INSTRUCTIONS FOR THE ASSEMBLY AND USE OF

DYNAKIT STEREO 35 POWER AMPLIFIER

SERIAL NUMBER

14635013

This number must be mentioned in all communications concerning Dynakit.

Price $1.00

046414

3916 POWELTON AVE

PHILADELPHIA 4 PA

CONTENTS

Description 3

General Wiring Practice 4

Mechanical Assembly 5

Wiring instructions 6

240-Volt Transformers 9

Installation 9

In Case of Trouble 10

Part List 11

Schematic Diagram Back Cover

SPECIFICATIONS

Power Output:

Frequency Response:

Power Response:

Intermodulation Distortion:

Hum and Noise:

Sensitivity:

Input Impedance:

Output Impedance:

Damping Factor:

Minimum Channel Separation:

Power Consumption:

Tube Complements:

Size:

Shipping Weight:

35 watts continuous, 45 watts

IHFM Music Power (both channels)

±1db from 10 cps to 40,000 cps.

20 cps to 20,000 cps without

exceeding 1% distortion within

1 db of 17,5 watts each channel.

Less than 1% at 17,5 watts each

channel. Less than 0.1% at

average listening levels.

Inaudible; more than 80 db below

rated output.

1 volt input for 17.5 watts output (each channel).

500,000 ohms.

8 and 16 ohms.

10 from 20 cps to 20,000 cps.

80 db.

100 watts, 50/60 cycle a.c.

7247 (2), 6BQ5/EL84/7189 (4),

silicon diodes (2).

4" high, 13" wide, 5½" deep.

16 lbs.

INSTRUCTIONS FOR ASSEMBLY AND USE OF

THE DYNAKIT STEREO 35 POWER AMPLIFIER

DESCRIPTION

The Stereo 35 is a dual power amplifier of deceptively

simple appearance and circuitry. Behind its seemingly

conventional design is an extremely sophisticated circuit

configuration representing the most recent advances in

power amplifier engineering and construction. This high

degree of technical refinement, combined with the conserva

tive use of premium-grade components, has resulted in a

typical Dynakit design offering superb performance at low

cost.

Each of the two channels in the Stereo 35 is rated as a

17,5-watt amplifier. Although not evident from this simple

rating, the power stated is available on a continuous basis

at any frequency from 20 to 2,000 cycles per second. A

"music power" rating would make the Stereo 35 a 45-watt

amplifier, although even this rating would non disclose that

full power is available at low distortion throughout the

audio spectrum. Nor would such a rating indicate that the

Stereo 35, even when driven to power output levels beyond

its rating, is able to handle these overloads gracefully, with

minimum detriment to the sound. As a result, the Stereo

35 can, if necessary, duplicate the sound intensity of

amplifiers with much higher power ratings when called

upon to do so.

The heart of the Stereo 35 is the special Dynaco Z-565

output transformer, a patented design tailored specifically

to this circuit. The transformer is free of resonances, has

extended frequency response (from 6 to over 60,000

cycles), and is wound by special techniques on a carefully

designed core to insure low distortion over a wide frequency spectrum. Transformers of this caliber have never

previously been used in low-cost equipment of moderate

power rating.

The transformer provides an optimum match between the

loud speaker load and the output tubes used. These tubes

are supplied as a matched group with the kit, and are

used in a circuit configuration which gives low inherent distortion and high stability of their d.c. operating point.

The output stage is preceded by a composite voltage

amplifier and cathodyne phase inverter (a 7247 tube with

direct coupling between sections). The phase inverter used

is unique; its operations is independent of the age of condition of the tube. The phase inverter stage is therefore

able to maintain its capabilities permanently with no need

for adjustment or balancing. Gain in this part of the amplifier is augmented by a feedback connection from cathode

to cathode.

Two negative feedback loops, one mostly resistive and

the other purely capacitive, are carried over the amplifier

to provide 20 db of negative feedback. This provides low

distortion and noise, a high damping factor, and further

benefits. The feedback loop is unconditionally stable under

all load arrangements, so that the Stereo 35 is suitable

for use with any loudspeaker, including electrostatic types

The values of components selected for the Stereo 35 have

been carefully determined, to be certain that the operating

conditions for each stage have been set at the center of

the optimum range. The use of close tolerance parts

provides additional assurance that these settings will not

shift, and will remain accurate, so that every amplifier will

meet its specifications. This is very important to the kit

builder, as it gives immunity from the variations to which

much electronic equipment is subject. Heavy-duty circuit

boards give additional stability and reproducibility of

characteristics, assuring a level of performance which takes

full advantage of the capabilities of the design. The conservatively rated power transformer, after testing, is completely sealed in a special encapsulating material which

prevents core vibration and also serves to dissipate heat

effectively.

One of the outstanding aspect of the design of the

Stereo 35 is the attention which as been paid to the reproduction of transient signals. Specifications commonly quoted

for amplifier refer only to performance with pure sinewaves as the signal content; however, music and speech

are actually composed of non-repetitive sounds which are

non-sinusoidal in character. It is this irregular, or transient

type of waveform which the amplifier will usually be called

upon to reproduce. Pulse tests and square wave measurements help to evaluate the transient performance of circuits, and these have been applied to derive the correct

operating parameters for the Stereo 35. The success of this

approach is particularly evident in listening tests where the

source material includes percussive sounds-drums, tambourines, piano, cymbals, etc. The Stereo 35 reproduces

these sounds with a transparency and absence of blurring

which is only obtained when an amplifier has extended

frequency response, without bounce, flutter or overshoot.

In addition, the Stereo 35 recovers almost immediately

from overload, so that the tones immediately following

are not affected by the overload signals. Thus, even whit

low-efficiency speaker systems, where an occasional peak

signal might overload the amplifier, reproduction of everything except the highest peak of the heaviest passage is

effortlessly reproduced.

It is this characteristic subtlety of design approach

which distinguishes the Stereo 35 from other equipment

with superficially similar specifications. These differences

provide a perceptible improvement in clarity and naturalness of sound; this was the design objective of the Stereo

35, and it has been achieved in a unit of remarkably low

cost.

