CONTENTS

Professional Specifications .................... 3 Schematic .............................................. 12

Description ............................................ 4 Component Values .............................. 13

Installation ........................................... 4 Initial Adjustment—Biaset ................... 18

Connections............................................. 4 Output Meter Reading ......................... 18

Assembly Instructions............................. 6 In Case of Difficulty .................................19

Mechanical Assembly ........................ 7 Voltages and PC-44 Board Layout ........... 20

Wiring the Output Stage ..................... 9 International AC Line Connections ......... 21

Wiring the Power and Bias Supplies. .11 Service Policy and Limited Warranty….22

Wiring PC-44 and Control Bracket . . .15 Parts List .................................................23

Final Assembly.....................................16

PROFESSIONAL SPECIFICATIONS

Power Output: 120 watts continuous.

Power Response: 20 Hz to 15 kHz within 1 dB of 120 watts with less than

Frequency Response: +0, -1 dB, 10 Hz to 40 kHz @ 1 watt.

Intermodulation Distortion: 1% or less at rated power using 60 Hz and 7000 Hz

Hum and Noise: Greater than 95 dB below rated output.

Input: 50,000-ohm load; unbalanced line.

Damping Factor: 14 at 16 ohms; 1 kHz.

Output Impedance: 4, 8 and 16 ohms. Power

Consumption: 250 watts.

Tube Complement: 8417 (4); 7199; silicon rectifiers; time delay relay

Fuses: 5 amp AC line; speaker.

Meter: Switchable for 3 output ranges and for output tube bias.

Finish: Satin charcoal 1/8” steel front panel and

Size: 19" x 101/2" x 83/4" high; add 11/2" for handles.

Weight: 55 lbs. (25 kg.)

1% total harmonic distortion.

Mixed 4:1. Distortion reduces at low er power levels.

1.6 volts for 120 watts.

electrostatically applied black epoxy coated 16 gauge

steel chassis.

3

DESCRIPTION

The Mark VI is a vacuum tube high power basic power

amplifier designed for the professional sound installer.

Vacuum tubes are most often favored in their ability to withstand enormous physical and electrical abuses—conditions

frequently encountered in discotheques, public address and

musical instrument applications. Its rugged construction

and utilization of superior components, including the

patented Dynaco Super Fidelity transformers, permit continuous duty at full power, while maintaining safe operating

margins. Protective isolation of the load from the driving

circuits, and uniform power output into a variety of load

impedances are inherent in all designs which use an impedance matching transformer.

The Mark VI employs a basic circuit arrangement which

all Dynaco vacuum tube amplifiers have used since the

inception of the Mark II amplifier in 1955. Refinements of

the operating parameters have been incorporated for circuit

balance, stability, and for drive capability. The components

used have been selected to protect against failure, and all

parts are operated conservatively to assure superior performance and proper operation for many years.

The pentode section of the 7199 tube is a high gain voltage

amplifier, which is direct-coupled to a cathodyne—split

load—phase inverter. The operation of this type of phase

inverter is independent of tube aging, a unique advantage

INSTALLATION

of its design. The input gain and inverter stages are refined

to provide an accurately balanced signal to the output tubes.

The 8417 output tubes are a matched set of four, to assure

proper operation of the Mark VI. The output tubes are operated in a fixed bias arrangement, which may be accurately

checked and adjusted with the lighted meter and recessed

potentiometer on the front panel.

The output tubes drive a Dynaco Super Fidelity output

transformer expressly designed for this circuit. Taps on the

plate windings connect to the screen grids, and contribute to

the linearity of the overall design. The impedance match

and bias conditions employed contribute to very low distortion over a wide range, even without feedback. The overall

feedback loop adds 20 decibels of additional distortion reduction.

In addition to front panel adjustment of bias, recessed controls for input level and a 4-position range switch (three

positions for observing output power levels on the meter,

plus one position for observing bias) are supplied. A speaker

fuse holder and lighted power switch complete the front

panel layout.

The simplicity of this circuit—a minimum of phase shift-

ing stages and very careful attention to output transformer

design—assures maximum stability.

