Page 1

5 3 D S --- 9 0 0 --- --- --- 1 1 7 ( 1 1 5 v )

02

2 -

7/8”

015 -

5/8”

5 3 D S --- 9 0 0 --- --- --- 1 1 8 ( 2 3 0 v )

Installation Instructions

Accessory Condensate Pump

for Ductless Split System

Cooling Only and Heat Pump High Wall Units

(Size 009---036)

NOTE: Read and become familiar with these instructions before

beginning installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock, or

other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency, or

your distributor or branch for information or assistance. The

qualified installer or agency must use factory--authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes

and current editions of the National Electrical Code (NEC) NFPA

70. In Canada, refer to current editions of the Canadian electrical

code CSA 22.1.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words; DANGER, WARNING, and CAUTION.

These words are used with the safety--alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

!

CAUTION

022 - 7/8”

015 - 5/8”

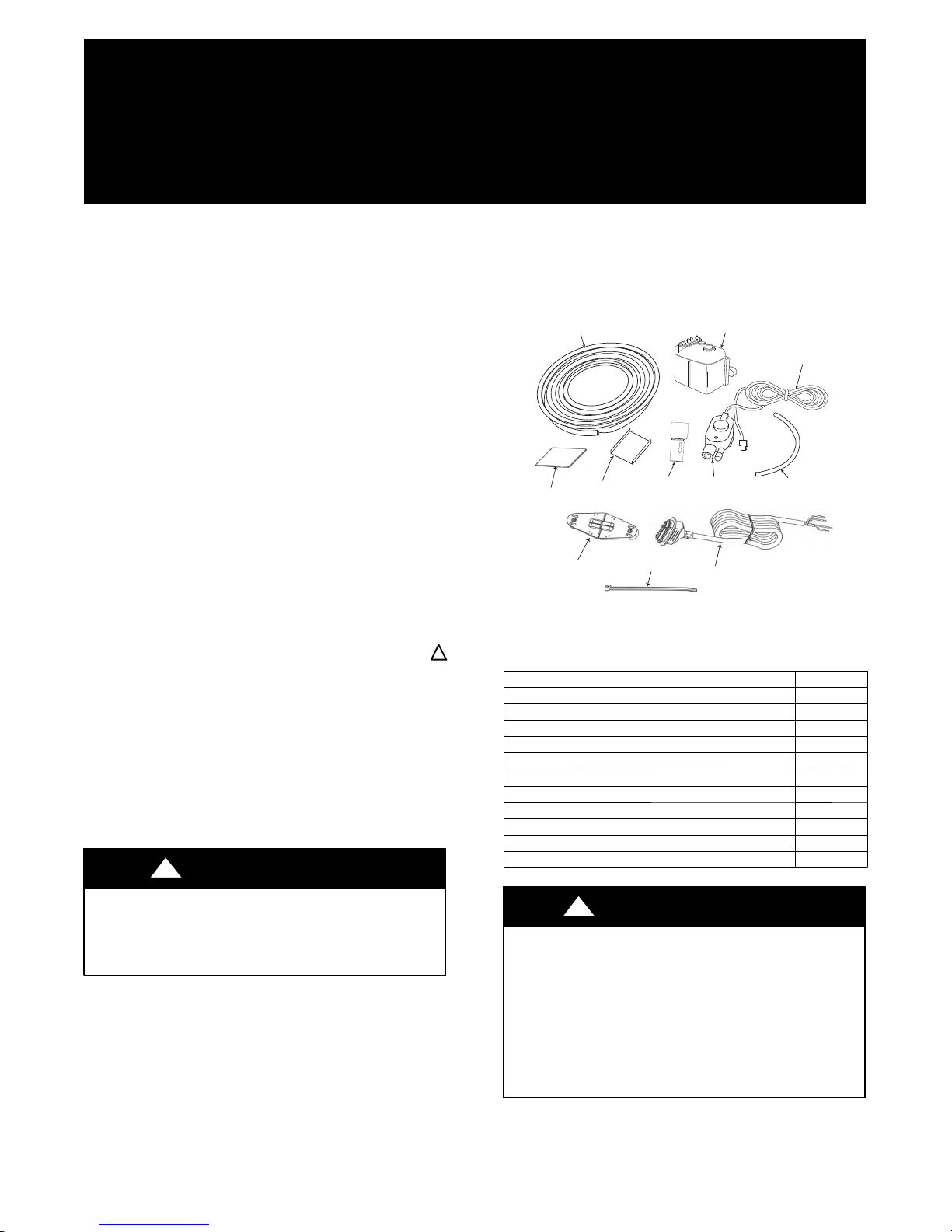

Condensate Pump

Assembly

Detection Unit

Power Cable

Low Voltage

Power Cord

Transparent

Detection

Unit Vent Tubing

A12227

16’ Transparent

Suction Discharge Tubing

Detection Unit

Mounting Bracket

Adhesive

Mounting Bracket

Rubber

Adapter

Wire Ties (6)

Fig. 1 --- Accessory Condensate Pump Kit

!

!

Table 1—Accessory Condensate Pump Kit Contents

ITEM QTY

16--- ft Transparent Suction/Discharge Tubing 1

Condensate Pump Assembly 1

L o w --- V o l t a g e Po w e r C o r d 1

Transparent Detection Unit Vent Tubing 1

Power Cable 1

Wire Ties 6

Wall Mount Bracket 1

Adhesive 1

Detection Unit Mounting Bracket 1

Rubber Adapter 1

Detection Unit 1

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit failure

and/or damage.

Always follow instructions properly.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before beginning any modification or installation of this kit,

be sure the main electrical disconnect is in the OFF position.

Ensure power is disconnected to the fan coil unit. On some

systems both the fan coil and the outdoor unit may be on the

same disconnect. Tag the disconnect switch with a suitable

warning label. There may bemore than one disconnect.

