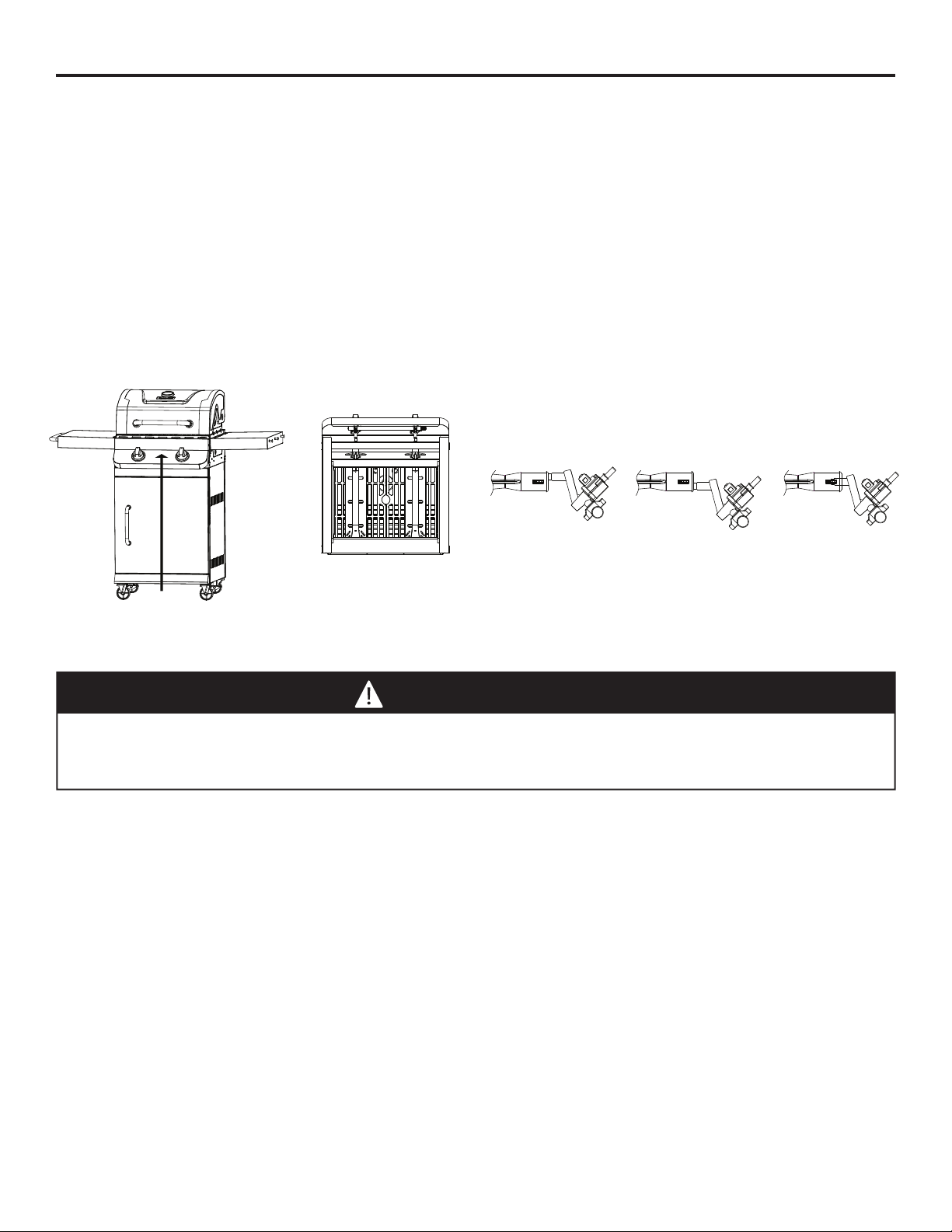

Dyna-Glo DGP321SNP, DGP321SNP-D, DGP321CNP, DGP321CNP-D, DGP321GNP User Manual

...

2 BURNER PREMIER

PROPANE GAS GRILL

Model # DGP321SNP / DGP321SNP-D

DGP321CNP / DGP321CNP-D

DGP321GNP / DGP321GNP-D

DGP321MNP / DGP321MNP-D

Français p. 32

Français p.

Español p. 63

Español p.

XX

XX

ATTACH YOUR RECEIPT HERE

Serial Number _____________________________ Purchase Date ______________________

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-877-447-4768, 8:00 a.m. – 4:30 p.m., CST, Monday – Friday or

e-mail us at customerservice@ghpgroupinc.com.

Rev. 06/07/2019

1

TABLE OF CONTENTS

Safety Information ...................................................................................................................... 3

Package Contents ...................................................................................................................... 5

Hardware Contents .................................................................................................................... 6

Preparation ................................................................................................................................. 6

Assembly Instructions ................................................................................................................ 7

Operation Instructions ................................................................................................................. 18

Care and Maintenance ................................................................................................................. 23

Troubleshooting ........................................................................................................................... 26

Warranty ...................................................................................................................................... 28

Replacement Parts List .............................................................................................................. 29

Assembler/Installer: This manual contains important information necessary for the proper

assembly and safe use of this appliance. Read and follow all warnings and instructions before

assembling and using this appliance. Leave these instructions with the consumer.

Consumer/User: Follow all warnings and instructions when using this appliance.

Retain these instructions for future reference.

If you smell gas:

DANGER

1. Do not store or use gasoline or

WARNING

other ammable liquids or vapors

in the vicinity of this or any other

1. Shut off gas to the appliance.

2. Extinguish any open ame.

3. Open lid.

4. If odor continues, keep away from

the appliance and immediately call your

local re department.

appliance.

2. An LP (liquid propane) cylinder not

connected for use shall not be stored

in the vicinity of this or any other

appliance.

3. This grill is for outdoor use only

and shall not be used in a building,

garage, under overhangs or any other

enclosed area.

4. Do not leave a lit grill unattended.

Keep children and pets away from the

grill at all times.

2

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or

install the product. If you have any questions regarding the product, please call customer

service at: 1-877-447-4768, 8:00 a.m. – 4:30 p.m., CST, Monday – Friday.

DANGER

• Do not use in an explosive atmosphere. Keep grill area clear and free from combustible

materials, gasoline and other ammable vapors and liquids.

WARNING

This product and the fuels used to operate this product (liquid propane or natural gas), and

the products of combustion of such fuels, can expose you to chemicals including benzene,

which is known to the State of California to cause cancer and reproductive harm.

For more information go to www.p65Warnings.ca.gov

CAUTION

• Never use charcoal or lighter uid with the grill.

• Do not use gasoline, kerosene or alcohol for lighting.

• The LP gas cylinder used with this appliance must be:

(a) Constructed and marked in accordance with the Specications for LP-Gas Cylinders

of the U.S. Department of Transportation (D.O.T.) or the National Standard of Canada,

CAN/CSA-B339, Cylinders, Spheres and Tubes for Transportation of Dangerous Goods;

and Commision, as applicable; and

(b) Provided with a listed overlling prevention device.

(c) Provided with a cylinder connection device compatible with the connector for outdoor

cooking appliances. This grill is not intended to be used in or installed on recreational

vehicles and/or boats.

• Never keep a lled container in a hot car or car trunk. Heat will cause the gas pressure to

increase, which may open the relief valve and allow gas to escape.

• Always open grill lid slowly and carefully as heat and steam trapped within the grill can burn

you severely.

3

SAFETY INFORMATION

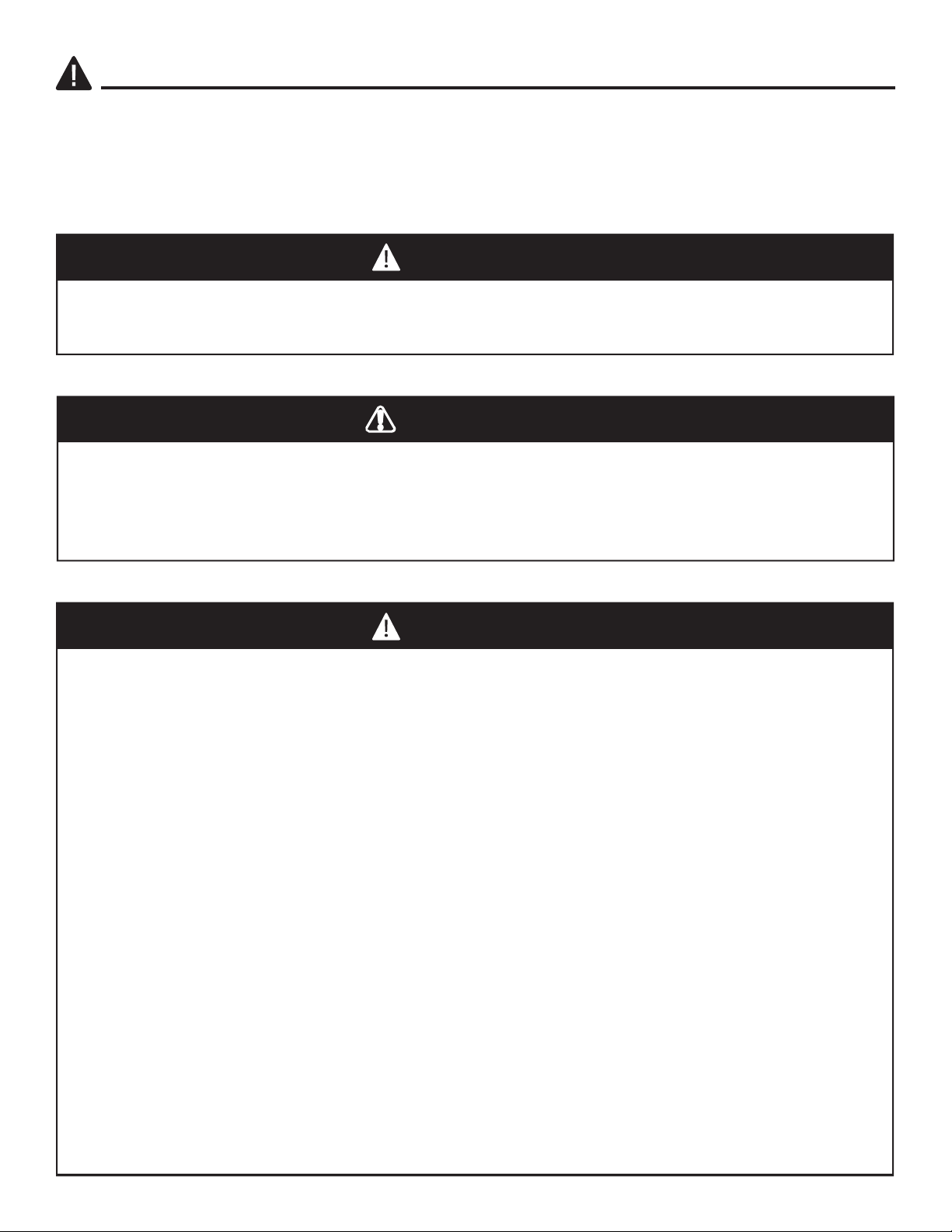

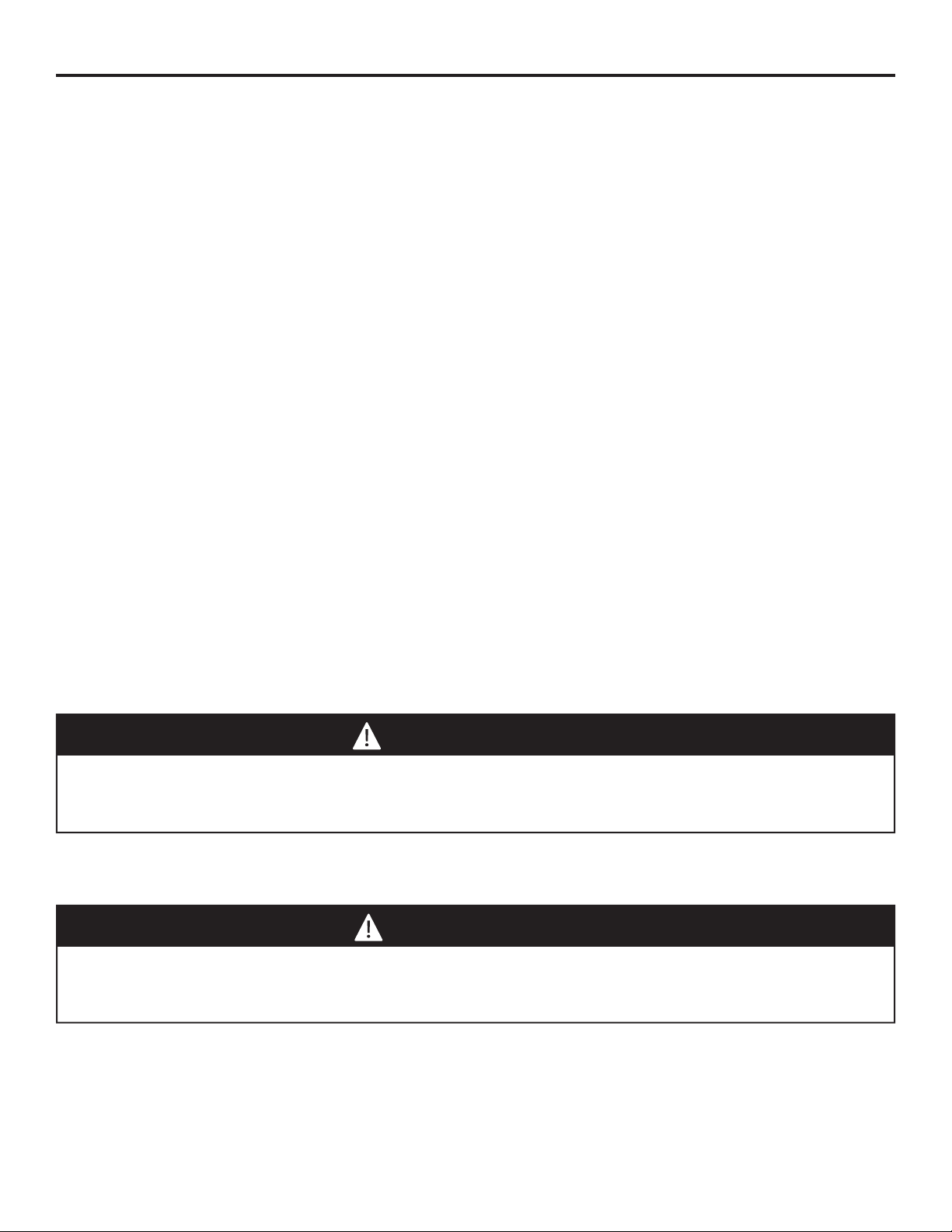

WARNING

• Do not place the grill under overhead

combustible construction or awnings.