The Mark VI is designed for mounting in a standard 19"

rack (mounting hardware for the rack is not supplied); its

supplied large feet also permit placement on any flat surface. The amplifier should be installed where the front panel

is accessible. If the Mark VI is to be mounted near a phonograph, check to make sure that the phono cartridge does not

pick up hum from the power transformer.

VENTILATION is an important consideration. This amplifier

generates almost the same heat under quiescent (no signal)

conditions as it does at full power—the equivalent of a 250

watt light bulb within the confines of the perforated cage.

Thus, ADEQUATE AIR CIRCULATION IS ESSENTIAL. If the Mark VI is rack mounted, 1 foot (30 centimeters) of unimpeded air space MUST be provided above

the unit. Otherwise fan cooling is recommended. Also, the

amplifier is intended to be installed horizontally, with its

CONNECTIONS

INPUT

A signal input is connected by a single conductor shielded

cable to a choice of two RCA type phono jacks or an XLR connector. One of the phono jacks and the XLR input provide flat

low frequency response; the other phono jack provides a low

frequency rolloff @ 6 dB per octave (—3 dB @ 70 Hz). The

input impedance is 50,000 ohms, unbalanced line. The input

sensitivity is 1.6 volts rms for 120 watts output with the input

level control turned fully clockwise. The Mark VI may

therefore be easily driven by one channel of many brands of

control preamplifiers, such as the Dynaco PAT-5, PAT-4,

PAS-3X, or PAS-2/3. The PAS tube type preamplifiers require

internal modification: To change the PAS-3X, simply locate

and remove the pair of 62,000 ohm resistors (blue-redorange) on the PC-5 printed circuit board; to change the

PAS-2 or PAS-3, remove the 62,000 ohm resistors, as indicated

4

feet providing clearance for air flow under the unit. Do not

allow the ventilation slots in the bottom to be restricted

(don't place the amplifier on a rug, for example), or there

will be excessive heat buildup within the enclosed section of

the chassis. Vertical mounting is not recommended, even

with fan cooling.

If the amplifier is to be permanently installed, the handles may be removed before installation, if desired. The

bolts which affix the handles to the front panel should be

reinstalled once the handles have been removed, since these

bolts also attach the front panel to the chassis. However, the

handles not only facilitate carrying the Mark VI, but they

also protect the front panel components from breakage.

Therefore, unless it is to be permanently mounted, their removal is not suggested.

above, and additionally remove the pair of 510,000 ohm resistors (green-brown-yellow) on the back panel of the preamplifier.

Some other tube type preamplifier brands may require

modification for optimum performance into a 50,000 ohms

load.

OUTPUT

Select speaker leads of sufficient size to preserve the

damping factor of your amplifier. Standard 18 gauge lamp

cord ("zip cord") is suitable for distances up to 30 feet.

Larger wire sizes are advised for longer distances—#16 for

50 feet; #14 for 80 feet. #18 and #16 lamp cord is available

from hardware and electrical supply stores, and is the

easiest to use and conceal.

Be s ure to maintai n simi lar wiring "se nse" fo r each

E

speaker in a mono, stereo, or quadraphonic system, so that

they will be connected in phase. Normally the "-", common, or

ground terminal of each speaker is attached to the "c"

terminal on the output barrier strip, or to the "sleeve" connection on the output jack. The other speaker terminal is

attached to the correct impedance terminal (4, 8, 16) on the

barrier strip (the "tip" connection on the output jack is normally wired to the 8 ohm tap of the output transformer,

although this connection may be changed to either the 4

ohm or the 16 ohm tap, if desired). Proper phase sense is

easily maintained with lamp cord because one conductor is

coded with a molded ridge on the outer insulation.

Two speakers are connected in phase when maximum low

frequency output is heard when they are driven from a monophonic source. Lowered output is observed when the connection to one of the speakers is reversed (out of phase, or

reversed polarity). When using multiple speakers on each

channel, or with 4-channel systems, it is important that all

of the speakers in the same area be wired in phase.

If stranded lamp cord is used, the wire ends should be

"tinned" first with solder to avoid fraying. In any case, make

certain that no wire strands can touch other than the intended terminal.

The "c" terminal of the amp lifier is connected to the

chassis, so the Mark VI may be used in multiples, if desired,

with special output connections which require common

grounds. If so, it will be necessary to connect together all

the "c" terminals of the Mark VI amplifiers being used in

the same system.

