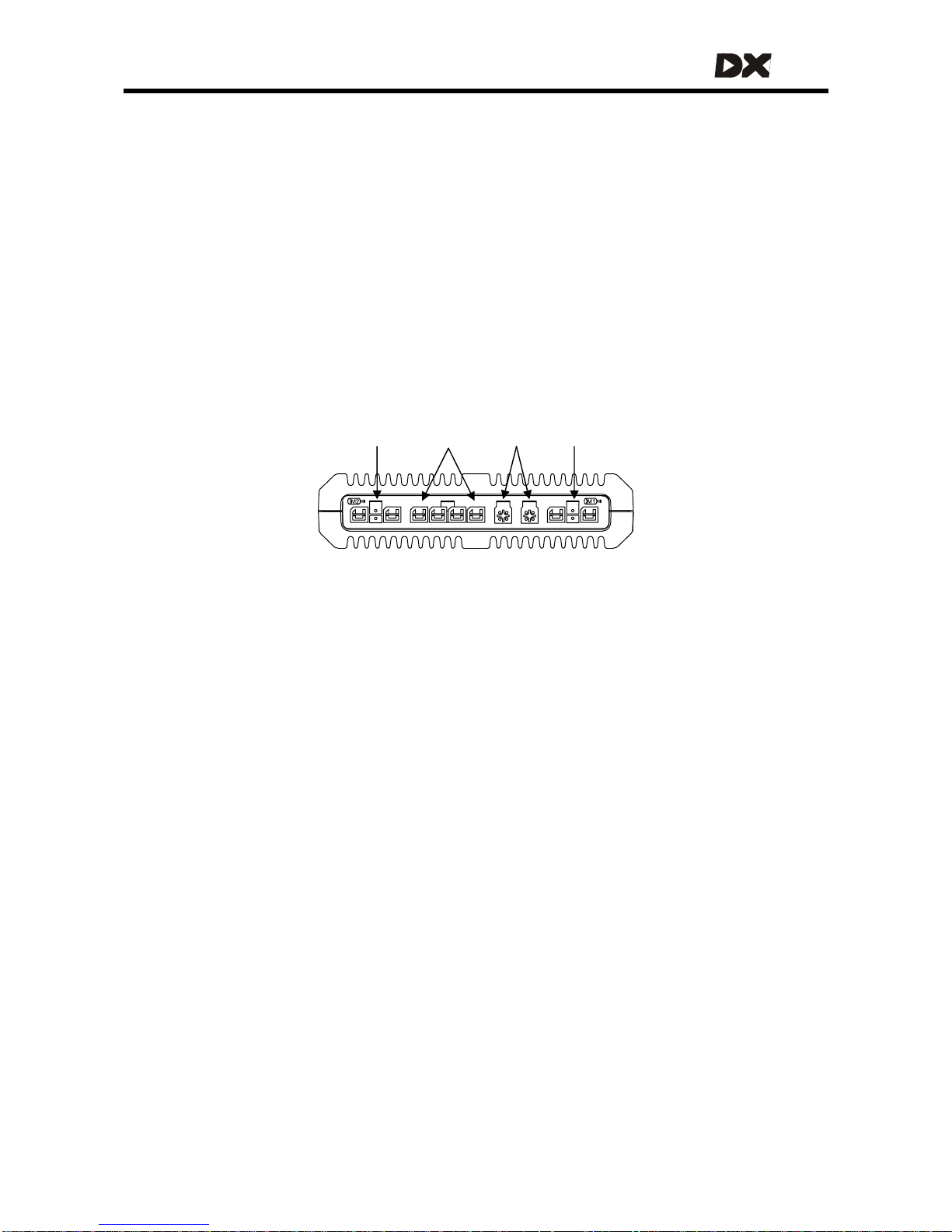

M/PB-2 Battery DX BUS M/PB-1

4.1 General Power Module features

• D i g ital motor con tro l

• Supply Voltage compensation

• Motor resistance and load compensation (see 4.3.2.3)