Minimum clearance from sides and

back of unit to combustible construction,

36 inches (914.4mm) from sides and

back.

NOTE: The installation must conform with

local codes or, in the absence of local

codes, with either the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, Natural

Gas and Propane Installation Code,

CSA B149.1, or Propane Storage and

Handling Code, B149.2.

CAUTION

914.4mm

36in

36in

914.4mm

• Do not store or use gasoline or other ammable liquids or vapors in the vicinity of this or any

other appliance.

• An LP cylinder not connected for use shall not be stored in the vicinity of this or any other

appliance.

• This grill is for use with propane gas only (propane cylinder not included).

• Never attempt to attach this grill to the self-contained propane system of a boat, camper trailer,

motor home or house.

• Do not attempt to move the grill while it is lit or when it is hot. The casters should be locked

when not moving the grill.

• Do not use the grill unless it is completely assembled and all parts are securely fastened and

tightened.

• Keep all combustible items and surfaces at least 36 inches (91.44 cm) away from the grill at all

times.

• Do not touch metal parts of grill until it has completely cooled (about 45 minutes) to avoid burns,

unless you are wearing protective gear (pot holders, gloves, BBQ mittens, etc…).

• Do not alter this grill in any manner.

• Clean and inspect the hose before each use. If there is evidence of abrasion, wear, cuts, or

leaks, the hose must be replaced prior to operating the appliance. The replacement hose

assembly will be that which is specied by the manufacturer.

• Move gas hoses as far away as possible from hot surfaces and dripping hot grease.

• Keep the grill’s valve compartment, burners and circulating air passages clean. Inspect the grill

before each use. Do not obstruct the ow of gas or ventilation air.

• The use of alcohol, prescription or non-prescription drugs may impair the operator’s ability to

properly assemble or safely operate the grill.

• Do not leave a lit grill unattended. Keep children and pets away from the grill at all times.

• Do not place this grill on any type of tabletop surface. The grill should be placed on a at and

level surface.

• Do not use the grill in high winds.

4

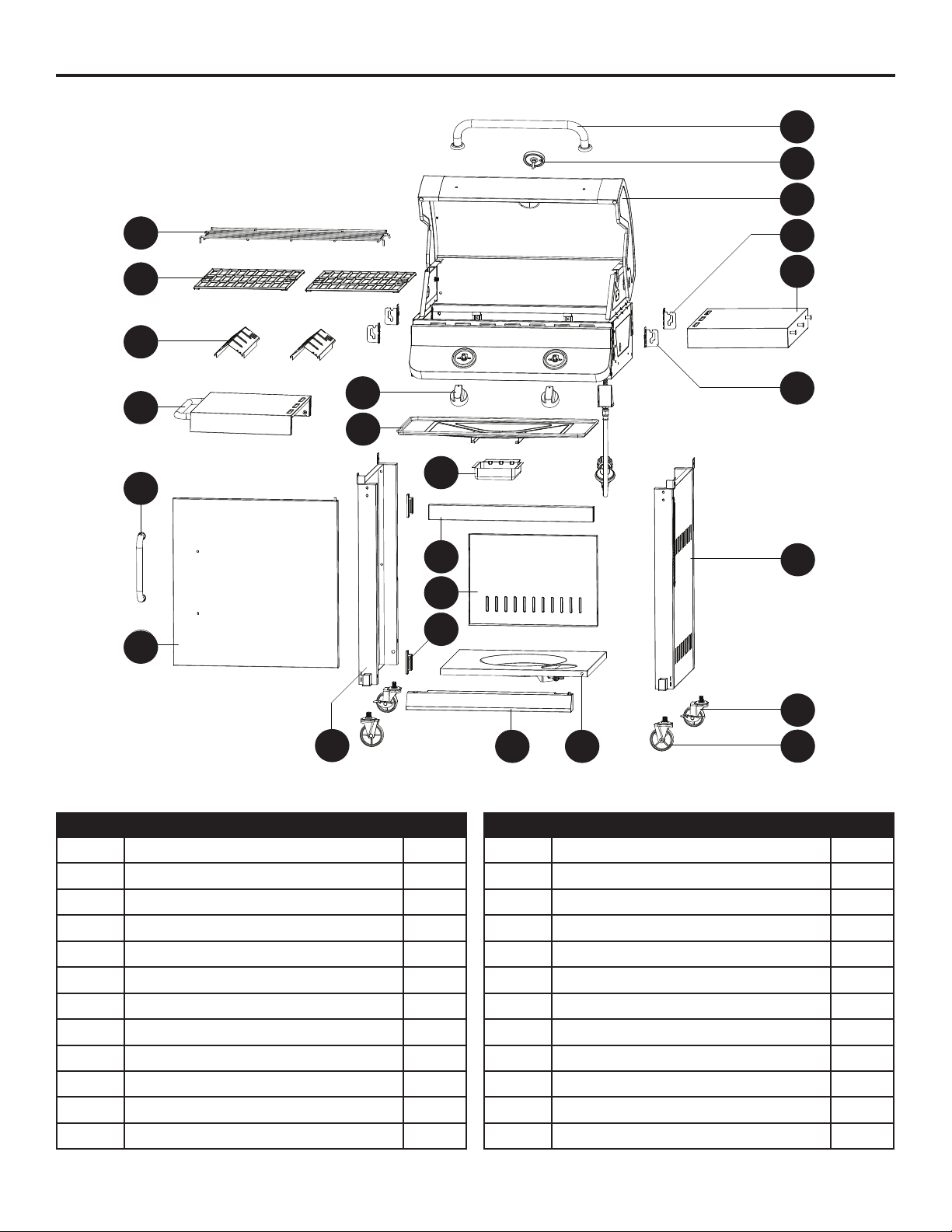

PACKAGE CONTENTS

R

R

Q

Q

P

P

O

O

N

N

S

S

T

T

U

U

A

A

B

B

C

C

D

D

E

E

F

F

V

V

W

W

X

X

M

M

L

L

PART DESCRIPTION QTY

A Hood Handle 1

B Temp Gauge 1

C Grill Body Assembly 1

D Side Shelf Bracket A 2

E Right Side Shelf Assembly 1

F Side Shelf Bracket B 2

G Cart Right Side Panel Assembly 1

H Locking Swivel Caster 2

I Non-Locking Swivel Caster 2

J Cart Bottom Panel Shelf 1

K Bottom Panel Skirt Assembly 1

L Cart Left Side Panel Assembly 1

G

G

H

H

K

PART DESCRIPTION QTY

M Door Assembly 1

N Door Handle 1

O Left Side Shelf Assembly 1

P Heat Tent 2

Q Cooking Grate 2

R Warming Rack 1

S Control Knob 2

T Grease Pan 1

U Grease Cup 1

V Upper Front Door Brace 1

W Cart Rear Panel 1

X Door Magnet 2

JK

J

I

I

5

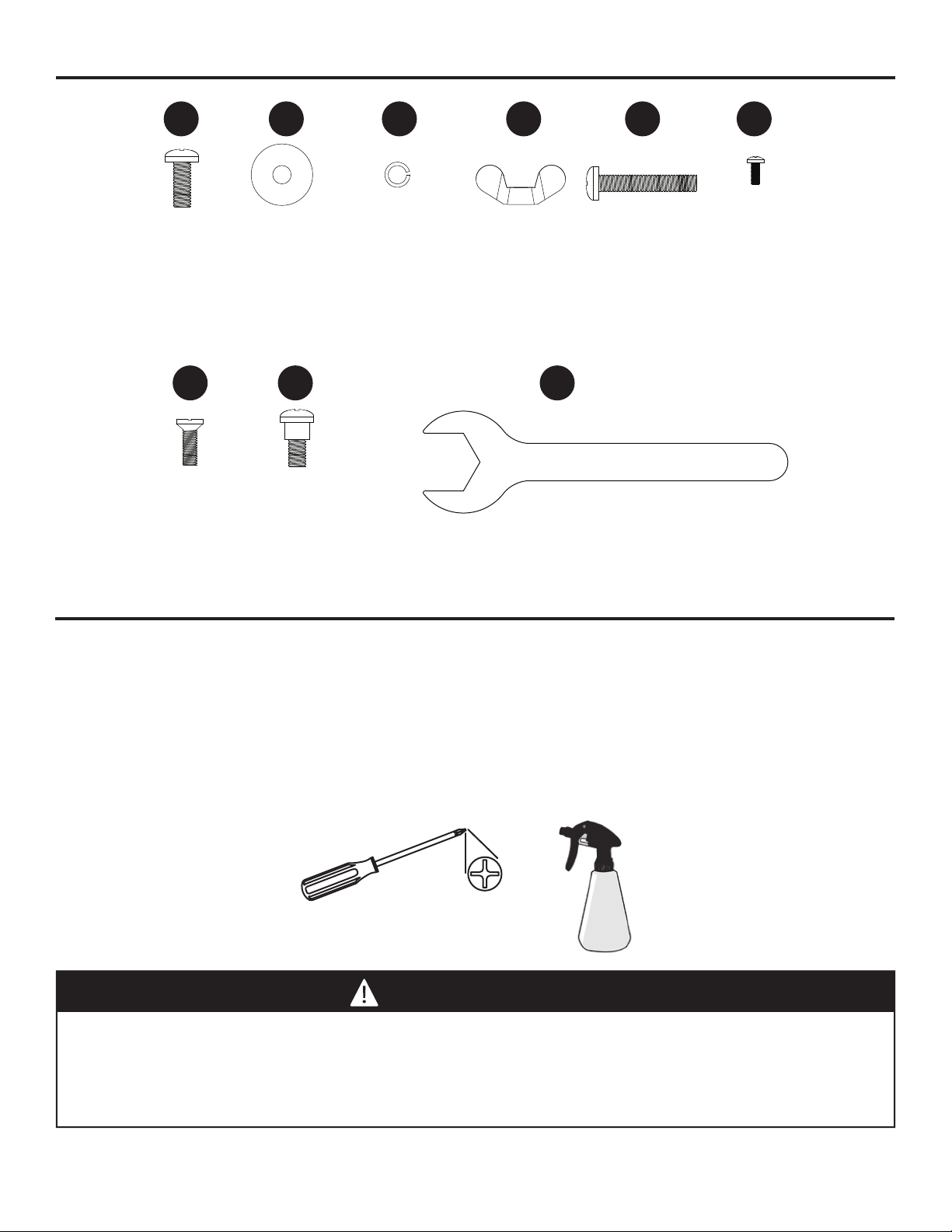

HARDWARE CONTENTS

AA

AA

M6x16

Bolt

Qty. 18

GG

GG

M6x12

Flat Bolt

Qty. 8

BB DD FF

BB

M6

Plain

Washer

Qty. 2

HH II

HH

CC

CC

M6

Spring

Washer

Qty. 2

DD

M6

Wing Nut

Qty. 2

II

EE

EE

M6x35

Bolt

Qty. 4

Shoulder

Bolt

Wrench

Qty. 1

Qty.4

FF

M3x10

Bolt

Qty. 4

PREPARATION

Before beginning assembly of product, make sure all parts are present. Compare parts with package

contents list on previous page and hardware contents above. If any part is missing or damaged, do

not attempt to assemble the product. Contact customer service for replacement parts.

Estimated Assembly Time: 50 minutes with 2 people.

Tools Required for Assembly and Leak Testing (not included): Phillips screwdriver, Spray bottle

CAUTION

THIS UNIT IS HEAVY. Two people required for safe assembly.

Two people required for safe assembly. Some parts may contain sharp edges. Wear protective

gloves if necessary. Read and follow all safety statements, warnings, assembly instructions and

use and care instructions before attempting to assemble and use.

