Dynabrade 57923, 57922, 57924, 57925, 57926 Operating, Maintenance And Safety Instructions

...Page 1

Always operate, inspect and maintain this tool in accordance with the Safety Code for portable air tools

(ANSI B186.1) and any other applicable safety codes and regulations. Please refer to Dynabrade

’s

Warning/Safety Operating Instructions for more complete safety information.

Parts Page Reorder No. PD03•11

Effective February, 2003

Supercedes PD00•03R

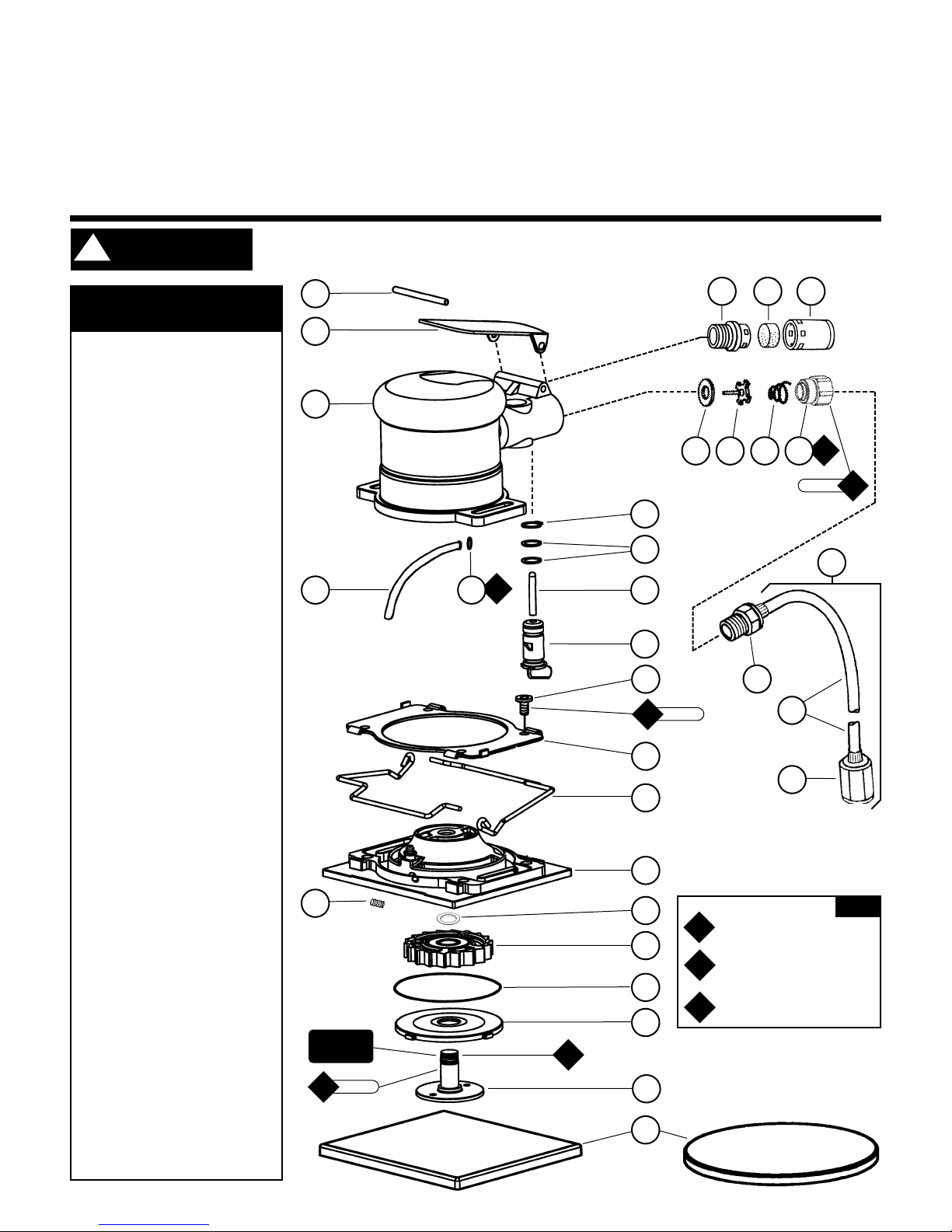

Air Motor and Machine Parts

Models:

57920 – 4" x 4-5/16" Thin, Vinyl Pad

57922 – 5" Dia. Thick, Vinyl Pad

57923 – 4-1/4" x 4-1/2" Thick, Hook Pad

57924 – 5" Dia. Thick, Hook Pad

57925 – 4-1/4" x 4-1/2" Thick, Vinyl Pad

57926 – 6" Dia. Thick, Vinyl Pad

57927 – 6" Dia. Thick, Hook Pad

Dynabug

“Model T” Sander

A

8

A

T

Adhesive: A

2

= Loctite #271

A8= Loctite #567

Torque: N•m x 8.85 = In. - lbs.

