Page 1

Dynorbital-Spirit

®

12,000 RPM Random Orbital Sander

SAFETY, OPERATION AND MAINTENANCE - SAVE THIS DOCUMENT, EDUCATE ALL PERSONNEL

Parts Page Reorder No. PD11•25

Effective June, 2011

Supersedes PD09•01

WARNING

Read and understand this tool manual before operating your air tool. Follow all safety rules for the protection of operating personnel

as well as adjacent areas. Always operate, inspect and maintain this tool in accordance with the American National Standards

Institute (ANSI) Safety Code for Portable Air Tools – B186.1. For additional safety information, refer to Safety Requirements for the Use,

Care and Protection of Abrasive Wheels – ANSI B7.1, Code of Federal Regulation – CFR 29 Part 1910, European Committee for Standards

(EN) Hand Held Non-Electric Power Tools – Safety Requirements and applicable State and Local Regulations.

Find The Most Current Offering of Support Documents and Accessories at www.Dynabrade.com

Read and understand tool manual before work starts

to reduce risk of injury to operator, visitors, and tool.

Ear protection to be worn when exposure to sound,

exceeds the limits of applicable Federal, State or

local statues, ordinances and/or regulations.

Practice safety requirements. Work alert, have proper

attire, and do not operate tools under the influence

of alcohol or drugs.

Air line hazard, pressurized supply lines and flexible

hoses can cause serious injury. Do not use damaged,

frayed or deteriorated air hoses and fittings.

Eye protection must be worn at all times, eye

protection to conform to ANSI Z87.1.

Respiratory protection to be used when exposed to

contaminants that exceed the applicable threshold

limit values required by law.

Some dust created by sanding, grinding, drilling, and other construction activities contain chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

SAFETY INSTRUCTIONS

Carefully Read and Understand the

Sander/Polisher sections found in Tool Safety

and Operating Guidelines (PN00001676)

Before Handling or Using Tool.

Carefully Read all instructions before operating or servicing

any Dynabrade®Abrasive Power Tool. Products offered by

Dynabrade are not to be modified, converted or otherwise

altered from the original design.

DO NOT USE Tool for Anything Other Than Its Intended Applications.

Training: Proper care, maintenance, and storage of your air tool will maximize tools performance and reduce chance for accident.

Employer's Responsibility: Provide operators with safety instructions and training for safe use of tools and accessories.

Report to Your Supervisor any Condition of the Tool, Accessories or Operation you Consider Unsafe.

Tool Intent: Dynorbital-Spirit®Random Orbital Sander is used for sanding and finishing a variety of materials

including wood, metal, plastic, fiberglass, solid surfaces, composites, rubber, glass and stone.

Models:

3/8" Orbit 3/16" Orbit 3/32" Orbit

59000 59010 58054 59024 59030 59040

59003 59013 59015 59025 59033 59043

59004 59014 59018 59028 59034 59044

59005 59100 59019 59029 59035 59110

59008 59103 59020 59105 59038 59113

59009 59104 59023 59108 59039 59114

59109

For Serial No. 09B1000G and Higher

Page 2

2

Filter

Regulator

Lubricator

90 PSIG

(6.2 Bar)

To Tool Station

Ball

Valve

Ball

Valve

Filter

Regulator

Lubricator

Air Flow

Drain

Valve

Drain

Valve

Air Tool

Air Compressor

and Receiver

Drain Valve

Air Hose

90 PSIG MAX

(6.2 Bar)

