Page 1

Rockers – DGRL, DGRM,

DSRL & DSRM series

OPERATING MANUAL

DGRL-01-01

Dynalab Corp.

November 2017

DGRM-01-02

1

Page 2

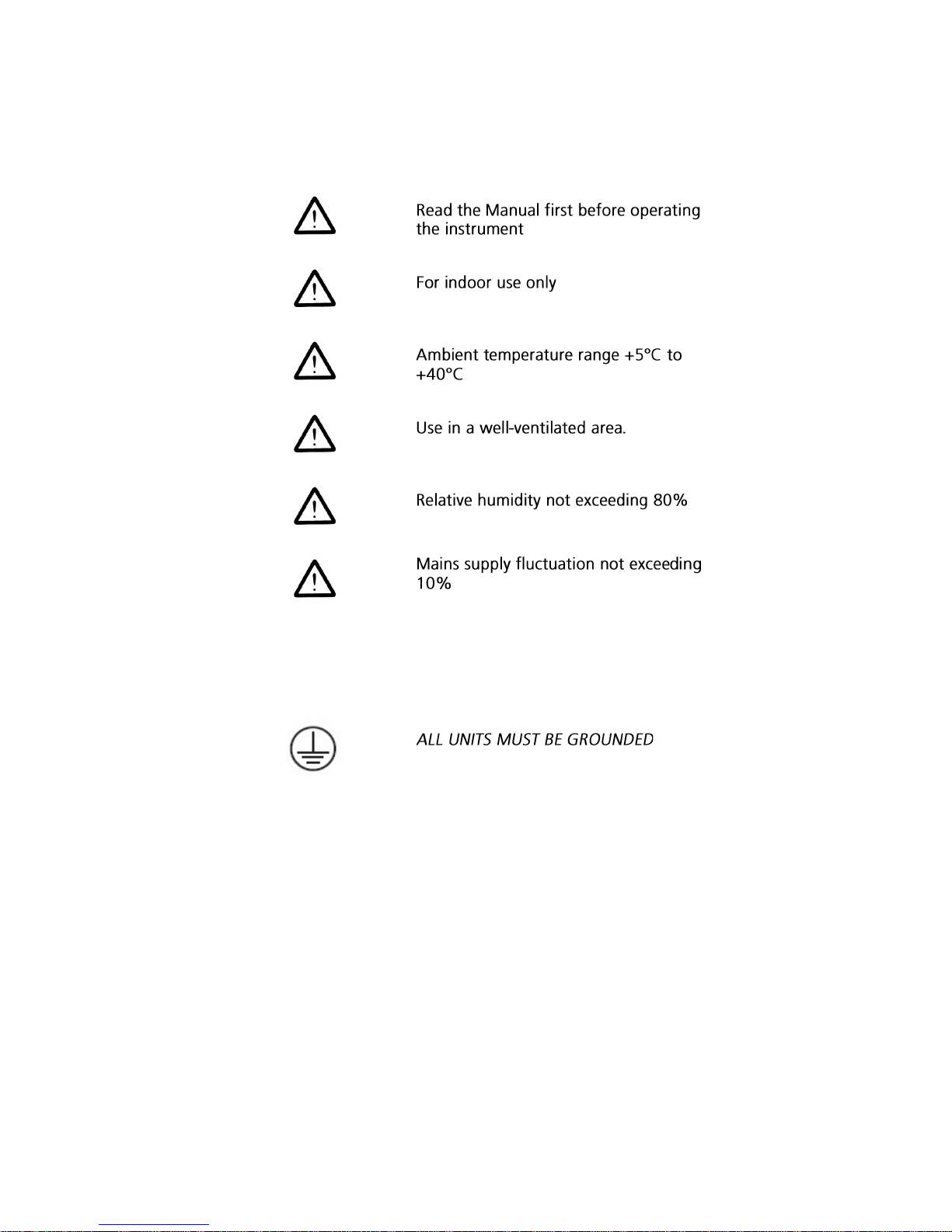

BEFORE USE:

Please read the following instructions:

Warning

Check the line supply is sufficient to meet the power requirement of the unit!