An in-phase signal at the input of the Mark VI amplifier

provides an in-phase signal at the output. This is characteristic of all Dynaco tube and solid state amplifiers.

AC POW E R

The power cord should be plugged into a wall outlet pro-

viding 120 volts, 50/60 Hz (alternately 100 volts, 220 volts

or 240 volts depending on the wiring of the primary of the

power transformer). Do not attempt to switch the amplifier

remotely by plugging it into a switched outlet on a control

preamplifier unless the outlet is designated as a 5 amp, or

higher capacity. The Dynaco PAT-5, which can handle 15

amps, may be used.

LOUDSPEAKE R RATINGS

Nominal speaker power ratings are a matter of concern.

There is currently no U.S. standard. Manufacturers usually

provide a "music power" rating, or indicate amplifier power

limits. These should not be confused with continuous, or

"rms" power acceptance for a sustained period which will be

substantially lower. It is rare for a speaker to be able to

handle as much power near the frequency extremes as in the

midrange. Single woofer high fidelity speaker systems rarely

have "music" ratings as high as 100 watts, or continuous

duty wide band sine wave ratings a s high as 40 watts.

In view of the power limitations of most high accuracy

speaker systems, the connection of two or four similar

speakers in the same location to a single channel is often

advisable, if high signal levels are wanted. Lacking more

definitive advice, a rough test is to place your hand in front

of the woofer when playing a loud passage at your anticipated listening level. If you can feel any heat generated by

the voice coil, you should consider the need for additional

speakers to reproduce that level safely. When high output,

high accuracy reproduction is desired, a series-parallel connection of four 8 ohm speakers (such as the Dynaco A-35)

on each channel provides a resultant 8 ohm load with exceptional power handling capacity.

Speaker impedance varies with frequency—often by a

factor of 4 or 5 to 1. Even the least variable speakers, like

Dynaco's, have a 2:1 change. While most nominal ratings

are close to the actual minimum impedance, when combinations approach the 4 ohm minimum recommended amplifier

load, the safest procedure is to measure the resistance across

the terminals with an ohmmeter. Speaker impedance usually varies upwards from this value. Use this figure to determine how multiple speakers should be connected:

IN PARALLEL: IN SERIES: IN SERIES-PARALLEL:

2 x 8 ohms =4 ohms 2x4 ohms = 8 ohms 4x16 ohms =16 ohms

2x16 ohms =8 ohms 2x8 ohms =16 ohms 4 x 8 ohms= 8 ohms

4x 16 ohms =4 ohms 4x4 ohms= 16 ohms 4 x 4 ohms= 4 ohms

These simple examples assume identical models. It is not

wise to connect dissimilar speakers in series or in seriesparallel because of adverse audio effects.

LOUDSPEAKER FUSING

The output of the Mark VI is provided with a speaker

fuse, which is mounted on the front panel. The 5 ampere,

3AG fuse supplied will not fail when the amplifier is operated

at full power (120 watts into 8 ohms), and therefore it provides NO PRO TEC TIO N for your speaker. The size of the fuse

should be determined by the type of speaker you are using.

The protective fuse rating determination for a speaker is

largely empirical, because the power passed by a fuse varies

with load impedance, test signals have little correlation with

music signals, and fuses vary in their tolerance of music

overloads. Logic would suggest the smallest fuse which does

not blow frequently at what are high, but nonetheless safe

levels for your speaker. There are few speakers capable of

safely handling more power than will blow a 2 ampere fuse.

The speaker manufacturer wh o specifies a fuse rating

solves your problem. Lacking this, remember that a fuse will

not blow until a sustained signal well above its rating is imposed for a time. A slo-blo fuse will allow appreciably more

overdrive than the same value standard fast-blow type, and

is thus not generally recommended for speaker protection.

The chart below shows the highest sustained power level

which will not blow the fuses shown. Remember that speaker

impedance typically rises well above its nominal value.

Experience suggests that on this basis power levels of 10

watts are safe starting points for most high fidelity speakers

using a single woofer.

