Page 1

Parts Page Reorder No. PD97•41

Effective July, 1997

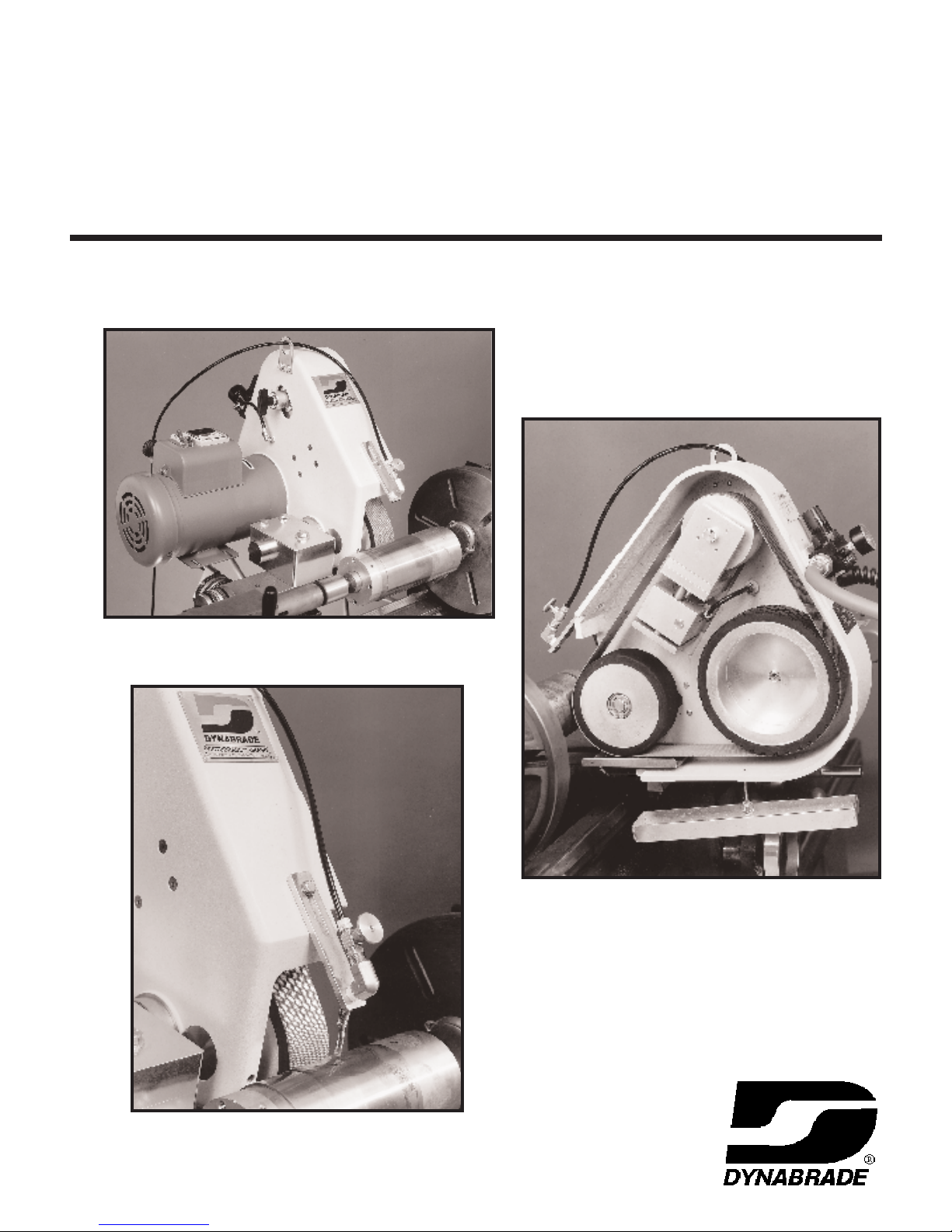

Precision Tool Post Grinder

:

Models

65750 – 3,450 RPM (Wet), 60 Hz

65751 – 2,850 RPM (Wet), 50 Hz

:

Instruction Manual

2" Wide x 48" Long Abrasive Belt Machine

Page 2

WARRANTY

ollowing the reasonable assumption that any inherent defect which might prevail in a product will become apparent

F

to the user within one year from the date of purchase, all equipment of our manufacture is warranted against defects

in workmanship and materials under normal use and service. We shall repair or replace at our factory, any equipment

or part thereof which shall, within one year after delivery to the original purchaser, indicate upon our examination to

have been defective.

