Page 1

Model: 11450

2" Wide Abrasive Belt Capacity, Extra Heavy Duty

Parts Page Reorder No. PD97•33

Effective May, 1997

Supersedes PD96•10

Dynabelter®Accu-Grinder

®

Always operate, inspect and maintain this tool in accordance with the Safety Code for portable air

tools (ANSI B186.1) and any other applicable safety codes and regulations. Please refer to

Dynabrade's Warning/Safety Operating Instructions for more complete safety information.

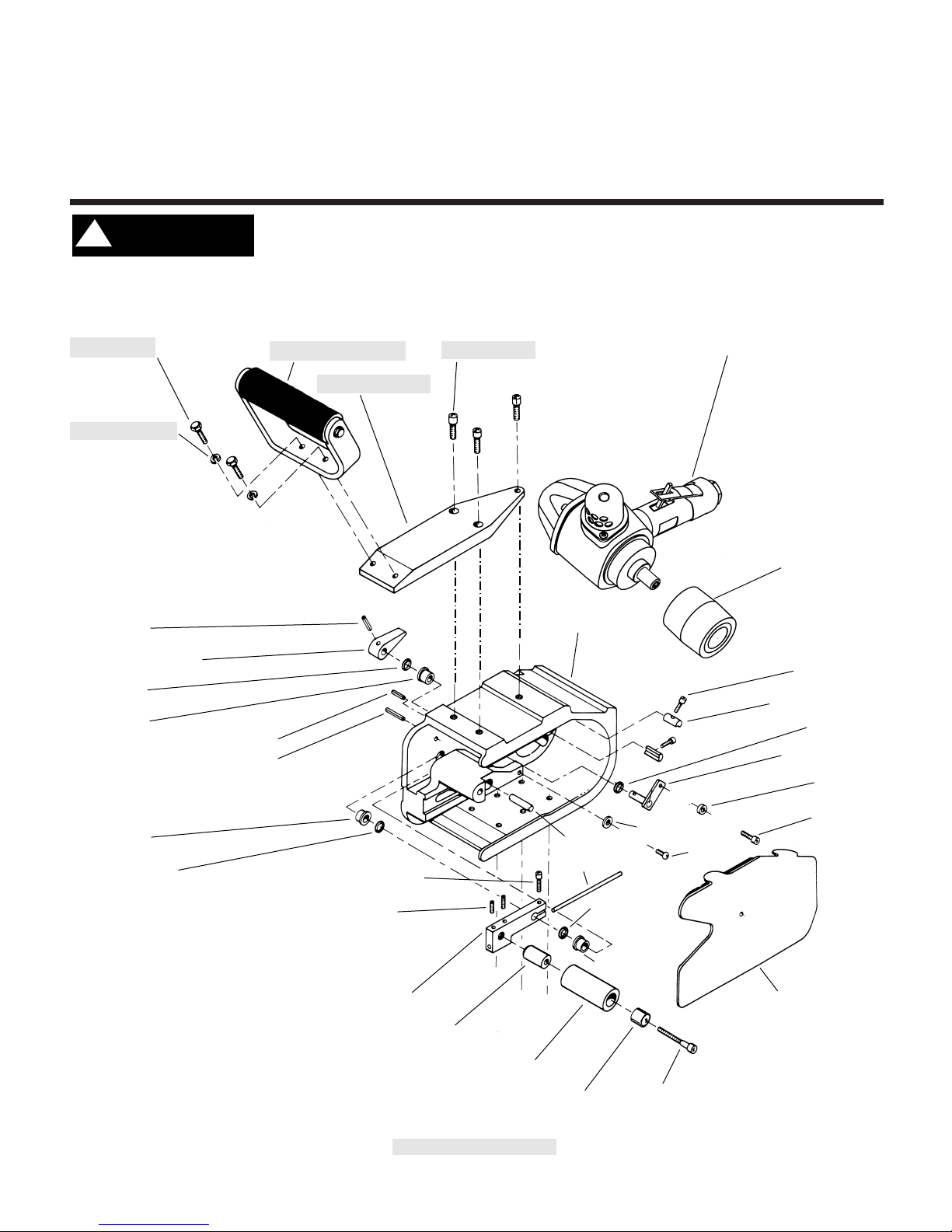

11548 Handle Assembly

95158 Bolt (2)

11544 Pressure Bar

95167 Washer (2)

95150 Screw (3)

11800 Housing

01845 Air Motor

(Includes 01794 Drive Wheel)