3AG FUSE TYP

1

/2 ampere

3

/4 ampere 2.2 watts 4.5 watts 9 watts

4 OHMS 8 OHMS 16 OHMS

l wat t 2 watts 4 watts

1 ampere* 4 watts 8 watts 16 watts

11/

ampere** 9 watts 18 watts 36 watts

*Dynaco A-10, A-25 and A-35 speakers

**Dynaco A-25XL, A-40XL, and A-50 speakers

5

ASSEMBLY INSTRUCTIONS

GE NER AL AS SE M BLY IN FOR M AT IO N

Construction of the Mark VI is very simple when compared to other kits. The printed circuit board for audio has

been preassembled to save you some of the work, and the

assembly that remains is in an open, uncluttered layout to

make wiring quick and easy. The construction time will be

several hours. It is better to work slowly and carefully rather

than concern yourself about the time.

When you unpack the kit, check off the components

against the parts list on page 23. Separate the hardware

items in an egg carton or similar container. You can identify

unfamiliar parts by checking them against the Pictorial

Diagram, bearing in mind that the drawing is necessarily

somewhat distorted for visual separation.

Have the proper tools at hand before starting construction.

The tools necessary are:

1. A pencil-type soldering iron with a 3/16" tip or

smaller of 40 to 60 watts rating, with a tip temperature of 700 to 800° F.

2. A damp sponge or cloth to wipe the tip of the iron.

3. 60/40 rosin core solder not larger than 1/16" diameter.

4. A medium sized screwdriver (1/4" blade).

5. Long nosed and diagonal cutting pliers.

6. Heavy "slip joint" pliers.

7. A single edged razor blade or inexpensive wire strip

ping tool for removing insulation.

8. Wood toothpicks.

9. Transparent or masking tape.

10. Heavy cardboard.

We do not recommend using a soldering gun. Not only

can a gun provide more heat than is necessary—an unskilled

user might damage printed circuit boards—but also many

users tend to make poor solder connections, simply because

they do not wait long enough for the gun to reach its operating temperature each time. Use a conventional pencil type

iron.

A good solder connection does not require a large amount

of solder around the joint. A well-made connection looks

smooth and shiny because the solder flows into the joint

when both parts are hot enough.

There are four steps to making a good solder connection:

1. Make a good mechanical connection.

2. Heat both parts with the tip of the iron at the junction.

3. Apply solder to the junction until it melts and flows.

4. Allow the connection to cool undisturbed.

ALL SOLDERING MUST BE DONE WITH

A GOOD GRADE OF ROSIN CORE SOLDER

Under no circumstances should acid core solder be used.

Unmarked solder, cheap solder or any of doubtful origin

should be discarded, and separate solder fluxes should never

be used. The warranty is voided on any equipment in which

acid core solder or acid type fluxes have been used. Silver

solder is not suitable. The recommended solder is 60/40

(60% tin, 40% lead) ROSIN CORE. Do not confuse this

with 40/60, which is harder to use.

You should realize that many of the more delicate components are less likely to be damaged in the soldering process if you use a hot iron for a short time, rather than a cooler

iron for a longer period. You will also make a better connection with the hot iron. If you keep the iron clean by wiping

the tip frequently, and occasionally add a small amount of

solder to the tip, it will aid the transfer of heat to the connection. Do not allow too much solder to build up on the

tip though, or it may fall onto adjacent circuitry.

