Page 1

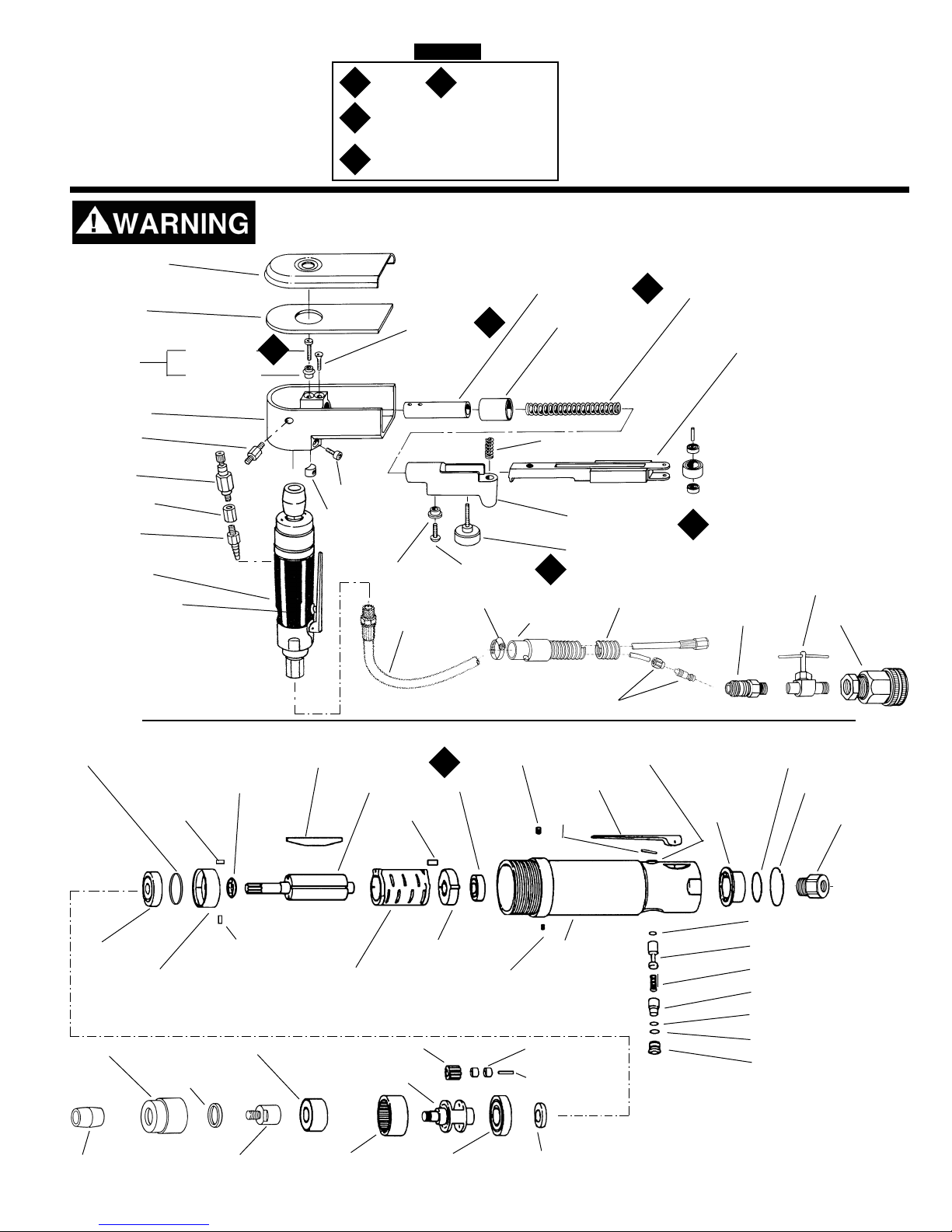

Parts Page Reorder No. PD97•99

Effective March, 1996

Models:

42630 – Standard Machine

42631 – Versatility Kit

Motor and Machine Parts

Always operate, inspect and maintain this tool in accordance with the Safety Code for portable air tools

(ANSI B186.1) and any other applicable safety codes and regulations. Please refer to Dynabrade's

Warning/Safety Operating Instructions for more complete safety information.

40365 Belt Guard

(Incl. 40371 Gasket)

40371 Gasket

42638 Housing

95931 Val ve

95943 Coupling

95929 Fitting

95928 Fitting

40314

Button Latch

Assembly

40025 Button

95425 Screw

95217 Screw

40362 Support Rod

40367 Dust Cover

Contact Arm Assembly

see page 4.

95426 Spring

11040 Spring

40361 Tension Arm

95218 Knob

95427 Screw

04037 Air Motor

42655 Shrink Tubing

See inside for Important Operating, Maintenance and Safety Instructions.

