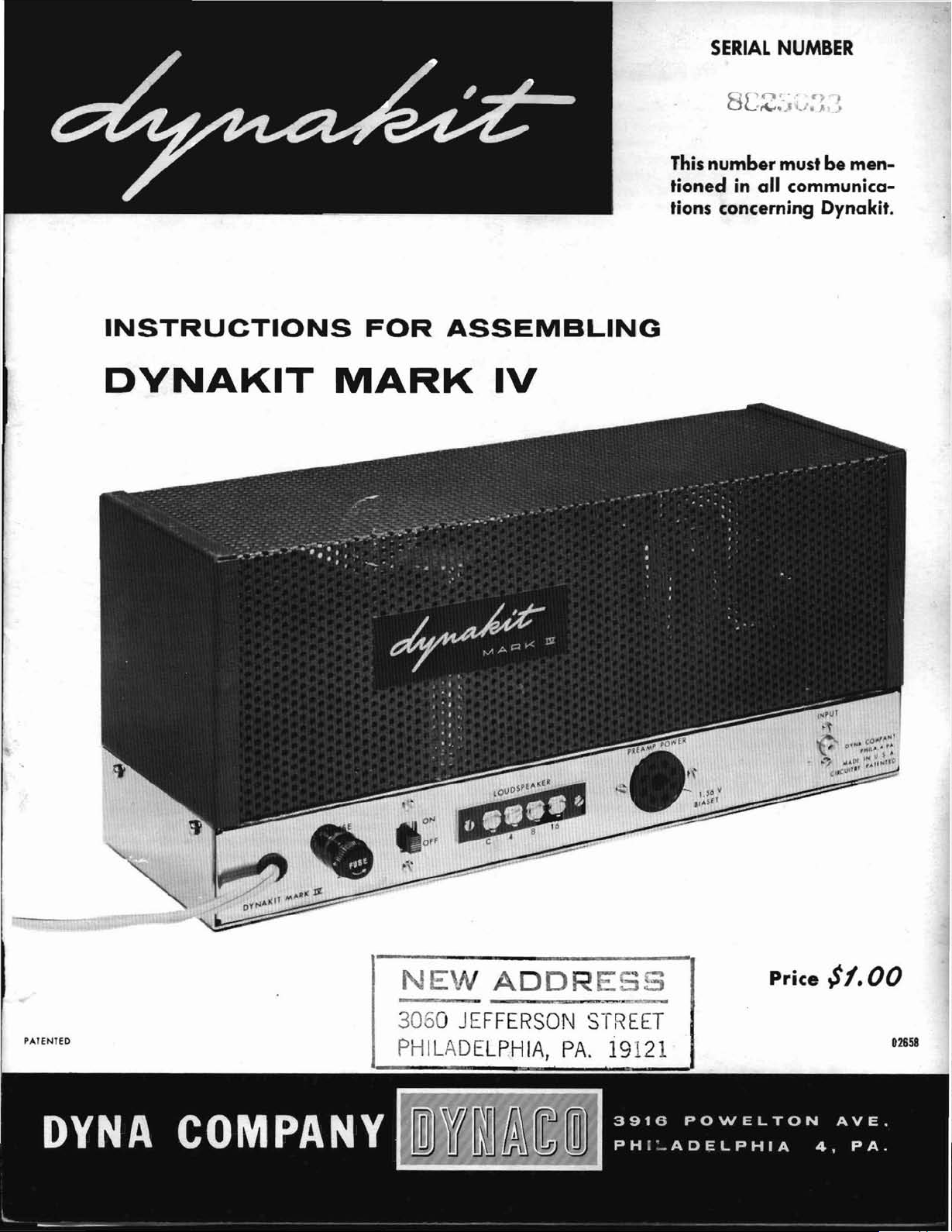

Dynakit MArk IV Instructions For Assembling

SERIAL

NUMBER

INSTRUCTIONS

DVNAKIT

FOR

MARK

ASSEMBLING

IV

0'.'-

8[

'~.J.'