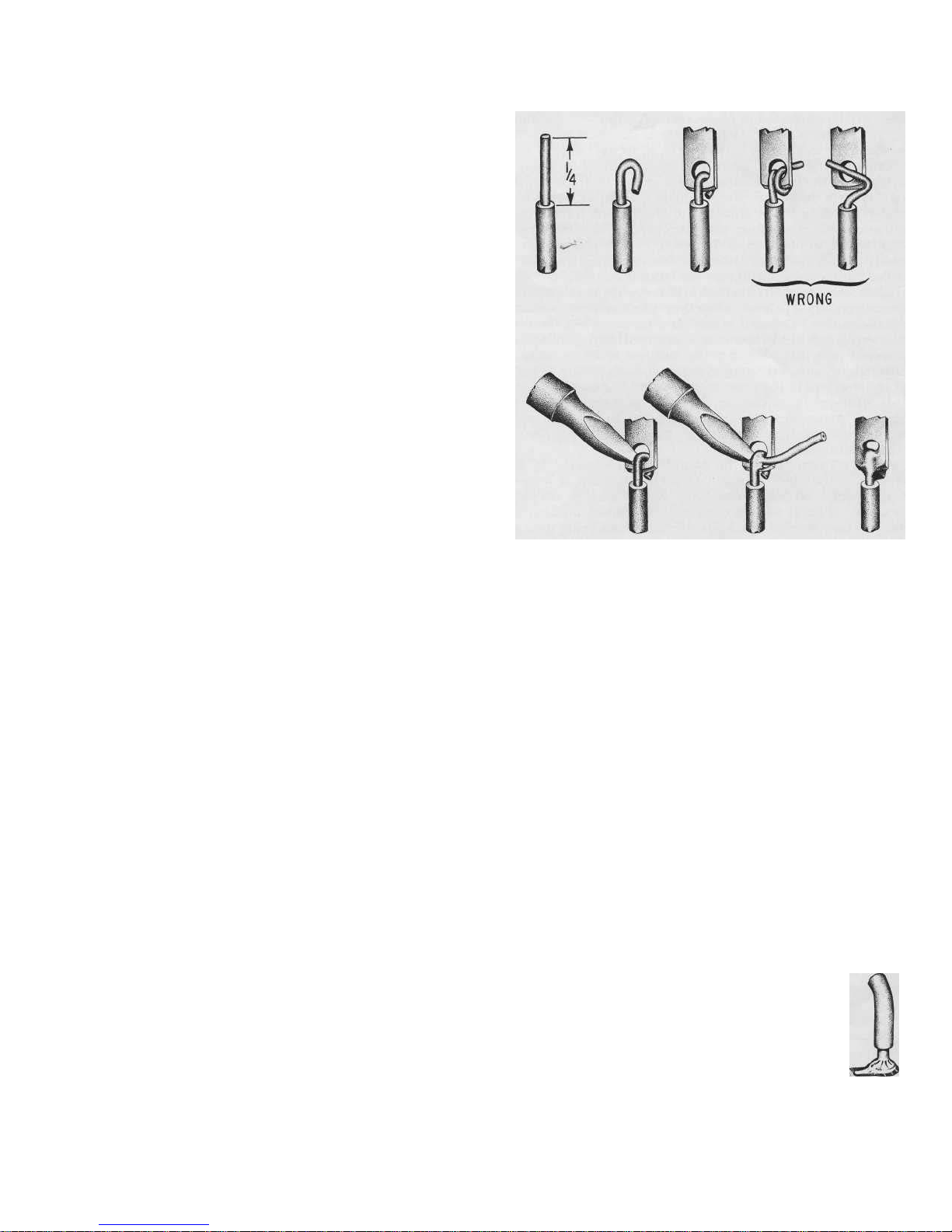

One of the best ways to make a good mechanical connec-

tion is to bend a small hook in the end of the wire, and then

to crimp the hook onto the terminal lug. The amount of bare

wire exposed need not be exactly 1/4 inch, but if it is too

long, the excess might touch another terminal lug or the

chassis. Do not wrap the wire around the lug more than one

time, as this makes the connection difficult to remove if an

error is made.

Many of the wiring steps will call for "preparing" a wire

of a certain length and color. This involves cutting the necessary length of wire and stripping 1/4 inch of insulation from

each end. This is most easily done with wire strippers, but

diagonal cutters can be used if you are careful not to nick

the wire and weaken it.

When soldering a lead to a numbered, platedthrough hole on a circuit board, push the lead

through the hole first. Do not push the wire all

the way into the hole up to the insulation. Apply

the solder and the hot iron at the same time to

the junction of the hole and lead. The solder

should melt very quickly; it should flow easily

and fully into the hole and completely around the lead.

Remove the iron and allow the connection to cool. It is

essential to have a smooth, shiny flow of solder from the lead

to the plated circuitry on the board.

6

WIRING THE KIT

The position of all wire leads should follow the diagram

closely, bearing in mind that the pictorial diagram has necessarily been distorted somewhat to show all connections

clearly. See that uninsulated wires do not touch each other

unless, of course, they are connected to the same point. It

is especially important that uninsulated wires or component

leads or terminals do not touch the chassis accidentally.