• Tracking (veer) compensation (see

4.3.2.5)

• Smart curre nt limiting and temperature limiting (see

4.3.2.1 and 4.3.4.7)

• Left/Right Motor swap option to facilitate motor cabling (see

4.3.2.7)

• Motor connector polarity swap for different motor polarity options (see

4.3.2.8)

• Single or dual parkbrakes (see

2.4.2)

• Programmable parkbrake delay (see

4.3.3.2)

• Dynamic braking in neutral

• Protected against external events such as:

o reverse battery polarity

o battery undervol tage and overvoltage (see

4.3.4.6)

o motor or parkbrake overload (see

4.3.2.9)

o external short circuits

• Extensive range of powerchair system safety and protection features such as:

o open circuit motor detection

o open and short circuit Park Brake detection

o controlled speed reduction to a stop if a fault is detected (see

4.3.2.6)

o protected against runaway in the event of an internal hardware failure

29

Page 30

• Electromagnetically compatible:

o low RF emissions

o high immunity to RF transmissions

• Built-in diagnostics with status LED and fault logging

• Watchdog, CPU, ROM and RAM testing at power up

• Compact, rugged enclosure with robust mounting points

• Environmentally compatible (sealed to IP54)

Warning:

This manual gives a description of a generic DX System and Power

Module use. It must be read together with the installation manual of

the actual Power Module that is installed on the powerchair.

Correct installation and programming are essential to ensure

optimum performance and safety.

4.2 Available Power Modules

DX

Power Module Current Motor type Lighting

DX-PMB 60A dual 24V DC no

DX-PMB2 80A dual 24V DC no

DX-PMB-S* 120A single (2x 60A parallel) 24V DC no

DX-GB

**

100A dual 24V AC no

* The PMB-S has its two motor and Park Brake channels driven in parallel, for a single

motor output with twice the current of each channel of a standard Power Module.

The PMB-S is used in DX Systems with only one drive motor, like many servo steered

powerchair systems.

** The DX-GB drives gearless brushless AC motors. The DX-GB is not covered in this

manual.

GBK60348

: Issue 1 – October 2007

30

Page 31

MT

4.3 Power Module programmable parameters

Warning:

Do not try to program the Power Module before you have read

• The programming chapter of this manual

• The manual of the specific Power Module

4.3.1 List of parameters

Key:

Editable at this level (see sec tion 7.1.2.1: Dongle versions)

