Page 1

Parts Page Reorder No. PD07•20

Effective May, 2007

Bandsaw Blade Grinder

Tool Manual – Safety, Operation and Maintenance

SAVE THIS DOCUMENT, EDUCATE ALL PERSONNEL

Model:

64500 (120v) 1 Phase 60 Hz

GENERAL SAFETY INSTRUCTIONS

Carefully Read and save all instructions before operating or servicing any Dynabrade

®

Abrasive Power Tool.

Products offered by Dynabrade are not to be modified, converted or otherwise alerted from the original design without expressed

written consent from Dynabrade, Inc.

Warning: When using electric tools, basic safety precautions should always be followed to reduce the risk of a fire, electric shock, and personal injury,

including the following:

1. Mount tool securely. Always fasten tool to bench or other support structure to prevent tipping.

2. Keep work area clean. Cluttered areas and benches invite accidents.

3. Consider work area environment. Do not expose tools to rain. Keep work area well lit. Do not use power tools in damp or wet locations. Do not

use tools in the presence of flammable liquids or gases.

4. Guard against electric shock. Be certain machine is adequately grounded before operating.

5. Keep children away. Do not let visitors contact tool. All visitors should be kept away from work area.

6. Do not force tool. It will do a better and safer job at its intended rate.

7. Use the right tool. Do not force a small tool or attachment to do the job of a heavy duty tool. Do not use tool for purposes not intended.

8. Dress properly. Do not wear loose fitting clothing or jewelry. Clothes can be caught in moving parts. Wear protective hair covering to

contain long hair.

9. Use safety glasses. Also use face-shield or dust mask if operation area is dusty.

SAFETY LEGEND

Read and understand tool manual before

work starts to reduce risk of injury to

operator, visitors, and tool.

Eye protection must be worn at all times,

eye protection to conform to ANSI Z87.1.

Respiratory protection to be used when exposed to

contaminants that exceed the applicable threshold

limit values required by law.

Practice safety requirements. Work alert,

have proper attire, and do not operate tools under

the influence of alcohol or drugs.

Ear protection to be worn when exposure to sound,

exceeds the limits of applicable Federal, State or

local statues, ordinances and/or regulations.

Electric shock hazard. Avoid bodily contact with

grounded objects, bodies of water.

Do not damage cord set.

G

Read and understand this tool manual before operating your tool. Follow all safety rules for the protection of operating personnel as well

as adjacent areas. For safety information, refer to Code of Federal Regulation – CFR 29 Part 1910, European Committee for Standards (EN)

Hand Held Electric Motor Operated Tools – Safety Requirements and applicable State and Local Regulations.

FIND THE MOST CURRENT OFFERING OF SUPPORT DOCUMENTS AND ACCESSORIES @ WWW.DYNABRADE.COM

WARNIN

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Page 2

Maintenance Instructions

Electric motor maintenance should be performed as recommended by the motor manufacturer.

There are three grease fittings found on this machine, grease these fittings as needed. Please see assembly views to locate grease fittings.

Good housekeeping is essential to insuring long life of any machine tool. By keeping the machine clean and visually inspected for any wear, the machine

will provide many years of service.

Before each use inspect the contact wheels, idler rolls and drive pulley for any signs of wear. Repairing or replacing worn parts early enough will prevent

other parts from becoming damaged.

2

(continued on next page)

10. Do not abuse cord. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil and sharp edges.

11. Do not overreach. Keep proper footing and balance at all times.

12. Maintain tools with care. Keep tools clean for better use and safer performance. Follow instructions for changing accessories. Inspect tool cords

periodically and if damaged, have repaired by authorized service facility. Inspect extension cords periodically and replace if damaged. Keep handles

dry, clean and free from oil and grease.

13. Do not leave tool running. Disconnect tools when not in use, before servicing, when changing belts, contact arms, etc.

14. Remove keys and wrenches. Form a habit of checking to see that all keys and adjusting wrenches are removed from tool before turning it on.

15. Avoid accidental starting. Be sure switch is off when plugging in.

16. Out-door use extension cords. When tool is used outdoors, use only extension cord suitable for outdoor use. They should be marked with the

suffix W-A (for UL) or W (for CSA in Canada).

17. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

18. Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function. Check for alignment of moving parts, breakage of moving parts, binding of moving parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced by an authorized

service center unless otherwise indicated elsewhere in this instruction manual. Have defective switches replaced. Do not use tool if switch does

not turn tool on or off.

19. Avoid gaseous areas. Do not operate electric tools in gaseous or explosive atmospheres. Motors in these tools normally spark, and the sparks

can ignite fumes.

20. Do not alter or misuse tool. This tool is precision built. Any alteration or modification not specified is misuse and may result in a dangerous condition.

Only these accessories and attachments that are found in this instruction manual are acceptable for use with this tool. The use of any other accessory or

attachment might present a risk to the operator.

21. Replacement parts. When servicing, use only identical replacement parts. When ordering replacement parts, please specify model and serial

numbers of your machine.

22. Do not operate tool without guards. Always replace guards after changing contact arm or abrasive belt.

23. Do not mix grind material. There is a potential combustion hazard if ferrous and non-ferrous grinding dust is mixed. Clean inside

machine between materials.

24. Use hearing protection. Permanent hearing loss can result from high process noise levels.

25. Use correct width abrasive belt. Using abrasive belt that is narrower than the contact wheel can cause snagging of the workpiece.

Voltage Warning

Before connecting the tool to a power source (receptacle, outlet, etc.), be sure the voltage supplied is the same as what is specified on the nameplate

of the tool. A power source with greater than that specified for tool can result in serious injury to the user as well as damage to the tool. Using a power

source with voltage less than the nameplate rating is harmful to the tool’s motor. If in doubt, do not plug in the tool.

Polarized Plugs: To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider than the other). This plug will fit in a polarized

outlet only one way. If the plug does not fit in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not change the plug in any way.

Warning: Keep extension away from the immediate working area.

One Year Warranty

Following the reasonable assumption that any inherent defect which might prevail in a product will become apparent to the user within one year from the

date of purchase, all equipment of our manufacture is warranted against defects in workmanship and materials under normal use and service. We shall

repair or replace at our factory, any equipment or part thereof which shall, within one year after delivery to the original purchaser, indicate upon our

examination to have been defective. Our obligation is contingent upon proper use of Dynabrade tools in accordance with factory recommendations,

instructions and safety practices. It shall not apply to equipment which has been subject to misuse, negligence, accident or tampering in any way so as to

affect its normal performance. Normally wearable parts such as bearings, contact wheels, rotor blades, etc., are not covered under this warranty.

Notice

All Dynabrade tools use the highest quality parts and metals available and are machined to exacting tolerances. Our warranty obligation is contingent upon

proper use of our tools and cannot apply to equipment which has been subjected to misuse or a lack of maintenance during the use of this tool.