2

Page 3

Warranty

Dynalab Corp. provides a 90 day warranty for the units in this series.

This warranty does NOT apply if damage is caused by fire, accident, misuse, neglect,

incorrect adjustment or repair, damage caused by incorrect installation, adaptation,

modification, fitting of non-approved parts or repair by unauthorized personnel. When

returned the defective products, customers should be responsible for the shipping and

insurance costs

LIMITATION OF LIABILITY

NOTWITHSTANDING ANY OTHER PROVISIONS HEREIN, UNDER NO CIRCUMSTANCES IS

EITHER PARTY LIABLE FOR ANYCONSEQUENTIAL, SPECIAL, INCIDENTAL, INDIRECT,

MULTIPLE, ADMINISTRATIVE, OR PUNITIVE DAMAGES, OR ANY DAMAGE OF AN INDIRECT

OR CONSEQUENTIAL NATURE ARISING OUT OF OR RELATED TO ITS PERFORMANCE,

WHETNER BASED UPON BREACH OF AGREEMENT, WARRANTY, OR NEGLIGENCE AND

WHETHER GROUNDED IN TORT, CONTRACT, CIVIL LAW, OR OTHER THEORIES OF LIABILITY,

INCLUDING STRICT LIABILITY, EVEN IF ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH

DAMAGES. THE COMPANY’S TOTAL LIABILITY INCLUDING, BUT NOT LIMITED TO, LIABILITY

FOR INDEMNITY, DEFENSE, AND HOLD HARMLESS OBLIGATIONS IS LIMITED TO NO MORE

THAN THE AMOUNT PAID TO THE COMPANY UNDER THE CUSTOMER’S ORDER AND THE

CUSTOMER AGREES TO INDEMNIFY THE COMPANY FOR ANY EXCESS AMOUNTS. TO THE

EXTENT THAT THIS LIMITATION OF LIABILITY CONFLICTS WITH ANY OTHER PROVISION(S)

OF THIS AGREEMENT, SUCH PROVISION(S) WILL BE REGARDED AS AMENDED TO

WHATEVER EXTENT REQUIRED TO MAKE SUCH PROVISION(S) CONSISTENT WITH THIS

PROVISION

3

Page 4

Overview

Rockers – The platform on the mixers move in non-horizontal direction as the motor rotated,

i.e. the rocking movement. There are two types of rockers provided: 1, the gyration type

and the wave type. With tilted angle in one end, the gyration mixers gyrate in threedimension. This mixing action is suitable for full flashing some floated object by liquid, such

as staining and de-staining gels and low foaming mixing purpose. The wave type is based on

see-saw action to create wave-like mixing of the liquid and suitable for Petri-dish and culture

fl

4

Page 5

Figure 4: Overview of the mini scale 3D gyrator rocker (RCK-31). ① Electrical socket;

② Slip-proof platform; ③ LED display on Digital front panel

Figure 5: Overview of the lab scale see-saw rocker (RCK-21). ① Electrical socket; ②

Slip-proof platform; ③ Digital front panel

5

Page 6

Operation

Always install the carrier or platform before turning on the machine. All platforms or

carriers are shipped in pre-installed status. For safety reason, please check all the locking

screw and tighten again if necessary. The locking screws might be loosened during

transportation!

Place the machines on the flat and steady surface and keep away from other objects for

safe operation.

Check the electrical safety status and the power switch must be in “OFF” position before

plug into the power outlet. The machines come with IEC electrical socket and double fuses

for safety operation.

For the 3D Gyrator Rockers, adjust the tilted angle before loading the samples. Set the

speed to the minimum rpm. And examine the nut underneath the center cylinder shaft

turning front, then stop the machines and tilt the platform to desired angle.

Figure 13: Overview of head box .