04014 Lock Screw

11016 Bearing

01009 Pin

54511 Bearing Plate

54508 O-Ring

54507 Valve Stem

01022 Valve Spring

54506 Speed Regulator

01024 “O” Ring

01025 “O” Ring

54505 Regulator Plug

54512 Cylinder

04027 Retaining Ring

95713 Adapter

95584 O- Ring

04020 Muffler

01004 Valve Bushing

*01016 Lever

01017 Pin

01041 Grease Fitting

54529 Shim Packet (as req.)

54515 Spacer

54514 Blade (4) (4/pkg.)

01042 Pin

06212 Rotor

54516 Front Bearing Plate

(with 01009 Pin and 01042 Pin)

02649 Bearing

01009 Pin

40366 Guide

40029 Motor Lock

95311 Screw

42648 Housing

54517 Spacer02654 Drive Wheel

42637 Lock Ring

42639 Seal

54520 Bearing

42636 Spindle 54520 Bearing

06213 Gear

06214 Carrier

01033 Bearing (2)

54518 Shaft

54522 Ring Gear

95816 Air Line

95956 Cuff

95717 Hose Clamp

95958 Hose

95962 Male Disconnect

95963 Female

Disconnect

95965

Needle

Val ve

95964 Hose Bib

KEY

L

T

O

Loctite/Hernon: L

2

= Loctite #271

Torque: N•m x 8.85 = In. - lbs.

T

2

= 22.5 N•m, T3= 28 N•m

G

Oil Grease

L

2

Wet Dynafile

®

II

G

O

04037 Air Motor

G

L

2

L

2

Page 2

Important Operating, Maintenance and Safety Instructions

Carefully read all instructions before operating or servicing any Dynabrade® Abrasive Power Tool.

Warning: Hand, wrist and arm injury may result from repetitive work motion and overexposure to vibration.

Important: All Dynabrade air tools must be used with a Filter-Regulator-Lubricator to maintain all warranties.

Operating Instructions:

Warning: Eye, face and body protection must be worn while operating power tools. Failure to do so may result in serious injury or death. Follow safety

procedures posted in workplace.

1. With power source disconnected from tool, securely fasten abrasive/accessory on tool.

2. Install air fitting into inlet bushing of tool. Important: Secure inlet bushing of tool with a wrench before attempting to install the air fitting to avoid damaging

valve body housing.

3. Connect power source to tool. Be careful not to depress throttle lever in the process.

4. Check tool speed with tachometer. If tool is operating at a higher speed than the RPM marked on the tool or operating improperly, the tool should be

serviced to correct the cause before use.

Maintenance Instructions:

1. Check tool speed regularly with a tachometer. If tool is operating at a higher speed than the RPM marked on the tool, the tool should be serviced to correct

the cause before use.

2. Some silencers on air tools may clog with use. Clean and replace as required.

3. All Dynabrade air motors should be lubricated. Dynabrade recommends one drop of air lube per minute for each 10 SCFM (example : if the tool

specification state 40 SCFM, set the drip rate of your filter-lubricator at 4 drops per minute). Dynabrade Air Lube (P/N 95842: 1pt. 473ml.) is recommended.

4. An air line filter-regulator-lubricator must be used with this air tool to maintain all warranties. Dynabrade recommends the following: 11289 Air Line Filter-

Regulator-Lubricator — Provides accurate air pressure regulation, two-stage filtration of water contaminants and micro-mist lubrication of pneumatic

components. Operates 40 CFM @ 100 PSI has 3/8" NPT female ports.

5. Use only genuine Dynabrade replacement parts. To reorder replacement parts, specify the Model #, Serial #, and RPM of your machine.

6. A motor tine-up kit (P/N 95604) is available which includes assorted parts to help maintain motor in peek operating condition.

7. Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids, esters, keytones,

chlorinated hydrocarbons or nitro carbons.

Safety Instructions:

Products offered by Dynabrade should not be converted or otherwise altered from original design without expressed written consent from

Dynabrade, Inc.

•

Important: User of tool is responsible for following accepted safety codes such as those published by the American National Standards Institute (ANSI).

•

Operate machine for one minute before application to workpiece to determine if machine is working properly and safely before work begins.

•

Always disconnect power supply before changing abrasive/accessory or making machine adjustments.

•

Inspect abrasives/accessories for damage or defects prior to installation on tools.

•

Please refer to Dynabrade’s Warning/Safety Operating Instructions Tag (Reorder No. 95903) for more complete safety information.

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality pneumatic motors can

most often be traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water contained in the air supply into motor bearings

causing early failure. It often scores the cylinder walls and the rotor blades resulting in limited efficiency and power. Our warranty obligation is contingent upon

proper use of our tools and cannot apply to equipment which has been subjected to misuse such as unclean air, wet air or a lack of lubrication during the use of

this tool.