Whenever one wire is to be soldered to a connection such

as a lug terminal or hole, the instructions will indicate this

by the symbol (S). If more than one wire is to be soldered

to the same point, the instructions will cite the number of

wires that should be connected to that point when it is to be

soldered. If no soldering instruction is specifically given, do

not solder; other connections will be made to that point

before soldering is called for.

Check your work after each step, and make sure the entire

step has been completed. When you are satisfied that it has

been correctly done, check the space provided and go on to

the next step. Be sure you read carefully the explanatory

paragraphs in the assembly instructions.

MECHANICAL ASSEMBLY

Where stranded wire is used, as on the transformer leads,

be very careful not to cut through the strands when stripping

the end. Where stranded wire is supplied for hookup wire

in the kit, the strands will be bonded together to minimize

this likelihood and make handling easier.

All mounting screws are installed from the outside of the

chassis, and a nut with lockwasher attached, called a KEP

nut, is used except when otherwise specified.

This kit uses a variety of hardware. Before starting as-

sembly, separate all the hardware by using an egg carton,

muffin pan, or small cups. #4, #6, #10 and 1/4" machine

screws with binder heads (flat tops with rounded sides) are

used in various lengths. Much of the hardware used is #4

binder head in a 5/16" length. There are also #6 oval head

screws with tapered sides, which are used only when attaching the XLR connector to the chassis.

TAKE THE TIME TO BE NEAT AND ACCURATE,

and your amplifier will operate properly at first, and for

many years.

1( ) Select the "U" shaped bottom plate with slanted

sides, the four rubber feet, and four of the 1/4" diameter bolts (the largest hardware). Insert a bolt

through each foot, and then mount a foot at each corner of the bottom plate on the outside (sides turned

away from you). No other hardware is required; the

bottom plate is supplied with threaded nuts for these

bolts. Set the assembly aside.