Viewable at this level

Parameter Possible Values Default Rev HHP Lite Std Adv

Motors

Current Limit 10 – 80A 40 A -,A -

Hardware Current Limit

Scaler

0 – 100 % 100 % -,A -

Load Compensation 0 – 500 mΩ 0 mΩ -,A

Temp Dependant Load

Comp

No / Yes No A -

Veer Compensation -10 - +10 % 0 % -,A

Emergency Deceleration 25 - 100 % 75 % -,A -

Left/Right Motor Swap Normal / Swap

Normal

-,A -

Left Motor Invert No / Yes No -,A -

Right Motor Invert No / Yes No -,A -

Stall Timeout No / Yes Yes -,A -

Stall Time 5 – 50 s 15 s -,A -

Motor I2T Protection No / Yes No -,A - - -

Motor I2T Threshold 10 – 90 % 33 % -,A - - -

Motor I2T Time Scale

10 – 200

decimal

32 dec -,A - - -

Maximum Motor Temp 70 – 200 °C 130 °C -,A - - -

Motor Continuity Test No / Yes Yes -,A -

Maximum Motor Volts 24 – 30 V 26 V -,A -

Input Demand Scaler 50 – 100 % 95 % -,A -

Park Brakes

Park Brake Single / Dual Dual -,A -

Brake / Bridge Off Delay 100 – 1000 ms 500 ms -,A -

Test Park Brake Driving No / Yes Yes A -

31

Page 32

Parameter Possible Values Default Rev HHP Lite Std Adv

Battery

Battery Guess Maximum 24.2 – 28.8 V 25 V -,A -

Battery Guess Minimum 22.3 – 26.2 V 22.7 V -,A -

Battery Guess Recover 0 – 30 decimal 15 dec -,A -

Voltmeter Battery Gauge No / Yes No A -

Slow Batt Time Scale Driving No / Yes No A -

Batt Gauge Ramp Up Rate 10 – 1600 s 120 s A -

Batt Gauge Ramp Down

Rate

10 – 1600 s 90 s A -

Batt Gauge High Threshold 0.1 – 33.4 V 33.4 V A -

Batt Gauge Failing Threshold 0.1 – 6.6 V 0.1 V A -

High Voltage Warning No / Yes Yes A -

High Voltage Rollback No / Yes No A -

High Voltage Threshold A -

Internal Setup

Temperature Rollback

Minimum

40 – 75 °C 50 °C -,A -

Temperature Rollback

Maximum

50 – 85 °C 70 °C -,A -

Halve Turning Gain No / Yes No A -

Note:

1. Wizard 5 uses the value of the Halve Turning Gain parameter to

determine the Power Module Revision (Rev –, or Rev A). Set this

parameter to Yes if you want to use the Rev A parameters. If the

Halve Turning Gain parameter is set to No, the Wizard will assume

that the program is meant for a "Rev–" Power Module, and will

return all Rev A parameters to their default values before it writes

the parameters to the Power Module.

2. The Load Compensation and Veer Compensation parameters

should be set using the HHP. The adjustable range for these two

parameters can be limited by the Wizard.

GBK60348

: Issue 1 – October 2007

32

Page 33

MT

4.3.2 Motors

4.3.2.1 Current Limit

Parameter Possible Values Default Rev HHP Lite Std Adv

Current Limit 10 – 80A 40 A -,A -

The Current Limit is the maximum sustained current that the Power Module is

programmed to deliver to the motor.

To protect the electronics of the Power Module, the maximum current will be

reduced further if the Power Module becomes too hot, dependent on the setting of

the

Temperature Rollback parameters (see 4.3.4.7).

Warning:

Do not set Current Limit too high for the type of motor used.

4.3.2.2 Hardware Current Limit Scaler

Parameter Possible Values Default Rev HHP Lite Std Adv

Hardware Current Limit Scaler

0 – 100 % 100 % -,A -

Normally the

Current Limit parameter (see 4.3.2.1) limits the current to the motor.

However, the Current Limit software algorithm has a slow response time, which allows

fast high-current transients to slip through. Fast high-current transients can

de-magnetise low current motors, resulting in motor damage.

To protect the motors from fast high-current transients, additional to the slower

software algorithm a very fast hardware algorithm is provided. This algorithm can be

programmed with the Hardware Current Limit Scaler parameter.

The value of Hardware Current Limit Scaler is given as a percentage of the nominal

current rating of the Power Module. For maximum motor protection, set this value to

match the value of the Current Limit parameter.

Current Limit

(see 4.3.2.1)

Hardware Current

Limit Scaler

Maximum

transient current

80 A 100 % 80 – 120A

60 A 75 % 60 – 90 A

40 A 50 % 40 – 60 A

25 A 31 % 25 – 37 A

Settings for a Power Module with a nominal current rating of 80 A

The actual maximum transient current is depend ent on the temperature of the Power

Module. If the Power Module is warm, the limit is equal to the value set with Hardware

Current Limit Scaler. If the Power Module is cold, the limit can be up to 50% higher.

Warning:

Do not set the Hardware Current Limit Scaler lower than the software

Current Limit. This will result in a Stall Timeout Fault (see

9.6) and an

emergency stop.