One Year Warranty

Following the reasonable assumption that any inherent defect which might prevail in a product will become apparent to the user within one year from the date

of purchase, all equipment of our manufacture is warranted against defects in workmanship and materials under normal use and service. We shall repair or

replace at our factory, any equipment or part thereof which shall, within one year after delivery to the original purchaser, indicate upon our examination to

have been defective. Our obligation is contingent upon proper use of Dynabrade tools in accordance with factory recommendations, instructions and safety

practices. It shall not apply to equipment which has been subject to misuse, negligence, accident or tampering in any way so as to affect its normal

performance. Normally wearable parts such as bearings, contact wheels, rotor blades, etc., are not covered under this warranty.

Model Length Height Machine Abrasive Belt Size Air Flow Rate Sound Motor Motor Air Pressure

Number Inch (mm) Inch (mm) Weight Inch (mm) SCFM (LPM) Level HP (W) RPM PSI (Bars)

42630 14-1/4" (362) 4-7/8" (124) 2.5 lbs. (1.1) 1/4"-3/4" 6-19)W x 18"-24" (457-610)L 15 (425) 81 dBA .27 (201) 5,000 1,450 (441)

Additional specifications: Air Inlet Thread 1/4" (6 mm) NPT • Hose Size 3/8" (9 mm) • Air Pressure 90 PSI (6.2 Bars)

(PD97•99)

2

Page 3

3

Disassembly/Assembly Instructions - Wet Dynafile II

Important: Manufacturer’s warranty is void if tool is disassembled before warranty expires.

A Motor Repair Kit (95604) is available which contains special tools for disassembly/assembly. Please refer to parts breakdown for part identification.

To Disassemble:

1. Remove Belt Guard, abrasive belt and contact arm assembly.

2. Loosen 01788 Screw and remove housing assembly from air motor.

3. Loosen 95427 Screw and remove 40366 Guide, this will release 40361 Tension Arm and 95426 Spring.

4. Remove 40367 Dust Cover. Remove 95217 Screw, 95425 Screw and 40362 Support Rod.

Motor Disassembly:

1. Secure tool in a soft jaw vise holding onto wrench flats on rear of motor housing. Important: Do not over tighten vise or housing could be damaged.

2. Remove drive wheel by inserting a 4 mm hex key through drive wheel and into the end of the rotor/drive shaft.

3. Using a wrench (

14 mm) or pliers, twist the drive wheel counterclockwise and remove.

4. Secure lock ring with a wrench and twist from motor housing (Note: Left hand threads).

5. Remove 42636 Spindle from planetary gear assembly.

6. Pull planetary gear assembly from motor housing. Pull motor from housing (if motor does not pull out freely, lightly tap end of housing with a rubber mallet).

7. Clamp a bearing separator between the 54522 Ring Gear of the planetary carrier assembly and front 54520 Bearing (nearest to spindle end of assembly).

Press bearing from carrier.

8. Remove ring gear and gears. Press rear 54520 Bearing from planetary carrier.

9. Press rotor from 02649 Bearing and front bearing plate. Remove spacer, cylinder and blades from rotor. Press 11016 Bearing from rear bearing plate.

10. Remove 54505 Plug from motor housing. Remove valve assembly.

11. Remove 95713 Inlet Adapter. Pry retaining ring from rear of housing and remove 04020 Muffler and 95584 O-Ring.

Motor disassembly complete.

Motor Reassembly:

Important: Be sure parts are clean and in good repair before reassembly. Follow all torque, grease and lubrication instructions.

1. Insert a .002" shim from 54529 Shim pack into front bearing plate.

2. Insert 02649 Bearing into front bearing plate.

3. Place 54515 Spacer onto pinion end of rotor. Make sure countersink faces rotor.

4. Press from bearing plate assembly onto rotor until tight against spacer.

5. Check clearance between rotor and bearing plate. Apply an outward (pulling) pressure on rotor. If rotor rubs bearing plate, reduce the spacing by removing

shim or substitute with .001" shim.

6. Insert 54514 Blades (lubricate blades with Dynabrade Air Lube P /N 95842 or equivalent before installation).

7. Place cylinder over rotor. Be sure pin holes and air inlet holes align with holes in bearing plate.

8. Press 11016 Bearing into rear bearing plate and press assembly onto rotor. Be sure pin holes and air holes line up with holes in cylinder.

9. Insert motor assembly into housing. The pin in front bearing plate should enter guide slot in housing wall.

10. Install 54517 Spacer with unrelieved face towards front bearing plate.

11. Press 54520 Bearing onto front end of planetary carrier. Replace gears, gear shafts and ring gear (notches face rear of carrier).