Air Flow

Refrigerated

Air Dryer

1 DROP/MIN.

20 SCFM

LUBRICATOR SETTING

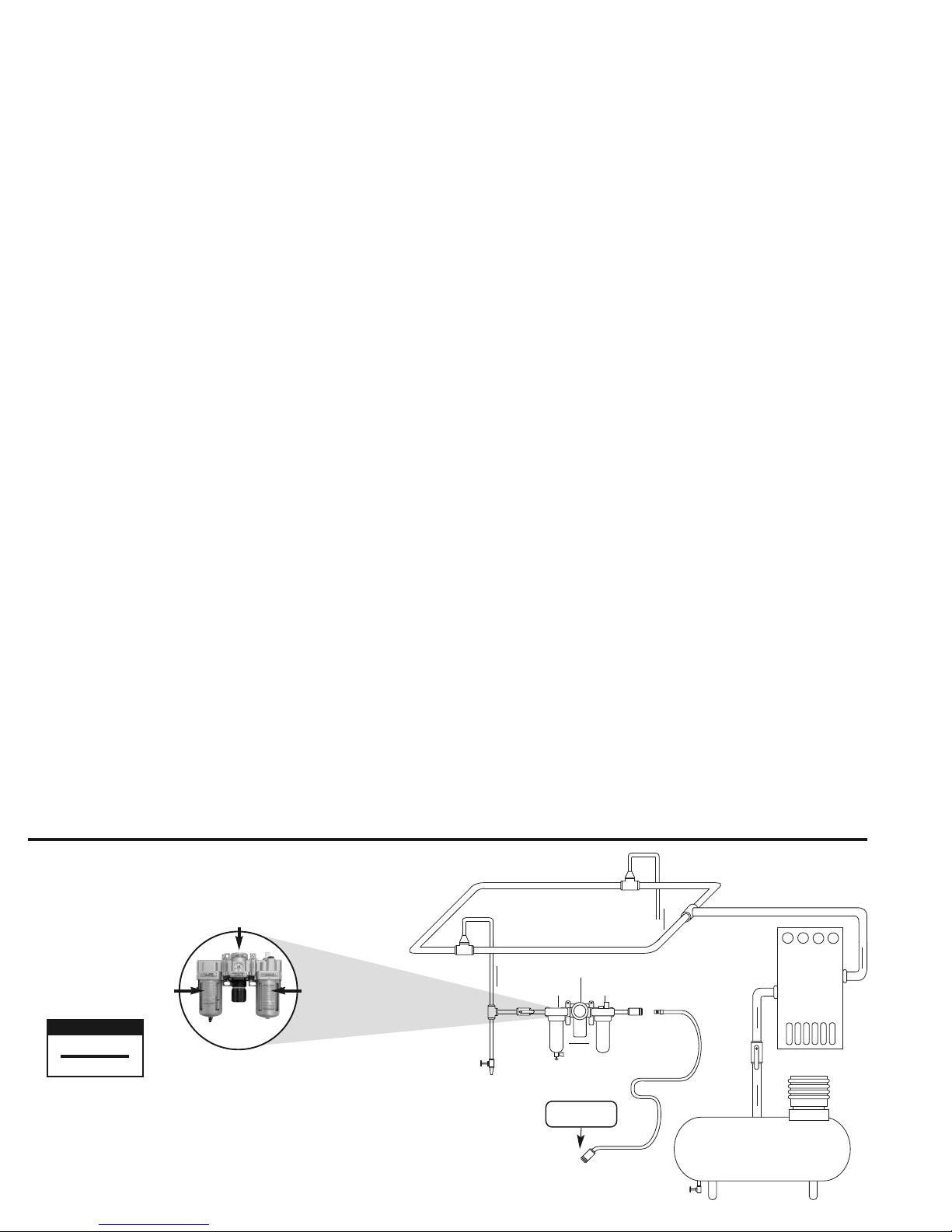

• Dynabrade Air Power Tools are designed to operate at 90 PSIG

(6.2 Bar) maximum air pressure at the tool inlet, when the tool is

running. Use recommended regulator to control air pressure.

• Ideally the air supply should be free from moisture. To facilitate

removing moisture from air supply, the installation of a refrigerated

air dryer after the compressor and the use of drain valves at each

tool station is recommended.

➤

➤

➤

➤

➤

➤

AIR SYSTEM

Closed Loop Pipe System, Sloped in Direction of Air Flow

MAINTENANCE INSTRUCTIONS

Important: To keep tool safe, a Preventative Maintenance Program is

recommended. The program should included inspection of the tool and all

related accessories and consumables, including air lines, pressure regulators,

filters, oilers, etc. refer to ANSI B186.1 for additional maintenance information.

If accessory or tool breakage occurs, investigate failure to determine the

cause and correct before issuing tool for work. Use the following schedule as

a starting point in developing a Preventative Maintenance Program. If tool

does not operate properly (RPM, Vibration, Start/Stop) after these scheduled

checks or at any time, the tool must be repaired and corrected before returning

tool to use.