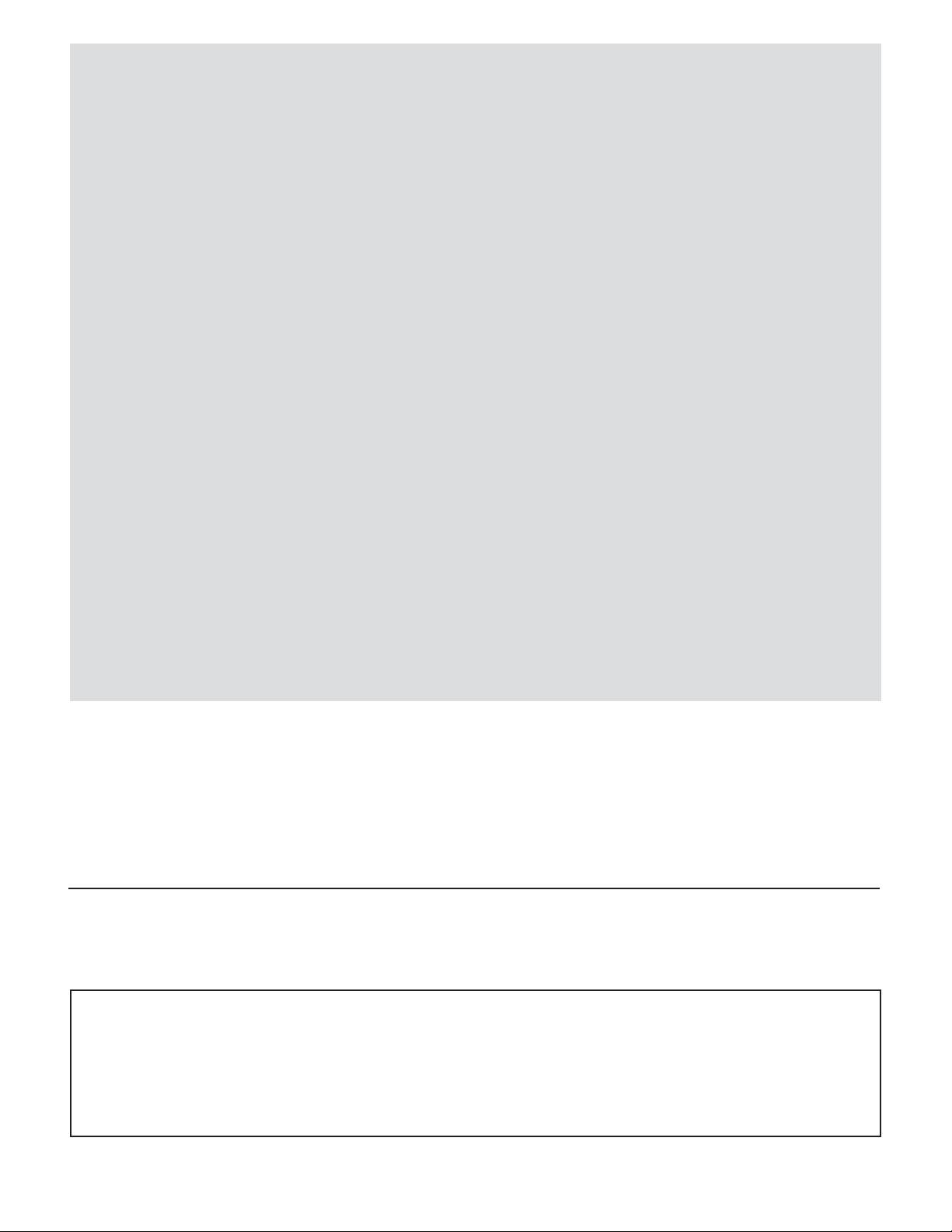

Page 3

Adhesive: A1= Loctite #609

A

2

= Loctite #271

A

8

= Loctite #567

Torque: N•m x 8.85 = In. - lbs.

Grease: G

1

= Lubriplate 630-AA

A

T

G

KEY

32

31

31

3

33

39

55

56

55

57

58

59

60

61

62

63

64

65

20

21

20

21

37

34

54

27

29

28

67

66

71

72

75

77

78

70

80

79

81

31

32

82

83

84

85

87

69

51

53

49

48

32

47

46

42

47

46

52

A

8

A

8

A

8

A

1

A

1

A

1

A

1

A

2

A

2

A

8

A

8

A

8

A

8

A

2

G

1

G

1

A

2

A

2

A

2

A

2

A

2

88

37

37

86

76

74

73

68

24

50

24

43

24

36

35

Bandsaw Blade Grinder Main Assembly View

1 57764 Pad

2 95207 Screw (11)

3 95202 Set Screw (3)

4 64526 Drive Wheel

5 64521 Resistor

6 95437 Screw

7 95007 Screw (4)

8 64523 Fuse

9 64847 Fuse Block

10 64520 Speed Control

11 97595 Thermal Compound

12 98613 Push on Terminal (3)

13 98610 Wire Terminal 8 Screw (2)

14 64930 Warning Plate

15 98499 Toggle Boot

16 98500 On/Off Plate

17 64525 Switch Plate

18 64929 Dynabrade Logo

19 98369 Toggle Switch

20 98751 Sealing Ring (3)

21 98746 Lock Nut (3)

22 98709 Elbow

23 14333 Hoist Bracket

24 95536 Screw (15)

25 98418 Cord

26 64948 Support (2)

27 95697 Ring (4)

28 64950 Idler Wheel (3)

29 11813 Bearing (6)

30 64949 Shaft

31 65217 Bushing (5)

32 97812 Rod Seal (4)

33 64943 Cylinder Mount

34 64947

Air Cylinder

35 97889 Vent

36 64933 Slide Valve

37 97828 Right Angle Fitting (3)

38 64944 Support Base

39 64946 Guide Rod

40 97496 Belt Location Label

41 95314 Tracking Knob

42 64596 Ball Joint

43 95186 Nut (2)