Page 2

Table 2—Accessory Package Usage

Detecon

Unit

Pump

C

A

B

ACCESSORY MODEL NUMBER

BASE UNIT

4 0 G V C 0 0 9 --- --- --- 1 16

4 0 G V C 0 1 2 --- --- --- 1 16

4 0 G V C 0 1 2 --- --- --- 3 18

4 0 G V C 0 1 8 --- --- --- 3 19

4 0 G V C 0 2 4 --- --- --- 3 19

4 0 G V C 0 3 6 --- --- --- 3 19

4 0 G V M 0 0 9 --- --- --- 3 20

4 0 G V M 0 1 2 --- --- --- 3 20

4 0 G V M 0 1 8 --- --- --- 3 20

4 0 G V Q 0 0 9 --- --- --- 1 17

4 0 G V Q 0 1 2 --- --- --- 1 17

4 0 G V Q 0 1 2 --- --- --- 3 18

4 0 G V Q 0 1 8 --- --- --- 3 19

4 0 G V Q 0 2 4 --- --- --- 3 19

4 0 G V Q 0 3 0 --- --- --- 3 19

4 0 G V Q 0 3 6 --- --- --- 3 19

4 0 G X C ( Q ) 0 0 9 --- --- --- 1 11

4 0 G X C ( Q ) 0 1 2 --- --- --- 1 11

4 0 G X C ( Q ) 0 1 8 --- --- --- 3 14 15

4 0 G X C ( Q ) 0 2 4 --- --- --- 3 14 15

4 0 G X M 0 0 9 --- --- --- 3 14 15

4 0 G X M 0 1 2 --- --- --- 3 14 15

4 0 G X M 0 1 8 --- --- --- 3 14 15

4 0 M V C ( Q ) 0 0 9 --- --- --- 1 8

4 0 M V C ( Q ) 0 1 2 --- --- --- 1 8

4 0 M V C ( Q ) 0 1 2 --- --- --- 3 9 10

4 0 M V C ( Q ) 0 1 8 --- --- --- 3 14 15

4 0 M V C ( Q ) 0 2 4 --- --- --- 3 14 15

4 0 Q N C ( Q ) 0 3 0 --- --- --- 3 13

4 0 Q N C ( Q ) 0 3 6 --- --- --- 3 13

40QNC018024--- --- ---3 12

4 0 Q N Q 0 1 8 --- --- --- 3 12

4 0 Q N Q 0 2 4 --- --- --- 3 12

PW3C(H)AM009 8

PW3C(H)AM012 8

PW3C(H)NM018 14 15

PW3C(H)NM024 14 15

R A S --- 0 9 E K C V --- U L 14 15

R A S --- 0 9 E K V --- U L 14 15

R A S --- 0 9 L K V --- U L 14 15

R A S --- 1 2 E K C V --- U L 14 15

R A S --- 1 2 E K V --- U L 14 15

R A S --- 1 2 L K V --- U L 14 15

R A S --- 1 5 E K C V --- U L 14 15

R A S --- 1 5 E K V --- U L 14 15

R A S --- 1 5 L K V --- U L 14 15

R A S --- 1 7 E K C V --- U L 14 15

R A S --- 1 7 E K V --- U L 14 15

R A S --- 1 7 L K V --- U L 14 15

R A S --- 2 2 E K C V --- U L 14 15

R A S --- 2 2 E K V --- U L 14 15

R A S --- 2 2 L K V --- U L 14 15

RAV---SP180KRT---UL 14 15

RAV---SP240KRT---UL 14 15

5 3 D S --- 9 0 0 --- --- --- 1 1

7

( 1 1 5 --- 1 --- 6 0 )

Wiring Fig. No. Wiring Fig. No.

5 3 D S --- 9 0 0 --- --- --- 1 1

(208/230---1---60)

GENERAL

Use the two--part accessory kit (condensate pump and detection

8

unit) with high wall fan coils. The pump operates whenever the

condensate level in the detection unit is high enough to cause the

magnetic float switch to send a signal to start the pump.