01794 Drive Wheel

95392 Screw (2)

11801 Motor Lock (2)

95226 O Ring

14056 Roller

11809 Tension Arm

95292 Screw

95422 Screw

40025 Button

95332 Pin

11831 Cover Guard

(Includes 11922

Contact Arm Jack)

11519 Bearing

95226 O-Ring

11804 Rod

95240 Roll Pin

11551 Belt Tension Lever

11519 Bearing

95236 Roll Pin

95216 Roll Pin

95226 O-Ring

11802 Bearing

95311 Screw

95231 Set Screw (2)

95226 O Ring

11805 Idler Wheel

11013 Bearing

95310 Screw

11806 Spacer

11803 Tension Arm

See Page 2 for 11961 Adjust-a-Wheel Contact Wheel Assembly and 11917 Rear Wheel Support.

See Page 3 for Important Operating, Safety and Maintenance Instructions before operating tool.

11705 Pressure Bar Assembly

!

WARNING

Page 2

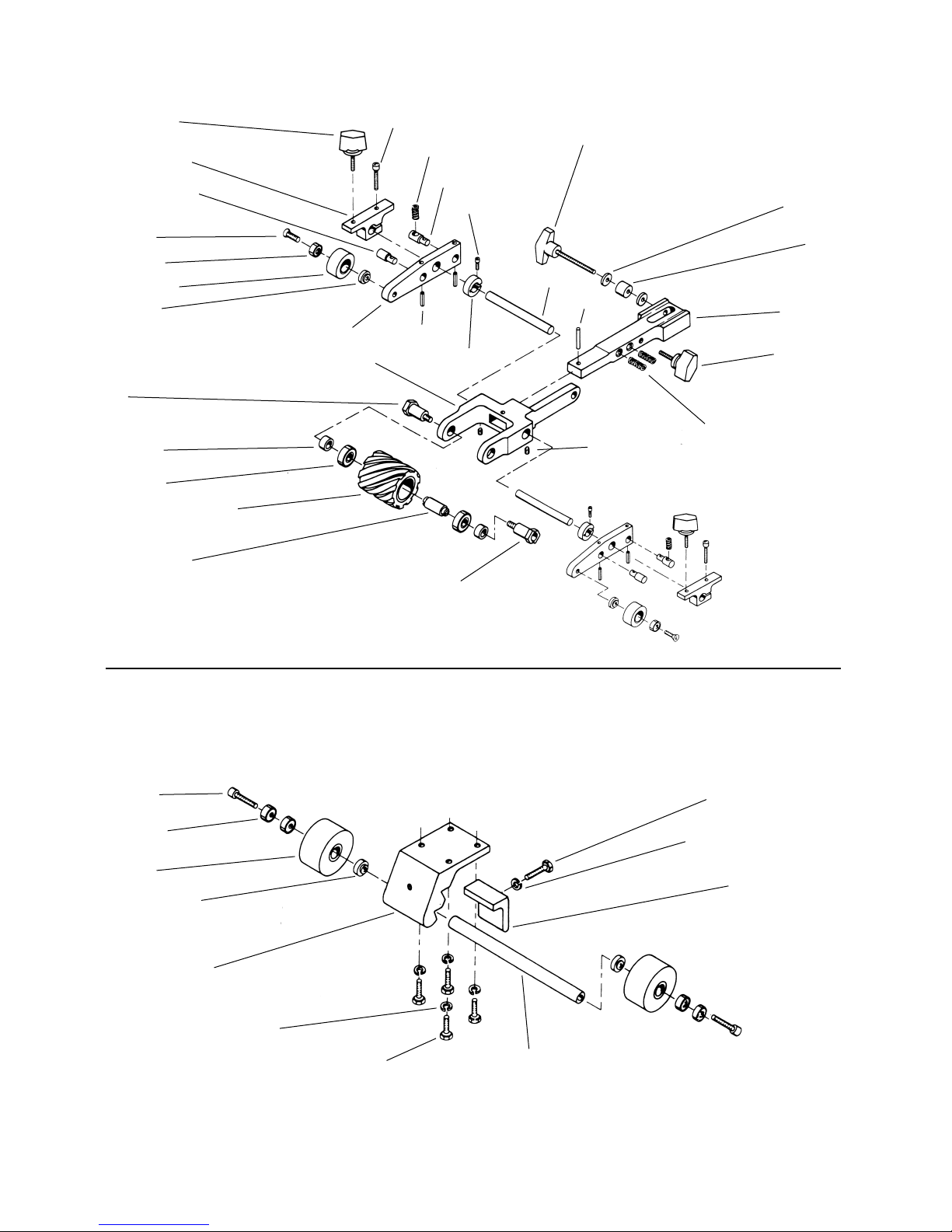

11807 Spacer

11912 Pressure Post (2)

95240 Pin (4)

11910 Shaft (2)

95420 Rough Adj. Knob (includes spacer and washer)

95339 Spring (2)

11913 Pressure Post (2)

95144 Screw (2)95232 Adj. Knob (2)

11915 Control Block (2)

11916 Guide Tire (2)

11016 Bearing (2)

95322 Screw (2)

11017 Spacer (2)

95149 Spring (2)

95323 Screw(2)

11850 Contact Wheel (90 Duro)

11813 Bearing (2)

11817 Bearing Spacer

11818 Spacer (2)

11815 Slotted Bolt

11816 Bolt

11812 Wheel Mount

11911 Collar (2)

11914 Tire Mount (2)

11961 Adjust-A-Wheel Contact Arm Assembly

95168 Screw (2)

95417 Washer (2)

95316 Pin

95232 Belt Tracking

Adj. Knob

11811 Contact Arm

95179 Screw

95158 Screw (4)

95156 Screw (2)

95167 Washer

11016 Bearing (4)

11017 Bearing Spacer(2)

11919 Clamp

11920 Axel

11918 Rear Wheel Support

95167 Washer (4)

11921 Wheel (2)

11917 Rear Wheel Support Assembly

2

(PD97•33)

Page 3

3

Important Operating, Maintenance and Safety Instructions