3

GENERAL WIRING PRACTICE

Assembly of the Stereo 35 is exceptionally simple when

compared to that the other kits. The circuit board are supplied with all components mounted, and the remaining parts

arranged on the chassis in an open, uncluttered way that

makes wiring quick and easy. The construction of the Stereo

35 should take no more than few hours.

When you unpack the kit, check the components against

the parts list first. You can identify unfamiliar components

by matching them to parts illustrated in the pictorial

diagram supplied.

Have the proper tools at hand before beginning to build

your kit. You will need a pencil-type soldering iron of 30to 60-watt rating; a long-nosed pliers; diagonal cutters; and

a screwdriver. If you have a soldering gun, it should be used

with care, especially when working on the circuit board,

because of its higher than necessary heat output. Although

not essential, a wire-cutting and stripping tool will help

considerably; these are available for less than a dollar.

The only procedure involved in building a Dynakit

which requires a bit of technique is soldering, and this is

quite easy to master. There are four steps to making a good

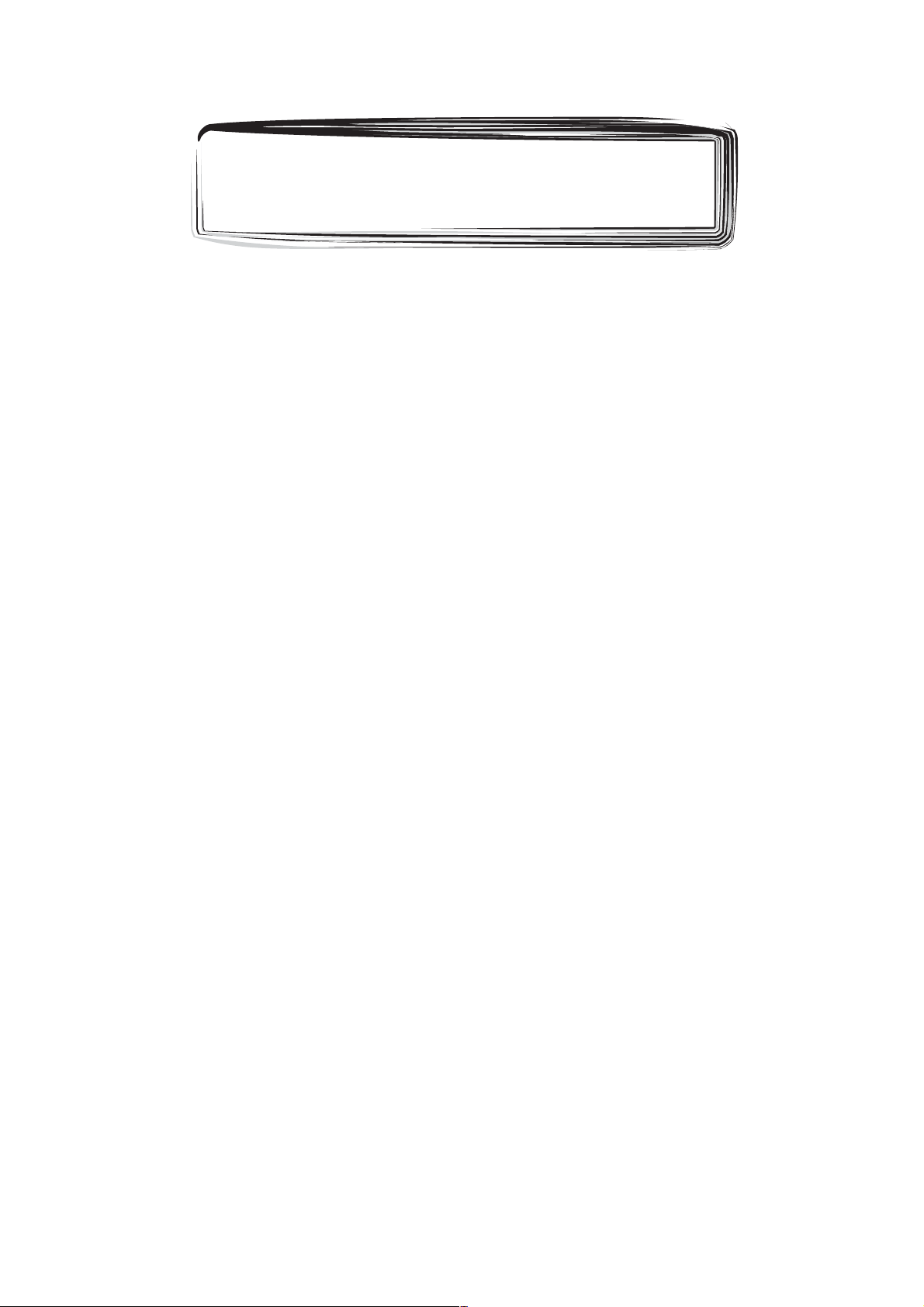

solder connection:

1. Make a good mechanical connection.

2. Heat both parts of the connection with the iron.

One of the best ways to make a good mechanical connection

is to bend a small hook in the end of the wire, and then to

crimp this hook onto the terminal to be connected. The

amount of bare wire exposed at the end need to be exactly

¼-inch; however, if it is too long, there is danger of the

excess touching another terminal or the chassis. There is

no need to wrap the wire around the terminal more than

one time, as this makes a connection that is much more

difficult to remove if an error has been made

3. Apply solder to the connection until it melts and

runs.

4. Allow the connection to cool undisturbed.

ALL SOLDERING MUST BE DONE WITH ROSIN

CORE SOLDER.

There is no warranty on any equipment in which acid

core solder has been used. Make sure that the solder you

use is plainly marked "Rosin Core". If you have solder on

hand of doubtful origin, it is wise to obtain a new roll of

50/50 or 60/40 rosin core solder.

Whenever a connection is to be soldered, the instructions

indicate this by the symbol (S). If this symbol is not

shown after a step, further connections must be made to

the same point before soldering.

A number of steps in the instructions begin,"Connect

one end of a wire...", with the length of the wire specified.