INSTALLATION

• To ensure long life and dependable service, use a Closed Loop Air System

and Filter-Regulator-Lubricator as diagramed below.

• Each tool should have its own dedicated hose connected to an air supply

manifold. Quick disconnects should be installed at the manifold in an effort

to reduce contamination into the tool.

• It is strongly recommended that all Dynabrade rotary vane air tools be used

with a Filter-Regulator-Lubricator to minimize the possibility of misuse due

to unclean air, wet air or insufficient lubrication. Dynabrade recommends

the following: 10681 Air Line Filter-Regulator-Lubricator — Provides

accurate air pressure regulation, two-stage filtration of water contaminants

and micro-mist lubrication of pneumatic components.

• Dynabrade recommends one drop of air lube per minute for each 20 SCFM

(example: if the tool specification states 40 SCFM, set the drip rate on the

filter-lubricator to 2 drops per minute) Dynabrade Air Lube (P/N 95842:

1pt/473ml) is recommended.

MAINTENANCE SCHEDULE

Daily (every 8 hours):

• Inspect tool and accessories for damage or broken parts. Replace items

as necessary to ensure proper operation and safety.

• Lubricate motor as recommended. Use Dynabrade Air Lube (P/N 95842:

1pt/473ml) 10W/NR. (1 Drop per minute of air lube per 20 SCFM.)

• Check air line pressure with a gage. (MAX. 90 PSIG or 6.2 Bar operating

pressure at the air inlet of the tool.)

• Right angled gear and wick system through gear case grease fitting with

3 plunges of gear oil (P/N 95848) and grease gun (P/N 95541). (Prime

grease gun prior to greasing.)

• Check tool for proper operation: If operating improperly or demonstrates

unusual vibration, the tool must be serviced and problem corrected before

further use.

Every 20 Hours or Once a Week Which Ever Comes First:

• Check free speed of tool without the abrasive accessory mounted. Measure

RPM (speed) with tachometer and with air pressure set at 90 PSIG while the

tool is running. If a governed tool is operating at a higher speed than the

RPM marked on the tool housing, the tool must be serviced and corrected

before use. A non-governed tool may exceed the RPM marked on the tool

by 10% when operated at free speed with no accessories.

• If tool is running fast look for worn, damaged or missing governors, air

control rings and silencers. Special care must be taken when servicing

governors and speed control devices. Injection molded governor assemblies

are non-serviceable and must be replaced.

• If tool is running slow look for clogged inlet screen, air stream, silencer(s)

or a malfunctioning governor (see concerns for servicing governors).

Service as required.

Every 50 Hours:

• Lubricate planetary gears through gear case grease fitting with 3 plunges

of grease (P/N 95542) and grease gun (P/N 95541). (Prime grease gun

prior to greasing.)

REPAIR

• Use only genuine Dynabrade replacement parts to ensure quality. To order

replacement parts, specify Model#, Serial# and RPM of your air tool.

• Mineral spirits are recommended when cleaning the tool and parts. Do

not clean tool or parts with any solvents or oils containing acids, esters,

ketones, chlorinated hydrocarbons or nitro carbons.

• DO NOT clean or maintain tools with chemicals that have a low flash point

(example: WD-40

®

).

• Motor Tune-Up Kit are available (when applicable) which includes high

wear and medium wear motor parts.

• Air tool markings must be kept legible at all times, if not, reorder housing

and replace. User is responsible for maintaining specification information.

• After maintenance is performed on tool, add a few drops of Dynabrade

Air Lube (P/N 95842) to the tool inlet and start the tool a few times

to lubricate air motor. Verify RPM (per 20 hr maintenance schedule),

vibration and operation.

HANDLING & STORAGE

• Use of tool rests, hangers and/or balancers is recommended.

• Protect tool inlet from debris (see Notice).

• DO NOT carry tool by air hose or near the tool throttle lever.

• Store accessories in protective racks or compartments to prevent damage.

• Follow the handling instructions outlined in the operating instructions when

carrying the tool and when changing accessories.

• Protect accessories from exposure to water, solvents, high humidity,

freezing temperature and extreme temperature changes.

END OF USE/ DISPOSAL

When tool has reached its end of useful service, disassemble tool into its

primary components (i.e. steel, aluminum and plastic part) and recycle or

discard per local, state and/or federal regulations as to not harm the

environment.