Our obligation is contingent upon proper use of Dynabrade tools in accordance with factory recommendations,

nstructions and safety practices. It shall not apply to equipment which has been subject to misuse, negligence,

i

accident or tampering in any way so as to affect its normal performance.

Normally wearable parts such as bearings, contact wheels, rotor blades, etc., are not covered under this warranty.

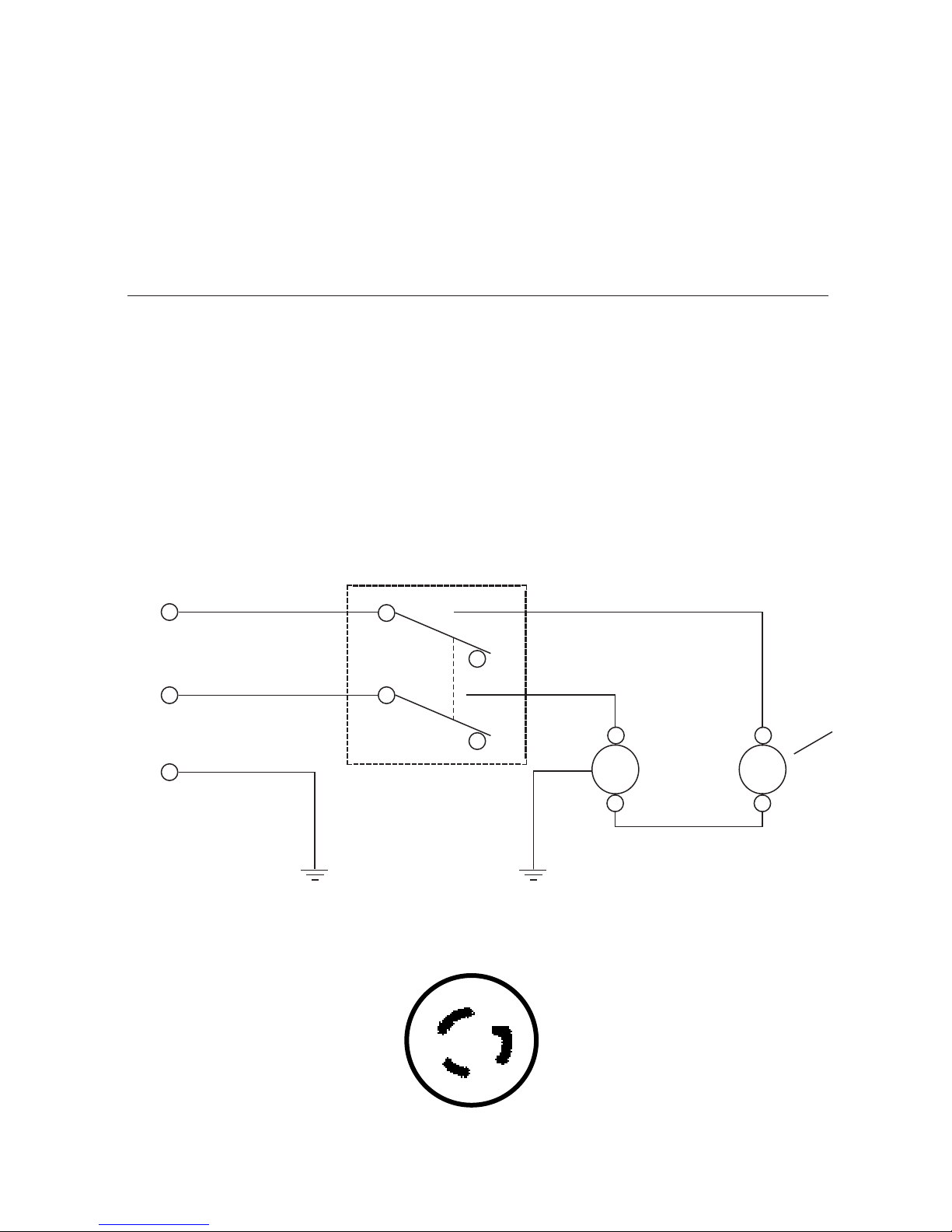

ELECTRICAL WARNING

Warning: This tool does “not” come equipped with overcurrent protection. It is the user’s responsibility to provide an

adequately grounded circuit with correctly rated fuse or circuit breaker. A “ground-fault” protected device is also

recommended if tool is to be operated “wet”.