33

Page 34

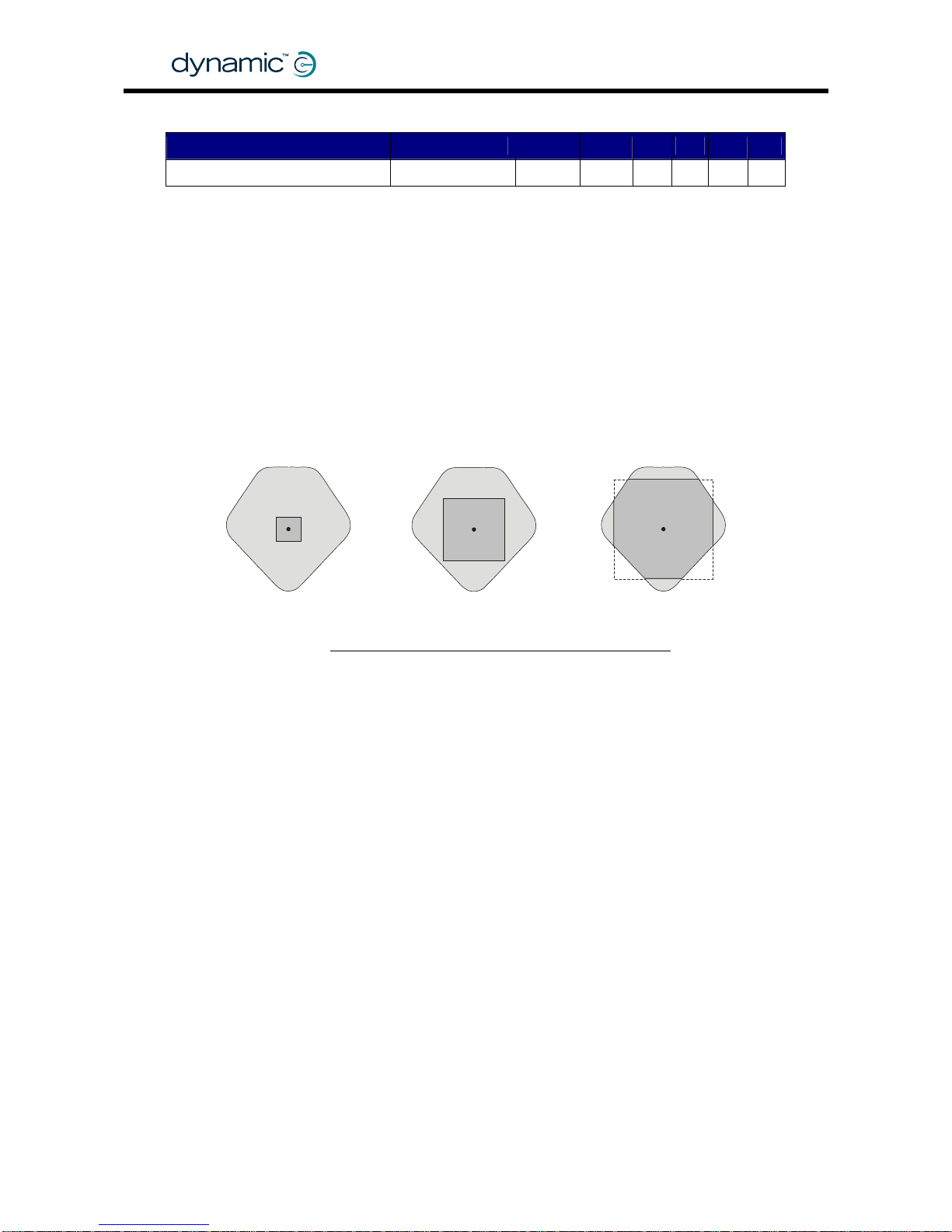

4.3.2.3 Load Compensation

Parameter Possible Values Default Rev HHP Lite Std Adv

Load Compensation 0 – 500 mΩ 0 mΩ -,A

Load Compensation automatically compensates for changes in motor speed when

the chair drives over loads such as sidewalks, curbs or slopes. Correct Load

Compensation is important for all chairs to reach acceptable performance,

especially when a chair has switched controls, for example a scanner or Sip and Puff.