12. Press 54520 Bearing onto carrier (there should be a slight drag between ring gear and bearings).

13. Install planetary assembly onto motor housing. Line-up notches in ring gear with hole in housing for lock screw.

14. Install 42637 Lock Ring onto motor housing.

15. Install O-rings and spring stem assembly and replace into motor housing.

16. Install 95584 O-Ring onto muffler and replace into housing. Replace snap ring and inlet adapter.

17. Install drive wheel.

Motor reassembly complete.

To Reassemble:

1. Place 40362 Support Rod into housing.

2. Apply one drop of #271 Loctite® (or equivalent) to 95217 Screw and tighten.

3. Install 40637 Dust Cover onto 40362 Support Rod. Lubricate (grease) inside of 40362 Support Rod and 40361 Tension Arm.

4. Install 95426 Spring into 40362 Support Rod and place 40361 Tension Arm over 95426 Spring.

5. Place 40366 Guide onto 95427 Screw, apply one drop of #271 Loctite® (or equivalent) to screw threads.

6. Compress tension arm and secure in place with 40366 Guide/95427 Screw. Adjust 95427 Screw so that 40361 Tension Arm slides freely.

7. Press 40025 Button onto 95425 Screw and apply one drop of #271 Loctite® to threads.

8. Place 40365 Belt Guard over 40360 Housing, tighten 95425 with 40025 Button into 40360 Housing

9. With 40373 Motor lock in place, install air motor assembly into housing and secure in place with 95311 Screw.

10. Complete assembly by installing contact arm assembly, abrasive belt and 40365 Belt Guard.

Tool assembly is complete. Please allow 30 minutes for adhesives to cure before operating tool.

Important: Motor should now be tested for proper operation at 90 PSI. If motor does not operate properly or operates at a higher RPM than marked on the

tool, the tool should be serviced to correct the cause before use. Before operating, place 2-3 drops of Dynabrade Air Lube (P/N 95842) directly into air inlet

with throttle lever depressed. Operate tool for 30 seconds to determine if tool is operating properly and to allow lubricating oils to properly penetrate motor

Loctite® is a registered trademark of Loctite Corp.

Page 4

95604 Motor Tune-Up Kit:

•

Includes assorted parts to help maintain

motor in tip-top shape.

Optional Accessories

DYNABRADE

®

DYNABRADE, INC.,

8989 Sheridan Drive •Clarence, NY 14031-1490 •Phone: (716) 631-0100 •Fax: 716-631-2073 •International Fax: 716-631-2524

DYNABRADE EUROPE S.àr.l.,

Zone Artisanale •L-5485 Wormeldange—Haut, Luxembourg •Telephone: 352 76 84 94 •Fax: 352 76 84 95

© DYNABRADE, INC., 1997 PRINTED IN USA PD97.99_rev.1_03/97

Visit our new Web Site via Industry.Net MROP On-Line: http://www.dynabrade.industry.net E-Mail: DynaTalk@aol.com

Arm Wheel Wheel Wheel Belt Shaft

Number Description Assy. Description Number Size Number

42642 3/4" Wide Platen 42652 3/4" Dia. x 5/8" W rubber 11281 3/4" x 18" / 5/8" x 18" 11285

42644 1/2" Wide Platen 42653 3/4" Dia. x 5/8" W rubber 11077 3/4" x 18" / 5/8" x 18" 11054

42646 No Platen - Offset design 42654 1" Dia. x 3/8" W radiused rubber 11079 1/2" x 18" / 1/4" x 18" 11054

42650 1/2" Wide Platen 42653 3/4" Dia. x 5/8" W rubber 11077 1/2" x 18" 11054

Specialized Contact Arms

Wet Dynafile®II Contact Arm Assemblies

Contact Wheel Assembly – Includes wheel, bearing and shaft.

Contact Arm

Shaft

Bearing

Contact Wheel

Bearing

Abrasive Belt/Contact Arm Change Instructions:

To Change Belt:

1. Disconnect power source.

2. Remove “pop-off” cover.

3. Pull back on tension arm assembly.

4. Remove and replace abrasive belt and cover.

5. Connect power source.

6. Adjust belt tracking by turning 95218 Rough Adjustment Knob to the left or right accordingly while machine is running.

To Change Contact Arm Assembly:

1. Disconnect power source.

2. Remove “pop-off” cover.

3. Pull back on tension arm assembly and remove abrasive belt.

4. Remove 95218 Rough Adjustment Knob.

5. Remove contact arm and replace with desired arm, making sure that the tab on the end of the arm is facing downward.

6. Replace 95218 Knob.

7. Install abrasive belt and cover.

8. Connect power source and adjust belt tracking by turning 95218 Knob to the left or right accordingly while machine is running.

Housing Angle Adjustment:

To pivot housing, loosen 95311 Screw on housing with the supplied 9/64" hex wrench (P/N – 95134). Pivot housing to desired angle and retighten 95311 Screw.

Loading...

Loading...