Carefully read all instructions before operating or servicing any Dynabrade® Abrasive Power Tool.

Warning: Hand, wrist and arm injury may result from repetitive work motion and overexposure to vibration.

Important: All Dynabrade air tools must be used with a Filter-Regulator-Lubricator to maintain all warranties.

Operating Instructions:

Warning: Eye, face and body protection must be worn while operating power tools. Failure to do so may result in serious injury or death. Follow safety

procedures posted in workplace.

1. With power source disconnected from tool, securely fasten abrasive/ accessory on tool.

2. Install air fitting into inlet bushing of tool. Important: Secure inlet bushing of tool with a wrench before attempting to install the air fitting to avoid damaging

valve body housing.

3. Connect power source to tool. Be careful not to depress throttle lever in the process.

4. Check tool speed with tachometer. If tool is operating at a higher speed than the RPM marked on the tool or operating improperly, the tool should be

serviced to correct the cause before use.

Maintenance Instructions:

1. Check tool speed regularly with a tachometer. If tool is operating at a higher speed than the RPM marked on the tool, the tool should be serviced to correct

the cause before use.

2. Some silencers on air tools may clog with use. Clean and replace as required.

3. All Dynabrade air motors should be lubricated. Dynabrade recommends one drop of air lube per minute for each 10 SCFM (example : if the tool

specification state 40 SCFM, set the drip rate of your filter-lubricator at 4 drops per minute). Dynabrade Air Lube (P/N 95842: 1pt. 473ml.) is recommended.