In each case, first cut a piece of wire to the correct length

from the roll supplied with the kit and then remove about

¼" of insulation from each end before making the connection. The leads on components should be trimmed as they

are used, the length chosen being that

nection to be made from point to point without strain on

terminals or components. The lead "dress", that is the

manner in which the wiring is arranged as it goes from one

point to another, should follow that shown in the pictorial

diagram as closely as possible. Care must be exercised to

see that uninsulated wires do not touch each other, and

cannot do so through vibration or sagging, unless of course,

they are connected to the same point. It is especially important that uninsulated wires and component leads or terminals do not touch the chassis or bottom plate accidentally.

Check your work after each step, and, when you are satisfied that it has been correctly done, mark the space provided and go on to the next step. Examine the pictorial

diagrams often; if you check your work methodically, your

amplifier should work as soon as the wiring is complete.

which permits a con-

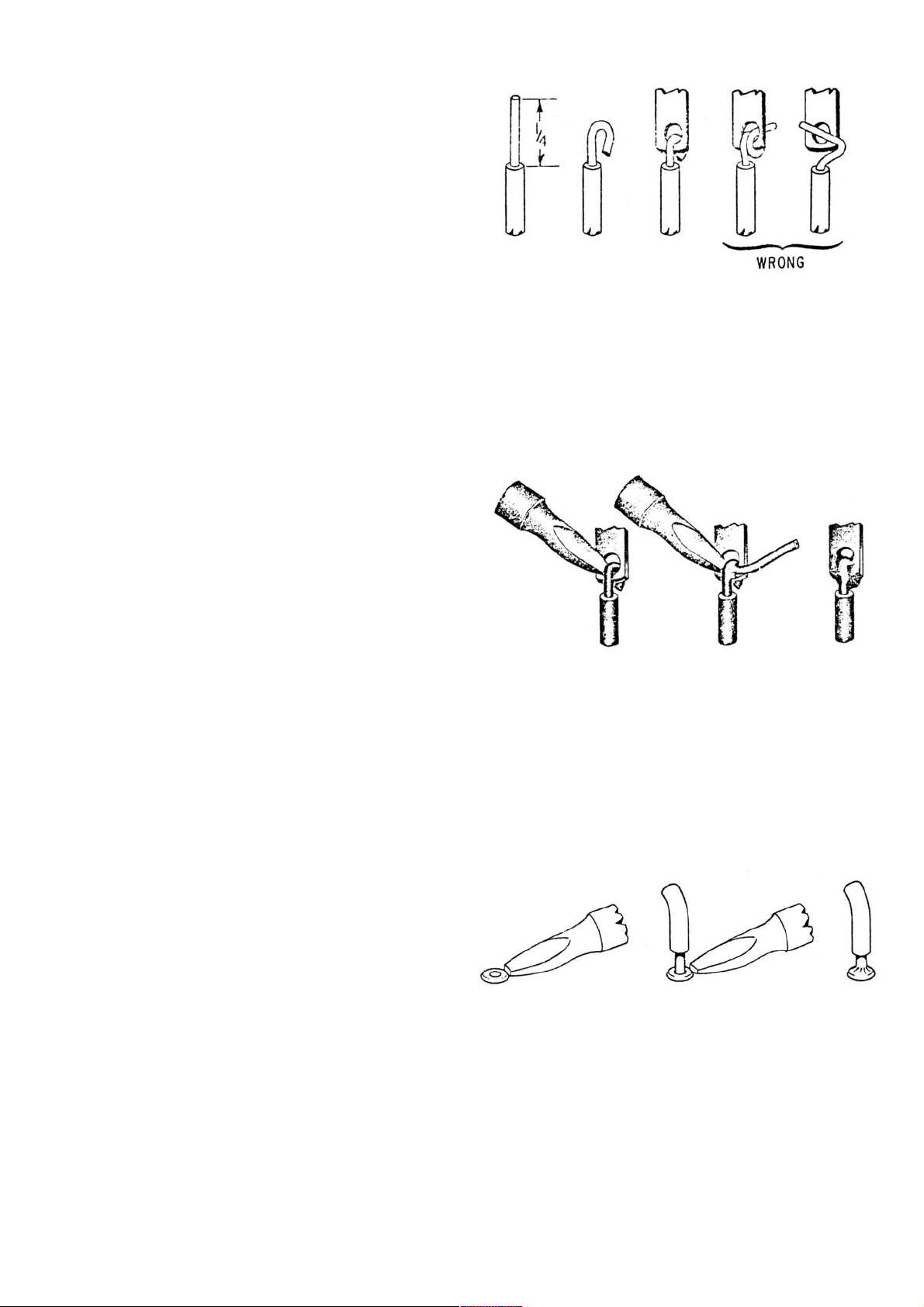

To transfer heat from the iron to the wire and terminal,

the tip of the iron should be kept brightly tinned with

solder. If this is properly done the first time the iron is

used, the tinning may be maintained by wiping the tip with

a cloth or sponge every few minutes while soldering. When

correctly tinned, the tip will heat both parts of the connection almost immediately. Solder should then be applied

directly to the parts to be soldered. as shown in the middle

illustration above, and both iron and solder removed as

soon as the solder flows freely.

The circuit boards of the Stereo 35 are supplied with all

components (resistors and capacitors) already mounted

and soldered in place. The circuit boards are connected to

the other sections of the amplifier channels by soldering

wires to eyelets on the boards. These eyelets, which are

numbered for identification, are filled with solder already.

To solder a wire to them, they are first heated with the tip

of the iron, and the end of the wire inserted as soon as the

solder in the eyelet flows. A correctly made connection looks

like the illustration at the right, above, which shows a smooth

transition from eyelet to wire.

4

CHECK PICTORIAL DIAGRAMS #1 AND #3

BEFORE AND AFTER DOING EACH STEP.

1( ) Mount the two 3-screw terminal strips on the out-

side of the chassis in the cutouts provided, using

#4 screws, nuts and lockwashers (the smallest size

supplied). The pictorial diagram shows the correct

orientation of the terminal strips.