Refer to

and the supply circuitry is in accordance with local electrical codes and ordinances.

The machine “as shipped” is intended to be used exclusively on a 230-volt, Single Phase power supply.

Always disconnect tool from power at plug before performing any maintenance tasks.

Electrical Schematic ES-65014 for machine wiring. A qualified electrician can determine if the tool (as shipped)

230 V

1 Phase

60 Hz

Electrical Schematic ES-65014

DPST

Nema Configuration

Locking Type Plug

M

OPT.

A

X

G

V

L6 – 2OP

2

Page 3

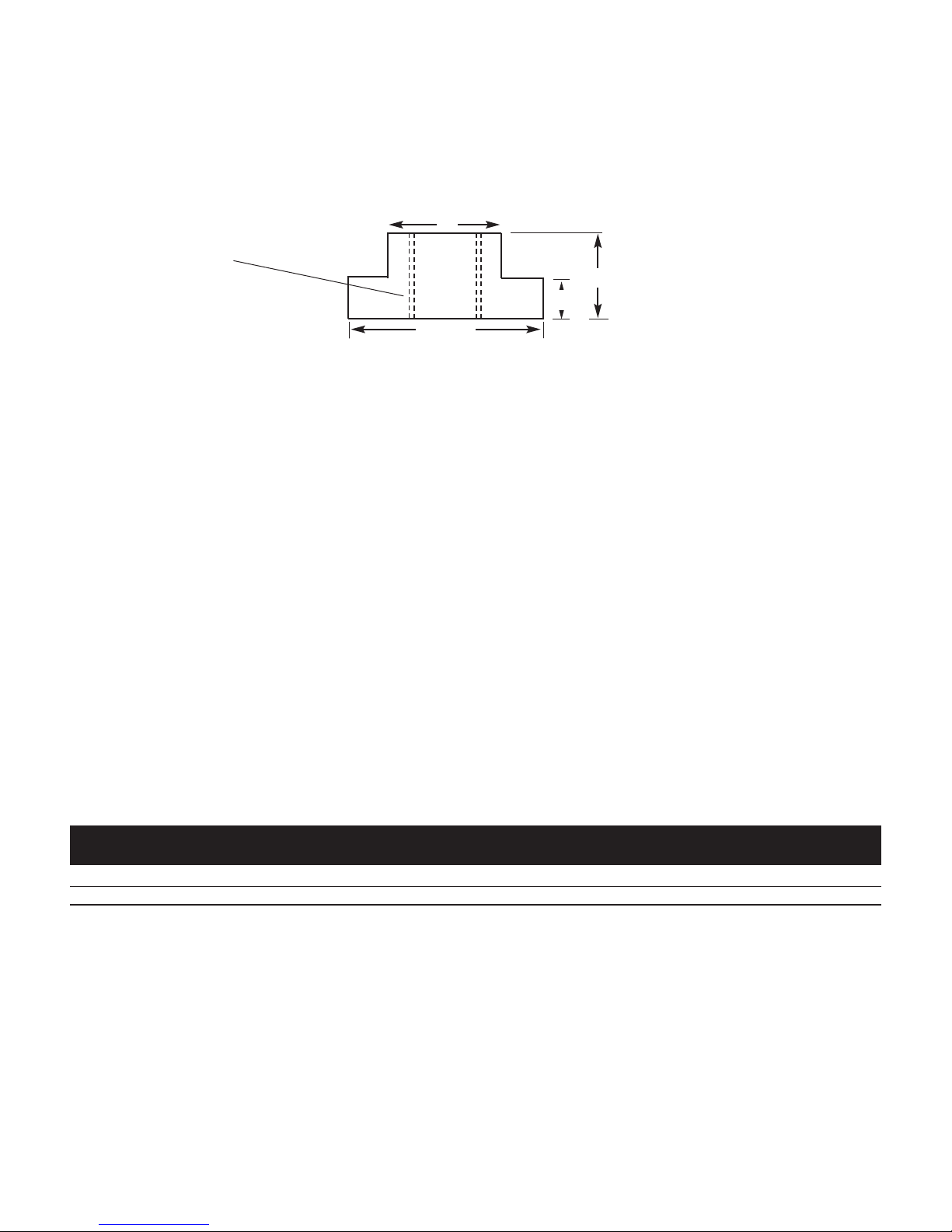

MOUNTING INSTRUCTIONS

This machine comes with a “T”-nut and hex head screw for mounting directly to the lathe compound. Due to the many

lathe types, it may be necessary to alter or replace the “T”-nut with one of the correct size for the particular lathe.