The float switch in the detection unit also prevents overflow and

can act as a safety device by shutting down the system. The

detection unit comes with normally closed (NC) alarm contacts

(user optional, but recommended). The normally closed alarm

contact is a dry contact rated for 8 amps at 250 volts. In the event

of a problem such as a clogged drain or pump discharge line, the

alarm contact can be wired to shut down the entire system. The

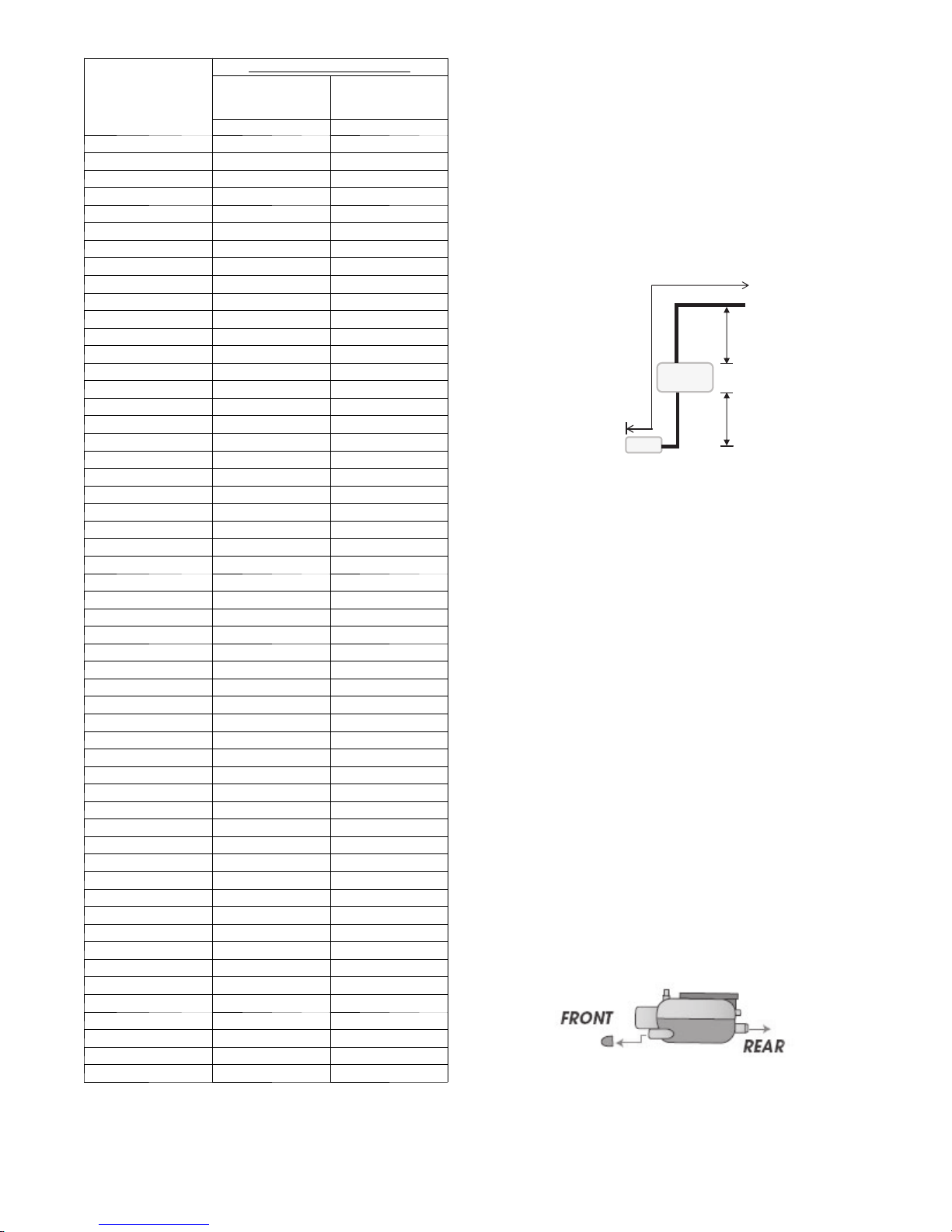

condensate pump provides 10 ft (3.0 m) maximum suction lift

(A)--Fig. 2.

Fig. 2 --- Maximum Lengths

A12134

INSTALLATION

Refer to Fig. 1 and Table 1 for kit content.

NOTE: To make the installation easier, install the detection unit

assembly before installing the fan coil unit.

1. Unpack the contents of the condensate pump accessory

package. Attach the rubber adapter and transparent vent

tubing to the detection unit (see Fig. 6). Rubber adapter

may be cut to size if 5/8” connection is required. If 7/8”

connection to unit drain pipe is required, use rubber

adapter as shipped. Do not use a vent tube longer than

2.95” (75 mm). Slide the mounting bracket onto the bottom of the detection unit. Uncoil the low voltage power

cord.

2. Remove the fan coil mounting bracket from the back of

the unit. Connect the detection unit with the rubber

adapter, to the condensate drain line (see Fig. 6).

3. Peel the adhesive cover on the back of the detection unit

mounting bracket and attach it to the inside of the unit adjacent to the fan coil drain as shown in Fig. 6. Make sure

the detection is installed horizontally for proper operation of the float switch.