This

numbermustbemen-

in

tioned

tions concerning Dynakit.

all communica-

...

f'")

~

/,

Jt,

.•

PATENTED

3060

JEFFERSON

PHILADELPHIA,

STREET

PA.

19121

Price

$1.00

1)2658

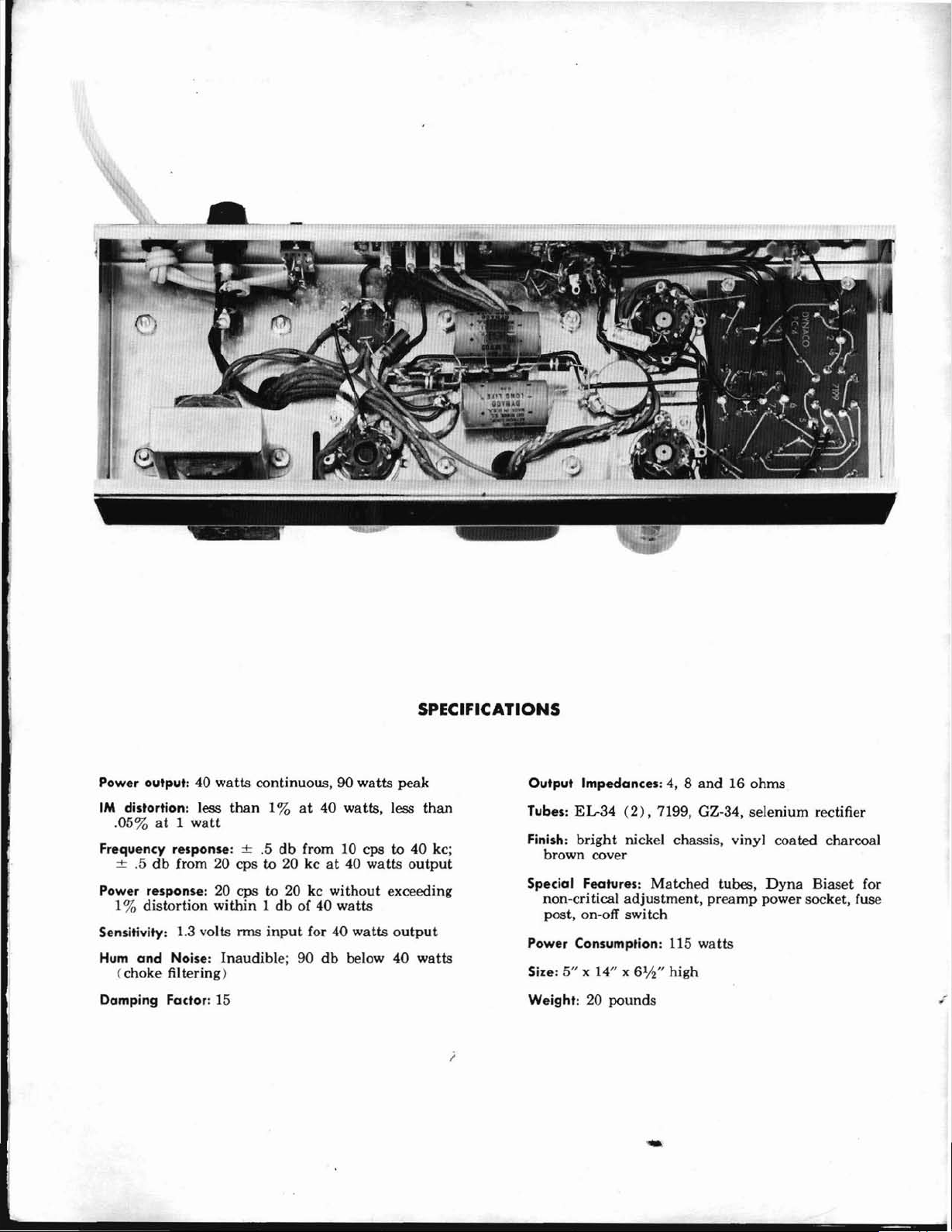

SPECIFICATIONS

Power output: 40

1M

distortion: less

.05%at1

watt

watts

continuous, 90

than

1%at40 watts, less

Frequency response: ±.5db

±

.5dbfrom 20 cps to 20kcat

Power response: 20

1

%

distortion

Sensitivity: 1.3 volts rms

Hum

and

Noise: Inaudible; 90

cps

to

within1db

input

(choke filtering)

Damping

Fador:

15

watts

peak

from 10 cps to 40 kc;

40 watts

20 kc

of 40

for 40

without

watts

db

exceeding

watts

output

below 40

than

output

watts

Output Impedances: 4, 8

Tubes:

Finish:

EL-34

bright

(2),

nickel chassis, vinyl coated charcoal

and

16 ohms

7199, GZ-34, selenium rectifier

brown cover

Special Features:

non-cri tical

adjustment,

Matched

tubes,

preamp

Dyna

Biaset for

power socket, fuse

post, on-off switch

Power Consumption: 115

Size: 5" x 14" x

Weight: 20

i

6%"

pounds

watts

high

INSTRUCTIONS FOR ASSEMBLING DYNAKIT

MARK

IV

DESCRIPTION

The

MarkIVAmplifier uses a

basedonthatofthe

which

have

become world famous for

while essentially

7199

tube

is usedasa

plifier

directly

All

parameters

This

typeofphase

that

its

operationisindependentoftube

no

adjustments

performance.

An

internal

phase

arrangement

signals to

ated

tubes use a fixed. bias

through useofDyna

provides

mizes

connection of

centage

lationofthe

uncritical of load impedance.

in

a very wide

negative voltage feedback lowers

unmeasurable

andtoless

40

stages

it

high

or

stability,

on

operated,

inverteratthe

the

well below

optimum

the

effects of

of screen loading which improves