G

Grease: G

1

= Lubriplate

630 AA

1

2

3

4

14

Index Key

No. Part # Description

1 95979 Pin

2 57986 Lever

3 57921 Housing - 57920

57963 Housing - 57922

57964 Housing - 57923

57967 Housing - 57924

57941 Housing - 57925

57911 Housing - 57926

57912 Housing - 57927

4 57988 Inlet Hose Assembly

5 12156 O-Ring

6 95697 Snap Ring

7 01025 O-Ring (2)

8 01477 Valve Stem

9 57064 Speed Regulator

10 95405 Button Head Screw (4)

11 57982 Clip Retainer

12 57980 Spring Clip (2)

(Used On Model-57920 Only)

13 57987 Square Base Plate Assy.

57997 Round Base Plate Assy.

14 96493 Set Screw

15 58092 Spacer

16 57981 Turbine Wheel Assembly

17 97121 O-Ring

18 57983 Base Plate Door

19 57979 Motor Shaft

20 57999 Vinyl Pad - 57920

56249 Vinyl Pad - 57922

57998 Hook Pad - 57923

56248 Hook Pad - 57924

56244 Vinyl Pad - 57925

56269 Vinyl Pad - 57926

56268 Hook Pad - 57927

21 57066 Muffler Body

22 56027 Muffler Insert

23 56028 Muffler Cap

24 01464 Seal

25 01472 Tip Valve

26 01468 Spring

27 01494 Inlet Bushing

28 96457 Male Hose Adapter

29 96458 Hose

30 96456 Female Hose Adapter

31 96455 Hose Assembly

6

7

8

9

10

11

28

31

29

30

12

13

17

16

15

18

19

20

21 23

22

24 26

25 27

G

1

A

2

5

15 N•m

T

23 N•m

T

3.4 N•m

T

KEY

Left Hand

Threads

!

WARNING

Page 2

2

(PD03•11)

One Year Warranty

Following the reasonable assumption that any inherent defect which might prevail in a product will become apparent to the user within one

year from the date of purchase, all equipment of our manufacture is warranted against defects in workmanship and materials under normal

use and service. We shall repair or replace at our factory, any equipment or part thereof which shall, within one year after delivery to the

original purchaser, indicate upon our examination to have been defective. Our obligation is contingent upon proper use of Dynabrade tools

in accordance with factory recommendations, instructions and safety practices. It shall not apply to equipment which has been subject to

misuse, negligence, accident or tampering in any way so as to affect its normal performance. Normally wearable parts such as bearings,

contact wheels, rotor blades, etc., are not covered under this warranty.

Important Operating, Maintenance and Safety Instructions

Carefully read all instructions before operating or servicing any Dynabrade®Abrasive Power Tool.

Warning: Hand, wrist and arm injury may result from repetitive work motion and overexposure to vibration.

Important: Turbine air motor, no oil required.

Operating Instructions:

Warning: Eye, face, sound, respiratory and body protection must be worn while operating power tools. Failure to do so may result in serious

injury or death. Follow safety procedures posted in workplace.

1. With power source disconnected from tool, securely fasten abrasive/accessory on tool.

2. Install air fitting into inlet bushing of tool. Important: Secure inlet bushing of tool with a wrench before attempting to install the air fitting

to avoid damaging valve body housing.

3. Connect power source to tool. Be careful not to depress throttle lever in the process.

Maintenance Instructions:

1. Check tool speed regularly with a tachometer. If tool is operating at a higher speed than the RPM marked on the tool, the tool should be

serviced to correct the cause before use.

2. Some silencers on air tools may clog with use. Clean and replace as required.

3. An Air Line Filter-Regulator must be used with this air tool to maintain all warranties. Dynabrade recommends the following: 11402 Air

Line Filter-Regulator – Provides accurate air pressure regulation, two-stage filtration of water contaminants.

Operates 40 SCFM @ 100 PSIG and has 3/8" NPT female ports.

4. Use only genuine Dynabrade replacement parts. To reorder replacement parts, specify the Model #, Serial #, and RPM

of your machine.

5. A Motor Tune-Up Kit (P/N 96169) is available which includes assorted parts to help maintain motor in peek operating condition.

Please refer to Dynabrade’s Preventative Maintenance Schedule for a guide to expectant life of component parts.

6. Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids,

esters, keytones, chlorinated hydrocarbons or nitro carbons.