2( ) Mount the fuse holder in its cutout, fastening it in

place with the circular brass threaded ring. The rubber washer goes on the outside of the chassis; by

maintaining pressure against the fuse holder from the

outside, with one hand, while tightening the brass

ring with the other hand. The fuse holder can be

mounted securely without tools. Be sure that the

fuse holder terminals are oriented exactly as shown

in the diagram. After mounting, terminal lug B

should be bent away from the body of the fuse

holder at the angle shown in the pictorial diagram.

3( ) Mount the 5-lug terminal strip on the side of the

chassis, as shown in the diagram, using a #4 screw,

lockwasher and nut.

4( ) Install the four sockets supplied for V-2, V-3, V-5

and V-6 on top of the two PC-13 circuit boards. Note

that the sockets are not all installed in the same way;

pictorial diagram #2 shows the correct orientation

for each socket. Mount each socket with two sets

of #4 hardware. Do not over-tighten.

5( ) Mount the two PC-13 circuit boards in the rectangu-

lar cutouts at each end of the chassis; note that the

boards are mounted from the

inside of the chassis.

Before mounting each board with four sets of #4

hardware, study the diagram to be sure that the

boards will be properly oriented on the chassis.

6( ) Install the two input sockets from the inside of the

chassis, using two sets of #4 hardware to mount

each socket. The long (center) lug of each socket

should be closest to the circuit board.

7( ) Mount the filter capacitor in the cutout provided.

First, look at the symbols stamped in the plastic

at the base of each connecting lug; These must be

oriented as shown in the pictorial diagram. Insert

the four mounting lugs of the capacitor in the slots

and then twist each of the mounting lugs one-quarter

turn with a pliers while holding the capacitor snugly

against the chassis with your other hand.

8( ) Pass the leads of one of the output transformers

(marked Z-565) through the two holes provided in

the chassis. The orange, black and yellow leads go

through the hole closest to the center of the chassis,

as shown in the diagram. Mount the transformer

loosely with four #8 screws, nuts and lockwashers

(the largest size supplied). After adjusting its position so that it is as close to the circuit board as

possible , tighten the screws.

9( ) Pass the leads of the other output transformer

(Z-565) through the two holes provided in the

chassis, again observing that the black, orange and

yellow leads go through the hole closest to the center

of the chassis. Mount the transformer loosely with

four sets of #8 hardware, position it as close to the

circuit board as possible, and tighten the screws.

10( ) Pass the leads of the power transformer (PA-774)

through the two holes provided at the center of the

chassis. A group of four leads go through the hole

nearest to the fuse holder, and five* leads through

the other hole. Mount the power transformer with

four sets of #8 hardware, but do not tighten the

screws immediately. First, center the power transformer so that it is evenly spaced between the two

output transformers. Then, tighten the screws.

11( ) Insert the rubber grommet in the hole in the chassis

through which the line cord is to pass.

*Seven leads in 240-volt transformer PB-028, for use outside the United

States. Special instructions for installing PB-028 begin at the conclusion of these instructions.

5

WIRING INSTRUCTIONS

Refer to pictorial diagram #2 before and after each

step. After making a connection, bend (dress) each

lead or wire so that it follows the path shown in the

diagram as closely as possible. After all connections

have been made to a terminal and it is soldered

cut off any excess wire.

1( ) Begin with the group of five leads from the power

transformer PA-774, all of which come through the

hole in the chassis opposite of fuse holder.

NOTE: Special instructions for wiring PB-028 the 240-volt power

transformer, are at the end of these instructions.

When cutting transformer leads to correct length

strip the insulation at the end of each lead to expose

about

¼" of wire. Tin the exposed end, by heating

it with the soldering iron and melting a bit of solder

onto it; this will keep the end from fraying, and

permits a more secure mechanical connection. Measure the length with a ruler, from the chassis to the

end of the lead, wile holding the lead straight out

from and perpendicular to the chassis. Cut one of

the black leads to 1

½" in length, and connect it to

lug #4 of the 5-lug terminal strip. Do not solder,

remember, a connection is only to be soldered when

the symbol (S) is printed after the instruction.

2( ) Cut the other black lead to 3½", and connect it

to terminal B of the fuse holder (S).

3( ) Twist together the two red power transformer leads.

Connect one of them to lug #1 of the 5-lug terminal

strip.

4( ) Connect the other red power transformer lead to lug

#2 of the 5-lug terminal strip.

5( ) Cut the red-and-yellow power transformer lead to

3½" in length, and connect it to chassis-mounting

lug A of the filter capacitor.

6( ) The four remaining power transformer leads are con-

nected next. Cut the green and green-and-white

leads to 6" each, and twist them together, as shown

in the diagram. Connect the green-and-white lead to

pin #5 of V-3 on the LEFT circuit board.

7( ) Connect the green power transformer lead to pin #4

of V-3. IMPORTANT: Because the tube sockets lugs

are small and closely spaced, it is imperative that

all connections to them be made with care. Keep

stripped wire ends as short as possible; insert them

in the lugs up to insulation; cut off excess immediately after soldering each connection; check each

time to be certain that nearby terminals and hardware cannot accidentally be touched by bare wire

ends.

8( ) Cut the brown and the brown-and-white power

transformer leads to 6". Twist them together, and

connect the brown-and-white lead to pin #5 of V-6

on the RIGHT circuit board.

9( ) Connect the brown power transformer lead to pin

#4 of V-6.

10( ) The LEFT output transformer leads are connected

next. Carefully cut the blue-and-white and green-

and-white leads from the LEFT output transformer

to exactly 2" in length. Strip and tin the ends, and

twist the leads together, as in the diagram. Connect

the blue-and-white lead to pin #7 of V-2 on the

LEFT circuit board (S).

11( ) Connect the green-and-white lead to pin #9 of V-2

(S).

12( ) Twist together the blue and green leads from the

LEFT output transformer. Connect the blue lead to

pin #7 of V-3 on the LEFT circuit board (S).

13( ) Connect the green lead to pin #9 of V-3.

14( ) Connect the red lead from the LEFT output trans-

former to lug #2 of the filter capacitor. This is the

lug next to square symbol on the plastic underside of the capacitor, and should be in the position

shown in the pictorial diagram.

6

15( ) Cut the black, orange and yellow leads of the LEFT

output transformer to 3

these leads together, and connect the black lead to

lug C of the LEFT 3-screw terminal strip.