6

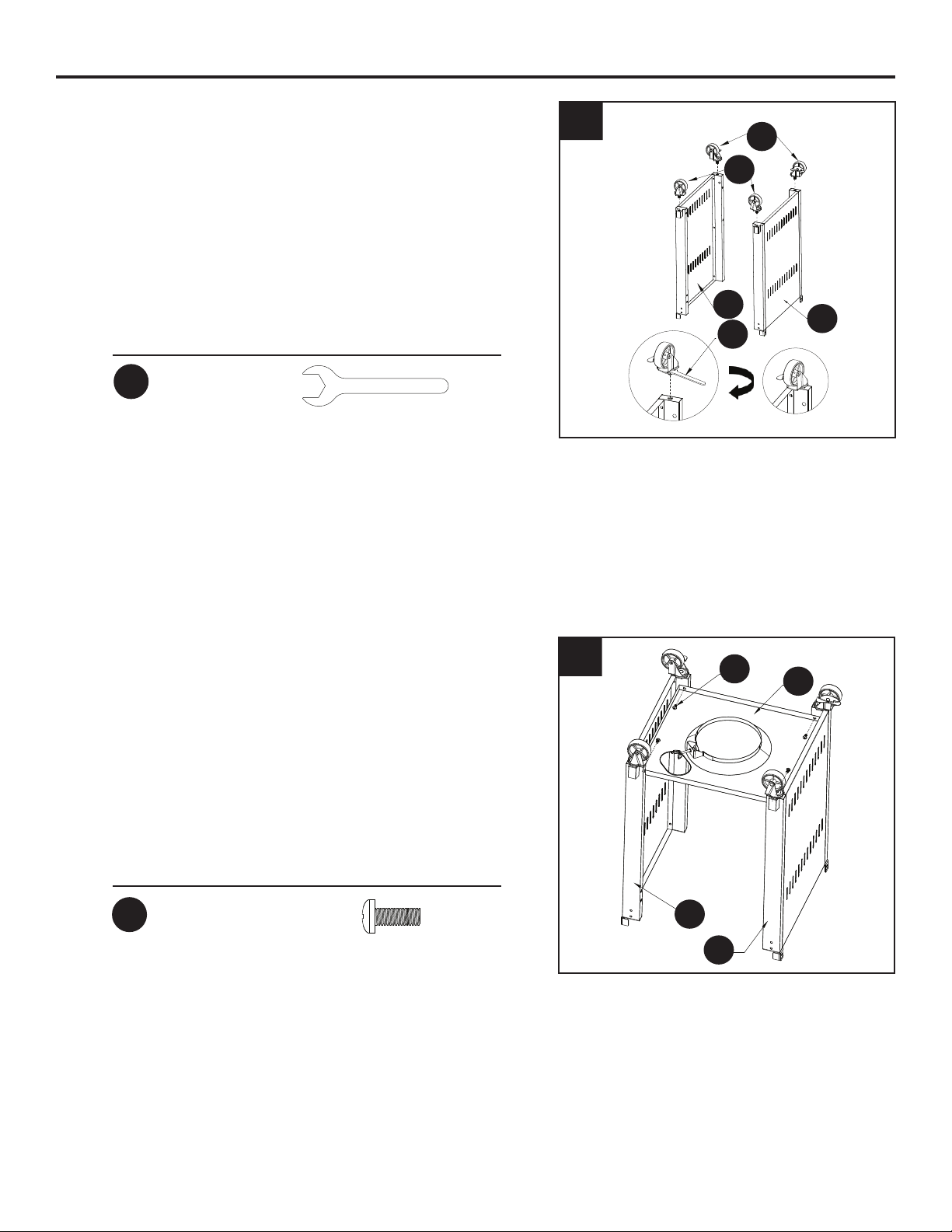

ASSEMBLY INSTRUCTIONS

M6

Plain

Qty. 2

M6

Qty. 2

M6x16

Bolt

Qty. 18

Washer

M6x35

Bolt

Qty. 4

Washer

M6

Wing Nut

Qty. 2

GG

M3x10

Bolt

Qty. 4

HH

M6x12

Flat Bolt

Qty. 8

Shoulder

Bolt

Qty.4

II

Qty. 1

Wrench

Spring

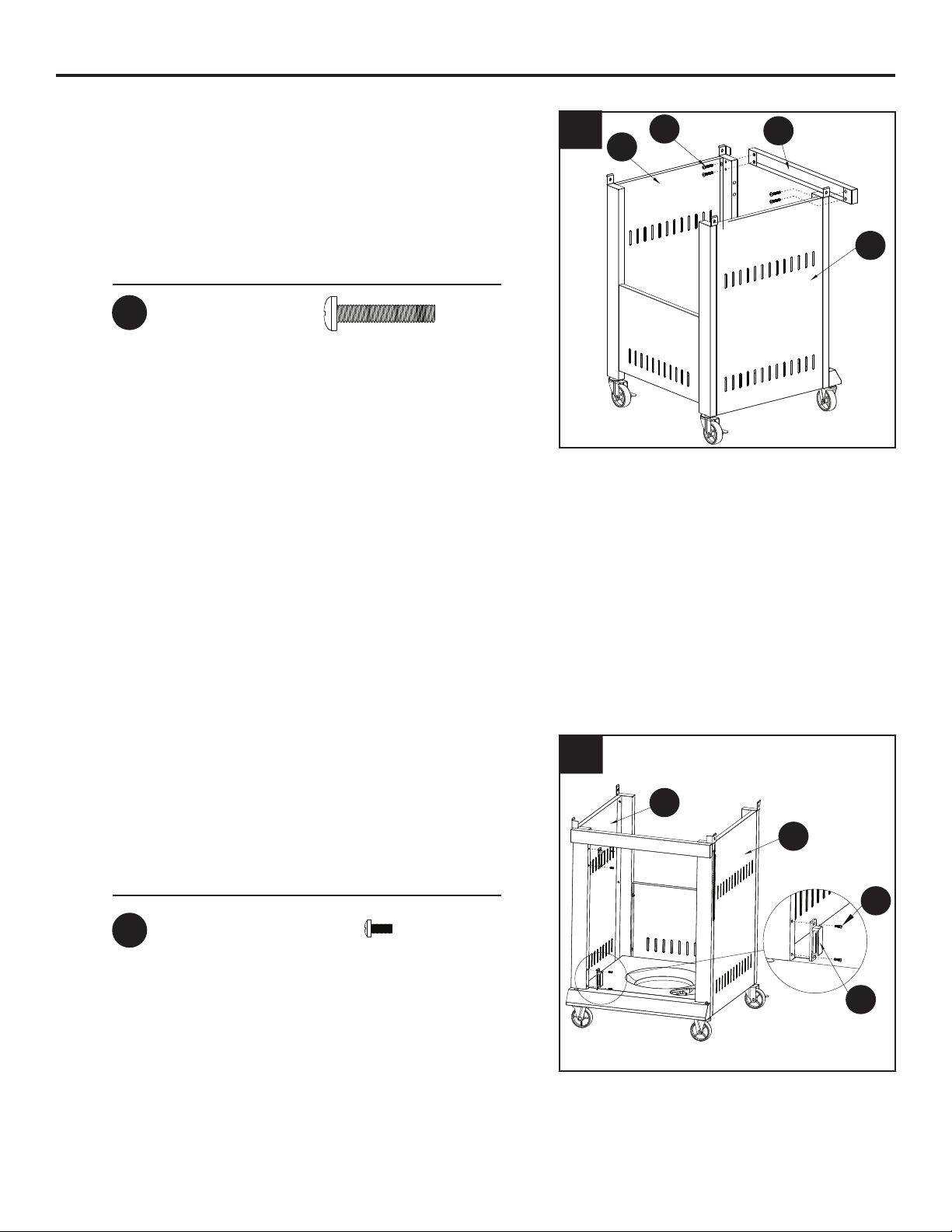

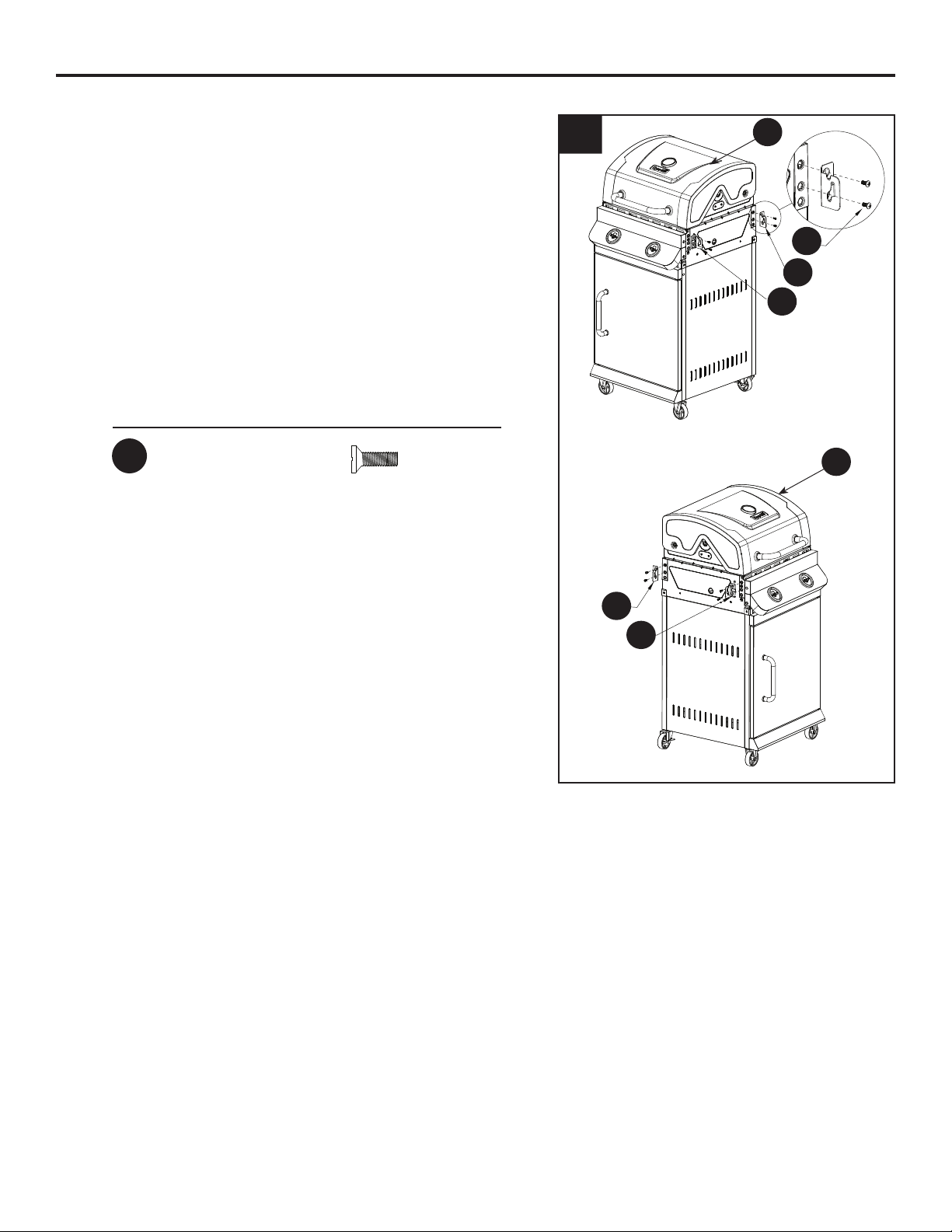

1. Attach the two locking swivel casters (H) and

the two non-locking swivel casters (I) to the

cart left side panel assembly (L) and the cart

right side panel assembly (G) with wrench (II).

Hardware Used

II

Wrench

1

G

G

II

H

H

I

I

L

II

L

2. Attach the cart left side panel assembly (L) and

the cart right side panel assembly (G) to the

cart bottom panel shelf (J) with four M6x16

bolts (AA).

Do not tighten bolts at this time.