44 64564 Pivot Post

45 97086 Screw (2)

46 64561 Arm Support (2)

47 97538 Bushing (2)

48 64563 Tracking Post

49 64562 Idler Support Arm

50 97034 Screw (6)

51 64566 Idler Axle (2)

52 64565 Pivot Block

53 95156 Screw (4)

54 64585 Rear Guard

55 98730 Elbow (2)

56 98403 Conduit

57 98020 DC Motor

58 98421 115V Label

59 98425 Single Phase Label

60 98420 Direction Arrow

61 98611 Wire Terminal

62 98407 Green Wire (2)

63 98406 Red Wire (2)

64 98405 Black Wire (2)

65 98616 Wire Connector (2)

66 64582 Vac Scoop

67 64560 Guide Block (2)

68

95926 Screw (4)

69 64581 Cover

70 97597 Knob (2)

71 64486 Tubing

72 64487 Tubing

73 97827 Tube Fitting

74 97008 Screw (2)

75 97894-C Regulator

76 95696 Pressure Gauge

77 64599 Tube Tee (2)

78 64558 Val ve

79 64489 Tubing

80 97826 Right Angle Fitting

81 64556 Support Bar (2)

82 64557 Side Block

83 64559 Bracket

84 95354 Screw (2)

85 97015 Screw (6)

86 64936 Fitting

87 64488 Tubing

88 95328 Screw (3)

89 95205 Screw (14)

90 64569 Base

91 64568 Leg (3)

92 98595 Screw (3)

93 97021 Screw (2)

94 64857 Spacer (4)

95 50722 Bearing (4)

96 64567 Wheel (2)

97 64584 Guard Post

98 97024 Screw

99 64510 Housing

100 64527 Shaft (2)

101 95716 Screw

102 95044 Lock Washer (4)

103 65059 Stick Screw (8)

104 95016 Set Screw

105 97499 Label

106 95334 Hex Nut

107 01041 Grease Fitting (2)

Index Key

No. Part # Description

18

19

26

29

30

38

104

105

27

28

17

16

21

20

23

22

10 11 12 13

9

8

3

2

4

1

7

102

103

50

101

92

99

97

94

96

85

100

40

41

91

89

90

6

5

25

15

14

2

For Model:

64500

A

8

A

1

A

2

A

2

A

2

A

2

A

2

98

93

A

1

A

1

95

45

24

106

44

107

Grease as needed.