4. An air line filter-regulator-lubricator must be used with this air tool to maintain all warranties. Dynabrade recommends the following: 11299 Air Line Filter-

Regulator-Lubricator — Provides accurate air pressure regulation, two-stage filtration of water contaminants and micro-mist lubrication of pneumatic

components. Operates 100 CFM @ 100 PSI has 1/2" NPT female ports.

5. Use only genuine Dynabrade replacement parts. To reorder replacement parts, specify the Model #, Serial #, and RPM of your machine.

6. A motor tune-up kit (P/N 96259) is available which includes assorted parts to help maintain motor in peek operating condition.

7. Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids, esters, keytones,

chlorinated hydrocarbons or nitro carbons.

Safety Instructions:

Products offered by Dynabrade should not be converted or otherwise altered from original design without expressed written consent from

Dynabrade, Inc.

• Important: User of tool is responsible for following accepted safety codes such as those published by the American National Standards Institute (ANSI).

• Operate machine for one minute before application to workpiece to determine if machine is working properly and safely before work begins.

• Always disconnect power supply before changing abrasive/accessory or making machine adjustments.

• Inspect abrasives/accessories for damage or defects prior to installation on tools.

• Please refer to Dynabrade’s Warning/Safety Operating Instructions Tag (Reorder No. 95903) for more complete safety information.

• Warning: Hand, wrist and arm injury may result from repetitive work, motion and overexposure to vibration.

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality pneumatic motors can

most often be traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water contained in the air supply into motor bearings

causing early failure. It often scores the cylinder walls and the rotor blades resulting in limited efficiency and power. Our warranty obligation is contingent upon

proper use of our tools and cannot apply to equipment which has been subjected to misuse such as unclean air, wet air or a lack of lubrication during the use of

this tool.

One Year Warranty

Following the reasonable assumption that any inherent defect which might prevail in a product will become apparent to the user within one year from

the date of purchase, all equipment of our manufacture is warranted against defects in workmanship and materials under normal use and service. We shall

repair or replace at our factory, any equipment or part thereof which shall, within one year after delivery to the original purchaser, indicate upon our

examination to have been defective. Our obligation is contingent upon proper use of Dynabrade tools in accordance with factory recommendations,

instructions and safety practices. It shall not apply to equipment which has been subject to misuse, negligence, accident or tampering in any way so as to affect

its normal performance. Normally wearable parts such as bearings, sanding pads, rotor blades, etc., are not covered under this warranty.

Machine Length Height Weight Abrasive Belt Size Air Flow Rate Sound Motor Motor Air Pressure

Number Inch (mm) Inch (mm) Pound (kg) Inch (mm) SCFM (LPM) Level HP (W) RPM PSI (Bars)

11450 20" (508) 9" (229) 18 lbs. (8.2) 2" (51) W x 30" (762) L 57 (1,614) 87 dBA 2.0 (1,491) 7,200 90 (6.2)

Additional specifications: Air Inlet Thread 1/2" (13 mm) NPT • Hose Size 1/2" (13 mm)

Page 4

Abrasive Belt/Contact Arm Change Instructions:

To Change Belt:

1. Disconnect power source. Remove 11831 Cover Guard and release 11551 Belt Tension Lever.

2. Loosen 95420 Rough Adjustment Knob. This will loosen contact arm assembly in housing track. Remove belt from contact arm and drive wheel.

3. Pull belt backwards and to the left until belt is released from drive wheel.

4. Install new belt by placing belt over contact wheel and drive wheel.

5. Using 11922 Tension Wrench, push contact arm forward until belt is tight. Tighten 95420 Knob to lock contact arm in place.

6. Reset 11551 Belt Tension Lever. Replace 11831 Cover Guard.

7. Connect power source and start motor.

8. Adjust belt tracking by turning 95232 Belt Tracking Knob on contact arm assembly to the left or right accordingly.

To Change Belt Contact Arm Assembly:

1. Disconnect power source. Remove 11831 Cover Guard.

2. Remove abrasive belt (see instructions).

3. Remove 95420 Rough Adjustment Knob.

4. Remove contact arm and replace with desired contact arm.

5. Replace 95420 Knob. Do not tighten knob at this point.

6. Replace abrasive belt (see instructions).

7. Using 11922 Tension Wrench, push contact arm assembly forward until the belt is tight. Tighten 95420 Knob and reset 11551 Belt Tension Lever.