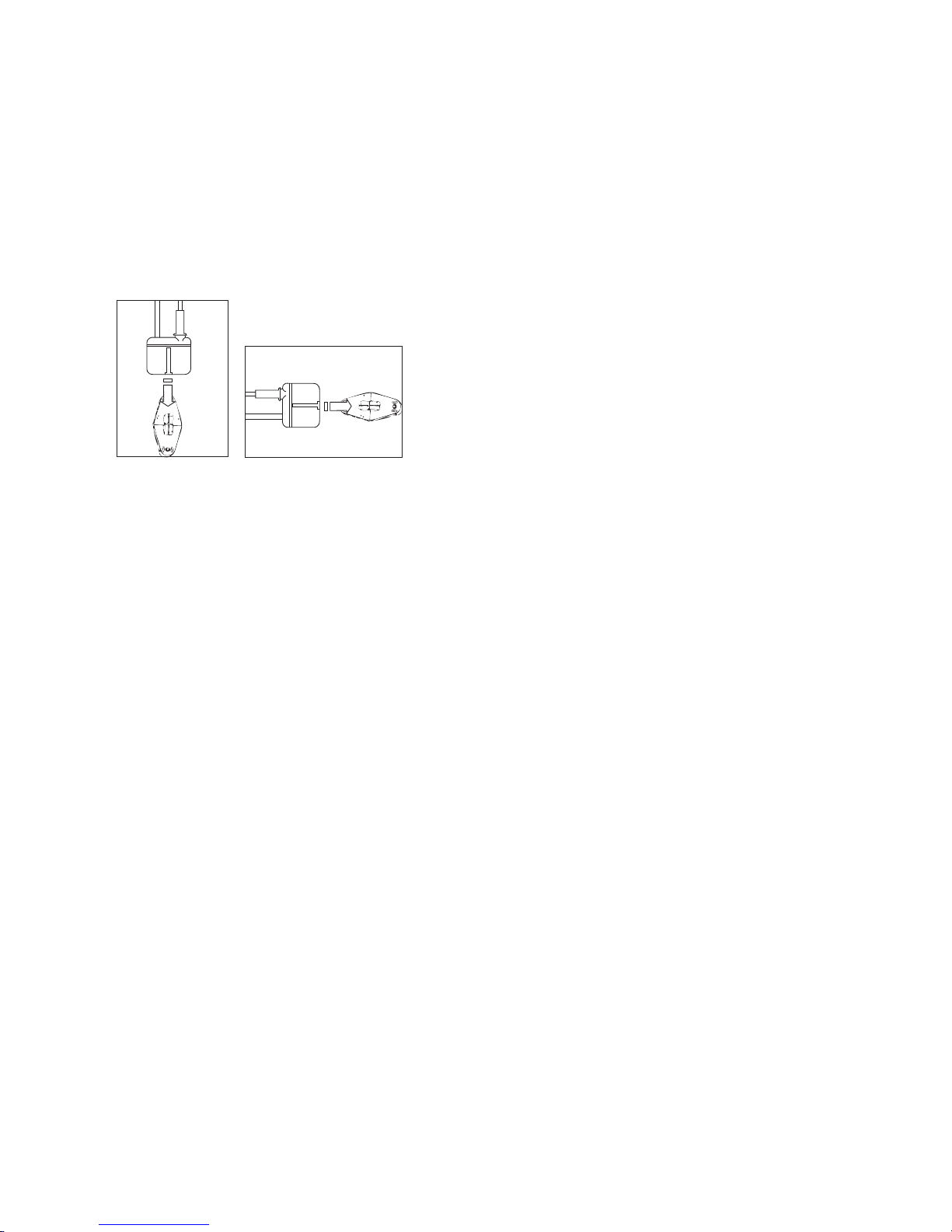

4. Attach one end of the transparent tubing to the detection

unit. The tube can be connected to either the front or the

rear as shown in Fig. 3. block the unused outlet with the

plug supplied.

A09398

Fig. 3 --- Detection Unit

2

Page 3

5. Connect one end of the low voltage power cord to the telephone jack socket in the detection unit and route the cord

and transparent drain tubing through the knockout on the

side of the unit enclosure (see Fig. 6).

6. Determine the mounting location of the pump assembly.

The pump assembly must always be above the level of

the detection unit. For best operation, it is recommended

that the pump assembly be mounted in a vertical position

with the flow arrow on the pump pointing up (see Fig. 7).

Do not exceed 10 ft. (3.0 m) maximum suction lift.

NOTE: in most applications, the pump will need to be mounted

outside of the high wall unit for proper orientation (i.e. above

drop ceiling).

7. Screw the bracket to the wall and attach the pump to the

bracket as shown in Fig. 4 and Fig. 5.

Fig. 4 --- Pump

Assembly Vertical

Fig. 5 --- Pump

Assembly Horizontal

A12228

If the pump is not mounted in the vertical position, make sure that

plug on the pump is above the refrigerant tubing. This is required

to avoid water leaking onto the pump causing a short circuit. The

pump cannot be splashed nor located in a damp

environment.

8. Connect the other end of the low voltage power cord from

the detection unit to the telephone jack socket in the pump

assembly.

9. Cut the suction, transparent drain tubing after determining

where it will connect to the inlet side of the pump mounted on the wall. Remove the cap on the pump inlet and

connect draining tubing.

10. Attach the remaining transparent tubing to the discharge

side of the pump. Keep the pipe vertical for at least 4 or 5

inches and do not exceed the 33 ft (10 m) limit or the

value shown in (B) of Table 3 and Table 4. In order to

avoid siphoning action and running the pump dry, always connect the discharge tube to the drain at a higher level than the pump itself (pump should be higher

than detection unit). Be sure the condensate is discharged

to a safe location where the presence of water does not

pose any safety or health hazards.

11. Install the transparent vent tube (provided) on top of the

detection unit. Route tube so it will stay vertical (see Fig.

6).

12. Wire the pump and the alarm circuit using the appropriate

wiring diagram listed in Table 2.

13. Prime the pump at start--up and after each maintenance operation. To ensure proper operation, the suction pipe and

part of the discharge pipe must be slowly filled with water

using a squeeze bottle.