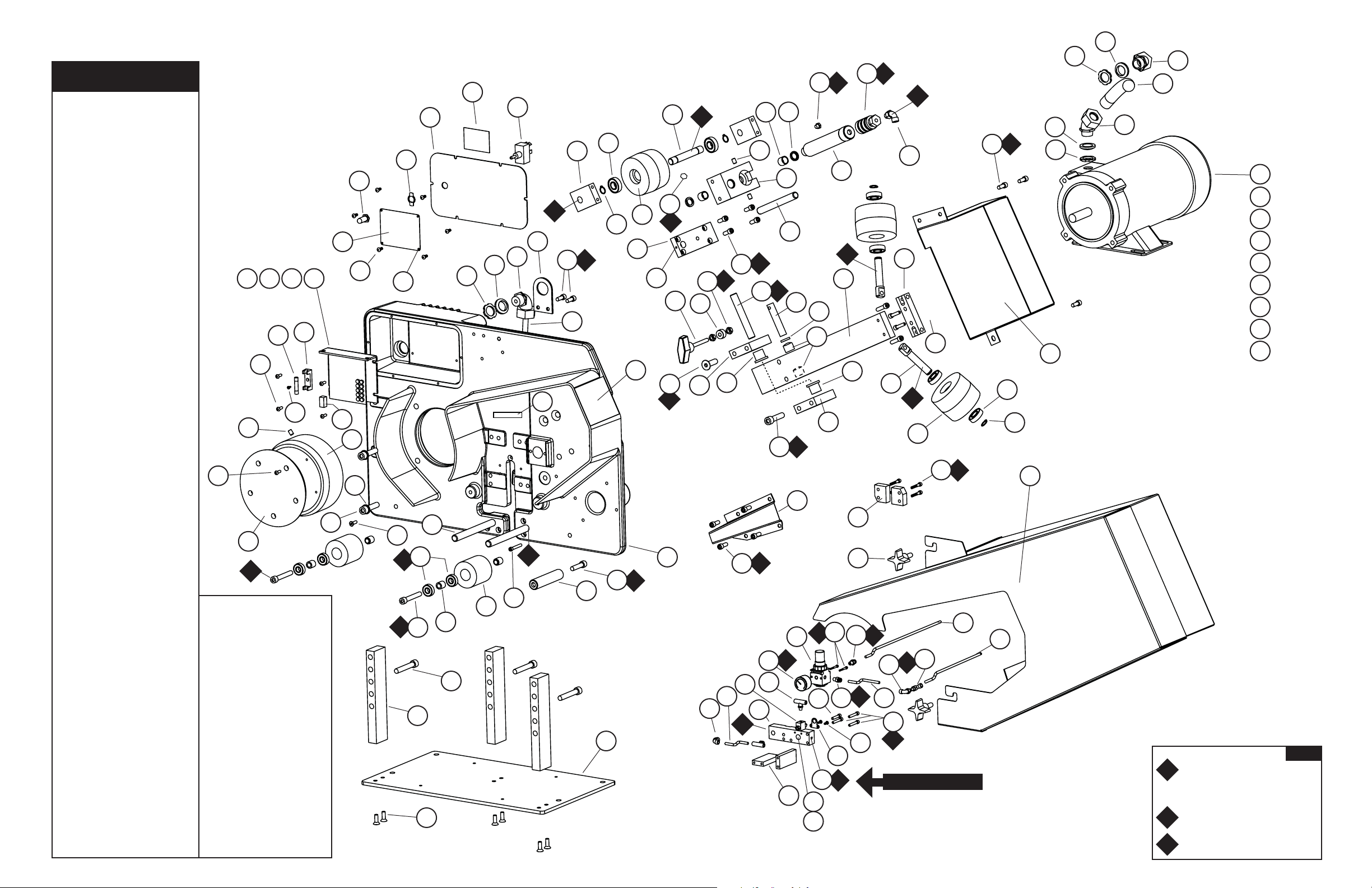

Page 4

Bandsaw Blade Grinder Depth Cut Assembly

1 64552 Stop Knob

2 64527 Shaft (2)

3 64551 Rod

4 95186 Nut (3)

5 65217 Bushing (5)

6 64550 Block

7 95156 Screw

8 95824 Plunger

9 97015 Screw (8)

10 64546 Support (3)

11 64598 Pin (2)

12 50722 Bearing (2)

13 97874 Clevis

14 95019 Screw (2)

15 64548 Block

16 98596 Screw

17 64549 Platten

18 95163 Screw (4)

19 64597 Spring (2)

20 64555 Clevis

21 64553 Cup Point

22 64547 Support

23 64554 Sleeve

Index Key

No. Part # Description

Adhesive: A1= Loctite #609

A

2

= Loctite #271

A

KEY

1

2

3

5

22

21

20

23

12

13

15

14

17

19

6

7

10

A

1

A

1

A

1

A

2

A

2

4

8

9

A

2

A

2

A

2

A

2

18

16

A

1

A

1

A

1

11

Adjust cut depth using this knob.

Note: One full turn equals .008 in.

Page 5

Bandsaw Blade Grinder Blade Lock and Slide

1 97593 Screw (4)

2 95935 Washer (5)

3 64529 Alignment Bar

4 95019 Screw (4)

5 95016 Screw

6 64543 Land (2)

7 64545 Knob

8 95970 Screw

9 95186 Nut (2)

10 95156 Screw

11 64532 Arm

12 95332 Pin

13 11519 Bushing (2)

14 64531 Arm Pivot

15 97015 Screw (9)

16 97024 Screw

17 64530 Shaft

18 97494 Shaft Collar (3)

19 95205 Screw (8)

20 64533 Blade Rest (2)

21 65217 Bushing (5)

22 64528 Bearing Support (2)

23 64595 Right Post Bar

24 97495 Spacer (2)

25 95218 Knob (2)

26 64587 Stop Post (2)

27 64536 Base Support

28 64542 Right Clamp Bar

29 97025 Screw (4)

30 64485 Tubing (2)

31 64527 Shaft

32 97828 Right Angle Fitting (2)