Load

compensation

Too low Correct Too high

Chair

behaviour

• Drives like it is going

through thick mud

• Slows down when it

goes up a sidewalk

edge or up a ramp

• Slows down with

heavier users

• Changes direction

when it drives over a

bump

• Changes direction

when the weight of

the user shifts.

• Drives smoothly

• Keeps the spe ed

reasonably

constant. Only

slightly slows down

on a slope.

• Keeps the

direction constant.

Only slightly

changes direction

when it drives over

a bump.

• Drives very

rough

• Hard to steer or

control, vibrates

• Swerves wh en it

drives over a

bump.

• Motor becomes

hotter than

normal very

easily,

decreased

motor life

GBK60348

: Issue 1 – October 2007

34

Aaagh!

Hnnng!

Set Load Compensation to the correct motor resistance value of the used motor (for

motor resistance see section

2.3.3).

Page 35

MT

Determining the motor resistance

There are three ways to determine the motor resistance:

1. Look at the motor data that is provided by the manufacturer of the motor.

2. Measure the motor resistance.

3. Look at the powerchair behaviour.

1. Find the resistance of a motor in the motor data sheets

• Look for "Motor Resistance", "Terminal resistance", "Minimum stall resistance",

"Armature winding resistance" or "Winding resistance" or "R". Use this value

directly when it is given in milliOhms, mOhms or mΩ. Multiply by 1000 when it is

given in Ohms or Ω.

• Look for the "Stall Current", some times this is located under "Sta ll Torque" or

"Peak Torque". In the motor graph it is the current when the speed is zero.

The motor resistance is the nominal voltag e divided by the stall current.

Motor resistance = Nominal Voltage / Stall Current

In the example above: 12V / 45A = 0.266 Ω = 2 66 mΩ

35

Page 36

2. Measure the resistance of a motor

Tools needed

• One 12V battery (capacity 20 Ah or more),

or a 12V DC power supply that can deliver at least 20A

• A resistance of approximately 1 Ohm - 100 Watt,

for example:

o A high power resistor

o Extra motors in series

o 50m/150ft of 1 mm

2

or AWG18 wire (for example 25m/75ft AC copper

extension cord or copper speaker wire that is shorted at one end)

o 75m/250 ft of AWG16 wire (for exam ple a 37m/125 ft AC copper extension

cord or copper speaker wire that is shorted at one end)

• One Voltage meter

• One A mpere meter that can measure at least 20A

(for example: a clamp meter)

• The mo tor

Procedure

Do not connect yet

Lock the

motor

1. Lock the motor so that the shaft

can not turn (for example with

the parkbrake). If you use additional

motors as resistors, lock those too.

A

GBK60348

: Issue 1 – October 2007

36

2. Connect the motor, the Volt meter, the

Ampere meter, the resistor and the battery

together as shown in the schematic.

Do NOT connect the positive terminal of

the battery yet

.

3. Put the Voltage meter a nd the Ampere meter in a position where you can

read them both at the same time

4. Set the range of the Voltme ter to 10V and the range of the Ampere meter to 20A

5. Perform the measurement

a. Connect the positive terminal of the battery and wait until the readings on

the meters are stable (typically one to three seconds)

b. Quickly read the value on the Voltage meter and the Ampere meter

c. Disconnect the battery immediately after you have read the meters.

Warning:

Try to disconnect the battery within 5 seconds to make sure that the

motor or the resistor does not heat up too much.

+

M

V

R

12V

1Ω, 100W

Include the motor cables (but not the

connector) in the Voltage measurement

Page 37

MT

6. If the current that you have measured is less than 8A, either use a 24V battery

or use half the resistor value and repeat the measurement. For a good

measurement the current should be between 8A and 20A.