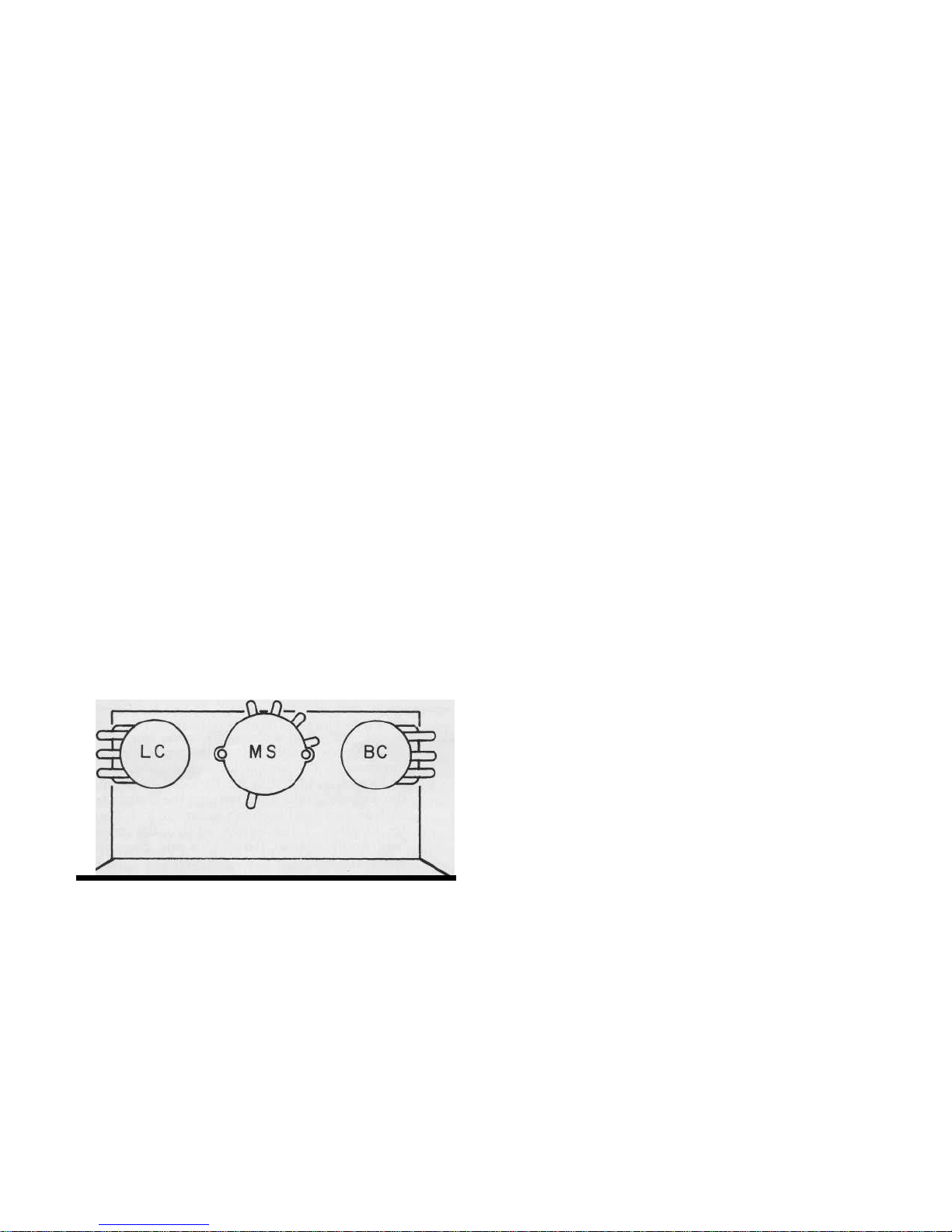

Select the black "L" shaped control bracket. Note that

the bottom edge of the inside surface turns toward you. The

three parts attached to this bracket will be mounted from

the inside.

2( ) Select the 10,000 ohm control, part #145103, a 3/8"

nut, and a 3/8" thin lockwasher. Do not confuse this

with the 100,000 ohm control, part #144104, which

will be called for in the next step. Place a lockwasher

on the threaded shaft, install the control in location

BC with the lugs positioned as shown, and tighten

the nut.

3( ) Select the 100,000 ohm control, part #144104, a 3/8"

nut, and a 3/8" thin lockwasher. Place the lockwasher

on the shaft, install the control in location LC, position the lugs as shown, and tighten the nut.

4( ) Select the meter switch, a 3/8" nut, and the last 3/8"

lockwasher. Place the lockwasher on the shaft, install

the switch in location MS, position the lugs as shown,

and tighten the nut.

Set this assembly aside, and place the front panel in front

of you. The front surface is printed. The parts attached to

this panel will be mounted from the front.

5( ) Select the square fuse holder. Notice that one face is

marked "top". With this surface facing the top edge

of the front panel, press the fuse holder into the right

bottom square cutout. No hardware is used.

6( ) Select the power switch. Observe that the dark red

jewel is positioned toward the bottom edge of the

front panel. Press it into the left bottom rectangular

cutout. No hardware is used.

7( ) Select the meter, the two small lamps, the two lamp

sockets, the two pieces of insulating tubing, and six

#4 KEP nuts (the smallest hardware). Install the

meter upright from the outside. Carefully secure the

meter with four KEP nuts. Avoid excessive force,

since the meter is plastic. Snap each lamp into a

lamp socket to where the socket engages the lamp detent, and then slip a piece of insulating tubing onto

the lamp socket to cover the metal portion of the

lamp and socket. Install a lamp socket on each of the

lower meter mounting studs. Fasten each socket

firmly with a second KEP nut.

Set this assembly aside, and select the chassis. The outside back edge is printed. Some of the parts will be mounted

from the outside, and others from the inside.

8( ) Select the 4-screw output barrier strip, and four each

5

/8" #6 screws and #6 KEP nuts (next to the smallest

hardware). This output strip mounts outside the

chassis at the right back, so that its four lugs protrude

through the slot. Insert the screws from the outside,

and fasten with the KEP nuts on the inside. Make

sure that the lugs do not touch any chassis metal.

9( ) Select the output jack, and the last 3/8" nut. Install

the jack from the inside in the round hole adjacent to

the output strip, and fasten with the nut on the outside. Position the lugs and the flattened corner of the

jack, as shown in the Pictorial Diagram. Avoid excessive force on the plastic threads.

7

Loading...

Loading...