33 64534 Air Cylinder (2)

34 64535

Support (2)

35 40546 Jamb Nut (2)

36 64540 Left Clamp Bar

37 64544 Base

38 97591 Screw (2)

39 64538 Support

40 64594 Left Post Bar

41 64588 Spacer (2)

42 64537 Support Bar

43 97812 Seal (4)

44 01041 Grease Fitting (2)

Index Key

No. Part # Description

Adhesive: A1= Loctite #609

A2= Loctite #271

A8= Loctite #567

Grease:

G1= Lubriplate 630 AA

A

G

KEY

5

6

4

3

2

19

21

43

23

18

24

25

21

26

30

31

42

41

27

37

40

33

36

39

34

9

12

13

13

9

2

16

17

18

11

20

28

14

A

8

A

8

32

35

A

1

A

2

29

A

2

A

2

A

2

A

2

16

38

15

15

22

G

1

A

2

44

A

2

A

2

A

2

A

2

A

2

A

1

7

1

8

G

1

44

10

15

Grease as needed.

19

Page 6

Bandsaw Blade Grinder Gullet Cut Assembly

1 64946 Guide Rod

2 97034 Screw (3)

3 64589 Support (2)

4 95150 Screw (2)

5 64570 Housing

6 50269 Flange Set

7 94903 Cut-Off Wheel

8 97538 Bushing (2)

9 53633 Guard

10 64575 Drive Wheel

11 97474 Spring

12 64590 Spring Base

13 64591 Spring Top

14 64572 Locking Pivot

15 97086 Screw

16 64571 Work Rest

17 64586 Pivot Guard

18 95335 Screw (2)

19 64577 Drive Wheel

20 11013 Bearing

21 95239 Screw

22 64583 Cover

23 97013 Screw (2)

24 56258 Bearing (2)

25 64574 Shaft

26 54520 Bearing (2)

27 64579 Drive Wheel

28 95536 Screw

29 64580 Wheel Plate

30 64578 Driven Wheel

31 64573 Axle

32 64592 Spring Rod

33 97330 Washer

34 64593

Knob

Index Key

No. Part # Description

Adhesive: A1= Loctite #609

A

2

= Loctite #271

A

KEY

1

3

4

8

9

10

11

12

13

6

7

6

32

5

31

29

27

25

19

16

17

20

2223

14

3

8

2

30

33

34

A

1

A

2

A

1

A

2

2

A

1

24

A

1

26

15

24

A

1

26

A

2

28

A

2

21

A

2

18

Page 7

DYNABRADE

®

DYNABRADE, INC.,

8989 Sheridan Drive •Clarence, NY 14031-1490 •Phone: (716) 631-0100 •Fax: 716-631-2073 •International Fax: 716-631-2524

DYNABRADE EUROPE S.àr.l.,

Zone Artisanale •L-5485 Wormeldange—Haut, Luxembourg •Telephone: 352 76 84 94 1 •Fax: 352 76 84 95 1

© DYNABRADE, INC., 2007 PRINTED IN USA

Visit Our Web Site: www.dynabrade.com Email: Customer.Service@Dynabrade.com

Abrasive Belts

Machine Specifications

Reference Contact Information

1. American National Standards Institute – ANSI 2. Government Printing Office – GPO

25 West 43

rd

Street Superintendent of Documents

Forth Floor Attn. New Orders

New York, NY 10036 P.O. Box 371954

Tel: 1 (212) 642-4900 Pittsburgh, PA 15250-7954

Fax: 1 (212) 398-0023 Tel: 1 (202) 512-1803

3. European Committee for Standardization

Rue de Stassart 36

B - 1050 Brussels, Belgium

Grit Material

1" x 104" 1-1/2" x 104"

(25mm x 2,640 mm) (38mm x 2,640 mm)

50 Alumina Zirconia 89226 89225

80 Alumina Zirconia 89228 89227

Abrasive Disc

M

odel

Weight Width Depth Height

Number

Voltage Phase Frequency Pound (kg) Inch (mm) Inch (mm) Inch (mm)

64500 120 V(AC) 1 60 Hz 145 (65.8) 34-1/2 (876) 23 (584) 26 (660)

Grit Material 6" Diameter

60

Non-Vac, Hook-It

93319

Loading...

Loading...