Hardware Used

AA

M6x16 Bolt

x 4

2

G

G

L

AA

AA

L

J

J

7

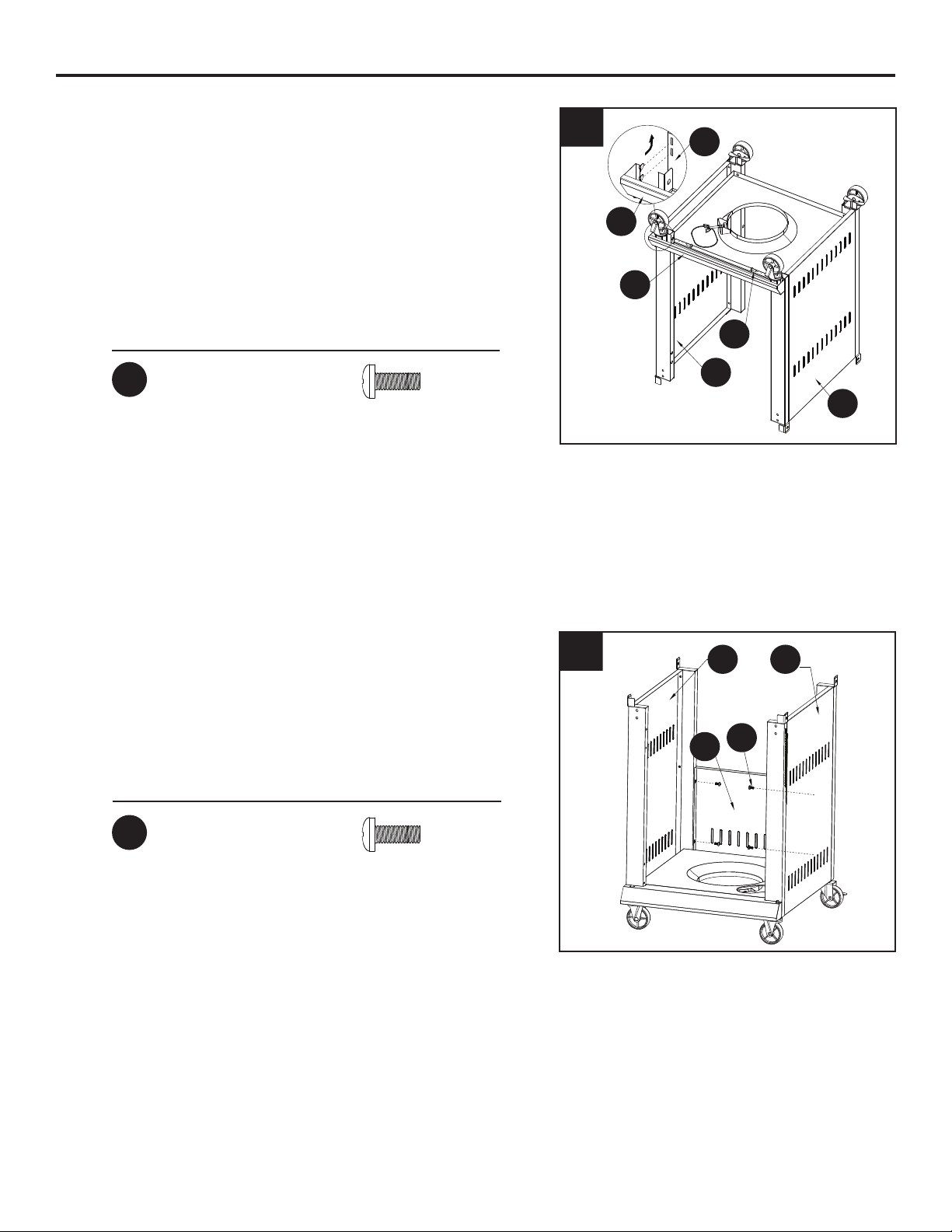

ASSEMBLY INSTRUCTIONS

M6

Plain

Qty. 2

M6

Qty. 2

M6x16

Bolt

Qty. 18

Washer

M6x35

Bolt

Qty. 4

Washer

M6

Wing Nut

Qty. 2

GG

M3x10

Bolt

Qty. 4

HH

M6x12

Flat Bolt

Qty. 8

Shoulder

Bolt

Qty.4

II

Qty. 1

Wrench

Spring

M6

Plain

Qty. 2

M6

Qty. 2

M6x16

Bolt

Qty. 18

Washer

M6x35

Bolt

Qty. 4

Washer

M6

Wing Nut

Qty. 2

GG

M3x10

Bolt

Qty. 4

HH

M6x12

Flat Bolt

Qty. 8

Shoulder

Bolt

Qty.4

II

Qty. 1

Wrench

Spring

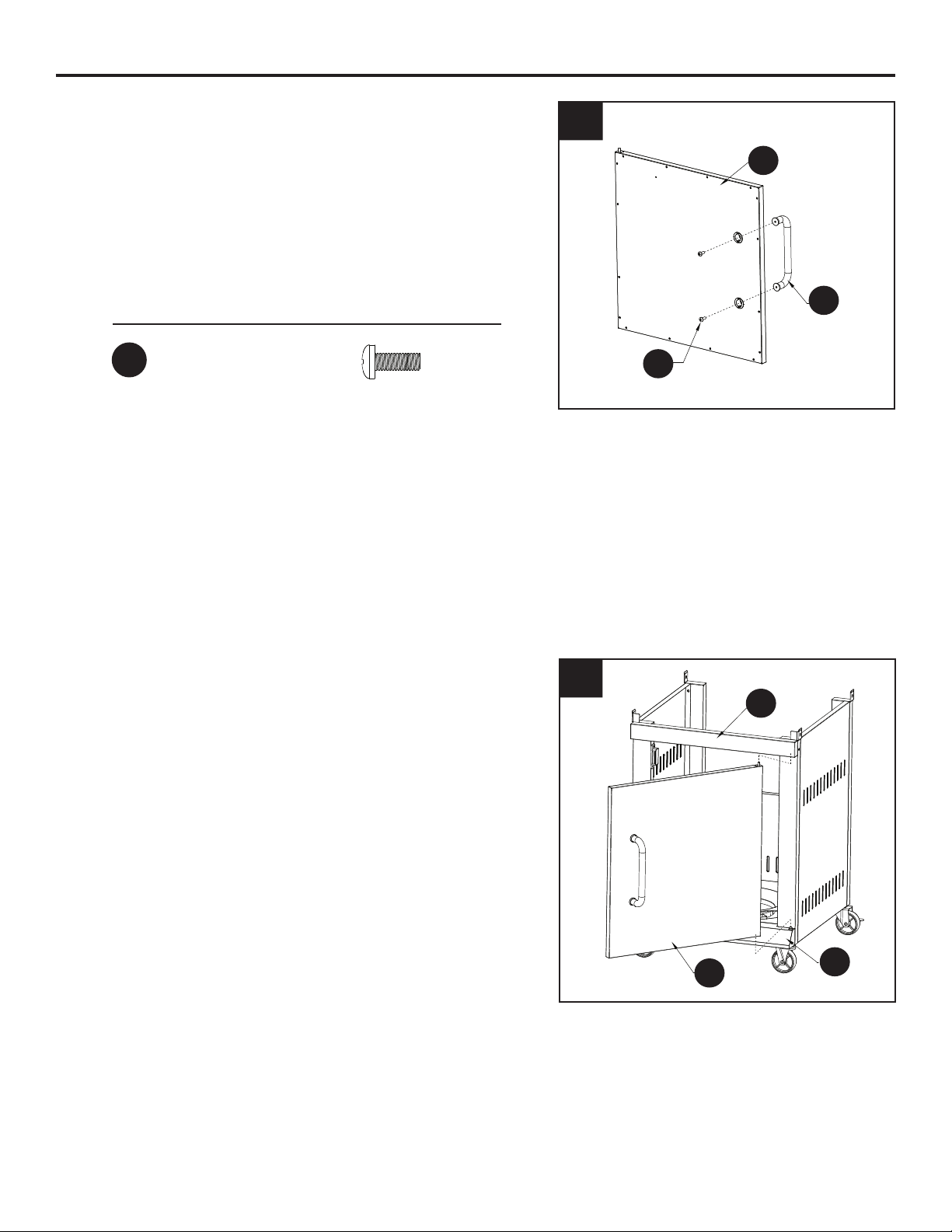

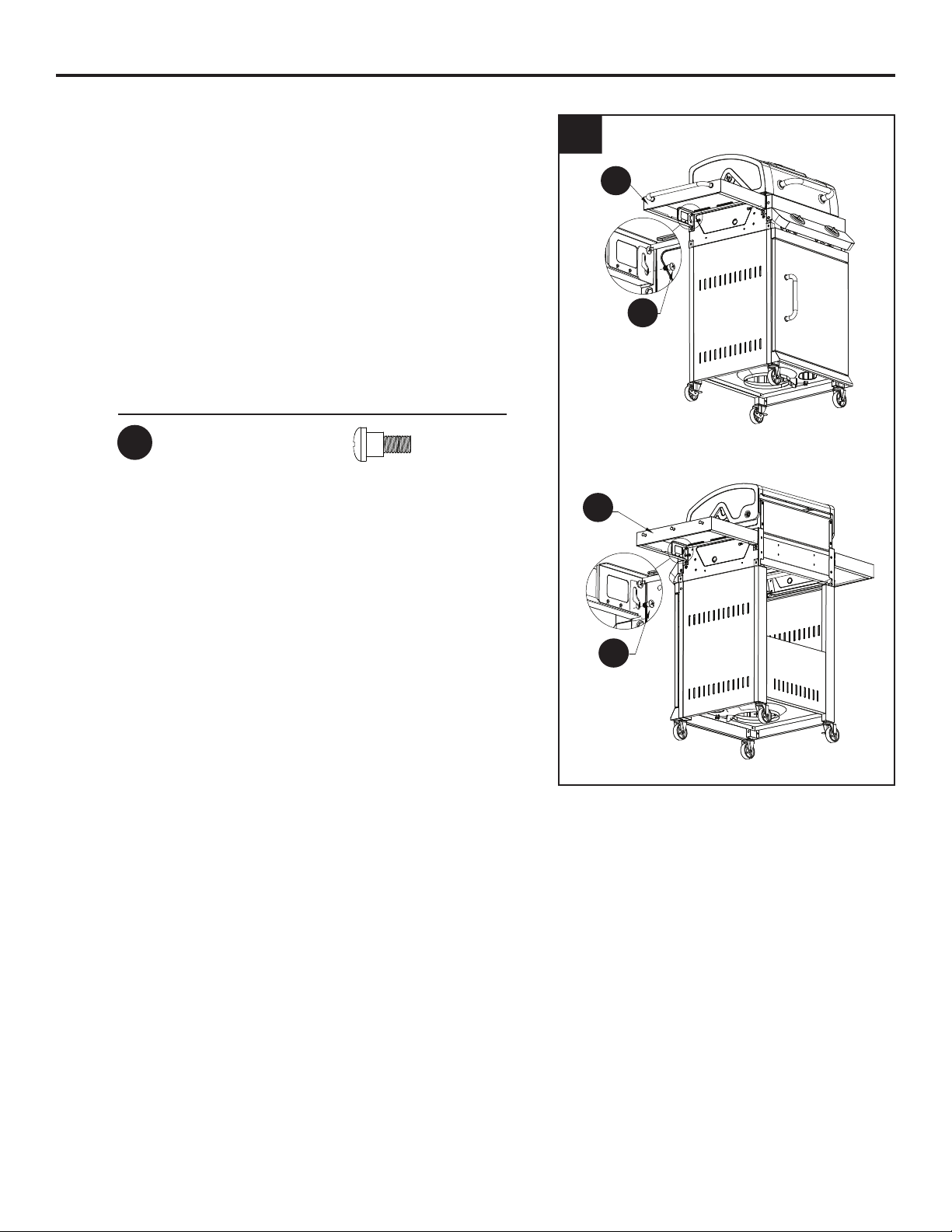

3. Insert the hook on the bottom panel skirt

assembly (K) into the slot on the cart left side

panel assembly (L) and the cart right side

panel assembly (G) as shown. Attach the

bottom panel skirt assembly (K) to the cart left

side panel assembly (L) and the cart right side

panel assembly (G) with two M6x16 bolts (AA).

Tighten ALL bolts from step 2 securely.

Hardware Used

AA

M6x16 Bolt

x 2

3

G

G

K

K

K

K

AA

AA

G

G

L

L

4. Attach the cart rear panel (W) to the cart left

side panel assembly (L) and the cart right side

panel assembly (G) with the four M6x16 bolts

(AA).

Hardware Used

AA

M6x16 Bolt

x 4

4

L G

L

AA

AA

W

W

G

8

ASSEMBLY INSTRUCTIONS

EE

FF

5. Attach the upper front door brace (V) to the cart

left side panel assembly (L) and the cart right

side panel assembly (G) with four M6x35

bolts (EE).

Hardware Used

EE

M6x35 Bolt

x 4

5

G

G

EE

EE

V

V

L

L

6. Attach the door magnet (X) to the cart left side

assembly (L) with four M3x10 bolts (FF).

Hardware Used

x 4

FF

M3x10 Bolt

6

L

L

G

G

FF

FF

X

X

9

ASSEMBLY INSTRUCTIONS

M6

Plain

Qty. 2

M6

Qty. 2

M6x16

Bolt

Qty. 18

Washer

M6x35

Bolt

Qty. 4

Washer

M6

Wing Nut

Qty. 2

GG

M3x10

Bolt

Qty. 4

HH

M6x12

Flat Bolt

Qty. 8

Shoulder

Bolt

Qty.4

II

Qty. 1

Wrench

Spring

7. Attach the door handle (N) to the door

assembly (M) with two M6x16 bolts (AA).

Hardware Used

AA

M6x16 Bolt

x 2

7

M

M

N

N

AA

AA

8. Insert the bottom hinge pin of the cart bottom

panel skirt (K) into the lower hole on the door

assembly (M), then press the upper door spring

hinge pin into the hole on the upper front door

brace (V) as shown.

8

V

V

K

M

M

K

10

ASSEMBLY INSTRUCTIONS

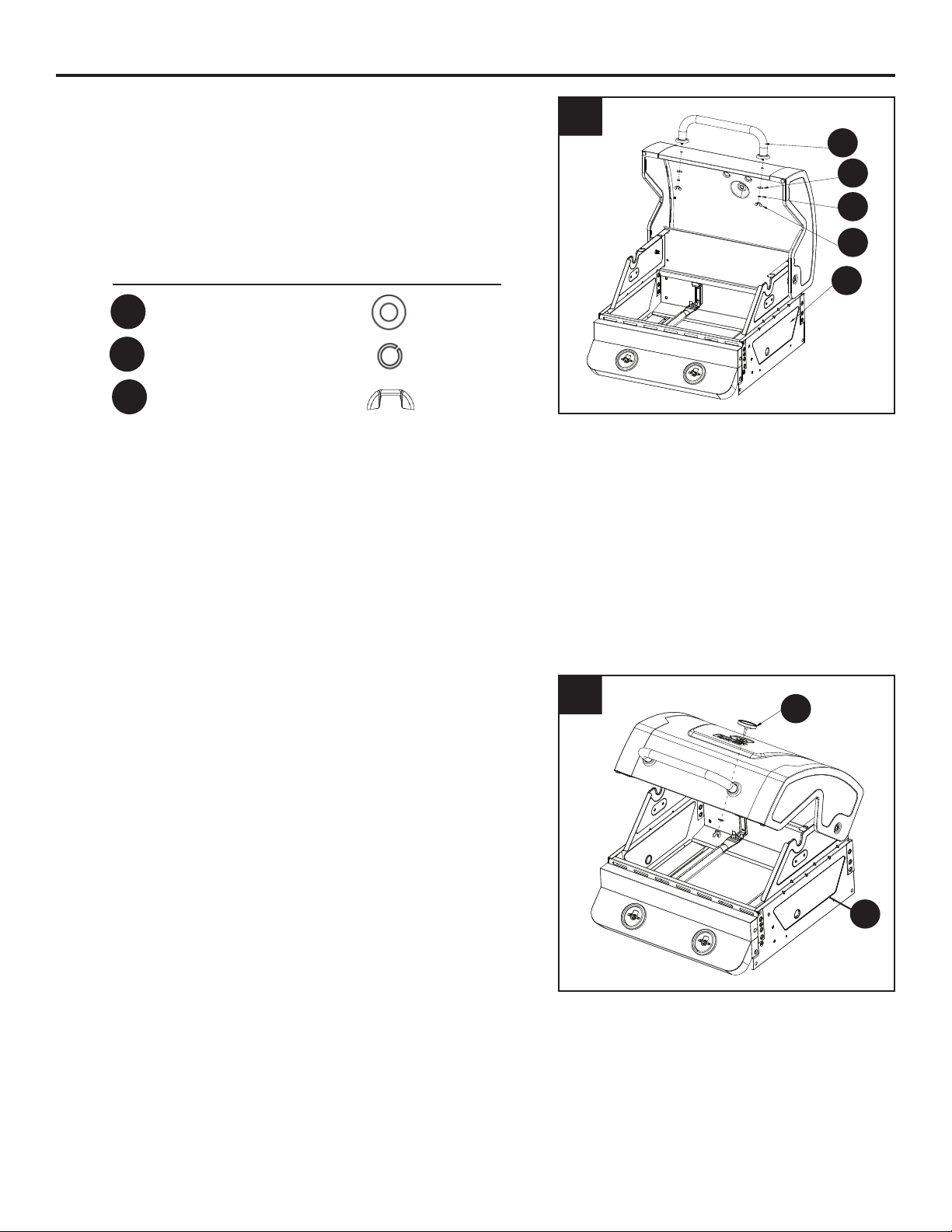

9. Attach the hood handle (A) to the grill body

assembly (C) with two M6 wing nuts (DD), two

M6 spring washers (CC) and two M6 plain

washers (BB).

Hardware Used

BB

CC

DD

M6 Plain Washer

M6 Spring Washer

M6 Wing Nut

x 2

x 2

x 2

9

A

A

BB

BB

CC

CC

DD

DD

C

C

10. Remove pre-assembled wing nut and plain

washer from the temp gauge (B), then attach

the temp gauge (B) to the grill body assembly

(C). Secure the temp gauge (B) with wing nut

and plain washer removed earlier in this step.