8. Replace 11831 Cover Guard. Connect power source and start motor.

9. Adjust belt tracking by turning 95232 Belt Tracking Knob on contact arm assembly to the left or right accordingly.

Remove 11831 Cover Guard

11922 Tension Wrench

11961 Adjust-A-Wheel Contact Arm Assembly

11548 Handle Assembly

4

11851 Contact Wheel Assembly

11805 Idler Wheel

95232 Belt Tracking Knob

11961 Adjust-A-Wheel Contact Arm Assembly

11851 Contact Wheel Assembly

11805 Idler Wheel

01794 Drive Wheel

11922 Tension Wrench

Remove 11831 Cover Guard

01794 Drive Wheel

(PD97•33)

Page 5

5

Belt Size: 1" wide x 30" long.

11650 Contact Wheel: 2" diameter x 1" wide 70

durometer standard serrated urethane.

11605 Platen: 1" wide x 2-1/2" long. 7-1/2" workable reach.

11672 Contact Arm Assembly available; same as 11681

except with 90-duro contact wheel.

Note: The higher the durometer the harder the wheel.

Durometer Serration Color Part No.

90 Scoop Amber 11614

90 Standard Amber 11618

80 Standard Blue 11652

70 Standard Green 11650

Belt Size: 2" wide x 30" long.

11847 Contact Wheel: 2" diameter x 2" wide 70 durometer

standard serrated urethane.

Platen: Optional 11659 Platen Assembly is available for

mounting 2" wide x 2-1/2" long Dynapad platen; has 7"

workable reach. 11872 Contact Arm Assembly available;

same as 11870 except with 90-duro contact wheel.

Note: 2" diameter x 2" wide urethane wheel assemblies are

for extra heavy-duty machines only.

11681

2" Dia. x 1" W Urethane Wheel Assemblies

Available For 11681

Durometer Serration Color Part No.

90 Standard Amber 11851

70 Standard Green 11847

70 Scoop Green 11849

90 Scoop Amber 11853

2" Dia. x 2" W Urethane Wheel Assemblies

Available For 11870

Dynabelter®Contact Arms

• Grind, blend, polish welds; strap

polish using slack of belt.

• 7" workable reach.

Belt Size: 1" wide x 30" long.

11616 Contact Wheel: 1" dia. x 1" wide 80 durometer smooth rubber.

11605 Platen: 1" wide x 2-1/2" long.

• Grind, deburr, polish over

Dynapad platen.

• 7-1/2" workable reach.

11663

11668 Stroke Sander

11682

• Grind, deburr fillet welds,

inside corners.

• 7" workable reach.

Belt Size: 1/2" or 1" wide x 30" long.

11638 Contact Wheel: 4" dia. x 1/2" wide 70 durometer radiused rubber.

Platen: None

Belt Size: 1" wide x 30" long.

11642 Contact Wheel: 4" dia. x 5/8" wide 40 durometer serrated rubber.

(60, 80, 90 duro urethane wheels available). Platen: None

• Polish contours without gouging

workpiece.

• Ideal for stainless pipe.

• 7" workable reach.

11684

Belt Size: 1" wide x 30" long.

11616 Contact Wheels: Two 1" wide x 1" dia. 80 durometer smooth rubber.

11605 Platen: 1" wide x 1-7/8" long.

• Wheel mount pivots to maintain

surface contact.

• Work on broad areas, blend stainless.

• Leaves "in-line" scratch pattern.

• 6" workable reach.

11677

Belt Size: 1" wide x 30" long.

11620 Contact Wheel: 4" dia. x 1" wide 40 durometer smooth rubber,

(80 duro available). Platen: None.

For best results when ordering 11717 Contact Arm:

For Dynabelter Model 11475:

Add 11705 Pressure Bar Assembly and 11794 Back Wheel Assembly.