“T”-nut dimensions are supplied as follows...

1"

1/2-13 UNC – 2B

Tapped Hole

3/4"

3/8"

1-3/4"

Mat’l 303-SS

MOUNTING:

STEP 1. - Remove any tooling, tooling holders, etc. from the lathe compound.

STEP 2. - Clear all chips and debris from the top of compound and “T”-slot.

STEP 3. - Providing the “T”-nut is of correct size for the lathe compound, lift (or hoist) the entire tool into position.

Align and insert “T”-nut into slot.

STEP 4. - Using your fingers, lightly snug the hex screw (P/N 97087) until the tool becomes parallel to the

workpiece centerline.

STEP 5. - The tool can now be swung from side to side and positioned for the desired angle between the contact

wheel and the workpiece. Once this is achieved, firmly tighten hex screw (P/N 97087).

STEP 6. - Position the contact wheel at or above the workpiece centerline. This will ensure proper belt tracking and

prevent chatter from occurring. The position can be altered by loosening the two cap screws (P/N 97088)

and allowing the tool to pivot on the pivot shaft (P/N 65266)

this task!) Firmly retighten the screws once proper positioning is achieved.

The machine is now ready for operation.

(tool must be supported while performing

Machine Specifications

Machine Width Length Height Machine Abrasive Motor

Model No. Inch (mm) Inch (mm) Inch (mm) Weight (kg) Belt Size Electrical RPM SFPM

65750 (Wet) 17" (432) 19" (483) 18" (457) 108 lbs. (49) 2"(50) x 48"(1219) 240 V/ 1 Ph/60 Hz 3,450 7,200 (2,187)

65751 (Wet) 17" (432) 19" (483) 18" (457) 108 lbs. (49) 2"(50) x 48"(1219) 240 V/ 1 Ph/50 Hz 2,850 6,000 (1,822)

3

Page 4

Item Part No. Description Qty.

1 66605 Housing 1

2

66608 Electric Assembly (50 Hz) 1

66607 Electric Assembly (60 Hz) 1

3 98378 Ammeter 1

4 98371 Switch 1

5 98370 Switch Guard 1

6 65195 Mounting Block 1

7 98493 T-Nut 1

8 65266 Pivot Bar 1

9 14333 Lift Bracket 1

10 66616 Tension Block 1

11 95696 Gauge 1

12 66617 Drive Wheel (2,850 RPM) 1

13 66614 Contact Wheel Shaft 1

14 97026 Screw 2

15 66622 Spacer Block 1

16 Reserved

17 65263 Tray (includes rod) 1

18 97773 Knob 1

19 65314 Tray Support 1

20 97061 Screw 2

21 66618 Cover 1

22 97760 Door Latch 1

23 97053 Screw 2

24 95179 Hex Screw 2

25 95167 Lock Washer 2

26 97088 Hex Screw 2

27 95183 Flat Washer 2

28 97057 Cap Screw 4

29 97059 Cap Screw 4

30 97087 Hex Screw 1

31 97310 Flat Washer 1

32 97085 Flathead Screw 4

33 97460 Key 1

34 97069 Carriage Bolt 2

35 97806 Air Cylinder 1

36 97112 Set Screw 1

37 97828 Fitting 2

38 97829 Hose 1 Ft.