10

B

B

C

11

ASSEMBLY INSTRUCTIONS

M6

Plain

Qty. 2

M6

Qty. 2

M6x16

Bolt

Qty. 18

Washer

M6x35

Bolt

Qty. 4

Washer

M6

Wing Nut

Qty. 2

GG

M3x10

Bolt

Qty. 4

HH

M6x12

Flat Bolt

Qty. 8

Shoulder

Bolt

Qty.4

II

Qty. 1

Wrench

Spring

M6

Plain

Qty. 2

M6

Qty. 2

M6x16

Bolt

Qty. 18

Washer

M6x35

Bolt

Qty. 4

Washer

M6

Wing Nut

Qty. 2

GG

M3x10

Bolt

Qty. 4

HH

M6x12

Flat Bolt

Qty. 8

Shoulder

Bolt

Qty.4

II

Qty. 1

Wrench

Spring

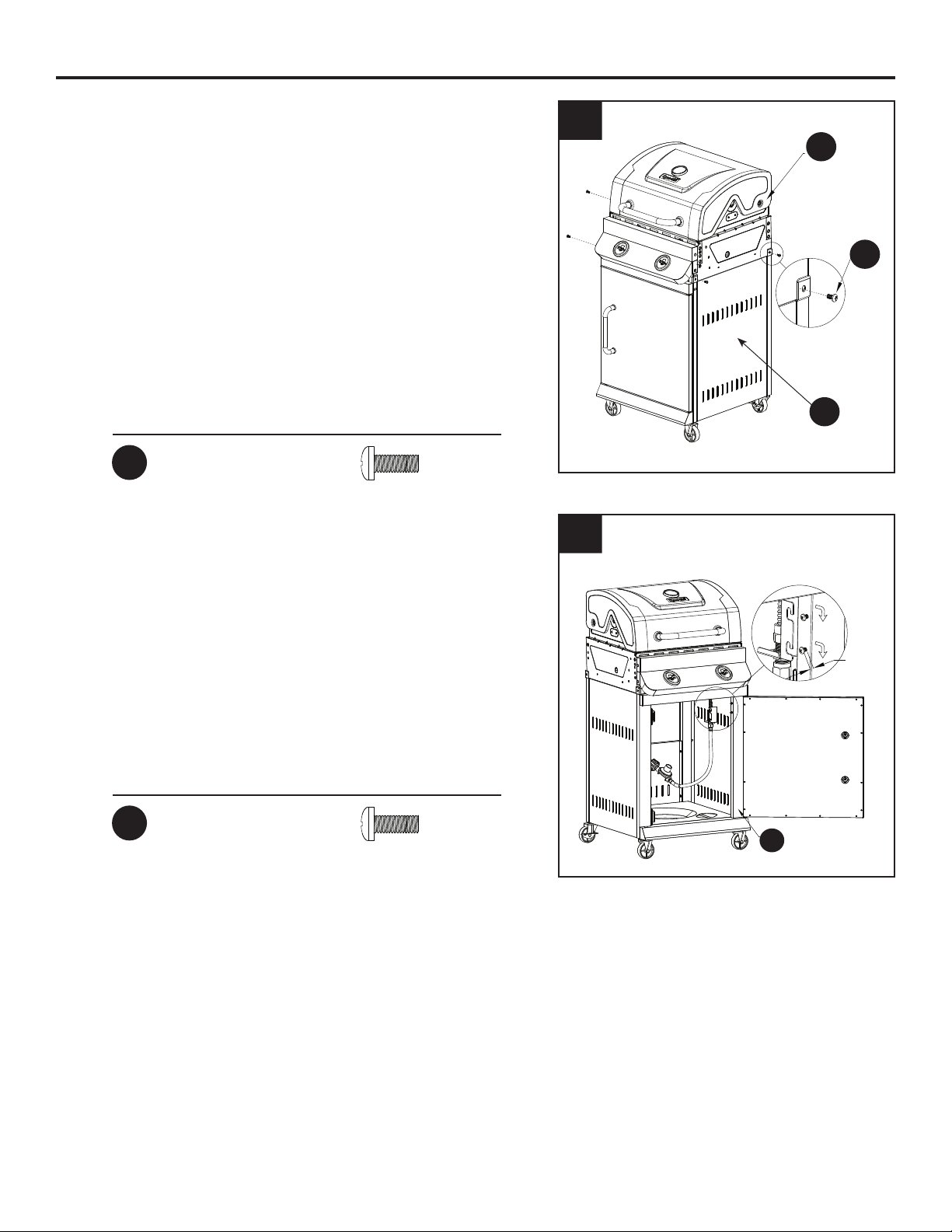

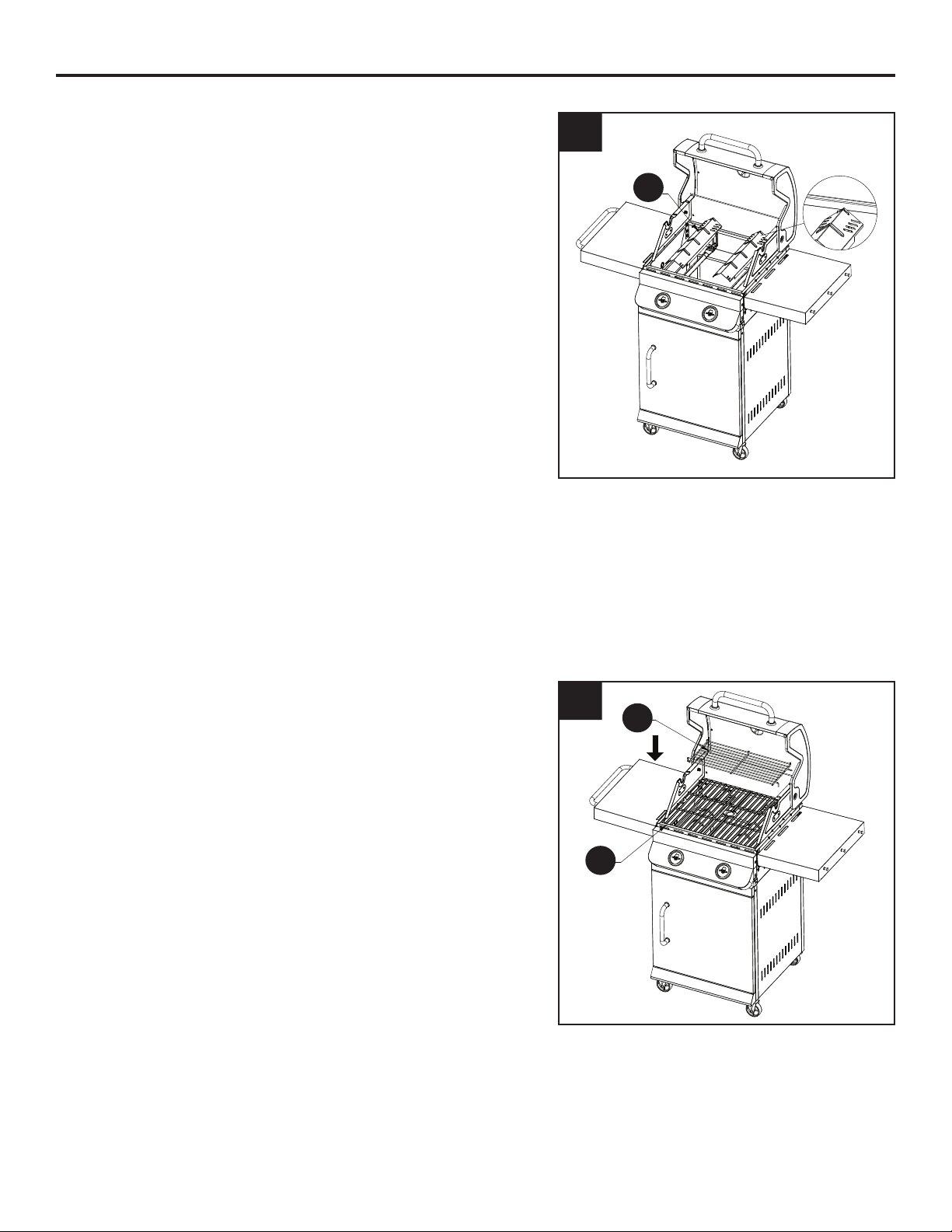

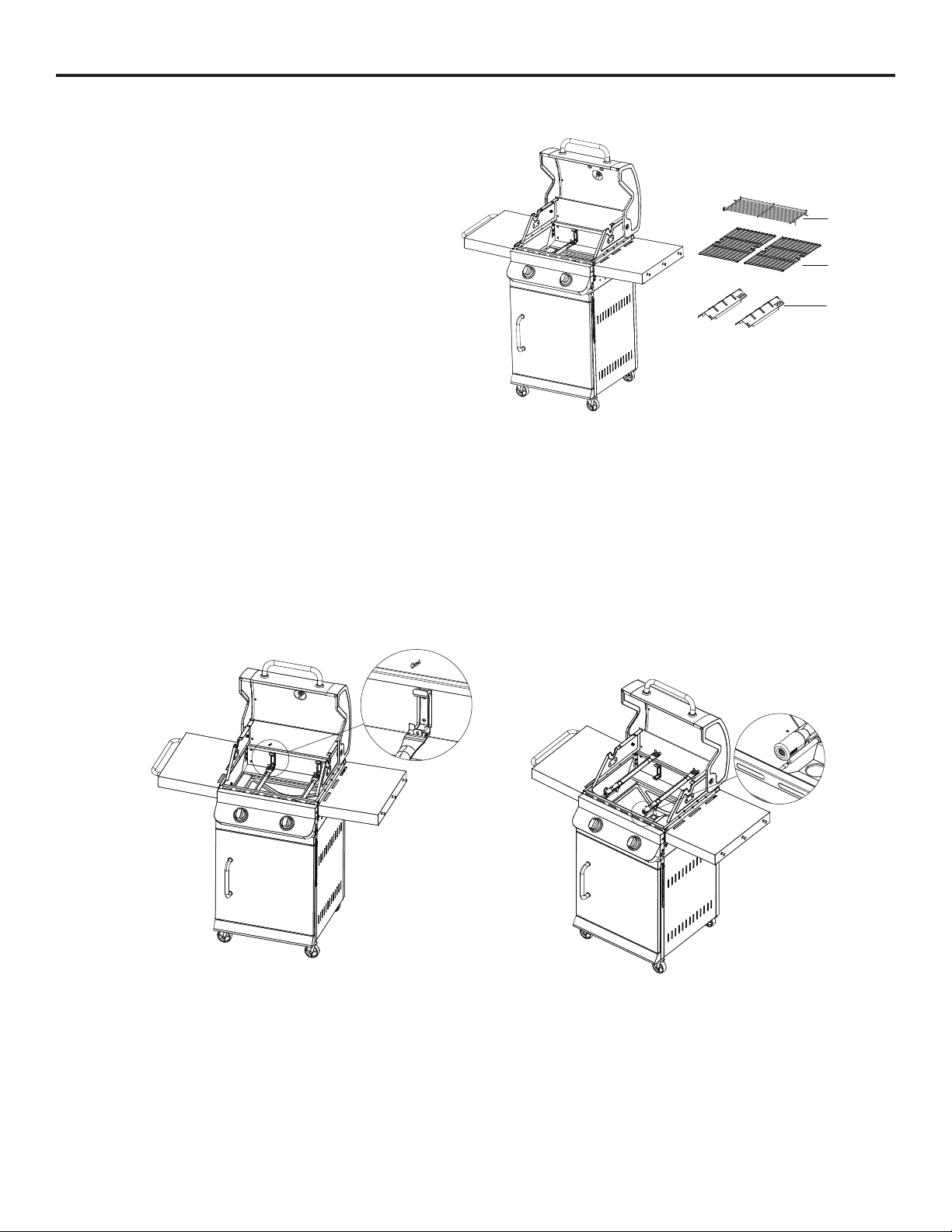

11. Carefully place the grill body (C) onto cart left

side panel assembly (L) and cart right side

panel assembly (G). Adjust the grill body (C)

so that the holes in the grill body (C) are

aligned with holes in the tabs of cart left side

panel assembly (L) and cart right side panel

assembly (G).

Note: Make sure the gas hose/regulator

assembly is inside the cart. Secure the grill

body (C) with four M6X16 bolts (AA).

Hardware Used

AA

12. Pre-assemble two M6x16 bolts (AA) onto the

cart right side panel assembly (G) and do not

tighten them. Make sure to leave a 5mm

gap between the bolt and the panel. Then

hang the regulator assembly bracket onto the

bolts and tighten the two bolts.

M6x16 Bolt

x 4

11

12

C

C

G

AA

AA

5mm

Hardware Used

AA

M6x16 Bolt

x 2

G

G

12

ASSEMBLY INSTRUCTIONS

M6x12

Qty. 8

Shoulder

Bolt

Qty.4

Qty. 1

Wrench

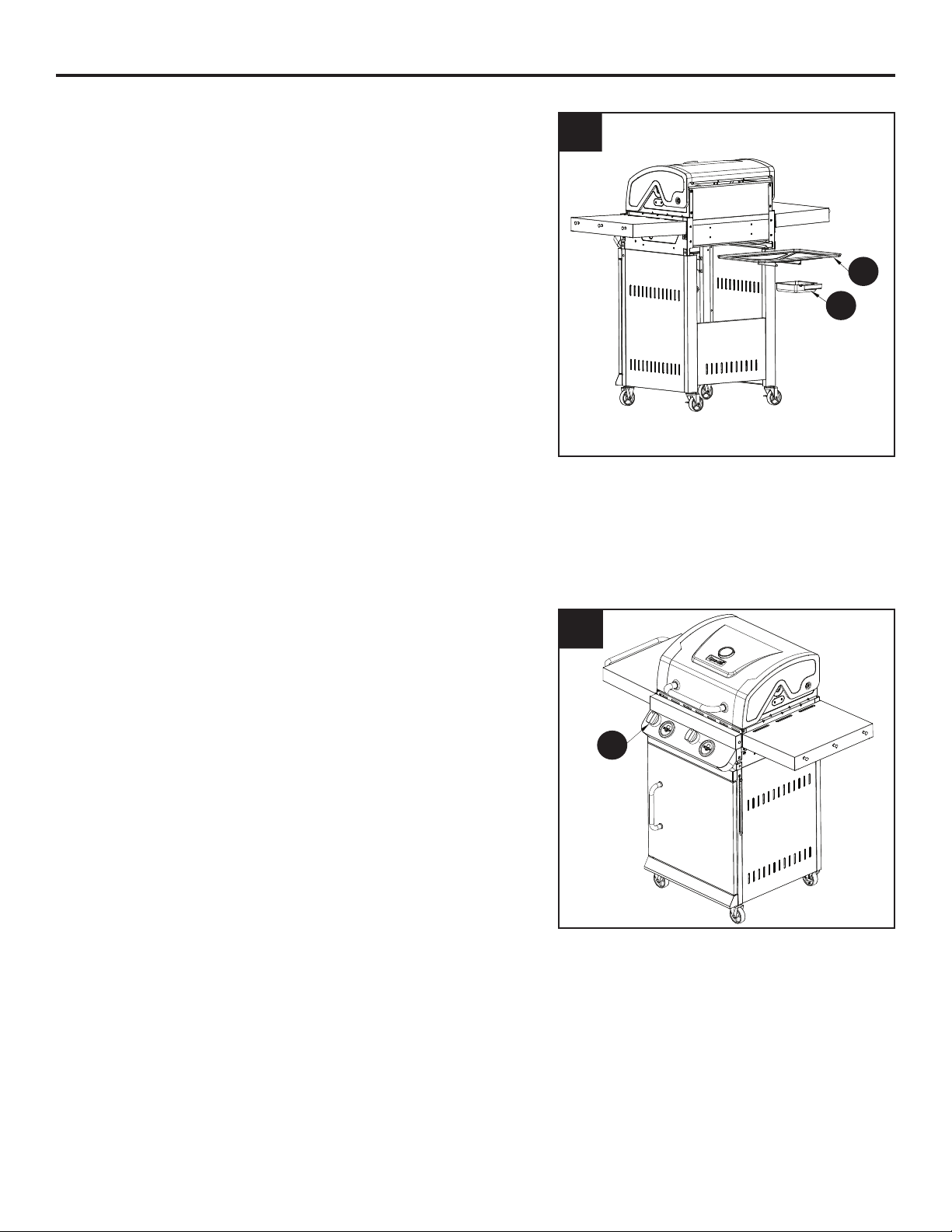

13. Attach the side shelf bracket A (D) and side

shelf bracket B (F) to the grill body assembly

(C) with eight M6x12 at bolts (GG).