14. Test the unit. When the unit is mounted in place, the condensate pump system must be tested.

a. Be sure theHi--Wall unit is installed on a level plane. Re-

move the front cover of the unit.

b. Slowly fill thecondensatedrain panwith water. Observe

thepump discharge tubing tobe surethat thepump isoperating.Ifcondensateis not being discharged throughthe

discharge tubing, check to be sure that the lines are not

kinked or obstructed, and installation parameters have

beenfollowed.If theoptionalalarmcontactis wired,continue to pour water until the alarm circuit triggers.

3

Page 4

RefertoFig.2for(A),(B),(C)

Suction Head (A)

ft

0

3.3

6.6

10

RefertoFig.2for(A),(B),(C)

Suction Head (A)

ft

0

3.3

6.6

10

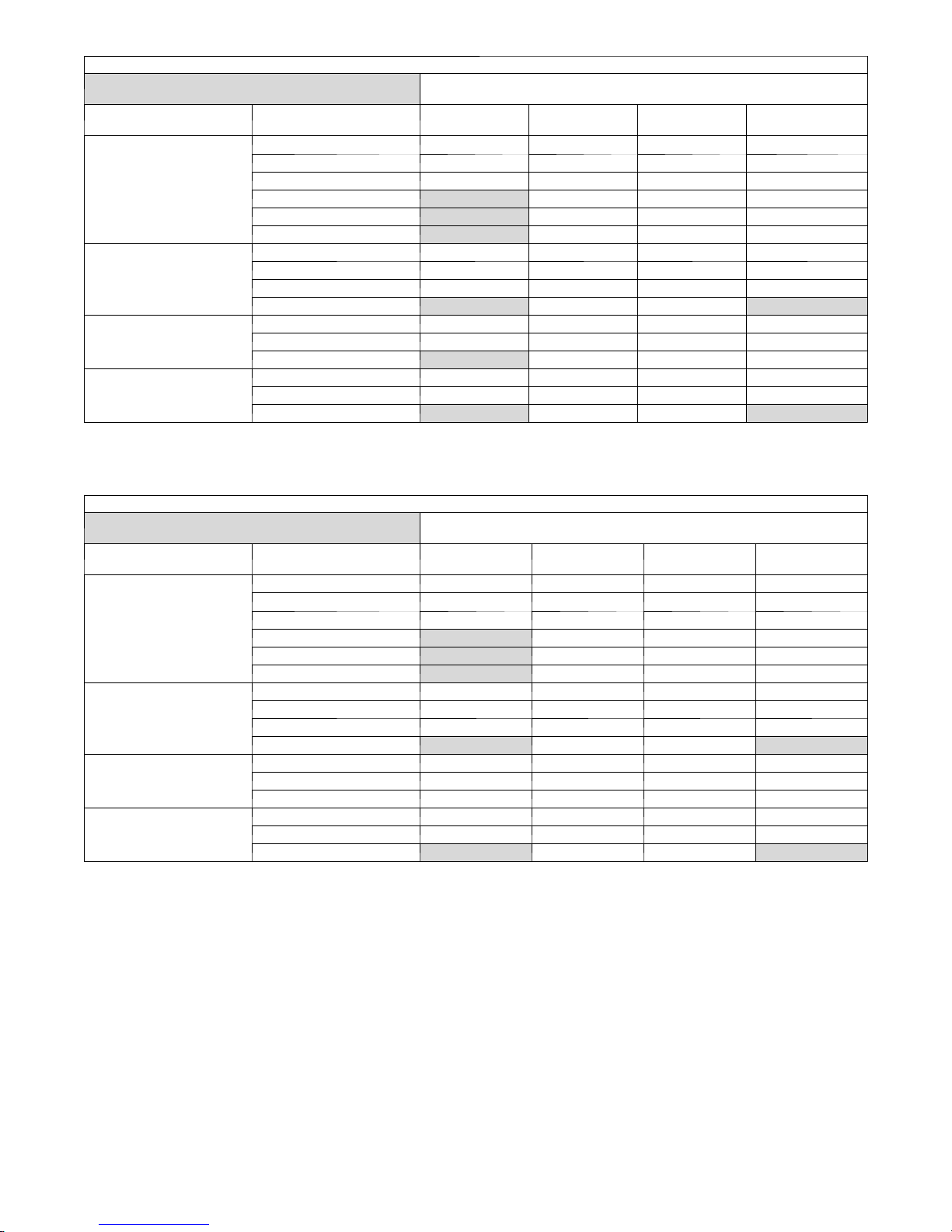

Table 3—True Flow Rates (Gallons / Hr)