output

The

impedance

the

output

dynamic

than

watts

output.

The

use of a

along

with

possible to

and

low frequencies.

means

that

there

oscillation

The

inherent

and

the

printed

completely non-critical.

highest

rior

and

dependable

time.

GENERAL

Assembly of

comparedtogeneral

is because all

assembled for

Other

parts

are

tered

layoutsothere

or

trouble shooting purposes. Con<;truction of

Dynakit

causeofthese

the

nents;

pictorial

Upon

parts

should

opening

list.

they

diagram

can

Dynakits

simple

coupledtoa

are

are

capacitive

provides

output

their

the

output

stage

proportionatnormal listening levels

minimum

have

is no

under

linearityofthe

the

prefabrication

circuit

the

critical

you

outinthe

not

simplifications.

your

Familiarize

be identified by

and

pentode

adjusted

inverter

requiredinmaintaining

feedback loop balances

highest

accurately

tubes, which

maximum

arrangement

Biaset

linearityofthe

unbalanced

tubes includes a small per-

stage

and

match

and

provide

range.

1%

intermodulation

careful

unconditional

tendency

any

condition

assembly

The

quality

operation

WIRING

Dynakit

kit

assembly requirements.

partsofthe

on

the

is easy accessibility for wiring

take

kit, check

andbyspecified color coding.

circuit

MarkIIand

superior

trouble

cathodyne

for

has

(patent

makesitcomparatively

bias conditions utilized

minimum

In

numberofphase

transformer

This

components insures supe-

MarkIVis

printed

open

more

yourself with

free.

high

gain

phase

minimum

the

unique

frequencies,

balanced driving

are

ratings.

pending)

tubes

components.

distortion

addition,20DB

the

distortiontoan

stabilityatboth

feature of

toward

of use.