Hardware Used

GG

M6x12 Flat Bolt

x 8

13

C

GG

GG

D

D

F

F

C

F

F

D

D

13

ASSEMBLY INSTRUCTIONS

Bolt

Qty.4

Qty. 1

Wrench

14. Attach the left side shelf assembly (O) to the

brackets installed at step 13 with two shoulder

bolts (HH). Repeat it for right side

shelf assembly (E).

Hardware Used

HH

Shoulder Bolt

x 4

14

O

O

HH

HH

E

E

HH

HH

14

ASSEMBLY INSTRUCTIONS

15. Put two heat tents (P) in place over each

burner.

15

P

P

16. Put two cooking grates (Q) and one warming

rack (R) in place.

16

R

R

Q

Q

15

ASSEMBLY INSTRUCTIONS

17. Put the grease pan (T) and grease cup (U) into

place.

17

U

T

T

U

18. Assemble the two control knobs (S) to the

valve stems.

18

S

S

16

Front View

ASSEMBLY INSTRUCTIONS

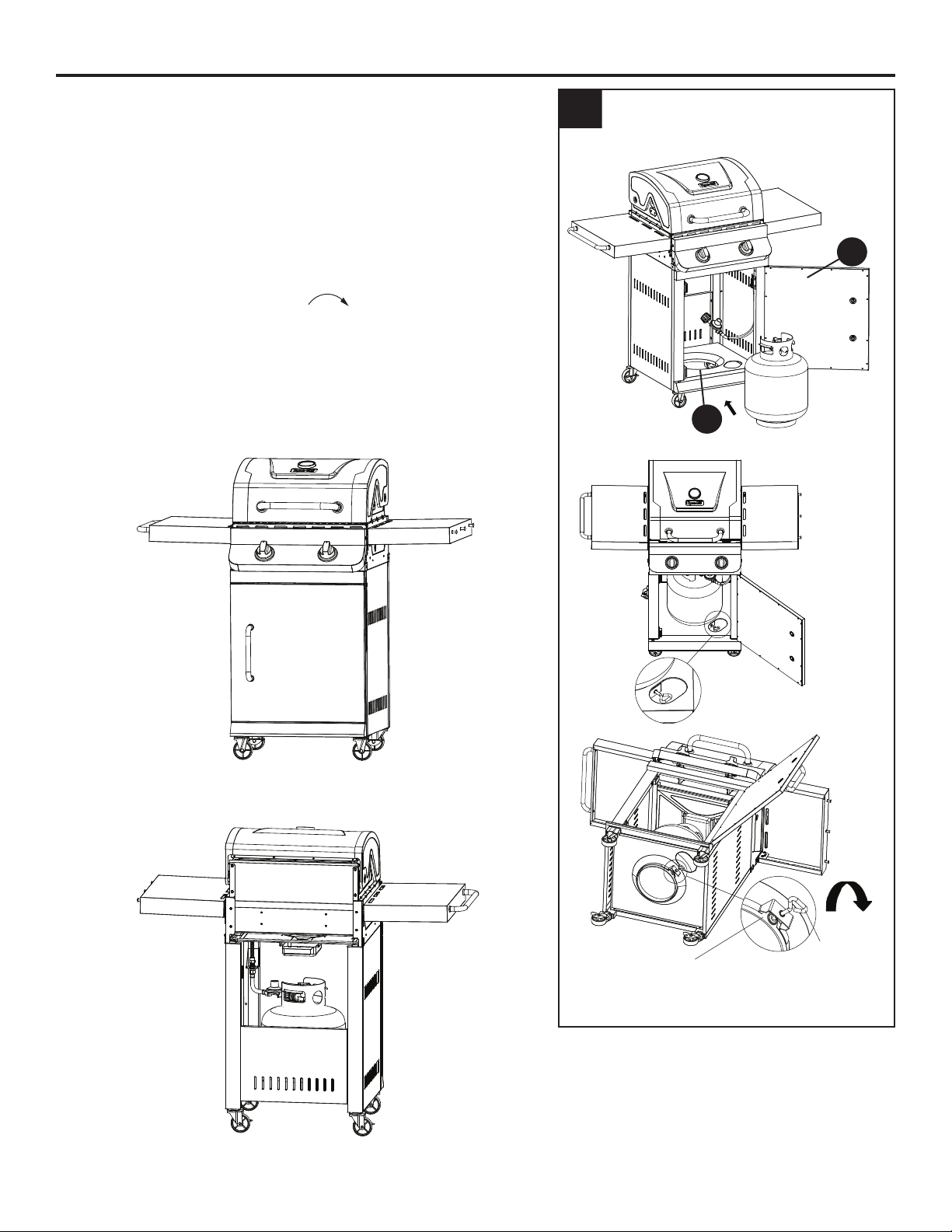

19. Open the door assembly (M). Place LP gas

cylinder (sold separately) into the nesting hole

located on the cart bottom shelf (J). Rotate

the LP gas cylinder until the hose/regulator

coupling aligns with the threaded valve of the

cylinder. Hand tighten the hose/regulator

coupling to the threaded valve of the LP

gas cylinder.

Tighten the tank screw clockwise in the

rear of the cart until the LP gas cylinder is

secured in place inside the nesting hole of the

cart bottom shelf (J).

Fully Assembled

19

M

J

Front View

Rear View

17

LP Gas

Cylinder

Tank

Screw

OPERATION INSTRUCTIONS

CHECKING FOR LEAKS

After all connections are made, check all connections and ttings on the LP gas tank valve, gas hose

and regulator for leaks with a water and soap solution.

To prevent re or explosion while testing for a leak:

• Always perform leak test prior to lighting the grill.

• Do not smoke while testing for a leak.

• Always perform leak tests outdoors in a well-ventilated area.

• Do not use any source of ame while testing for leaks.

• Do not use the grill until any and all leaks are corrected.

• If you are unable to correct a leak, disconnect the propane supply and call a gas appliance service

dealer.

PERFORM LEAK TEST

• Prepare leak test solution by 50/50 ratio of liquid dish soap and water.

Total solution required is approximately 2 - 3 ounces (70 - 90 ml).

Put leak test solution in a spray bottle.

• Ensure all control knobs are in the

• Connect the gas hose to the gas supply.

• Open the LP gas tank valve.

• Spray leak test solution on all gas carrying connections and ttings. Presence of bubbles at areas

of applied test solution indicates a gas leak. If leaks are detected or you smell or hear gas, shut off the

gas supply valve immediately and repair or replace the defective part. Do not use the grill until

all leaks are corrected.

O OFF position.

CAUTION

Only use the regulator and hose assembly provided! If a replacement is necessary, please call

our customer service center. Do not use replacement parts that are not intended for this grill.

WARNING

ALL INSTRUCTIONS AND SAFEGUARDS ON THIS PAGE MUST BE FOLLOWED TO

PREVENT FIRE, DAMAGE AND/OR INJURY.

18

OPERATION INSTRUCTIONS

CONNECTING GAS CYLINDER

The propane gas supply cylinder to be used must be constructed and marked in accordance with the

Specications for LP Gas Cylinders of the U.S. Department of Transportation (D.O.T.) or the National

Standard of Canada, CAN/CSA-B339, Cylinders, Spheres and Tubes for Transportation of Dangerous

Goods; and Commission, as applicable; and provided with a listed overlling prevention device.

Use only 20-pound cylinders (height: 18.11 inches, tank diameter: 9.84 inches, foot diameter: 8.03 inches)

equipped with a cylinder connection device compatible with the connection for outdoor cooking appliances.

The cylinder must include a collar to protect the cylinder valve. The gas cylinder should not be dropped

or handled roughly!

If the appliance is not in use, the gas cylinder must be disconnected. Storage of an appliance indoors

is permissible ONLY if the cylinder is disconnected and removed from the appliance. Cylinders must

be stored outdoors out of the reach of children and must not be stored in a building, garage or any

other enclosed area. Your cylinder must never be stored where temperatures can reach over 125°F.

Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type of

dust cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or

plugs may result in leakage of propane.

Before connection, be sure that there is no debris caught in the outlet of the gas cylinder, outlet of the

regulator valve or in the outlet of the burner and burner ports. Connect regulator valve and

hand-tighten rmly. Keep the propane cylinder valve closed and disconnect the propane cylinder from

the regulator valve when the grill is not in use.

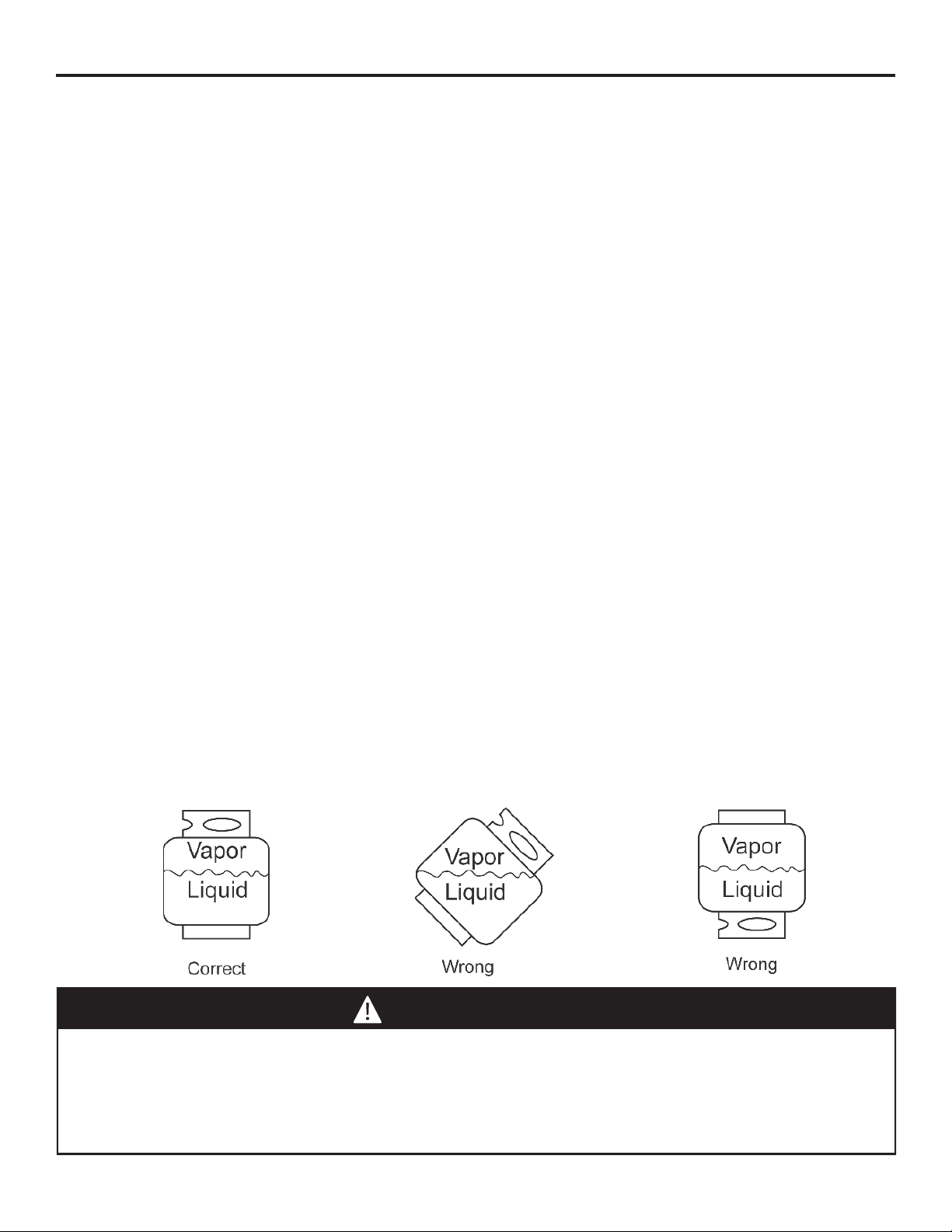

DO NOT obstruct the ow of combustion air and ventilation air to the grill. The propane cylinder must

be arranged for vapor withdrawal and equipped with a listed overlling prevention device. Please use

the proper cylinder orientation to provide vapor withdrawal. NOTE: The cylinder must be fully upright

for the cylinder to have vapor withdrawal only.

CAUTION

a. Do not store a spare LP-gas cylinder under or near this appliance.

b. Never ll the cylinder beyond 80 percent full.

c. If the information in (a) and (b) is not followed exactly, a re causing death or serious

injury may occur.

19

OPERATION INSTRUCTIONS

NOTE: Other cylinders may be acceptable for use with this appliance provided they are compatible

with the appliance nesting hole and retention means. Refer to Step 19 of the Assembly Instructions

for correct cylinder to cylinder holder connection.

WARNING

ALL INSTRUCTIONS AND SAFEGUARDS ON THIS PAGE MUST BE FOLLOWED TO

PREVENT FIRE, DAMAGE AND/OR INJURY.