39 97083 Flathead Screw 4

40 65232 Tension Strap 1

41 97883 Breather Vent 1

42 97894-B Valve 1

43 97898-C Regulator 1

44 97812 Oil Seal 4

45 65217 Bushing 4

46 66619 Contact Wheel 1

47 66611 Tension Shaft 2

48 Reserved 2

49 Reserved 4

50 97015 Cap Screw 4

51 65269 Tension Support 1

52 95202 Set Screw 3

53 97549 Bushing 2

54 97405 Roll Pin 2

55 66613 Idler Support 2

56 66615 Tracking Wheel (3,450 RPM) 1

57 97548 Ball Bearing 4

58 97442 Retaining Ring 3

59 66612 Tracking Shaft 1

60 65132 Tracking Hub 1

61 97152 Low Head Screw 4

62 95417 Nylon Washer 2

63 95186 Hex Nut 1

64 95314 Knob 1

65 65264 Drip Pan 1

66 95166 Flat Washer 1

67 95167 Lock Washer 1

68 95170 Wing Nut 1

69 97151 Eye Screw 1

70 65262 Nozzle Support 1

71 95761 Valve 1

72 95084 Reducer 1

73 96063 Elbow 1

74 97213 Nut 1

75 97827 Fitting 1

65750 –3,450 RPM (Wet), 60Hz

65751 –2,850 RPM (Wet), 50Hz

Precision Tool Post Grinder – Machine Parts Breakdown – Models 65750 and 65751

17

19

20

18

3

33

24

25

4

2

26

30

31

6

7

8

28

24

24

65

66

74

75

66 67 68 69

71

70

72

73

36

13

44

45

40

39

38

58

39

50

57

46

12

52

61

60

63

59

53

54

58

56

57

55

54

53

21

22

51

47

44

45

10

62

64

1

11

23

32

9

29

27

5

14

42

43

41

37

38

23

23

34

37

35

15

52

Page 5

MACHINE ADJUSTMENTS

Belt Change/Installation:

. Remove Belt Guard by grasping door latch

1

(P/N 97760) and rotate 1/4 turn counter-clockwise.

2. Turn off air supply at valve (item #42). This will retract air

ylinder (item #35) and thus removes tension from the belt.

c

3. Remove and replace belt.

4. Important: With hands clear from moving parts, turn air supply

back on at item #42. Regulator pressure should be set to 90 PSI

for proper belt tensioning.

5. "Jog" motor by turning on momentarily to ensure proper belt

tracking. Tracking procedure is described below.

Replace belt guard and turn door latch 1/4 turn clockwise until

“click” is heard.

Belt Tracking:

Belt tracking is accomplished by turning the tracking knob (P/N

95314). Turning clockwise moves belt to the right. Turning

counter-clockwise moves belt to the left.

Coolant Nozzle:

The coolant nozzle can be extended or retracted (if dia. allows) for good placement of coolant flow by loosening hex

screw (P/N 95179). Retighten once placement is achieved. The coolant nozzle has an adjustable flow valve which

connects to 1/4" diameter flexible nylon tubing.

Drip Pan:

The drip pan is hinged on a #10 eye screw and can be tilted fore and aft to direct coolant toward lathe bed.

Catch Tray Assembly:

Each machine comes equipped with an adjustable catch tray which positions underneath the contact wheel. Its

purpose is to collect the major portion of grind dust/swarf and direct it away from the lathe ways. It should be placed

within 1/8" of workpiece. Position can be changed by loosening knob (P/N 97773). When grinding into a shoulder, it

will be necessary to remove tray entirely.

MAINTENANCE

The grinders described in this manual have been designed to be maintenance-free. All bearings and moving parts

are sealed/shielded and lubricated for life. Electric motor maintenance should be performed as recommended by the

motor manufacturer.

Good housekeeping is essential to insuring long life of an

inspected for any wear, the machine will provide many years of quality service.

y machine tool.

By keeping the machine clean and visually

iodically inspect the contact wheels

er

P

parts early enough will prevent other parts from becoming damaged.

, idler rolls and dr

e pulley for any signs of wear. Repairing or replacing worn

iv

6

Page 6

ELECTRICAL SAFETY INSTRUCTIONS

Warning: When using electric tools, basic safety precautions should always be followed to reduce the

risk of a fire, electric shock, and personal injury, including the following:

1. Keep work area clean. Cluttered areas and benches invite accidents.

2. Consider work area environment. Keep work area well lit. Do not use tools in the presence of flammable

liquids or gases.

3. Guard against electric shock. Prevent body contact with grounded surfaces. For example; pipes, radiators,

ranges, refrigerator enclosures.

4. Keep children away. Do not let visitors contact tool or extension cord. All visitors should be kept away from work area.

5. Do not force tool. It will do the job better and safer at the rate for which it was intended.

6. Use the right tool. Do not force a small tool or attachment to do the job of a heavy duty tool. Do not use tool for

purposes not intended.