7. The motor resistance is the voltage divided by the current:

Motor resistance =

Measured Voltage at the motor connector

Measured Current

8. Lock the motor shaft in a different position and repeat the procedure from

step 5. Measure the resistance for at least five different positions of the shaft to

reduce the chance that the brushes do not mak e good contact with the

rotor.

When you have used extra motors as resistance, you do not have to change

the shaft position of those motors as well.

Use the lowest measured resistance and decrease it by 20%

37

9.

to compensate

for temperature variations and age variations. Multiply the found resistance by

1000 (for milliohm) and program this value into the Load Compensation

parameter with either the HHP or the Wizard.

10. Test the powerchair behaviour with this Load Compensation setting. Drive up

a slope or a sidewalk edge. If Load Compensation has the correct value:

• The chair only slightly slows down when it goes up the slope/edge

• The chair only slightly changes direction when it goes up the slope/edge.

Notes:

1. If the motor is connected to the battery longer than 5 seconds, the

motor becomes warm. If the motor is warm, let the motor cool down

before you do the next measurement.

2. A new motor usually has a higher motor resistance than a motor that

has been used for some time, because the motor brushes that are

inside the motor do not make optimal contact until they are "worn

in". If possible, perform this procedure when the motor has been

used for several hours.

3. Extremely low ambient temperatures can affect the motor

resistance. If the powerchair has been in the garage on a cold day,

the response when it is turned on can be a bit rough. This rough

behaviour stops as soon as the motor heats up. If the powerchair will

be used in extremely low ambient temperatures decrease Load

Compensation accordingly.

4. If the found motor resistance is 100 mΩ or less, perform the same

measurements with a warm motor. Use the lowest value of all

measurements.

Page 38

3. Determine the motor resistance by looking at the powerchair behaviour

1

2

3

Tools needed

1. A powerchair with a DX System fitted

2. A Hand Held Programmer (HHP)

3. A bump or a sidewalk edge that you can

drive up to

Procedure

Summary

• Set Load Compensation to a lo w value.

• Drive the powerchair into a Load and increase the motor resistance value

until the powerchair does not slow down.

Step by step

1. Turn the DX System ON

2. Position the powerchair in front of the edge

3. Connect the HHP to the DX Master Remote

GBK60348

: Issue 1 – October 2007

38

4. Enter Technician Mode (see section

7.1.1.1, 'HHP Technician Mode')

5. Press NEXT

Technician mode

Master JS Module

JOYSTICK CALIBRATION

EXIT YES NEXT

6. Press YES 7. Press NEXT

8. Press DOWN or UP to set the motor resistance to 20 milliohms

9. Push the joystick slightly f orward to drive

at a VERY LOW SPEED

10. Keep the joystick in exactly the same

position all t h e time

VIEW/EDIT POWER MOD

Load compensation

19 milliohms

EXIT NEXT UP DOWN

VIEW/EDIT POWER MOD

Load compensation

99 milliohms

EXIT NEXT UP DOWN

** MAIN MENU **

View or Edit Power

Module ? (Tech only)

NEXT YES

VIEW/EDIT POWER MOD

Veer compensation

RIGHT 0 %

EXIT NEXT LEFT RIGHT

SLOW

Page 39

11. The chair will probably stop when you arrive

at the edge, but still k e ep the joys tick

in exactly the same position.

Press UP

12. Press the UP button on the HHP until you

can feel that the front wheels try to pull up the

edge. Every time you press UP you will

feel this more.

13. Press “UP” SLOWLY until the chair smoothly

climbs over the edge with the joystick still in

exactly the same position as in step 11.

14. Turn the powerchair around and drive

to the location of step 1

15. Push the joystick forward to go over the

edge. If load compensation has the

correct value, the chair will not slow down

much, it will go smoothly over the edge.