• Important: User of tool is responsible for following accepted safety codes such as those published by the American National

Standards Institute (ANSI).

• Always disconnect power supply before changing abrasive/accessory or making machine adjustments.

• Inspect abrasives/accessories for damage or defects prior to installation on tools.

• Please refer to Dynabrade’s Warning/Safety Operating Instructions Tag (Reorder No. 95903) for more complete safety information.

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality

pneumatic motors can most often be traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water

contained in the air supply into motor bearings causing early failure. It often scores the cylinder walls and the rotor blades resulting in limited

efficiency and power. Our warranty obligation is contingent upon proper use of our tools and cannot apply to equipment which has been

subjected to misuse such as unclean air, wet air or a lack of lubrication during the use of this tool.

Safety Instructions:

Products offered by Dynabrade should not be converted or otherwise altered

from original design without expressed written consent from Dynabrade, Inc.

Page 3

Motor Assembly/Disassembly Instructions – “Model T” Dynabug

Important: Manufacturers warranty is void if tool is disassembled before warranty expires.

A complete Repair Kit, part number 96169, is available which includes special tools for correct disassembly/assembly of tool.

To Disassemble

1. Disconnect tool from power source.

2. Unhook 57980 Spring Clips and remove sanding pad (if necessary).

3. Unscrew 95405 Button Head Screws (4).

4. Remove 57980 Spring Clips (if equipped) and lift 57982 Clip Retainer up about 1/2", to expose 57987 or 57997 Base Plate Assembly.

5. Remove 57988 Hose from 57987 or 57997 Base Plate Assembly.

6. Disassemble housing assembly from base plate assembly, by pulling apart.

7. Invert assembly and insert adjustable pin spanner wrench or 50971 Lock Ring Wrench to 57979 Motor Shaft, and remove

(left-hand threads).

8. Remove 58092 Spacer from motor shaft. Note: Spacer orientation on motor shaft.

9. Remove 57981 Turbine Wheel Assembly. Note: Turbine orientation of wheel assembly on motor shaft.

To Assemble:

Important: Be certain parts are clean and in good repair before assembling.

1. Slide 57983 Base Plate Door onto 57979 Motor Shaft.

2. Replace 57981 Turbine Wheel Assembly on motor shaft using the same orientation as when it was disassembled.

3. Replace 58092 Spacer on motor shaft using the same orientation as when motor was disassembled.

4. Install 97121 O-Ring onto base plate assembly.

5. Apply a slight amount of #271 Loctite®(or equivalent) to threads of 57979 Motor Shaft and install onto base plate assembly, torque 15

N•m/133 in. - lbs.

6. Install 57988 Inlet Hose assembly into housing. Apply some grease to 12156 O-Ring and install.

Note: Speed regulator should be installed at this time. Slide other end of tube over barb fitting in base plate.

7. Install housing assembly onto base plate assembly.

8. Install 57980 Spring Clips onto base plate assembly (if necessary).

9. Slide 57982 Clip Retainer down onto 57987 or 57997 Base Plate Assembly and install 95405 Button Head Screws (4), torque 3.4

N•m/20 in. - lbs.

Tool Assembly Complete. Please allow 30 minutes for adhesives to cure before operating tool.

Valve and Speed Regulator Assemblies:

1. Secure housing in vice using 57092 Collar or padded jaws.

2. Remove inlet bushing, 01468 Spring, 01472 Tip Valve and 01464 Seal from housing.

3. Remove 95697 Snap Ring. Push the speed regulator and valve stem out of the housing. Remove the 01025 O-Rings (2).

4. Place new 01025 O-Rings (2) on the speed regulator and place in housing with valve stem. Install new 95697 Snap Ring.

5. Place new 01464 Seal in housing, Using tweezers or needle nose pliers, place the tip valve into housing so that the pin goes through the

hole in the valve stem. Place new 01468 Spring into housing so small end is towards tip valve.

6. Spread 1 drop of #567 Loctite®(or equivalent) around the threads of the inlet bushing and tighten into housing to 23 N•m/200 in. - lbs.

Note: This tool is an oil-free Dynabrade Tool. Therefore no air lube should be placed into the tool. Operate the machine for approximately 30

seconds before application to workpiece to determine if machine is working properly and safely.

Loctite® is a registered trademark of the Loctite Corp.