Load the samples first before turning on the machine. Be aware of loading sample evenly

and never overload the samples.

Always start with low speed and gradually adjust the speed, especially for the analog

model.

There are two different types of control in most of the mixers: digital and analog. Both

control modes can adjust the speed and timer of the mixers.

1. Digital Control of Speed and Timers

Figure 14: Overview of the front panel of the digital control mode. ①Start/stop

button; ②Mode button; ③Indicator beneath “rpm”; ④ Indicator beneath “time”

There are two buttons and one knob on the digital panel: The knob is the main switch for

turning on the machine and adjusting the speed and timer; the mode button has the

6

Page 7

selection function to either adjust the timer or the speed; the start/stop button is used to

start or stop the mixing process. The panel has LED numeric display and red indicators.

When starting the mixers, the red indicator between the start/stop and mode buttons

illuminate, and when pressing the mode button, the read indicators underneath the rpm

and minute alternatively illuminate to show the status of display.

1.1 Press the knob to turn on the unit. The LED display the number of last saved rpm and

timer setting. And the indicator underneath the rpm illuminate, adjust the rpm by the knob

to desired value. And move the illuminated indicator from underneath rpm to minute by

pressing the mode button, the display will show the set timer and change to the desired

timing value, and finally press the start/stop button to start the machine. If using the knob

to turn off the machine, the set timer and speed will automatically be saved, and carry on

the next time operation.

1.2 Adjust the timer: press mode button until the indicator underneath of min illuminate,

turn the knob to desired count-down minute. To disable the timer, just turn the knob to ---,

the unit will continuously operate until manually stopping the unit. When the timer reaches

to zero, the unit stops and sounds an alert.

The default time unit is minute (displayed nnnn), but it can be changed to Hour: Minute

(displayed H:nn) or Minute: Second (displayed nn:ss). To do so, turn off the machine

completely with the main electrical switch, press the knob and mode button simultaneously,

and turn the machine back on. The display will display 88:88 and then off. Turn the

machine on using the knob, the display will show nn:ss (for minute: second) or H:nn (for

hour : minute) or nn (for minute), and turn the knob to the desired unit and press the knob

again to turn off the machine, the display will show OFF. When turning on the machine next

time, the newly set unit will take effect.

1.3 The speed and timer can be adjusted during operation without stopping the machine.

Suggest users to use lower speed to start the machine and adjust the speed to optimum

mixing status slowly to avoid the spill or safety problems during the operation.

2. Analog Control of Speed and Timers

Figure 15: Overview of the front panel of the analog control mode. ①Timer knob;

②Main switch; ③Speed knob

7

Page 8

There are two knobs and one main switch on the front panel of the analog types of the

mixers. The main switch has three stages function: ON, OFF and Timer. For continuous

operation, place the switch to the “ON” position, and turn the rpm knob (on the right hand

side) to desired speed. When using timer, place the switch to “Timer” position, and adjust

the speed using speed knob. Before turning on the machine, please turn the speed knob all

the way to the left hand side (minimum level)! And adjust the speed gradually.

3. The temperature setting of the mixer incubator (*MI series)

The mixer incubators have two separate control panels: The bottom panel is for the control

of speed and timing which is exactly the same setting procedures describe above; and the

top control panel is for temperature control (see Figure 16). To set the temperature, hold

the set button, and turn the knob to the desired temperature. After release the set button,

the temperature setting takes in effect immediately. For CMI-100, the temperature can only

be set from 5˚C above room temperature to 60 ˚C maximum.

Maintenance and Service

This range of equipment only requires routine cleaning for the maintenance. Before

cleaning, Always unplug the equipment from the electrical outlet. Use soft cloth with mild

detergent to clean the surface of the equipment.

Dynalab Corp. | 175 Humboldt Street, Suite 300 | Rochester, NY 14610

Tel: 800-334-7585 | Fax: 585-334-0241

www.dynalon.com | E: dynaloninfo@dyna-labware.com

8

Loading...

Loading...