For Dynabelter Model 11476: Add 11544 Pressure Bar, three 95150

Mounting Screws and 11794 Back Wheel Assembly.

Belt Size: 1" wide x 30" long.

11618 Contact Wheel: 2" dia. x 1" w 90-durometer scoop serrated urethane.

Platen: None.

• Provides 9" workable reach. Grind off contact wheel; excellent for polishing off slack of belt.

• For use with extra heavy-duty models 11450 and 11477 only.

Belt Size: 2" wide x 34" long.

11902 Contact Wheel: 4" diameter x 2" wide 80-durometer scoop serrated urethane.

Platen: None.

11894

Twist Knobs (2)

11870

11717 Adjust-A-Wheel

Page 6

6

Disassembly/Assembly Instructions

Important: Manufacturer’s warranty is void if tool is disassembled before warranty expires.

A Motor Repair Kit (96259) is available which contains special tools for disassembly/assembly. Please refer to parts breakdown for part identification.

Tool Disassembly:

1. Disconnect tool from power source.

2. Remove back-up pad with a 24mm wrench.

3. Insert 01697 Inlet Bushing securely into vise.

4. Roll 07136 Handle Grip Back away from housing.

5. Remove 52495 Nut by using a 32mm wrench (P/N 96079).

6. Separate valve body from housing.

7. Remove 95720 Screws (4) and 01791 Washers (4) from 52461 Housing Cap. Remove housing cap and 52477 Gasket.

Motor Disassembly:

1. Grip onto governor cage assembly and pull motor assembly from housing.

Note: If motor assembly does not come out freely, gently tap tool rotor side down to "pop" motor from housing.

2. Remove governor cage assembly from 52466 Rotor (left hand thread).

3. Insert a tap pin into rear bearing plate and press the 52466 Rotor from the rear bearing plate.

4. Place motor assembly in softjaw vise.

5. Remove 01823 Washer and 01835 Shim from assembly.

6. Remove 01815 Rotor Nut with an adjustable wrench. Twist rotor nut from shaft.

7. Remove 52475 Cylinder, blades (4) and spacer from rotor.

8. Remove 52472 Front Bearing Plate , front bearing and shims from 52466 Rotor. Note: Bearing, front bearing plate and spacer are a slip fit into rotor.

9. Press 01036 Bearing from bearing plate.

Motor disassembly complete.

Motor Reassembly:

Important: Be certain all parts are cleaned and in good repair before reassembly.

1. Place 52466 Rotor in padded vise with threaded spindle facing upwards.

2. Slip 52467 Spacer onto rotor.

3. Place .002" shim into front bearing plate as initial spacing and slip 01825 Bearing into plate. Note: 52471 Shim Pak contains .001" and .003" shims.

4. Install bearing/bearing plate assembly onto rotor.

5. Install 01815 Rotor Nut onto assembly.

6. Tighten rotor nut onto rotor, torque 22.5 N•m/200 in. - lbs.

7. Check clearance between rotor and bearing plate by using a .001" feeler gauge. Clearance should be at .001" to .0015". Adjust clearance by repeating

steps 1-5 with different shims if necessary.

8. Once proper rotor/gap clearance is achieved, install well lubricated 52474 Blades (4) into rotor slots. Dynabrade Air Lube P/N 95842 (or equivalent) is

recommended for lubrication before installation in rotor slots.

9. Install cylinder over rotor.

10. Press the 01036 Rear Bearing into 52476 Rear Bearing Plate. Press bearing/bearing plate assembly onto rotor. Be sure that pin and air slot line-up

with pin hole and air inlet slot in cylinder.

11. Place the tool into a soft jaw vise and tighten the governor assembly (52478 Governor Cage) torque 9.0 N•m/80 in. - lbs. (left hand thread).

12. Place 01835 Shim and 01823 Washer into housing.

13. Install 52477 Gasket and 52461 Housing Cap with 95720 screws and 01791 Washers, tighten screws to 9 N•m/80 in. - lbs.