NOTICE

All Dynabrade motors use the highest quality parts and metals available and

are machined to exacting tolerances. The failure of quality pneumatic motors

can most often be traced to an unclean air supply or the lack of lubrication.

Air pressure easily forces dirt or water contained in the air supply into motor

bearings causing early failure. It often scores the cylinder walls and the rotor

blades resulting in limited efficiency and power. Our warranty obligation is

contingent upon proper use of our tools and cannot apply to equipment

which has been subjected to misuse such as unclean air, wet air or a lack

of lubrication during the use of this tool.

Page 3

Orbit 3" 3-1/2" 5" 6"

3/8" 59122 59070 59071 59072

3/16" 59120 59060 59061 59062

3/32" 59121 59065 59066 59067

1 Back-Up Pads - See Chart Below

2 Non-Vacuum Shroud

54458 3" & 3-1/2"

56051 5" & 6"

3 Vacuum Shroud

57084 3" & 3-1/2"

69362 5"

69363 6"

4 57069 Balancer Shaft

5 95630 Snap Ring

6 59084 V-Seal

7 56052 Bearing

8 Motor Shaft Balancer

9 56047 Key

10 59058 Lock Ring

11 59057 “Top Hat” Seal

12 59083 Felt

13 58368 Bearing (2)

14 59076 Front Bearing Plate

15 57113 Rotor/Blade Set

16 59051 Cylinder

17 01024 Seal

18 59077 Rear Bearing Plate

19 98463 Retaining Ring

20 Drop-In Motor Assembly

(See Chart - Page 4)

21 Housing (See Chart - Page 4)

22 69356 Throttle Lever - 3/8"

69360 Throttle Lever - 3/16"

69357 Throttle Lever - 3/32"

23 94590 Pin

24 57041 Comfort Platform

25 98459 O-Ring

26 58363 Valve Stem

27 59075 Speed Regulator

28 01025 O-Ring (2)

29 95697 Retaining Ring

30 01464 Seal

31 58365 Tip Valve

32 01468 Spring

33 01494 Inlet Bushing

34 69364 Shroud Adapter

35 57083 Vacuum Adapter

36 96197 Dowel Pin

37 57066 Muffler Body

38 95526 O-Ring

39 59088 Vac Nozzle

40 57067 Vac Tube

41 57093 Vacuum Adapter

42 56027 Muffler Insert (2)

43 69359 Muffler Cap

44 69272 Muffler Assembly

Index Key

No. Part # Description

A

8

A

2

Note: To order replacement parts specify the Model # and Serial # of your machine.

1

O

T

A

Oil: O

1

= Air Lube

Adhesive: A

2

= Loctite #271

A8= Loctite #567

Torque: N•m x 8.85 = In. - lbs.

KEY

4

5

6

7

O

1

O

1

O

1

O

1

A

2

8

9

11

10

12

13

20

14

15

16

18

13

19

23

21

22

24

26

27

30 31 32

29

17

2

3

Models:

58054, 59000, 59003, 59004, 59005, 59008, 59009, 59010, 59013, 59014, 59015, 59018, 59019,

59020, 59023, 59024, 59025, 59028, 59029, 59030, 59033, 59034, 59035, 59038, 59039, 59040,

59043, 59044, 59100, 59103, 59104, 59105, 59108, 59109, 59110, 59113, 59114

23 N•m

T

23 N•m

T

O

1

50679 26mm

Open-End Wrench

33

25

28

Pad Chart - Vinyl Face

Hook-Face

Style 3" 3-1/2" 5" 6"

Non-Vac 56084 56098 56106 56107

Vacuum – – 56104 56105

Style 5" 6"

Vacuum - Multi-Hole 56320 56321

Dynorbital-Spirit

®

Complete Assembly

Self Generated Vacuum Non-Vacuum

34

35

36

37

38

39

40

Central Vacuum

1 N•m

T

34

41

42

43

1 N•m

T

42

44

43

Speed Regulator

Flow Control

Maximum Flow:

Turn Clockwise.

Minimum Flow:

Turn Counter-clockwise.

+-

Exhaust

Assemblies

(See Below)

Optional: 30 quantity Muffler

Insert available, P/N 56054.