16( ) Connect the orange lead to lug 8 of the LEFT

3-screw terminal strip (S).

17( ) Connect the yellow lead to lug 16 of the LEFT

3-screw terminal strip.

18( ) The RIGHT output transformer leads are connected

next. First, cut the blue-and-white and green-andwhite leads to exactly 2" long. Strip and tin the ends,

and twist the leads together. Connect the blue-andwhite lead to pin #7 of V-5 on the RIGHT circuit

board (S).

19( ) Connect the green-and-white lead to pin #9 of V-5

(S).

20( ) Twist

together the blue and green leads from the

½" long. Twist all three of

RIGHT output transformer. Connect the blue lead

to pin #7 of V-6 on the RIGHT circuit board (S).

21( ) Connect the green lead to pin #9 of V-6. Be sure

that exposed wire or stray filaments from them

cannot touch other wires or terminals, or cause a

short-circuit to the chassis hardware.

22( ) Cut the red lead from the RIGHT output trans-

former to 4½" long, and connect it to lug #2 of the

filter capacitor (square symbol).

23( ) Cut the black, orange and yellow leads of the RIGHT

output transformer to 3½" long. Twist these three

leads

together, and connect the black lead to lug

C of the RIGHT 3-screw terminal strip.

24( ) Connect the orange lead to lug 8 of the RIGHT

3-screw terminal strip (S).

25( ) Connect the yellow lead to lug 16 of the RIGHT

3-screw terminal strip.

7

REFER TO PICTORIAL DIAGRAM #3.

26( ) Connect one end of the 6800-ohm (blue, gray, red),

1-watt resistor to lug #2 (square symbol) of the

filter capacitor. Connect the other end to lug #3

(triangle symbol) of the capacitor. The resistor leads

should be cut to permit mounting exactly as is shown

in the diagram.

27( ) Connect one end of the 50-ohm, 5-watt resistor to

lug #1 (curved line symbol) of the filter capacitor.

Connect the other end to lug #2 (square symbol)

of the capacitor (S). Check to be sure that all four

of the connections at lug #2 have been soldered,

and that excess wire has been trimmed away ,and

cannot touch the chassis or adjacent lugs.

28( ) Connect one end of the 95-ohm, 5-watt resistor to lug

#4 ( no symbol) of the filter capacitor. Connect the

other end to chassis-mounting lug B of the capacitor.

29( ) Connect one end of a 5" wire to chassis-mounting

lug B of the filter capacitor (S). Connect the other

end to lug #3 of the 5-lug terminal strip (S).

30( ) The silicon rectifier diodes supplied with the kit may

be of any of the three types shown in the illustration;

although differing in external appearance, the three

types are elettrically equivalent.

Connect the CATHODE lead of one

of the rectifier diodes to lug #1

(curved line symbol) of the filter

capacitor. Connect the ANODE lead

to lug #2 of the 5-lug terminal strip

(S). IMPORTANT: Arrange the

diode leads exactly as shown in the

pictorial diagram. When soldering,

hold a pliers on the lead between the diode body and

the solder connection to avoid application of excessive

heat to the diode.

31( ) Connect the CATHODE lead of the other rectifier

diode to lug #1 (curved line symbol) of the filter

capacitor (S). Connect the other lead to lug #1 of

the 5-lug terminal strip (S). Observe the same precautions when soldering as in the preceding step.

32( ) Connect one end of a 4" wire to lug C of the RIGHT

3-screw terminal strip (S). Connect the other end

to chassis-mounting lug A of the filter capacitor.

33( ) Connect end of a 9" wire to lug C of the LEFT

3-screw terminal strip (S). Connect the other end

to chassis-mounting lug A of the filter capacitor

(S).

34( ) Connect one end of a 4" wire to lug '#3 (triangle

symbol) of the filter capacitor. Connect the other end

to eyelet #7 of the RIGHT circuit board (S).

NOTE : Before making a connection to an ayelet on the circuit board, tin the end of the wire

by heating it with the soldering iron and touching solder to it. The wire end is tinned when

the solder melts and runs onto the wire. The

eyelets on the board already have solder in

them. To solder to the eyelet, heat it with the

soldering iron and insert the end of the wire

when the solder in the eyelet flows. Remove the

iron and hold the wire in place until the solder

hardens.

35( ) Connect one end of a 5" wire to lug #4 (no symbol)

of the filter capacitor. Connect the other end to pin

#3 of V-5 on the RIGHT circuit board.

36( ) Prepare a 1

lation from one end, and ¼" from the other end.

¾" piece of wire by stripping ½" of insu-

Push the longer bare end through pin #3 of V-6 on

the RIGHT circuit board (S), and bend it around

to connect to pin #4 of V-6 also. Connect the other

end to pin #3 of V-5 (S).

37( ) Connect one end of a 4½" wire one to eyelet #4 of the

RIGHT circuit board (S). Connect the other end

to eyelet #10 (S).

38( ) Twist together a 2½" and a 4" wire so that one pair

of end is even. Connect the matching end to pins

#4 and #5 of V-5 on the RIGHT circuit board.

Connect the shorter of the remaining end to eyelet

#5 (S), and the longer remaining end to eyelet #3

(S).

39( ) Twist together a pair of 2½" wires. Connect one

pair of ends to pin #4 (S) and pin #5 (S) of V-5

on the RIGHT circuit board. Connect the other ends

to pin #4 (S) and pin #5 (S) of V-6.

40( ) Connect one end of a 7" wire to lug 16 of the RIGHT

3-screw terminal strip (S). Connect the other end

to eyelet #6 of the RIGHT circuit board (S).

41( ) Connect one end of a 1¼" wire to pin #9 of V-6

on the RIGHT circuit board (S). Connect the other

end to eyelet #11 (S).

42( ) Connect one end of a 1" bare wire to pin #2 of V-6

on the RIGHT circuit board (S). Connect the other

end to eyelet #9 (S).

43( ) Connect one end of a 1" bare wire to pin #2 of V-5

on the RIGHT circuit board (S). Connect the other

end to eyelet #8 (S).