14. Place complete motor assembly into housing. Be sure motor drops all the way into housing.

15. Motor adjustment must now be checked. With motor housing still mounted in vise, pull end of rotor and twist (10-15 lbs. force), rotor should turn freely

without drag. If drag or rub is felt, then increase preload or remove shim. Also, push end of rotor and twist (10-15 lbs. force), rotor should turn freely

without drag. If drag or rub is felt, then deload or add a shim.

16. Apply 2 drops of #271 Loctite® (or equivalent) to threads of adjustment bushing before tightening.

17. Slip 52491 Bushing through 52495 Nut and packing, and secure into housing.

18. Tighten 52491 Adjustment Bushing into housing torque 50 N•m/ 450 in. - lbs. Tighten valve body into housing.

19. Secure inlet bushing into vise. Place 52495 Nut and 01746 O-Ring onto valve body. Swivel 52494 Valve Body to desired throttle lever position.

20. Tighten 52495 Nut to 45 N•m/400 in. - lbs. Roll 07136 Grip back into place.

Tool assembly is complete. Please allow 30 minutes for adhesives to cure before operating tool.

Important: Motor should now be tested for proper operation at 90 PSI. If motor does not operate properly or operates at a higher RPM than marked on the

tool, the tool should be serviced to correct the cause before use. Before operating, place 2-3 drops of Dynabrade Air Lube (P/N 95842) directly into air inlet

with throttle lever depressed. Operate tool for thirty seconds to determine if tool is operating properly and to allow lubricating oils to properly penetrate motor.

Loctite® is a registered trademark of Loctite Corp.

(PD97•33)

Page 7

7

01845 Air Motor

(Includes 01794 Drive Wheel)

01815 Rotor Nut

52446 Housing

01829 Governor Spring

52467 Spacer

01825 Bearing

52472 Bearing Plate

52173 Shim Pak

50548 Spring Holder

52476 Bearing Plate

01036 Bearing

52475 Cylinder

50511 Screw (2)

01791 Washer (2)

52461 Housing Cap

52165 Gasket

52180 Clamp

52164

Exhaust

Cover

01089 Lever

01697 Inlet Bushing

01017 Pin

52494 Valve Body

(Inc. 07142 Bushing)

07168 Valve Stem Assembly

07145 Spring

07146 Packing

07147 Plug

01746 “O” Ring

52491 Adj. Bushing

52495 Nut

52496 Packing07136 Handle Grip

52477 Gasket

50541 Governor Valve

52478 Governor Cage

96059 Governor Pin (2)

52466 Rotor

01791 Washer (4)

95720

Screw (4)

01673 Pin

KEY

L

T

O

Loctite/Hernon: L

2

= Loctite #271, L3= Loctite #380,

L

4

= Hernon #940

Torque: N•m x 8.85 = In. - lbs.

T

2

= 4.5 N•m, T3= 7 N•m, T4= 9 N•m, T5= 17 N•m,

T

6

= 22.5 N•m, T7= 45 N•m, T8= 50 N•m, T9= 56 N•m

G

Oil

Grease

T

7

L

2

L

3

T

8

L

2

T

5

T

2

01823 Washer

01835 Shim Packet

T

6

52471 Shim Pak

01672 Pin

T

4

52474

Blade (4/pkg.)

O

T

4

T

9

95375 O-Ring

94522 Muffler Cap

52498 Governor Weight (2)

50468 Pin

L

4

52166 Seal

Page 8

DYNABRADE

®

Toll Free (USA) 1-800-828-7333

Toll Free (Can.) 1-800-344-1488

DYNABRADE, INC., 8989 Sheridan Drive • Clarence, NY 14031-1490 • Phone: (716) 631-0100 • Fax: 716-631-2073 • International Fax: 716-631-2524

DYNABRADE EUROPE S.àr.l., Zone Artisanale • L-5485 Wormeldange—Haut, Luxembourg • Telephone: 352 76 84 94 • Fax: 352 76 84 95

© DYNABRADE, INC., 1997 PRINTED IN USA

Visit our new Web Site via Industry.Net MROP On-Line: http://www.dynabrade.industry.net E-Mail: DynaTalk@aol.com

Loading...

Loading...