VIEW/EDIT POWER MOD

Load compensation

80 milliohms

EXIT NEXT UP DOWN

16. Press EXIT to save the motor resistance

17. Turn the DX System OFF

18. Disconnect the HHP.

Notes:

1. This test procedure causes the motor to become hot. For this reason

the resulting value for Load Compensation is too high. Reduce Load

Compensation by 20% to make sure that the powerchair is not

uncomfortable to drive when the motor is cold.

2. A new motor usually has a higher motor resistance than a motor

that has been used for some time, because the motor brushes that

are inside the motor do not make optimal contact until they are

"worn in". If possible, perform this procedure when the motor has

been used for several hours.

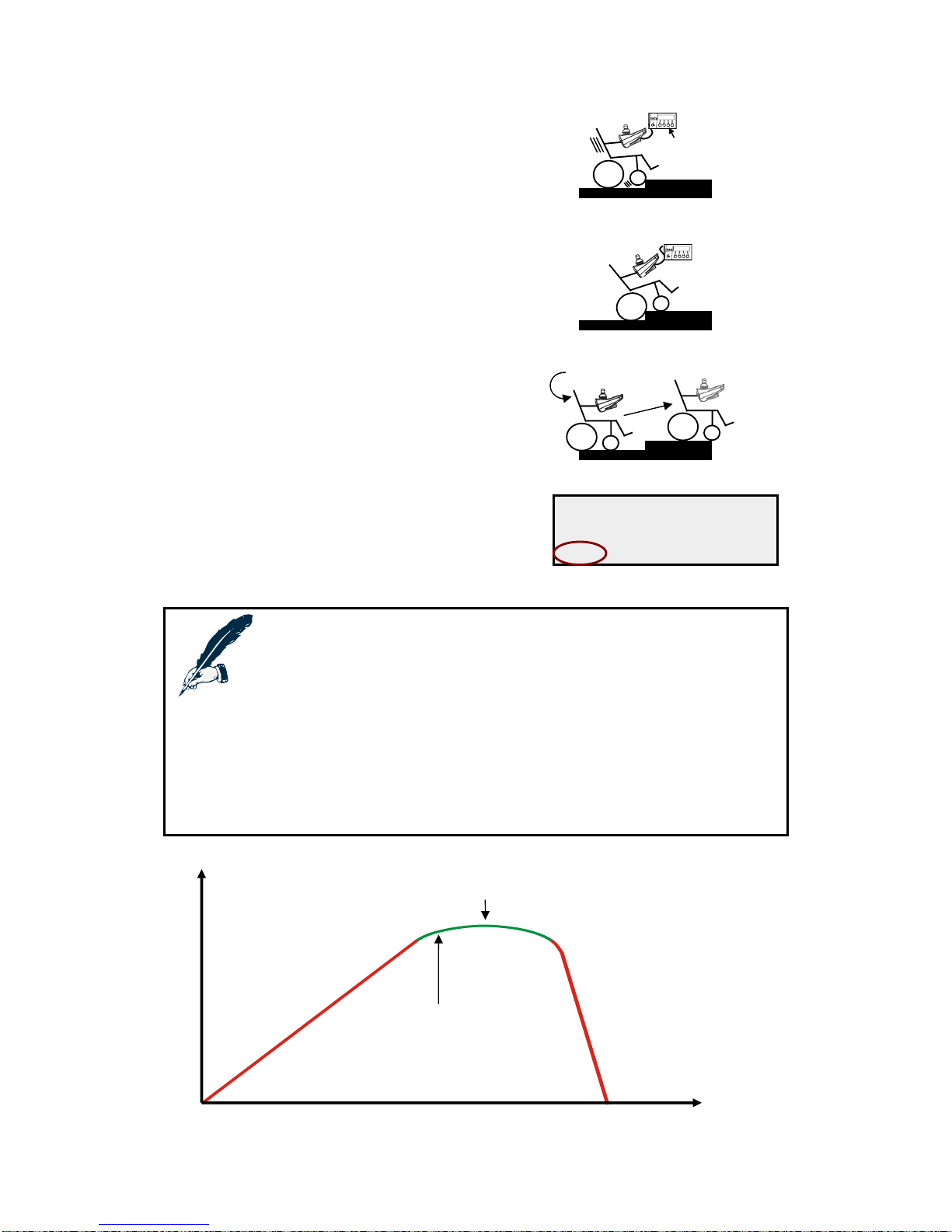

Optimum Load Compensation.