44 ( ) Connect one end of a 1" wire to the long lug of the

RIGHT input socket (S). Connect the other end

to eyelet #1 (S).

45( ) Connect one end of a 1½" wire to the short lug of

the RIGHT input socket (S). Connect the other end

to eyelet #2 (S).

46( ) The next group of steps are performed on the LEFT

circuit board. Connect one end of a 12" wire to lug

#3 (triangle symbol) of the filter capacitor (S).

Connect the other end to eyelet #7 of the LEFT

circuit board (S).

47( ) Connect one end of a 10" wire to lug #4 (no sym-

bol) of the filter capacitor (S). Connect the other

end to pin #3 of V-2 on the LEFT circuit board.

48( ) Strip ½" insulation from one end of a 1¾" piece

of wire; strip about ¼" from the other end. Push the

longer bare end through pin #3 of V-3 on the LEFT

circuit board (S), and then bend it back to connect

it to pin #4 of V-3. Connect the other end to pin

#3 of V-2 (S).

49( ) Connect one end of a 4½" wire to eyelet #4 of the

LEFT circuit board (S). Connect the other end to

eyelet #10 (S).

50( ) Twist together a 2½" and a 4", so that one pair

of ends is even. Connect the matching ends to pins

#4 and #5 of V-2 on the LEFT circuit board. Connect the shorter of remaining ends to eyelet #5

(S), and the longer end to eyelet '#3 (S).

51 ( ) Twist a pair of 2½" wires together. Connect one pair

of ends to pin #4 (S) and pin #5 (S) of V-2 on

the LEFT circuit board , and the other ends to pin

#4 (S) and pin #5 (S) of V-3.

52( ) Connect one end of 5" wire to lug 16 of the LEFT

3-screw terminal strip (S). Connect the other end

to eyelet #6 of the LEFT circuit board (S).

8

53( ) Connect one end of a 1¼" wire to pin #9 of V-3 on

the LEFT circuit board (S). Connect the other end

to eyelet #11 (S).

54 ( ) Connect one end of a 1" bare wire to pin #2 of V-3

on the LEFT circuit board (S). Connect the other

end to eyelet #9 (S).

55( ) Connect one end of another 1" bare wire to pin #2

of V-2 on the LEFT circuit board (S). Connect the

other end to eyelet #8 (S).

56( ) Connect one end of a 1" wire to the long lug of the

LEFT input socket (S). Connect the other end to

eyelet #1 (S).

57( ) Connect one end of a 1

the LEFT input socket (S). Connect the other end

to eyelet #2 (S).

58( ) Insert the line cord through the rubber grommet

mounted on the chassis, and push it through far

enough to tie a knot about 5" from the end. Tie the

knot. Then separate the two conductors of the line

cord for about 4". Cut 1½" from one of them, and

strip and tin the ends of both.

59( ) Connect the longer of the two line cord conductors

to lug #4 of the 5-lug terminal strip (S). Connect

the other conductor to lug A of the fuse holder (S).

This completes the wiring of the Stereo 35.

PLACES TO DOUBLE CHECK AFTER WIRING

( ) Be sure that all mounting screws and nuts are tight.

( ) Compare the wiring of each of the tube sockets to that

shown in the pictorial diagram. All connections should

securely soldered, with enough space between connections to the tube pin lugs so that there is no chance

of an accidental short-circuit.

( ) Compare the wiring to each lug of the filter capacitor

with that shown on the diagram. Check carefully to see

that all connections are soldered, and that excess lead

length has not caused any connection to short-circuit

to the chassis. Count the wires going to each terminal

on diagram and amplifier.

( ) Use special care in examining all connections, to be sure

that none of them are high enough to touch the bottom

plate when it is installed. Check the 5-lug terminal

strip and filter capacitor closely.

The tubes and fuse may now be installed. The socket on

each board which is supplied already mounted is for the

7247 tube. Each of the two sockets installed and wired

during assembly receives one of the 6BQ5 tubes. IMPORTANT: When inserting the tubes in their sockets for the

first time, the socket should be supported from below to

avoid strain on the circuit board, due to the tight fit of new

sockets. The amplifier a.c. cord should NOT be plugged

into a wall outlet until after the tubes are installed, and

the cover and bottom plate are securely in place.

The cover and bottom plate are attached at the same

time, by setting the amplifier chassis on the bottom plate,

which fits inside the chassis, and then lowering the cover

onto the chassis. The three pieces are fastened together by

four sheet metal screws through the sides of the chassis. The

four rubber feet are installed by pressing them into the

corner holes of the bottom plate. The cover should be used

whenever the amplifier is operated where it may be touched

accidentally; not only do the tubes become quite hot in

operation, but some point on the circuit board carry a

voltage which, while non lethal, can be quite uncomfortable

if touched while the amplifier is on.

½" wire to the short lug of

SPECIAL INSTRUCTIONS FOR OPTIONAL

120-240 VOLT POWER TRANSFORMERS

Dynakit Stereo 35 amplifiers supplied with power transformer PB-028 can be wired for used with either 120- or

240-volt a.c. power sources, in the following way:

For 120-volt operation.

( ) Begin with the group of seven leads from the power

transformer, all of which should come through the hole

in the chassis farthest from the fuse holder. Connect

the black lead to terminal B of the fuse holder.

( ) Connect the black-and-white lead to terminal B of the

fuse holder (S).

( ) Connect the violet lead to lug #4 of the 5 lug terminal

strip.

( ) Connect the violet-and-white lead to lug #4 of the

5-lug terminal strip.

Proceed with the wiring steps in the regular assembly

portion of this booklet, beginning with wiring step #3.

For 240-volt operation.

( ) Connect the violet-and-white lead to lug #5 of the

5-lug terminal strip.

( ) Connect the black-and-white lead to lug #5 of the

5-lug terminal strip (S).

( ) Connect the black lead to terminal B of the fuse holder

(S).

( ) Connect the violet lead to lug #4 of the 5-lug terminal

strip.

Proceed with the wiring steps in the regular assembly

portion of this booklet, beginning with the wiring step #3.

INSTALLING THE STEREO 35

In addition to the Stereo 35, your complete stereo system

will include one or more signal source (

tape transport), a stereo preamplifier (unless included with

the signal source), and two loudspeakers.