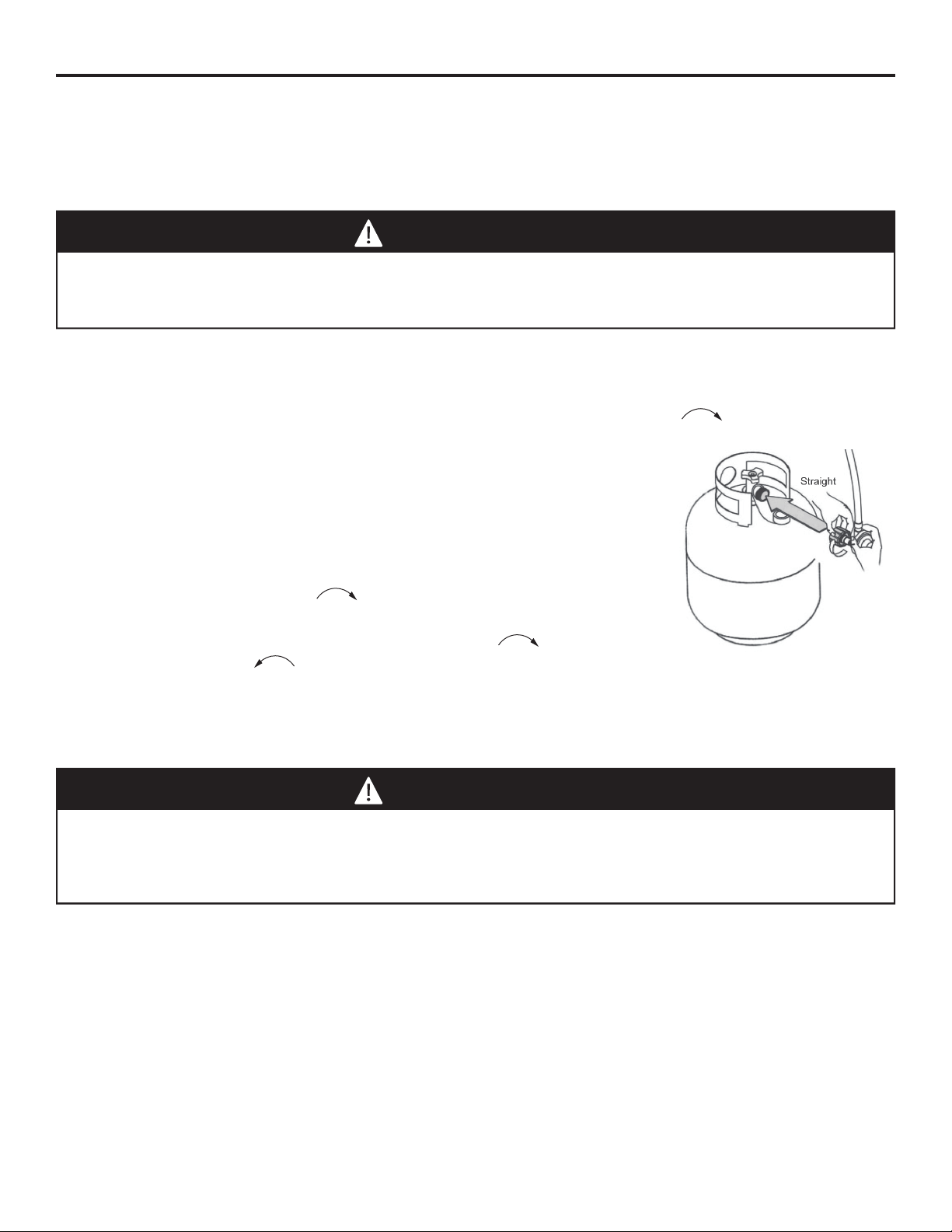

CONNECTING THE LP TANK

1. The knob on the LP tank must be closed. Make sure that the knob is turned clockwise to a

full stop. The cylinder supply system must be arranged for vapor withdrawal.

2. Check that the control knob on the control unit is turned off.

3. Remove the protective cap from the LP tank valve and coupling nut.

4. Hold the regulator in one hand and insert the nipple into the valve

outlet. Be sure the nipple is centered in the valve outlet. The coupling

nut connects to the large outside threads on the valve outlet. Use

care – do not cross thread the connection.

5. Hand-tighten the coupling nut clockwise until it comes to a full

stop. Firmly tighten by hand only. Do not use tools.

To Disconnect: Fully close the tank valve by turning clockwise.

Turn the coupling nut counterclockwise until the regulator assembly detaches.

WARNING

In the connection process, make sure:

• the regulator inlet connector mates with the cylinder valve outlet properly, safely and rmly, and;

• the LP gas hose does not come in contact or remain in contact with the rebox.

20

OPERATION INSTRUCTIONS

Lighting The Grill

Before rst use:

Remove all hangings or plastic straps, if present. Before you cook on your new gas grill, it is important

to clean your grill with heat. To do this, operate the grill for approximately 15 minutes with the lid closed

and the control knob in the highest position. This will clean the internal parts by burning off any residue

and odor from the manufacturing process.

CAUTION

If the ame extinguishes accidentally during ignition or operation, immediately TURN OFF the

cylinder valve and then TURN OFF the control knob.

WARNING

Do not lean over grill when lighting. Read instructions before lighting. Do not put pots on the

sear side burner. Using pots on the sear side burner will result in high carbon monoxide levels.

1. Check that the control knobs are in the OFF position.

2. Open the tank valve fully by turning it counter-clockwise.

3. Open the lid during the lighting process.

4. Depress and turn the control knob counter-clockwise from the OFF position, past the ignite

position, to the HIGH position. You may need to repeat this several times to ignite the burner.

If ignition does not occur in 5 seconds, turn the control knob(s) to the OFF position, wait 5 minutes, and

repeat the lighting procedure.

If the burner still does not light, check that there is gas in the cylinder and follow the match lighting

instructions. Check the Troubleshooting Guide on page 26 for more information.

21

OPERATION INSTRUCTIONS

LIGHTING THE GRILL WITH A MATCH

1. Open the lid.

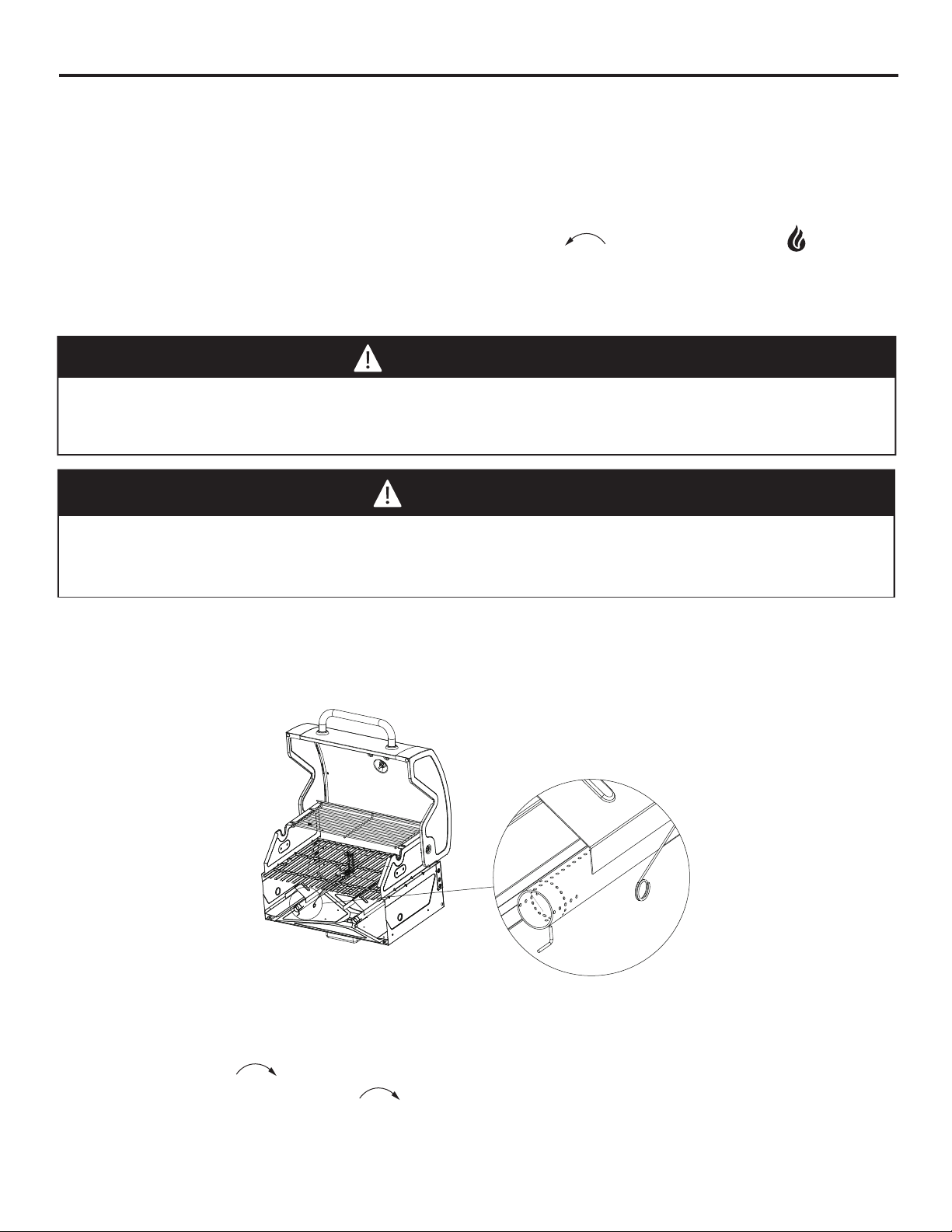

2. Insert a match in the end of the match holder that is installed on the inside of the cabinet door.

3. Light the match.

4. Immediately place the lit match through the spaces in the grill gates near the ports of the burner

between the heat tents as shown. Make sure the lit match is close to the burner ports.

5. Press in the control knob that operates the burner and rotate counter-clockwise to High

position and burner should light immediately.

6. Repeat 2~5 steps to lighting the remaining burners.

7. Adjust burners to desired cooking settings.

CAUTION

Make sure all burners controls are off except for the burner being lit and the

burners that have been lit.

WARNING

If ignition does not occur in 5 seconds, turn the control knob(s) to “O” OFF position, wait 5

minutes, and repeat the lighting procedure.

Main Burner Match Lighting

SHUTDOWN INSTRUCTIONS

1. Turn control knobs clockwise to the O OFF position.

2. Close valve at tank fully by turning clockwise.

3. Close lid.

Turn off LP supply at cylinder when appliance is not in use.

22

CARE AND MAINTENANCE

Bad Flame

Good Flame

Cooking Grates

The best time to ‘burn-off’ the cooking grates is after every use (approx. 15 minutes). The grill is

already hot from cooking thus requiring less fuel to obtain necessary temperature for ‘burn-off’.

To ‘burn off’ or heat clean your grill, turn the burners to highest position and run for 15 minutes

with the lid closed. Then turn off the burners and use a wire brush to clean excess food residue

from the grates.

The porcelain grates have an enamel nish (similar to glass) and should be handled with care

not to chip.

CAUTION

Ensure the grill is cool before cleaning and conducting maintenance and with the gas supply

turned off at the LP-Gas Cylinder.

Recommended Cleaning Supplies

Mild liquid dish soap, warm water, nylon cleaning pad, wire brush

DO NOT use cleaners that contain acid, mineral spirits or any abrasive substance.

Outside Surfaces

It is recommended to use only mild dish soap and hot water to clean grill and grill parts.

Rinse with warm water.

Inside Bottom Pan of Grill Body

To avoid are-ups, the bottom pan of the cooking box should be kept clean on a regular basis.

Remove residue using a brush, scraper and/or cleaning pad. Wash with mild dish soap and warm

water. Rinse with warm water. Avoid water splashing into venturi tubes of burners.

Heat Tents

Clean residue with wire brush and wash with mild dish soap and

warm water. Rinse with warm water.

Grease Cup

Empty the grease cup and clean with mild dish soap and

warm water on a regular basis.

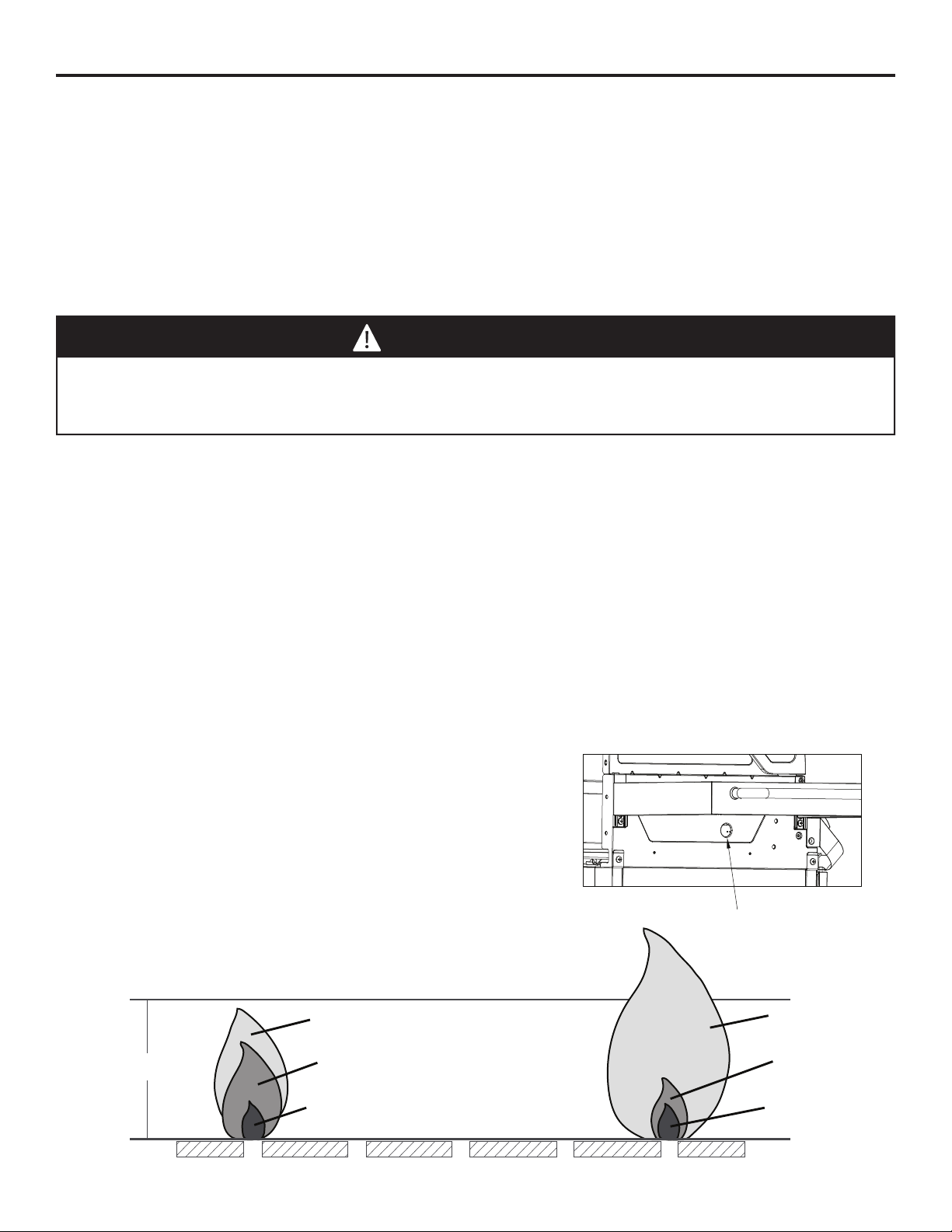

Checking The Flame

For maximum fuel efciency and cooking performance, ame

should be a blue-yellow color and be between 1- 2 inches high.