Page 4

DYNABRADE, INC. www.dynabrade.com

8989 Sheridan Drive • Clarence, NY 14031-1419 • Phone: (716) 631-0100 • Fax: 716-631-2073 • International Fax: 716-631-2524

© DYNABRADE, INC., 2011 PRINTED IN USA PD11.25_06/11

1. American National Standards

Institute – ANSI

1899 L Street, NW

11th Floor

Washington, DC 20036

Tel: 1 (212) 642-4900

3. Power Tool Institute, Inc.

P.O. Box 818

Yachata, Oregon 97498-0818

Tel: 1 (503) 547-3185

4. European Committee for

Standardization

Rue de Stassart 36

B - 1050 Brussels, Belgium

2. Government Printing Office – GPO

Superintendent of Documents

Attn. New Orders

P.O. Box 371954

Pittsburgh, PA 15250-7954

Tel: 1 (202) 512-1803

REFERENCE CONTACT INFORMATION

REPLACEMENT HOUSINGS

Model Vacuum Tool Dia. Dia. Orbit Sound Weight Length

Number Style Inch (mm) Inch (mm) Level Pound (kg) Inch (mm)

59000 Non-Vac 3-1/2 (89) 3/8 (10) 78 dB(A) 1.4 (.6) 6 (152)

59005 Non-Vac 5 (127) 3/8 (10) 82 dB(A) 1.5 (.7) 6-1/2 (165)

59010 Non-Vac 6 (152) 3/8 (10) 82 dB(A) 1.6 (.7) 7 (178)

59015 Non-Vac 3-1/2 (89) 3/16 (5) 80 dB(A) 1.4 (.6) 6 (152)

59020 Non-Vac 5 (127) 3/16 (5) 80 dB(A) 1.4 (.6) 6-1/2 (165)

59025 Non-Vac 6 (152) 3/16 (5) 81 dB(A) 1.5 (.7) 7 (178)

59030 Non-Vac 3-1/2 (89) 3/32 (2) 80 dB(A) 1.4 (.6) 6 (152)

59035 Non-Vac 5 (127) 3/32 (2) 79 dB(A) 1.4 (.6) 6-1/2 (165)

59040 Non-Vac 6 (152) 3/32 (2) 80 dB(A) 1.5 (.6) 7 (178)

59100 Non-Vac 3 (76) 3/8 (10) 78 dB(A) 1.4 (.6) 6 (152)

59105 Non-Vac 3 (76) 3/16 (5) 80 dB(A) 1.4 (.6) 6-1/2 (165)

59110 Non-Vac 3 (76) 3/32 (2) 79 dB(A) 1.3 (.6) 7 (178)

59003 Self-Gen 3-1/2 (89) 3/8 (10) 87 dB(A) 1.5 (.7) 8-1/2 (216)

59008 Self-Gen 5 (127) 3/8 (10) 87 dB(A) 1.6 (.7) 8-1/2 (216)

59013 Self-Gen 6 (152) 3/8 (10) 86 dB(A) 1.7 (.7) 9 (229)

59018 Self-Gen 3-1/2 (89) 3/16 (5) 87 dB(A) 1.4 (.6) 8-1/2 (216)

59023/58054 Self-Gen 5 (127) 3/16 (5) 85 dB(A) 1.5 (.7) 8-1/2 (216)

59028 Self-Gen 6 (152) 3/16 (5) 86 dB(A) 1.6 (.7) 9 (229)

Model Vacuum Tool Dia. Dia. Orbit Sound Weight Length

Number Style Inch (mm) Inch (mm) Level Pound (kg) Inch (mm)