53DS--- 900--- --- --- 117, 118 Condensate Pump Flow Rates

Total tube length, 1/4ä flexible hose (C)

Discharge Head (B)

ft

0 5.0 4.7 4.5 4.2

6 4.2 3.9 3.7 3.5

13 3.0 2.9 2.8 2.6

20 2.5 2.0 1.7

26 1.6 1.3 1.1

33 1.1 0.9 0.7

0 3.7 3.4 3.2 2.9

6 2.9 2.6 2.4 2.1

13 0.5 1.8 1.6 1.3

20 1.2 1.1

0 2.9 2.6 2.4 2.1

6 2.4 2.1 1.8 1.6

13 1.5 1.3 1.2

0 2.6 2.4 2.1 1.8

6 2.1 1.8 1.6 1.3

13 1.3 1.1

15 30 60 100

ft

Table 4—True Flow Rates (Liters / Hr)

53DS--- 900--- --- --- 117, 118 Condensate Pump Flow Rates

Total tube length, 1/4ä flexible hose (C)

Discharge Head (B)

ft

0 18.9 17.8 17.0 15.9

6 15.9 14.8 14.0 13.2

13 11.4 11.0 10.6 9.8

20 9.5 7.6 6.4

26 6.1 4.9 4.2

33 4.2 3.4 2.6

0 14.0 12.9 12.1 11.0

6 11.0 9.8 9.1 7.9

13 1.9 6.8 6.1 4.9

20 4.5 4.2

0 11.0 9.8 9.1 7.9

6 9.1 7.9 6.8 6.1

13 0.0 5.7 4.9 4.5

0 9.8 9.1 7.9 6.8

6 7.9 6.8 6.1 4.9

13 4.9 4.2

15 30 60 100

ft

NOTE: Maximum suction plus discharge head is 33 ft (10 m). Longer lengths indicate horizontal condition.

4

Page 5

POWER AND

ALARM CIRCUIT

CONNECTING

WIRES

DETECTION

UNIT VENT TUBING

LOW VOLT

FAN COIL CONDENSATE

DRAIN LINE

RUBBER

ADAPTER

DETECTION

UNIT

DETECTION UNIT

MOUNTING BRACKET

POWER CORD

SUCTION TUBING

Fig. 6 --- Rear of High Wall Unit with Mounted Condensate Pump

PUMP DISCHARGE LINE

(PROVIDED)

CONDENSATE PUMP

(RECOMMENDED

VERTICAL POSITION)

DISCHARGE

DISCHARGE

TUBING

COMDENSATE

PUMP

ASSEMBLY

A12229

(5) WIRES

(3) POWER L1, L2, G

(2) ALARM CIRCUIT

DETECTION DEVICE

(MUST BE MOUNTED HORIZONTALLY)

FAN COIL

CONDENSATE

DRAIN LINE

RUBBER ADAPTER

(PROVIDED)

VENT TUBE

(PROVIDED)

PUMP SUCTION LINE

(PROVIDED)

MOUNTING BRACKET

(PROVIDED)

Fig. 7 --- Accessory Condensate Pump Connections

SUCTION

LOW VOLT

POWER CORD

W/RJ11 CONNECTIONS

(TELEPHONE JACK)

A12230

5

Page 6

115-1-60 POWER REQUIRED FOR PUMP

PUMP ALARM BREAKS SIGNAL

115-1-60

POWER SUPPLY

(from outdoor or dedicated source)