circuit, its

of all critical wiring

make

use of conservatively

over a long period of

PRACTICE

Dynakit

circuit

in a free

than

three hours be-

the

components

comparison

arrangement

Mark

III

quality

The

new

voltage am-

inverter.

distortion.

advantage

aging so

EL-34's oper-

The

which is

distortion

design makes

motorboating

construction

quite

and

that

optimum

and

output

which

and

mini-

The

the

regu-

over

shifting

the

design

absolute

simple

This

are

factory

assembly.

unclut-

your

with

the

compo-

with

the

the

set

the

of

at

Tools required for easy assemblyofyour

are

a soldering

long nose pliers, screwdriver,

though

cutterofthe

thanadollar

ping

satIsfactory results from

ALL

ROSIN

any

used.

"Rosin

of which is doubtful,itis wisetoobtain

or

required,

"(S)

is specified,itindicates

be

the

touched to

soldertothe

iron

be held in place for a few seconds

it

the

It

transition

and

mechanical security.Itis

around

ing together

there should be no

wiggled

soldering

:ating.

III

be used with discretion since

availableisfar more

wires.

used;

nection

strain

cised

they

for simplified procedure in which

done

tions of

structions

ing off each

diagrams

nections Checked

next step.

each

work

not

the

various leadsinthe

c,;ood

soldering technique is

SOLDERING

CORE

equipmentinwhich

Make

Core."Ifyou

60/40

".Ifthis symbol is

madeatthat

Soldering is accomplishedbyheating

iron

and

joint. After

is seen

connection-the

should

Before

the lead

contacts

withapair

A small

confined space.Ifa soldering gunisused

Component

the

can

on lugs or components.

not

are

actually

The

instructions which follow have been

without

the

step

without

iron

(small

essential, a low

type

which

win

greatly

SOLDER.

sure

that

have

rosin core solder.

the

assembly

point

before soldering.

until solder is

the

joint.Itis

iron.Itshould

the

that

the

solder

lug

not

show a ballofsolder,

from solder to

applying

with

length should be

to allow wires to touch

be followedona

should be used for reference

If

checked carefully,

solder

shouldbecrimped in

many

times. A single

with

pliers is suitable. After soldering

playatthe

of pliers.Itis practical todoall

a pencil

tipisextremely useful when working

than

leads

should

be

made

connectf::.j to the

interference between

wiring.Itis recommended

stepasit

against

the wiring is done methodically

difficultyassoonasit

tip)

or

and

wire

cost

wire

canbepurchased

facilitate

any

MUST

Thereisno

acid

the

solderisplainly

solderonhand

instructions

not

shown

that

hot

not

solder

has

and

component

the

not

type

required

such

from

stepbystep

is completed.

these before going on to

cutting

kit.

valuableinobtaining

electronic equipment.

BE

DONE

core solder has been

Whenever

after

further

be fedtothe

contacted

the

iron

be trimmed as

pointtopoint

connections will

enough to

desirabletofeed

flows,

and

wire connectedtoit.

lead.

joint

shouldbec1e.an

placesoas

necessary to

joint

wi~h

the

amount

fOl'

that

Care

should

one

same

the

the

your

amplifier

soldering gun,

the

removed when

turn

soldering

the

another

is completed.

Dynaldt

cutters. Al-

stripper

warranty

soldering is

specifyitby

a connection

the

iron

both

hut

if the )Pad is

a low

proper

point.

work can be

various por-

that

basis, check-

The

and

for less

and

strip-

WITH

marked

the

origin

new

50/50

joint

flow

when

junction

should

parts

a smooth

to have

wrap

leads

and

pinch-

wattage

it

should

of

they

without

be exer·

unless

arranged

the in-

pictorial

all con-

should

and

on

with

the

heat

light

are

con-

tlw

and

of

of

Refer

1

2

3

4

5

6

7

8

9

10

11

MECHANICAL

Pictorial

Mount

( )

screws,

est

screws

small

a

of

each

that

showninthe

the

screws from

mount

each

Mount

of

the

lockwashers.