To check the ame, view the ame through the holes in both

sides of the rebox.

Hole for viewing the ame

2”

Yellow

Light Blue

Blue

Yellow

Light Blue

Blue

23

Heat Tents

Cooking Grates

Warming Rack

CARE AND MAINTENANCE

Burner Assembly

Removing The Burner Assembly

1. Make sure all control knobs are in the OFF

position, gas supply valve is closed, and the

gas hose is disconnected from the gas supply.

Warming Rack

Cooking Grates

2. Open lid and remove warming rack, cooking

grates, and heat tents.

3. Remove hinge pin as illustrated in Figure 1.

4. Slide main burners out of rebox.

5. Detach ignition wire from electrode in Figure 2.

Heat Tents

Figure 1

Figure 2

24

CARE AND MAINTENANCE

Cleaning the Burner Assembly

– Make sure the grill is cool

1. Ensure all burner ports are clear of clogs. Use of a pin or paper clip works well.

2. Ensure burner is free of any damage. If damage is found, replace with new burner.

3. Ensure the end of the burner and primary air screen are clear from insect nests, dirt or debris.

Re-installing the Burner

Ensure that gas valve orices are correctly positioned inside burner inlet (venturi).

The use of a ashlight may be necessary to ensure the correct position.

It is recommended to view the correct position through the rebox vent holes as illustrated below.

Reattach each burner with the hinge pin and reattach the ignition wire to electrode.

Incorrect Incorrect Correct

Bottom View

View the correct position

from the bottom of the firebox

WARNING

If the instructions above are not followed, a re or explosion may result, possibly

causing serious bodily injury or death.

Other Care and Maintenance

It is recommended that inspection and service on this appliance be conducted annually by a qualied

service person.

It is recommended that you always check that the outdoor cooking appliance area is clear and free

from combustible material, gasoline and other ammable vapors and liquids before lighting.

It is recommended that you regularly check that the ow of combustion and ventilation air is not

obstructed.

It is recommended that you regularly check that the ventilation openings of the grill cabinet

are free and clear from debris.

It is recommended that you regularly check and clean the burner/venturi tubes for insects and insect

nests. A clogged tube can lead to a re beneath the grill.

25

TROUBLESHOOTING

If you have any questions regarding the product, please call customer service at 1-877-447-4768,

8:00 a.m. – 4:30 p.m., CST, Monday – Friday.

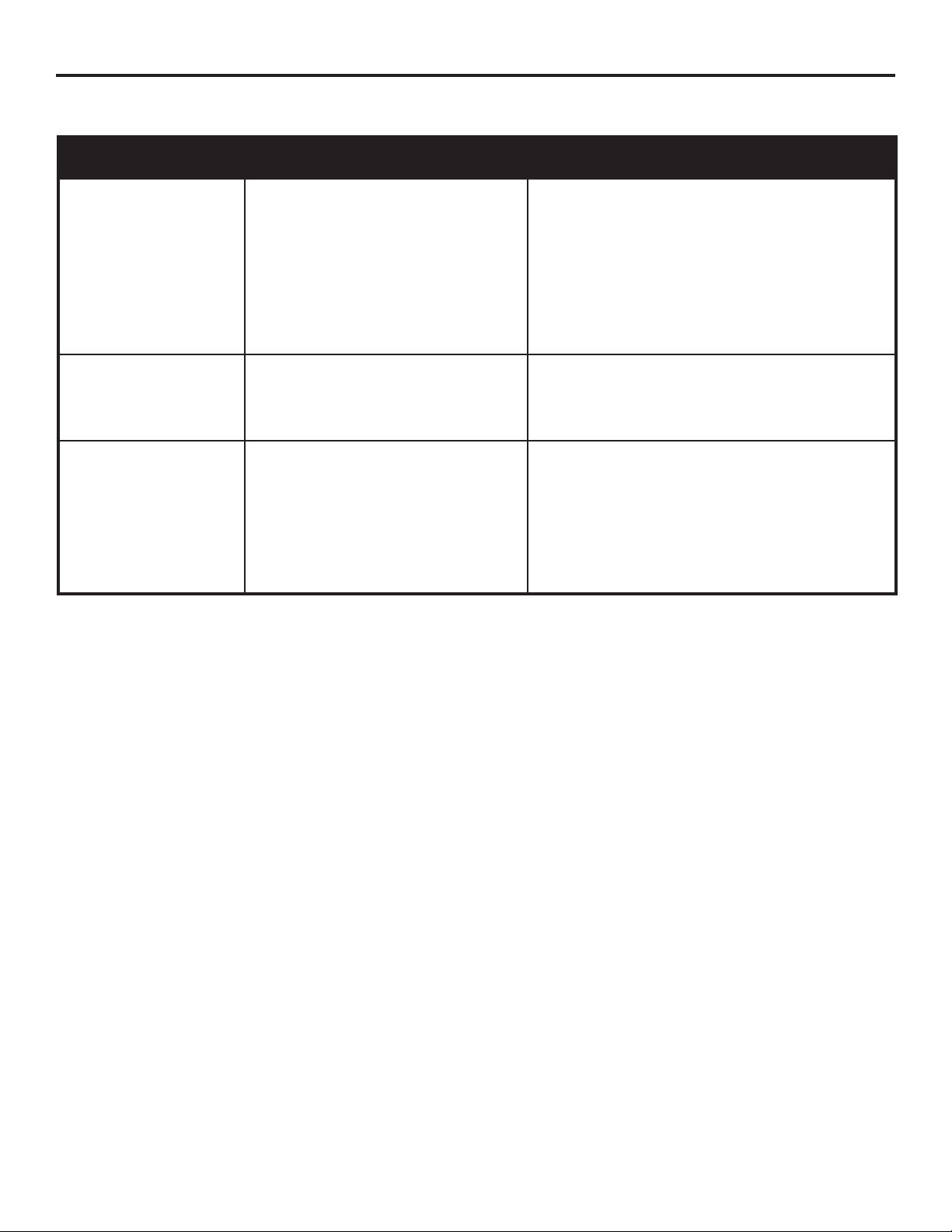

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

The burner will

not light using the

ignitor procedure

(weak or no spark

being generated).

Low Heat. 1. Insufcient gas pressure to

Excessive Flare

Ups.

1. The igniter electrode may be

covered with grease or residue.

2. The igniter electrode may

have a loose or disconnected

wire.

3. Cracked or broken ignition

electrode.

the unit.

1. Grease and/or residue build-up

on heat tents or in rebox.

2. Excessive dripping of fat or

marinade from food.

3. Cooking temperature too high.

1. Clean the ignitor electrode.

2. Check the connection and reconnect any

loose or disconnected wires.

3. Replace ignition electrode (see

Replacement Parts List).

1. Call a qualied service agency to check

the gas supply pressure and correct the

pressure.

1. Clean the grill components.

2. Trim the fat from meat and use non-oil

based marinades.

3. Lower temperature accordingly.

26

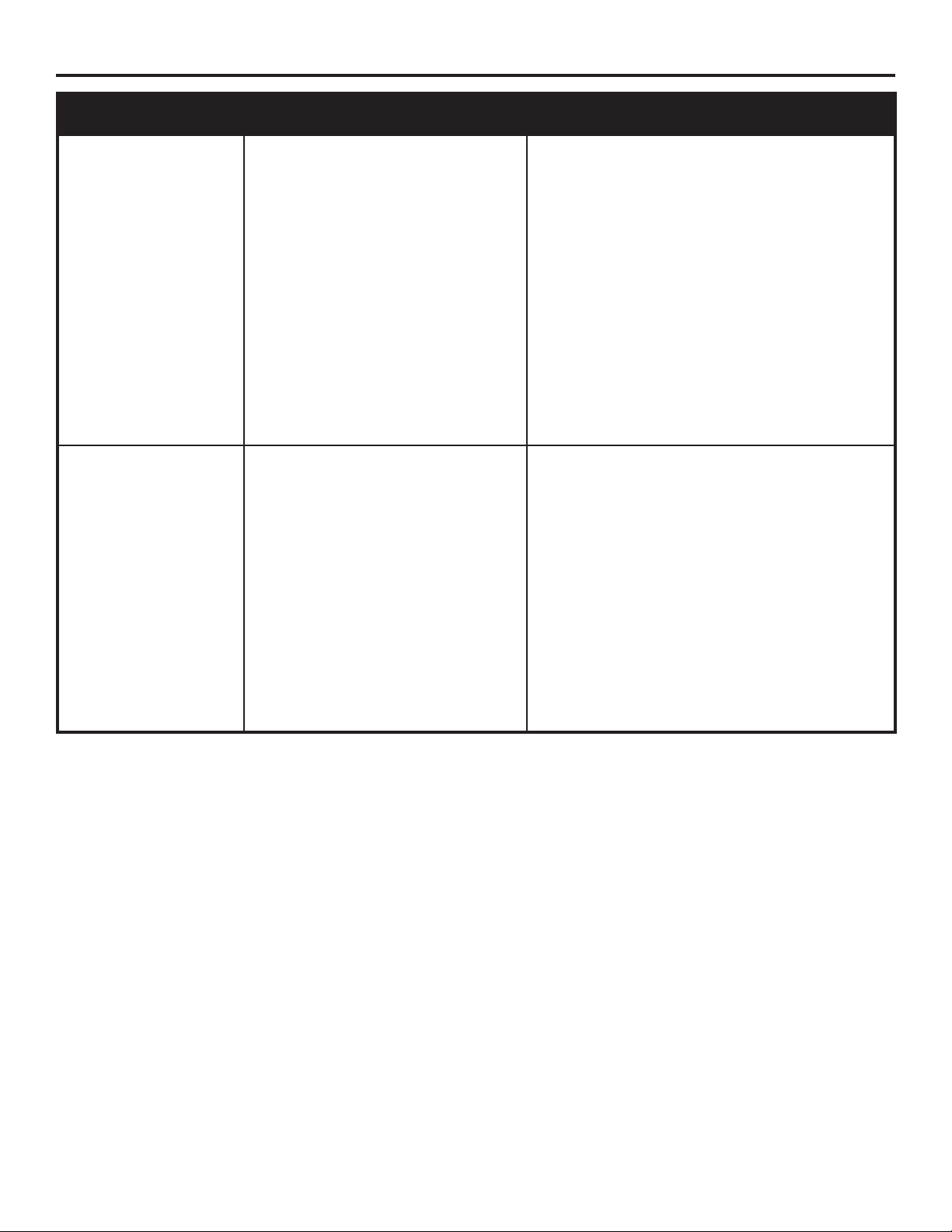

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

The burner will not

light with a match.

No gas ow or an

obstructed gas

ow.

1. Match not reaching burners

(when holding match with

hand).

2. Empty tank.

3. Poor connection between

valve regulator and LP

cylinder coupling.

4. Burner inlet blocked.

1. Tank valve not on or fully

opened.

2. Empty tank.

3. Poor connection between

valve regulator and LP

cylinder coupling.

4. Burner inlet blocked.

1. Use match holder found in

cabinet door.

2. Check fuel level and rell tank if

necessary.

3. Turn off grill knobs, close the LP cylinder

valve at top of cylinder and check the

connection between the regulator valve

and cylinder coupling. Disconnect and

reconnect, if necessary.

4. Clean the burner inlet (venturi) and

burner as described by the Care and

Maintenance section in the manual.

1. Fully open tank valve by turning

counterclockwise.

2. Check fuel level and replace fuel if

necessary.

3. Turn off grill knobs, close the LP cylinder

valve at top of cylinder and check the

connection between the regulator valve

and cylinder coupling. Disconnect and

reconnect, if necessary.

4. Clean the burner inlet (venturi) and

burner as described by the Care and

Maintenance section in the manual.

27

LIMITED WARRANTY

1-Year Limited Warranty

This LP gas grill is warranted for 1 year (5 years on the Stainless Steel burners) against broken or

damaged parts at the time of purchase. It is warranted to be free of defects. Paint is warranted to be

free of defects except for rust, which may appear after repeated use.

This warranty does not cover damage or issues related to neglect, abuse, or modications to the

appliance. Repair labor is not covered.

All parts that meet the warranty requirements will be shipped at no charge via the discretion of the

manufacturer (ground shipments, US Mail, or Parcel Post ONLY). Any special handling charges (i.e.

Second Day, overnight, etc.) will be the responsibility of the consumer.

All warranty claims apply only to the original purchaser and require a proof of purchase verifying

purchase date. Do not return parts without rst obtaining a return authorization number from our

customer service. This service is available by calling toll free 1-877-447-4768, 8:00 a.m. – 4:30 p.m.,

CST, Monday – Friday.

NOTICE: Some states do not allow the exclusion or limitation of incidental or consequential damages

or limitations on how long an implied warranty lasts, so the above limitations or exclusions may not

apply to you. This warranty gives you specic legal rights and you may also have other legal rights

which may vary from state to state.

GHP Group Inc.

6440 W. Howard Street

Niles, IL, USA

60714-3302

Item Name: 2 Burner Premier Gas Grill

Model #: DGP321SNP / DGP321SNP-D / DGP321CNP / DGP321CNP-D

DGP321GNP / DGP321GNP-D / DGP321MNP / DGP321MNP-D

Main burner total rated BTU: 24,000 BTU/Hr

28

Loading...

Loading...