WHT

BRN

YEL

OUTDOOR UNIT

TERMINAL BLOCK

optional

BLU

Fig. 8 --- 009, 012 (115--1--60) WIRING SCHEMATIC

115-1-60 POWER REQUIRED FOR PUMP

PUMP ALARM BREAKS SIGNAL

A12393

OUTDOOR UNIT

TERMINAL BLOCK

WHT

BRN

YEL

BLU

A12136

Fig. 9 --- (208/230--1--60) WIRING SCHEMATIC

6

Page 7

PUMP POWERED FROM OUTDOOR UNIT

PUMP ALARM BREAKS SIGNAL

BLU

OUTDOOR UNIT

TERMINAL BLOCK

BRN

PUMP

208/230-1-60

WHT

YEL

208/230-1-60

MAIN POWER SUPPLY

A13106

Fig. 10 --- (208/230--1--60) WIRING SCHEMATIC

PUMP POWERED FROM INDOOR UNIT

PUMP ALARM BREAKS SIGNAL

WHT

BRN

YEL

BLU

Fig. 11 --- (115--1--60) WIRING SCHEMATIC

7

A12395

Page 8

INDOOR UNIT

TERMINAL BLOCK

PUMP POWERED FROM INDOOR UNIT

PUMP ALARM BREAKS SIGNAL

BLU

B

A

R

DT

G

O

Y

TO OUTDOOR

UNIT

BRN

WHT

YEL

A12396

Fig. 12 --- (208/230--1--60) WIRING SCHEMATIC

INDOOR UNIT

TERMINAL BLOCK

PUMP POWERED FROM INDOOR UNIT

PUMP ALARM BREAKS SIGNAL

BLU

B

A

DT

G

O

Y

R

TO OUTDOOR

UNIT

BRN

WHT

YEL

A12430

Fig. 13 --- (208/230--1--60) WIRING SCHEMATIC

8

Page 9

Pump

115-1-60

L

N

AL

AL

L1

L2

S

Indoor Unit Terminal Block

GND

L1

L2

S

L1

L2

Outdoor Unit T erminal Block

GND

Field Power Wiring

208/230-1-60

Legend

Field Power Wiring

Interconnec ting Wiring

Pump Wiring

Field Splice Connec tion

115-1-60

Dedicated

Power Supply

115-1-60 DEDICATED POWER SUPPLY FOR PUMP

Pump

208/230-1-60

L1

L2

AL

AL

L1

L2

S

Indoor Unit Ter minal Block

GND

L1

L2

S

L1

L2

Outdoor Unit T erminal Block

GND

Field Power Wiring

208/230-1-60

Legend

Field Power Wiring

Interconnec ting Wiring

Pump Wiring

Field Splice C onnection

PUMP ALARM BREAKS SIGNAL

WHT

BRN

YEL

BLU

Fig. 14 --- (115--1--60) WIRING SCHEMATIC

PUMP POWERED FROM INDOOR UNIT

PUMP ALARM BREAKS SIGNAL

BLU

BRN

WHT

YEL

A13107

A13108

Fig. 15 --- (208/230--1--60) WIRING SCHEMATIC

9

Page 10

N

L

AL

AL

WHT

BRN

YEL

BLU

Fig. 16 --- 40GVC 9k, 12k (115--1--60) WIRING SCHEMATIC

A13098

WHT

N

BRN

L

YEL

AL

AL

BLU

A13099

Fig. 17 --- 40GVQ 9k, 12k (115--1--60) WIRING SCHEMATIC

BLU

BRN

WHT

YEL

Fig. 18 --- 40GVC/Q 12k (208/230--1--60) WIRING SCHEMATIC

A13100

10

Page 11

BLU

BRN

WHT

YEL

Fig. 19 --- 40GVC/Q 18k, 24k, 30k, 36k (208/230--1--60) WIRING SCHEMATIC

BLU

BRN

WHT

YEL

Fig. 20 --- 40GVM 9k, 12k, 18k (208/230--1--60) WIRING SCHEMATIC

A13101

A13102

11

Page 12

CLEANING AND MAINTENANCE

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect all power to unit to avoid possible electrical

shock during cleaning or maintenance. Set unit power

switch to OFF position.

N730--03--Edition 13/11

WARNING

At the beginning of each season clean the detection unit.

1. Disconnect tubing and low voltage power cord from the

detection unit and slide unit out of mounting bracket

2. Remove the top of the detection unit and take out the float.

3. Clean the detection unit and the float using a solution of

water containing 5% bleach.

4. Replace the float in its original position with the magnet

side facing up.

5. Snap cover back into place.

6. Perform an operational test (see item 13 under installation

section).

Copyright 2014 CAC / BDP S 7310 W. Morris St. S Indianapolis, IN 46231

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

Edition Date: 04/14

12

C a t a l o g N o : I I K --- 5 3 D S 9 0 0 --- C P --- 0 7

R e p l a c e s : I I K --- 5 3 D S 9 0 0 --- C P --- 0 6

Loading...

Loading...