Using#4hardware,

terminal

chassis.

Mount

with

are

not

the

positionofthe

pictorial.

Mount

provided.

outsideofthe

only

mounted.

Insert

at

the

Mount

in

the

sockets.

insert

at

the

Note

Mount

solder

Insert

the

terminal

the

small

With

clamp

Feed

former, PA-135,

provided.

place

nearest

lockwashers

bottom,

ing

two

fastcn

#8

hardware.

former

nexttothe

clamp

(J )

Mount

the

remaining

the

chassis.

orange,

ASSEMBLY

Diagrams

the

nuts,

supplied).

slotorkeywayinthe

socket;besureineach

this

keywayisproperly

the

sockets

screw

withanut

the

chassis

strip

the

#4 screws.

necessaryinthis

the

fuse

The

one

correct

the

rubber

endofthe

the

10,000

%" hole

Put

the

controlinthe

top

of chassis

orientationofconnecting

the

five lug

lugatthe

a #4 screw from

solder

#4

hardware,

loosely

all

the

with

the

place

transformer

bothinplace

leads

rectifier socket;

maybetightened.

the

output

and

for

LocationofParts

four

octal

sockets

and

lockwashers

Note

pictorial

the

input

using#4screws,

on

slide

post

rubber

chassis.

the

strip

lug,

near

wires

Fasten

two

frontofthe

and

the

All

go

setofholc-t;atthe

Note

yellow leads

diagrams.

topofthe

from

the

and

socket

mount

the

switch

Nuts

and

connecting

with

bushing

Note

way

for

grommetinthe

chassis.

ohm

bias

near

the

lockwasheronthe

with

terminal

centerofthe

the

over

then

mount

the

single

of

the

through

the

#8

screws in

chassis

nut<>.

choke

over

mounting

with

but

the

under

the

transformer,

that

the

inside.

lockwasher.

from

the

outside of

from

instance.

the

the

potentiometer

hole

outside.

the

the#4nut.

the

transformer

Now,

two

come

with

(the

small-

that

there

center

hole

instance

oriented

Insert

chassis

lockwashers

lugs in

special

goesonthe

that

pair

and

the

strip

screw,

octal

power

single

the

more

black trans-

cable

and

black, brown

and

Fasten

the

inside

nuts,

and

four screw

the

the

inside

Follow

the

nut

there

posttobe

%"

hole

of

octal

shaft,

fasten

%"

nut.

lugs.

and

the

chassis.

Place

then

the

cable

socket.

trans-

hole

the

holes

using

from

the

remain-

holes

and

sets

clamp

then

this

A-470,

center

through

#4

as

#8

on

in

of

of

the

hole

near

the

four screw

strip.

transformer.

12

is

Each

approximately

end

maybetrimmed

1

2

is

3

4

5

6

7

8

9

10

Mount

pacitorinthe

symbolsatthe

lug.

in

giving

ter

snugly

lengthofhookup

unless

(j)

Connect

mer

B of

(-J;

Connect

leadtopin

nect

socket

Twist

nect

nect

VI

Twist

leads

socket

one

and

of

Connect

lug

lug

Connect

Connect

circle)ofthe

nect

(~

)

Connect

output

screw

lead to lug

lead

lead to lug #4.

Connect

themtosockets

TORIAL.

to pin #3 of

green/white

These

the

turn

WIRING

%" of

otherwise

as

leadstolug

(8).

Connect

the

the

position

one

the

(8).

green

the

Connect

the

at

strip,

the

five lug

the

the

filter

terminal

to lug

to lug

the

remaining

Use

#8

hardware

the

quadruple

special

baseofeach

shouldbeorientedasshown

pictorial.

eachofthe

while

against

the

cutout.