Chair responsive AND smooth

Nervous

Uncontrollable

Aim for this point: 20% back

from the top of the hill

Unresponsive

Performance

Load Compensation

Page 40

4.3.2.4 Temp Dependent Load Comp

GBK60348

: Issue 1 – October 2007

40

Parameter Possible Values Default Rev HHP Lite Std Adv

No / Yes No -,A -

Temp Dependent Load Comp

Temperature Dependent Load Compensation calculates the correct

Load

Compensation

values for different temperatures of the Power Module. This will make

sure that Load Compensation does not become too high when the Power Module is

cold, or too low when the Power Module is hot.

4.3.2.5 Veer Compensation

Parameter Possible Values Default Rev HHP Lite Std Adv

Veer Compensation -10 - +10 % 0 % -,A

If the two motors of the powerchair do not perform exactly the same, the chair will

not drive in a straight line. The chair wi ll slightly change its direction (veer) when it

drives forward.

Veer Compensation calculates how much the chair must correct its direction to go in

a straight line.

Veer

Actual

direction

Veer

Compensation

Intended

direction

Actual

direction

Veer

The chair does not drive straight when the

performance of the two motors is not equal

The chair now drives straight because Veer

Compensation corrects the direction

Notes:

1. Adjust this parameter every time a motor is replaced.

2. Other factors than motor performance can cause chair veer, for

example bent frames, flat tyres or faulty castor wheels. Correct

these problems at the source, do not use Veer Compensation.

3. Do not use Veer Compensation to compensate for out-of-centre

joystick deflection by the user.

Page 41

MT

Adjusting Veer compensation with the HHP

1. Turn the DX System ON

2. Connect the HHP to the DX Master Remote

41

3. Enter Technician Mode (see section

7.1.1.1: HHP Technician Mode)

4. Press NEXT 5. Press YES

Technician mode

Master JS Module

JOYSTICK CALIBRATION

EXIT YES NEXT

** MAIN MENU **

View or Edit Power

Module ? (Tech only)

NEXT YES

6. Press LEFT or RIGHT until the powerchair 7. Press EXIT to save the Veer

drives in a straight line when the Compensation value

joystick is deflected forward

8. Turn the DX System OFF

9. Disconnect the HHP

4.3.2.6 Emergency Deceleration

Parameter Possible Values Default Rev HHP Lite Std Adv

Emergency Deceleration 25 - 100 % 75 % -,A -

Emergency Deceleration sets the rate at which the powerchair comes to a halt when

• a fault that requires an emergency stop occurs

• the user switches off the system while driving.

If Emergency Deceleration is set to a higher value, the powerchair will stop in a

shorter time period. The optimum value depends on the powerchair type, the

preference of the manufacturer and the regulations that apply to the country of use.

Test this parameter by switching off the system while driving.

Warning:

The powerchair can tip over or throw the user out of the chair when

this parameter is set too high.

VIEW/EDIT POWER MOD

Veer compensation

RIGHT 0 %

EXIT NEXT LEFT RIGHT

VIEW/EDIT POWER MOD

Veer compensation

RIGHT 0 %

EXIT NEXT LEFT RIGHT

Page 42

4.3.2.7 Left/Right Motor Swap

GBK60348

: Issue 1 – October 2007

42

Parameter Possible Values Default Rev HHP Lite Std Adv

Left/Right Motor Swap Normal / Swap Normal -,A -