Installation of the Stereo 35 is simple. You will need

two shielded audio cables for the inputs (usually provided

with the preamplifier) and two

wire with

ers. Ordinary lamp cord will do for the latter.

The Stereo 35 is designed for use with stereo preamplifiers which have their own power supply, such as the Dyna

PAS-3. In addition to a high level of performance, the

preamplifier should be capable of delivering a signal of

about 1 volt to drive the Stereo 35 to its full output. The

Stereo 35 a.c. line cord should be connected to a switched

auxiliary a.c. outlet on the preamplifier; in this way, it

will be turned on and off automatically when the preamplifier is switched on and off. Since the Stereo 35 contains its

own fuse, an outlet which is not fused may be used.

which to make the connections to the loudspeak-

lengths of two-conductors

turntable, tuner,

9

The Stereo 35 may also be used with an FM tuner

without need for a preamplifier, provided that the tuner

is equipped with a volume control and switched a.c. outlet,

and has an out put of at least 1 volt.

The loud speakers chosen may be of any impedance or

efficiency, since the Stereo 35 has sufficient power reserve

beyond that usually required for home listening so that no

lack of volume is likely to be observed, even with relatively

inefficient speakers. The loudspeakers connection for each

channel is made between the COM (common) and either

the 8- o 16-ohm tap provided; the bottom plate is printed

to identify these terminals. The 8-ohm tap will permit

satisfactory operation with loudspeakers of 4- to 12-ohm

nominal impedance, while the 16-ohm tap may be used with

loudspeakers of 12- to 20-ohm rating.

PHASING THE LOUDSPEAKERS

The two loudspeakers used in a stereo system must be

phased properly for correct stereo reproduction. The phasing process itself is simple, after the amplifier is operating

and the two loudspeakers are connected.

Play a monophonic record, or tune in a monophonic

broadcast on your tuner. As you walk across the room in

front of the loudspeakers, there should be a smooth, continuous transition of sound from one side of the room to the

other. When you are directly between the loudspeakers,

the sound should appear to come from a source that is

directly in front of you, that is, also centered between the

loudspeakers. If you have any doubt as to whether or not

the phasing is correct, after making this test, transpose the

two connections at one of the amplifier terminal strips; that

is, connect the wire which was connected to "8" or "16" to

"COM", and vice versa. If you have changed to the correct

phasing, the sound will now be distinctly centered, and the

bass tones will appear to have increased. If you have

changed the connection to incorrect phasing, the sound

will seem to jump from one side to the other as you move

slightly to the right and left of center.

LISTENING WITH STEREO HEADPHONES

Headphones can be used with the Stereo 35 in place of

loudspeakers or connected in addition to loudspeakers.

Most headphone manufacturers supply instructions and

special junction boxes which permit direct connection of

headphones to the loudspeaker outputs of the amplifier.

With low impedance headphones (4 to 16 ohm rating),

without instructions from the manufacturer, a 1-watt resistor

of about 100 ohms should be connected in series with the

output of each channel. This will attenuate the signal to each

headphone, improving the signal to noise ratio.

CONNECTING A THIRD LOUDSPEAKER

TO YOUR STEREO SYSTEM

In most stereophonic systems, the usual arrangement of

two loudspeakers which form an equilateral triangle with

the listener's position will yield optimum performance. In

cases where the program contains exaggerated separation,

judicious use of the blend control on the preamplifier will

provide a more natural and pleasing effect.

When room arrangement or size does not permit the ideal

placement of loudspeakers, the addition of a third loudspeaker, playing a combination of the left- and rightchannel material, may improve the spatial effect considerably. Those listeners who feel a need for a third loudspeaker,

can try this arrangement without need for a third amplifier

or a special output on their preamplifier by using the following method. A monophonic extension loudspeaker may be

connected to a stereo system in the same way.

The circuit shown below provides output from a central

loudspeaker with full control over its level. For best results,

the speakers used should be identical.

Be certain that the loudspeakers are properly phased.

IN CASE OF TROUBLE

The Stereo 35 has been carefully engineered to give

long, trouble-free service. However, a mistake in assembly

or a defective component can affect its performance or

make it inoperative. If difficulty is encountered, a methodical analysis of the trouble will usually lead to a quick

cure. The first thing to check is the wiring to be sure that

all of the steps have been performed, and that all connections

have been soldered. It is especially helpful to have someone

other than the builder do the checking.

If the tubes do not light at all ( on both channels), it is

likely that a.c. power is not being delivered to the amplifier.

In all likelihood, the fuse will have blown, indicating the

possibility of a short-circuit in either the filament or high

voltage supply lines. If the resistance between chassis

ground and the quad filter capacitor lugs is less than

100,000 ohm, this indicates a probable short-circuit in

the high-voltage supply.

If the tubes of one channel light, but those of the other

do not, the filament leads from the power transformer to

one of the circuit boards are probably non properly connected, or these may be defective in the power transformer.

If all tubes light but one, the tube in question should be

interchanged with one of the same type from another socket

on either board. This should show whether the tube or

its associated circuitry is at fault; if the tube still fails to

light, it is faulty. If it lights in its new position, and the

tube inserted in its place is now dark, a close examination

of the tube socket wiring will usually reveal the source of

the difficulty. Should an output tube (6BQ5) ever require

replacement, it is preferable, but not essential, that the

pair be replaced.

If all of the tubes light, but there is no sound from the

loudspeakers when the system is in operation, it is first

necessary to eliminate other components in the system as

possible cause of the trouble. Inserting or removing the

input plugs at the input sockets of the Stereo 35, while it

is on should produce a loud momentary hum or "thump".

If the loudspeakers are properly connected, and no noise

is produced by inserting or removing the input plugs, the

high voltage supply is probably not connected. check the

wiring around the quad filter capacitor. If one channel

plays, and the other does not, check the signal path in the

defective channel, as well as the high voltage supply. Another possibility is that strands of wire from the output

transformer leads going to the output terminal strip are

accidentally shorting, or that the wires leading to the loudspeakers are touching the chassis or each other.