Fasten

mounting

holding

chassis.

section

the

INSTRUCTIONS

wire

specified

insulation

specified.

required

oneofthe

the

fuse

one

yellow power

#2ofsocket

other

VI.

the

two red

them

red leadtopin

other

the

two green power

together

V2.

8EE

leadtopin

other

green

the

green/yellow

five lug

the

red/yellow

the

mounting

the

red/black

strip.

one

choke

quad

other

capacitor.

the

black

transformer

#2

#3

the

red

#2ofthe

Connect

socket

leadtolug

'stripped

Transformer

for a

/

post

yellow

around

red

and

terminal

choke

strip.

(8).

(8).

output

leads

V2

neat

black

#2ofthe

other

black

(8).

leadtopin

leads

socket

lead

position

PICTORIAL.

#2ofsocket

lead to

strip.

screw of

lead

leadtoJug #1 (semi-

filter

capacitor.

leadtolug

lead

to lug # I of

Connect

Connect

Connect

transformer

filter

capacitor.

together

and

the

blue/white

V2

(8).

#4 of

terminal

to

secure

Observe

connecting

capacitor

lugsaquar-

the

should

from

wiring

power transfor-

slide

leadtolug

transformer

V1

(8).

together

#4

(8).

to

pin

transformer

pin#7of

lead

lead

to lug#4of

of

the

the

the

the

and

V3.

8EE

Connect

socket

the

filter ca-

the

capacitor

have

each

leads

job.

switch

Con-

#8

and

VI.

Con-

Con-

#6

them

Connect

V2,

V2.

to lug

to

solder

the

five

Con-

#2

A-470

the

four

brown

orange

yellow

lead

Twist

carry

PIC-

lead

the

V2

by

#2

of

of

to

of

-

2

11

12

13

14

15

16

17

18

19

20

21

22

23

(S).

Connect

(S).

V3

#4

of V3.

Connect

the

Connect

one

end

blue

lead to

the

green

of a 10,000

pin#3of

leadtopin

(brown-black-orange) resistor to lug

of

the

five

lug

strip.

end

to lug #1 of

tentiometer

Connect

selenium

lug

strip

endtolug

Connect

mfd

bias

lug

strip

(S).

the positive

rectifiertolug

(S).

#5 of

the

negative

capacitor

(S).

endtolug#3of

Connect

other50mfd

the

to

lug#2of

five

lug

the

positive

bias

strip.

the

Connect

the

10,000

(+)

Connect

the

the

strip.

(-)

to lug

Connect

the

the

strip.

(+)

capacitortolug#3of

Connect

10,000

ohm

the

ohm

bias po-

end

#4ofthe

negative

end

of a 50

#5ofthe

positive

end

the

other

bias poten-

tiometer.

Connect

to lug

nect

If

nakit

fier,

#2

Connect

one

end

#2ofthe

the

other

the

amplifier istobe

PAM-1

this

wire

should

soldered.

one

of a

short

five

lug

piece of wire

strip

endtolug#3of

used

(monophonic)

be'

omitted

end

of a 10,000

(S).

the

withaDy-

preampli-

and

(brown-black-orange) resistortolug

of

the

five lug

other

endtolug #1 of

Connect

#1 of

other

one

the

end

potentiometer

Connect

one

mounting

capacitor

solder

lugatmounting

end

five lug

to lug

(S).

end

lug

(ground

(S).

strip

of a

strip

#3ofthe

of a 2

Connect

(S).

Connect

the

strip.

4%"

wiretolug

(S).

Connect

bias control

1

h"

wire

lug)ofthe

the

other

screw of

the

lug strip.

8trip

Ih" of

a

5"

wire.

#8ofsocket

#1

(S).

#8ofsocketV3and

Connect

of V3

#8ofpower

of

chassis)

Connect

to

pin

end

to

SEE

PICTORIAL.

Connect

of

socket

to lug #1 of

(8)

.

Connect

of

the

insulation

Feed

V2

Feed

one

end

(S).