59033 Self-Gen 3-1/2 (89) 3/32 (2) 87 dB(A) 1.4 (.6) 8-1/2 (216)

59038 Self-Gen 5 (127) 3/32 (2) 84 dB(A) 1.5 (.6) 8-1/2 (216)

59043 Self-Gen 6 (152) 3/32 (2) 86 dB(A) 1.5 (.7) 9 (229)

59103 Self-Gen 3 (76) 3/8 (10) 87 dB(A) 1.5 (.7) 8-1/2 (216)

59108 Self-Gen 3 (76) 3/16 (5) 87 dB(A) 1.4 (.6) 8-1/2 (216)

59113 Self-Gen 3 (76) 3/32 (2) 87 dB(A) 1.4 (.6) 9 (229)

59004 Central 3-1/2 (89) 3/8 (10) 78 dB(A) 1.5 (.7) 7 (178)

59009 Central 5 (127) 3/8 (10) 82 dB(A) 1.5 (.7) 7-1/4 (184)

59014 Central 6 (152) 3/8 (10) 83 dB(A) 1.6 (.7) 7-3/4 (197)

59019 Central 3-1/2 (89) 3/16 (5) 80 dB(A) 1.4 (.6) 7 (178)

59024 Central 5 (127) 3/16 (5) 81 dB(A) 1.5 (.6) 7-1/4 (184)

59029 Central 6 (152) 3/16 (5) 82 dB(A) 1.6 (.7) 7-3/4 (197)

59034 Central 3-1/2 (89) 3/32 (2) 80 dB(A) 1.4 (.6) 7 (178)

59039 Central 5 (127) 3/32 (2) 81 dB(A) 1.4 (.6) 7-1/4 (184)

59044 Central 6 (152) 3/32 (2) 81 dB(A) 1.5 (.7) 7-3/4 (197)

59104 Central 3 (76) 3/8 (10) 78 dB(A) 1.5 (.6) 7 (178)

59109 Central 3 (76) 3/16 (5) 80 dB(A) 1.4 (.6) 7-1/4 (184)

59114 Central 3 (76) 3/32 (2) 80 dB(A) 1.4 (.6) 7-3/4 (197)

Non-Vacuum to

Vacuum Conversion Kits

Original Converts Kit

Non-Vac Tool to Part Number

3-1/2" (89mm) Self-Generated Vac-Ready 57118

3-1/2" (89mm) Central Vac-Ready 57119

5" (127mm) Self-Generated Vac-Ready 57120

5" (127mm) Central Vac-Ready 57121

6" (152mm) Self-Generated Vac-Ready 57122

6" (152mm) Central Vac-Ready 57123

Drop-in Motor Assemblies

Note: 59058 Lock Ring ONLY included with

3/8" Orbit Drop-in Motors.

Orbit 3" 3-1/2" 5" 6"

3/8" 59488 59450 59453 59456

3/16" 59489 59451 59454 59457

3/32" 59490 59452 59455 59458

OPTIONAL ACCESSORIES

MACHINE SPECIFICATIONS

96510 Tune-Up Kit

• Tune-Up Kit contains high

and medium wear parts.

LIFETIME WARRANTY

To validate Dynabrade Lifetime Warranty, you must register each tool at: www.dynabrade.com. Registration of each tool at website is required.

Dynabrade will not honor Lifetime Warranty on unregistered tools. Please view the entire Lifetime Warranty Policy at : www.dynabrade.com.

59000 ..................56620

59003 ..................56621

59004 ..................56622

59005 ..................56623

59008 ..................56624

59009 ..................56625

59010 ..................56626

59013 ..................56627

59014 ..................56628

58054 ..................56669

59015 ..................56629

59018 ..................56630

59019 ..................56631

59020 ..................56632

59023 ..................56633

59024 ..................56634

59025 ..................56635

59028 ..................56636

59029 ..................56637

59030 ..................56638

59033 ..................56639

59034 ..................56640

59035 ..................56641

59038 ..................56642

59039 ..................56643

59040 ..................56644

59043 ..................56645

59044 ..................56646

59100 ..................56647

59103 ..................56648

59104 ..................56649

59105 ..................56650

59108 ..................56664

59109 ..................56665

59110 ..................56666

59113 ..................56667

59114 ..................56668

Model # Housing # Model # Housing # Model # Housing # Model # Housing #

Motor .25 hp (186 W) • Motor 12,000 RPM • Tool Height 3-1/2" (89 mm) • Pad Thread 5/16"-24 Female

Air Inlet Thread 1/4" NPT • Hose I.D. Size 1/4" (6 mm) • Air Flow Rate 14 SCFM/396 LPM •

Air Pressure 90 PSIG (6.2 Bar)

Sound Level is the pressure

measurement according to the method

outlined in ISO regulation ISO-15744

Loading...

Loading...