10

If hum and noise are present to any unusual degree, first

remove the inputs plugs from the Stereo 35, and replace

them with short-circuited input plugs (or temporarily connect a jumper between eyelets 1 and 2 on each circuit

board). If the hum and noise become virtually inaudible,

the amplifier is probably working properly, and the cause

should be sought elsewhere in the system. If plainly audible

hum or noise persist, there may be an error or defective

component in the power supply, or an open ground connection. If the hum is in one channel of the amplifier only,

check to see that eyelet #2 of its circuit board is soldered

to the input ground lug. Occasionally, a bad tube will cause

this condition, which is easily determined by switching

tubes until the hum appears in opposite channel. Hum

on both channels is probably due to a power supply defect,

a bad capacitor section or defective diode.

Intermittent hum, noise or silence are usually the result

of a poor solder connection. If the trouble occurs in both

channels, check the power supply first; if in one channel

alone, examine the solder connections on that side.

Filament glow is normal, but if the plate (the large

metal area) of a tube tends to glow red, either the tube or

its associated circuitry is faulty. It all four of the output

tubes glow in this manner, there is a short circuit in either

the cathode (pin #3 of any 6BQ5) or filament (pin #4

and #5), or at lug '#4 of the filter capacitor.

The voltage chart printed alongside the schematic diagram may be helpful in trouble-shooting. If readings made

at any of the points indicated differ from those listed by

more than 10%, it is likely that a wiring error or defective

component is nearby in the circuit.

The Stereo 35 should never be operated with any of its

tubes removed from their sockets.

FACTORY SERVICE AND WARRANTY

The Stereo 35 is designed to provide reliable, troublefree performance for a long period of time. when properly

assembled and installed. It is intended for use with the

120-volt a.c. power supplied to most homes. Although variations of several volts above or below this figure will have no

pronounced effect upon performance or component life, the

normal guarantee on the equipment is not applicable if it

is operated with a.c. inputs greater than 130 volts. If your

local power is this high or higher in voltage, it is suggested

that a voltage regulating or adjusting device be installed

to protect the amplifier.

All parts used in the Stereo 35 are guaranteed for a

period of one year from the date of purchase except tubes,

which carry the standard electronic industry (EIA) 90-day

warranty. Defective parts will be replaced at no charge if

they are returned prepaid to the factory either directly or

via the dealer from whom the kit was purchased. Many

Dynakit dealers carry parts in stock which may be used

for replacements. After the guarantee period has passed,

Dynaco, Inc. will supply any non-standard parts used at

net prices. Parts which are standard (resistors, capacitors,

tubes) can generally be purchased from a local electronics

supply store.

If it is believed that a transformer is defective, it should

be disconnected by unsoldering, never by cutting its leads

so short that it cannot be re-used.

If the kit has been completely assembled, yet cannot be

made to function properly, or if difficulty is apparent after

a short period of use, we will service the kit for a fixed

charge of $6.00, plus the cost of the parts which are outside

the warranty or have been damaged by the user.

Factory assembled amplifier include a one-year warranty on labour as well as parts.

IMPORTANT: FIXED-CHARGE SERVICE AND

MAINTENANCE ARE NOT AVAILABLE FOR

KITS WHICH ARE INCOMPLETELY WIRED,

OR KITS WIRED WITH SOLDER OTHER THAN

ROSIN CORE TYPE, OR KITS PHYSICALLY

OR ELETTRICALLY MODIFIED WITHOUT

PRIOR FACTORY AUTHORIZATION. ADDITIONALLY, NO PARTS WILL BE REPLACED

AND NO SERVICE MADE AVAILABLE FOR

KITS FOR WHICH THE WARRANTY POST

CARD HAS NOT BEEN RETURNED. THE

SERIAL NUMBER ON THE FRONT COVER OF

THIS INSTRUCTIONS BOOK MUST BE MENTIONED IN ALL CORRESPONDENCE AND IN

ANY CASE WHERE PARTS ARE RETURNED,

OR KITS SENT OR BROUGHT TO THE FACTORY FOR SERVICE.

It is the factory prerogative to limit the service facility

to one year from the date of purchase.

When shipping the amplifier to Dynaco, Inc., for service,

attach a note specifying the symptoms, the name and

address of the sender, and the serial number of the kits.

The kit should be securely packed to withstand the abuses

of handling in transit. It should be placed in a rugged carton surrounded by several inches of shredded paper or

other soft packing material. The original kit carton is not

suitable for shipment of a wired amplifier.

Shipment should be made by prepaid EXPRESS, where

possible, repaired kits will then be returned EXPRESS

C:O:D: for freight and service charges (unless these charges

have been prepaid). Parcel post is not a safe method for

the shipment of assembled kits, and should not be used

for this purpose.

The Dyna Company assumes no liability or responsibility

for damages or injuries sustained in assembly or operation

of this Dynakit.

1 Chassis set

(chassis, cover and bottom plate)

1 Power Transformer PA-774

2 Output Transformers Z-565

4 Output Tubes 6BQ5/EL84/7189

2 Driver Tubes 7247

2 Rectifier Diodes 500 ma 1000 PIV (Silicon)

1 Quadruple Section Filter Capacitor

60/40/20 @450 v.; 100 @ 25v.

2 3-Screw Terminal Strips

1 Fuse Holder with Rubber Washer and

1 Circular Nut

STEREO 35 PART LIST

1 5-Lug Terminal Strip

1 Fuse 2-Ampere Slo-Blo

1 Line Cord with Plug

2 Input Sockets

1 Roll Hookup Wire

2 PC-13 Circuit Board Assemblies

RESISTORS

1 50 ohms, 5 watts

1 95 ohms, 5 watts

1 6,800 ohms (blue-gray-red), 1 watt

HARDWARE

4 Rubber Feet

½" Grommet

1

12 8/32 x

12 8/32 Nuts

12 #B Lockwashers

25 4/40 x

25 4/40 Nuts

25 #4 Lockwashers

4 #6 Sheet Metal Screws

1 Instruction Manual with Pictorial Diagrams

1 Warranty Card

¼" Machines Screws

¼" Machine Screws

11

Loading...

Loading...