7. Dress properly. Do not wear loose fitting clothing or jewelry. They can be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working outdoors. Wear protective hair covering to contain long hair.

8. Use safety glasses. Also use face-shield or dust mask if operation area is dusty.

9. Do not abuse cord. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil

and sharp edges.

10. Secure work. Use clamps or a vice to hold workpiece. It’s safer than using your hand and it frees up both

hands to operate tool.

11. Do not overreach. Keep proper footing and balance at all times.

12. Maintain tools with care. Keep tools clean for better use and safer performance. Follow instructions for

lubricating and changing accessories. Inspect tool cords periodically and if damaged, have repaired by

authorized service facility. Inspect extension cords periodically and replace if damaged. Keep handles dry,

clean and free from oil and grease.

13. Do not leave tool running. Disconnect tools when not in use, before servicing, when changing belts, contact arms, etc.

14. Remove keys and wrenches. Form a habit of checking to see that all keys and adjusting wrenches are

removed from tool before turning it on.

15. Avoid accidental starting. Do not carry around plugged in tool with finger on switch. Be sure switch is off when plugging in.

16. Out-door use extension cords. When tool is used outdoors, use only extension cord suitable for outdoor use.

They should be marked with the suffix W-A (for UL) or W (for CSA in Canada).

17. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

k damaged parts

Chec

18.

checked to determine that it will operate properly and perform its intended function. Check for alignment of

ving parts, breakage of moving parts, binding of moving parts, mounting and any other conditions that may

mo

ect its oper

aff

authorized service center unless otherwise indicated elsewhere in this instruction manual. Have defective

switches replaced. Do not use tool if switch does not turn tool on or off.

19. Avoid gaseous areas. Do not operate portable electric tools in gaseous or explosive atmospheres. Motors in

these tools normally spark, and the sparks can ignite fumes.

20. Do not alter or misuse tool. This tool is precision built. Any alteration or modification not specified is misuse

and ma

instruction manual are acceptable f

present a risk to the operator.

21. Replacement parts. When servicing, use only identical replacement parts. When ordering replacement parts,

please specify model and serial numbers of your machine.

Voltage Warning

Before connecting the tool to a power source (receptacle, outlet, etc.) be sure the voltage supplied is the same as

what is specified on the nameplate of the tool.

serious injury to the user as well as damage to the tool. Using a power source with voltage less than the nameplate

rating is harmful to the tool’s motor. If in doubt, do not plug in the tool.

ation. A guard or other part that is damaged should be properly repaired or replaced by an

y result in a dangerous condition.

ore further use of the tool, a guard or other part that is damaged should be carefully

Bef

.

Only these accessories and attachments that are found in this

or use with this tool.

er source with greater than that specified for tool can result in

w

A po

The use of any other accessory or attachment might

7

Page 7

The following safety rules apply when contact wheel grinding:

1. Never use an abrasive belt that is narrower than the contact wheel, as the uncovered wheel face will cause

snagging of the workpiece.

2. Always use an upward stroke of the workpiece against the abrasive belt and always use the grind area below the

centerline of the contact wheel.

There is a potential combustion hazard if ferrous and non-ferrous grinding dust is mixed. Do not

grind materials of different types without thoroughly cleaning grinding residue from inside machine.

oist Bracket ideal for assisting in

H

lifting onto the lathe.

Easily accessible belt-tracking adjustment.

Water-tight on/off switch.

Coolant drip-pan on side of tool (not

hown) deflects stray coolant.

s

90 durometer fixed contact

wheel is standard.

Rigidly mounts to lathe

compound for close

ance work.

toler

.l.,

Zone

On-Line: http://www

Visit our new Web Site via Industry

DYNABRADE, INC., 8989 Sheridan Drive • Clarence, NY 14031-1490 • Phone: (716) 631-0100 • Fax: 716-631-2073 • International Fax: 716-631-2524

DYNABRADE EUROPE S.àr

© DYNABRADE, INC., 1997 PRINTED IN USA

.Net MROP

Artisanale

.dynabrade.industry

• L-5485 W

ormeldange—Haut, Luxembourg

.net

E-Mail: DynaT

alk@aol.com

elephone: 352 76 84 94

• T

• Fax: 352 76 84 95

Loading...

Loading...