Connect

takeoff

(8).

one

endofthe

#8

of V3

ground

one

end

VI

(8).

one

end

four screw

from

each

one

end

through

(8)

and

connecttopin

the

other

end

through

connecttopin

of a 2" wiretopin

the

other

socket

(8).

lug

13.5

Connect

of

socket

(on

ohm

of a3"wire to

the

Connect

quad

the

filter

of a 4" wire to

terminal

endtopin

front

resistor

the

V3

other

capacitor

strip

other

of

of

Con-

strip.

end

end

other

pin

lug

ohm

#5

the

five

(-)

five

(+)

the

end

lug

ohm

#3

the

the

to

filter

five

of

pin

pin

#I.

#1

side

(8).

#8

end

#1

(8)

Connect

the

(!>

24

Twist

connect

Connect

othertopin

the

nect

25

Twist

so

Connect

(S)

socket.

of V3

to

26

Connect

black-black) resistor

power takeoff

other

(S)

27

Connect

(red-red-orange)

takeoff

endtopin

(v)

28

Connect

#4ofthe

nect

#4.

DYNApreamp

Mount

cutout

that

of

mounted

with#4screws,

The

already

a

to

hasanumber

the

tiontothe

to

dering

soldertothe

the

in

allow a few seconds for

Although

the

small

sive

29

Connect

of

other

the

30

Connect

socket

endtoeyelet

31

Twist

nect

nect

oneofthe

Connect

.

(8)

the

five lug

other

strip

(S).

togetherapair

one

endofonetopin#2of V2.

the

corresponding

#7

of V2.

other

endstopin#2of V3,

the

last

onetopin#7of V3.

together

that

one

the

and

Connect

(S).

pin#7of V3

#2

one

a 5

pair

even

pairofendstopins

(S)

the

Connect

(S).

end

of a 10

socket

endtoground

.

one

end

of a 22,000

to

socket

(S).

#4.

one

end

of a

power takeoff

the

other

end

(See

application

is tobeused.) .

the

printed

at

the

end

the

socketislocated

the

chassis.

from

The

the

nuts,

eyelets on

have

the

solder

which

instructions. Before

board,

be

connectedbyheating

iron

and

"tin"

touching

eyelet,

iron,

insert

the

the

eyelet

flows, remove

the

printed

iron

heatonthe

the

circuit

endtothe

inputsocket

long lug

metal

wiring from overheating, a

shouldbeusedtoavoid exces-

printed

one

end

of a 2" wire to

board

ground

(S).

one

end

of a 2" wiretoinput

(S).

#2

(8).

togetherapair

one

endtopin#2of V2

the

other

endtopin#7(S).

other

endstoeyelet

the

.

remaining

endtoground

of 5" wires

end

Connect

and

1

h"

anda4%"

of

ends

are

uneven.

of

the

power takeoff

long

endtopin

the

remaining

ohm

(brown-

to

pin

#3

(8).

Connect

lug

at

that

ohm

pin#5of

Connect

5%"

socket

to filter

notes if

circuit

of

the

the

the

wire to

(8).

capacitor

other

boardinthe

chassis.

nearest

board

bottom

and

printed

in them.

should

of

the

lockwashers.

circuit

Each

will be referred to

making

the

a connec-

stripped

with

soldertoit.

heat

the

eyelet

wire

when

the

the

iron

the

solder

eyelet

does

circuit

board.

eyelet

(S).

Connect

(short)

Connect

the

of 6" wires. Con-

(S).

Connect

#4

endtoeyelet

lug

and

of

the

one

con-

wire

#1

#2

end

of

the

the

socket

resistor

power

other

pin

Con-

lug

than

Note

the

end

chassis

board

eyelet

wire

the

sol-

To

with

solder

and

to set. .

protect

#1

the

lug

other

Con-

(S).

#5

at

of

be

in

of

3

Loading...

Loading...