3

Model Motor Motor Sound Air Flow Rate Air Pressure Air Inlet Weight Length Height

Number HP (W) RPM Level CFM/SCFM (LPM) PSIG (Bars) Thread Pound (kg) Inch (mm) Inch (mm)

57920 N/A 20,000 83 dB(A) 1/9 (255) 90 (6.2) 1/4" NPT 1 (.45) 5 (127) 3 (76)

57922 N/A 20,000 83 dB(A) 1/9 (255) 90 (6.2) 1/4" NPT 1 (.45) 5 (127) 3 (76)

57923 N/A 20,000 72 dB(A) 1/9 (255) 90 (6.2) 1/4" NPT 1 (.5) 5 (127 3 (76)

57924 N/A 20,000 72 dB(A) 1/9 (255) 90 (6.2) 1/4" NPT 1 (.5) 5 (127 3 (76)

57925 N/A 20,000 83 dB(A) 1/9 (255) 90 (6.2) 1/4" NPT 1 (.45) 5 (127) 3 (76)

57926 N/A 20,000 72 dB(A) 1/9 (255) 90 (6.2) 1/4" NPT 1 (.5) 5 (127) 3 (76)

57927 N/A 20,000 72 dB(A) 1/9 (255) 90 (6.2) 1/4" NPT 1 (.5) 5 (127) 3 (76)

Additional Specifications: Hose I.D. Size 1/4" (8 mm)

Machine Specifications

Page 4

96169 Motor Tune-Up Kit

•

Includes assorted parts to help

maintain and repair motor.

98846 Hook-Face Backing

•

A replacement Hook-Face Backing

for 57978 Square Base Plate.

98848 Hook-Face Backing

•

A replacement Hook-Face Backing

for 57943 Round Base Plate.

57092 Repair Collar

•

Specially designed collar for use in vise to

prevent damage to motor housing during

disassembly/assembly.

50971 Lock Ring Tool

•

Lock Ring Tool has a 3/8 in. square socket

for use with 3/8 in. drive; breaker bar,

ratchet head, or torque wrenches.

Abrasive Grit

80 100 120 150 180 220

93101 93102 93103 93104 93105 93106

120 Grit & Coarser – 125/Roll; 10 Rolls = Unit. 150 Grit & Finer – 175/Roll;

6 Rolls = Unit. Complete rolls only. Note: Other grits available upon request.

Abrasive Grit

80 100 120 150 180 220

93051 93052 93053 93054 93055 93056

120 Grit & Coarser – 125/Roll; 8 Rolls = Unit. 150 Grit & Finer – 250/Roll;

4 Rolls = Unit. Complete rolls only. Note: Other grits available upon request.

5" (127mm) Diameter PSA & Hook-Face Discs

Reattachable & Non-Adhesive Abrasive Sheets

Abrasive Grit

Sheet Size Description 80 120 180 320

4-1/2" (114mm) x 4-1/4" (108 mm) PSA w/Liner 93840 93841 93842 93843

4-1/2" (114mm) x 4-1/4" (108 mm) Hook-Face 93850 93851 93852 93853

4-1/2" (114mm) x 5-1/2" (140 mm) No Adhesive 93854 93855 93856 93857

Coated Aluminum Oxide Sheet Abrasives

Unit = 100 Sheets

Premium Aluminum Oxide Discs / PSA Mounted

Silicon Carbide Discs / PSA Mounted

Abrasive Grit

36 40 60

93311 93312 93313

125 Discs = Unit.

Aluminum Oxide Discs / Reattachable

Abrasive Grit

80 100 120 150 180 220

93209 93200 93201 93202 93203 93204

120 Grit & Coarser – 125/Roll; 10 Rolls = Unit. 150 Grit & Finer – 175/Roll;

6 Rolls = Unit. Complete rolls only. Note: Other grits available upon request.

Abrasive Grit

80 100 120 150 180 220

93069 93070 93071 93072 93073 93074

120 Grit & Coarser – 125/Roll; 8 Rolls = Unit. 150 Grit & Finer – 250/Roll;

4 Rolls = Unit. Complete rolls only. Note: Other grits available upon request.

6" (152mm) Diameter PSA & Hook-Face Discs

Premium Aluminum Oxide Discs / PSA Mounted

Silicon Carbide Discs / PSA Mounted

Coated Abrasive Sheets & Discs For Dynabug “Model T” Finishing Sanders

Optional Accessories

DYNABRADE

®

DYNABRADE, INC., 8989 Sheridan Drive • Clarence, NY 14031-1490 • Phone: (716) 631-0100 • Fax: 716-631-2073 • International Fax: 716-631-2524

DYNABRADE EUROPE S.àr.l., Zone Artisanale • L-5485 Wormeldange—Haut, Luxembourg • Telephone: 352 76 84 94 1 • Fax: 352 76 84 95 1

© DYNABRADE, INC., 2003 PRINTED IN USA

Visit Our Web Site: www.dynabrade.com Email: Customer.Service@Dynabrade.com

Loading...

Loading...