Dynabrade Dynafine 10800, Dynafine 10810, Dynafine 10820, Dynafine 10821, 57900 Safety, Operation And Maintenance Manual

...

Parts Page Reorder No. APD08•02

Effective January, 2008

Supersedes APD97•08

Dynafine®Sanders

Detail Sander/Finger/Wet

Air Tool Manual – Safety, Operation and Maintenance

Models: (Sander)

10800 – 13,000 RPM, Detail Sander

10810 – Detail Sander Versatility Kit

10820 – 13,000 RPM, Finger Sander

10821 – Finger Sander Versatility Kit

Model: (Wet)

10880 – 13,000 RPM, Wet Sander

SAFETY LEGEND

G

Read and understand tool manual before

work starts to reduce risk of injury to

operator, visitors, and tool.

Eye protection must be worn at all times,

eye protection to conform to ANSI Z87.1.

Respiratory protection to be used when exposed to

contaminants that exceed the applicable threshold

limit values required by law.

Practice safety requirements. Work alert,

have proper attire, and do not operate tools under

the influence of alcohol or drugs.

Ear protection to be worn when exposure to sound,

exceeds the limits of applicable Federal, State or

local statues, ordinances and/or regulations.

Air line hazard, pressurized supply lines and flexible

hoses can cause serious injury. Do not use damaged,

frayed or deteriorated air hoses and fittings.

Read and understand this tool manual before operating your air tool. Follow all safety rules for the protection of operating personnel

as well as adjacent areas. Always operate, inspect and maintain this tool in accordance with the American National Standards

Institute (ANSI) Safety Code for Portable Air Tools – B186.1. For additional safety information, refer to Safety Requirements for the

Use, Care and Protection of Abrasive Wheels – ANSI B7.1, Code of Federal Regulation – CFR 29 Part 1910, European Committee for

Standards (EN) Hand Held Non-Electric Power Tools – Safety Requirements and applicable State and Local Regulations.

SAFETY INSTRUCTIONS

Carefully Read all instructions before operating or servicing any Dynabrade

®

Abrasive Power Tool.

Products offered by Dynabrade are not to be modified, converted or otherwise altered from the original design without expressed written

consent from Dynabrade, Inc.

Tool Intent: Dynafine

®

Sanders are designed for finishing. Excellent for removing milling and machining marks from wood, solid surface and metal. Defect

removal in painted surfaces and clear coats.

Do Not use tool for anything other than its intended applications.

This power tool is not intended for use in potentially explosive atmospheres and is not insulated against contact with electrical power.

Training: Proper care, maintenance, and storage of your tool will maximize its performance.

• Employer's Responsibility – Provide Dynafine

®

operators with safety instructions and training for safe use of tools and accessories.

(continued on next page)

SAVE THIS DOCUMENT, EDUCATE ALL PERSONNEL

FIND THE MOST CURRENT OFFERING OF ACCESSORIES AND SUPPORT DOCUMENTS @ WWW.DYNABRADE.COM

Some dust created by sanding, grinding, drilling, and other construction activities contain chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

Model 10800

AUTOMOTIVE

WARNIN

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

SAFETY INSTRUCTIONS - Cont.

Accessory Selection:

• Abrasive/accessory RPM (speed) rating MUST be approved for AT LEAST the tool RPM rating.

• Before mounting an accessory, visually inspect for defects. Do not use defective accessories.

• Mount only recommended accessories. See back page of manual and Dynabrade literature.

• Follow tool specifications before choosing size and type of accessory.

• Only use recommended fittings and air line sizes. Air supply hoses and air hose assemblies must have a minimum working pressure rating of 150 PSIG

(10 bars, g) or 150 percent of the maximum pressure produced in the system, whichever is higher. (See tool Machine Specifications table.)

OPERATING INSTRUCTIONS

Warning: Always wear personal protection equipment. Operator of tool is responsible for following: accepted eye, face, respiratory, hearing and

body protection. Adjacent personnel must be protected from potential injury.

Caution: Hand, wrist and arm injury may result from repetitive work, motion and overexposure to vibration.

• Keep hand and clothing away from working end of the air tool.

Operation: Be sure that any loose clothing, hair and all jewelry is properly restrained.

• Secure inlet bushing on air tool with a wrench before attempting to install the air fitting to avoid damaging housing assembly.

• Check tool RPM (speed) with tachometer with air pressure set at 90 PSIG (6.2 Bars, g) while the tool is running. If tool is operating at a higher speed than

the RPM marked on the tool housing, or operating improperly, the tool must be serviced and corrected before use.

Caution: Tool RPM must never exceed abrasive/accessory RPM rating. Check accessory manufacturer for details on maximum operating speed or special

mounting instructions.

• With power source disconnected from air tool, mount recommended accessory.

• Connect air tool to power source. Be careful NOT to depress throttle lever in the process.

Do not expose air tool to inlet pressure above 90 PSIG or (6.2 Bars, g).

Caution: After installing the accessory, the tool must be started at a reduced speed to check for good balance.

Gradually increase tool speed. DO NOT USE if tool vibration is excessive. Correct cause, and retest to insure safe operation.

• Make sure that work area is uncluttered, and visitors are at a safe range from the tools and debris.

• Use a vise or clamping device to hold work piece firmly in place.

• Do not apply excessive force on tool or apply “rough” treatment to it.

• Always work with a firm footing, posture and proper lighting.

Report to your supervisor any condition of the tool, accessories, or operation you consider unsafe.

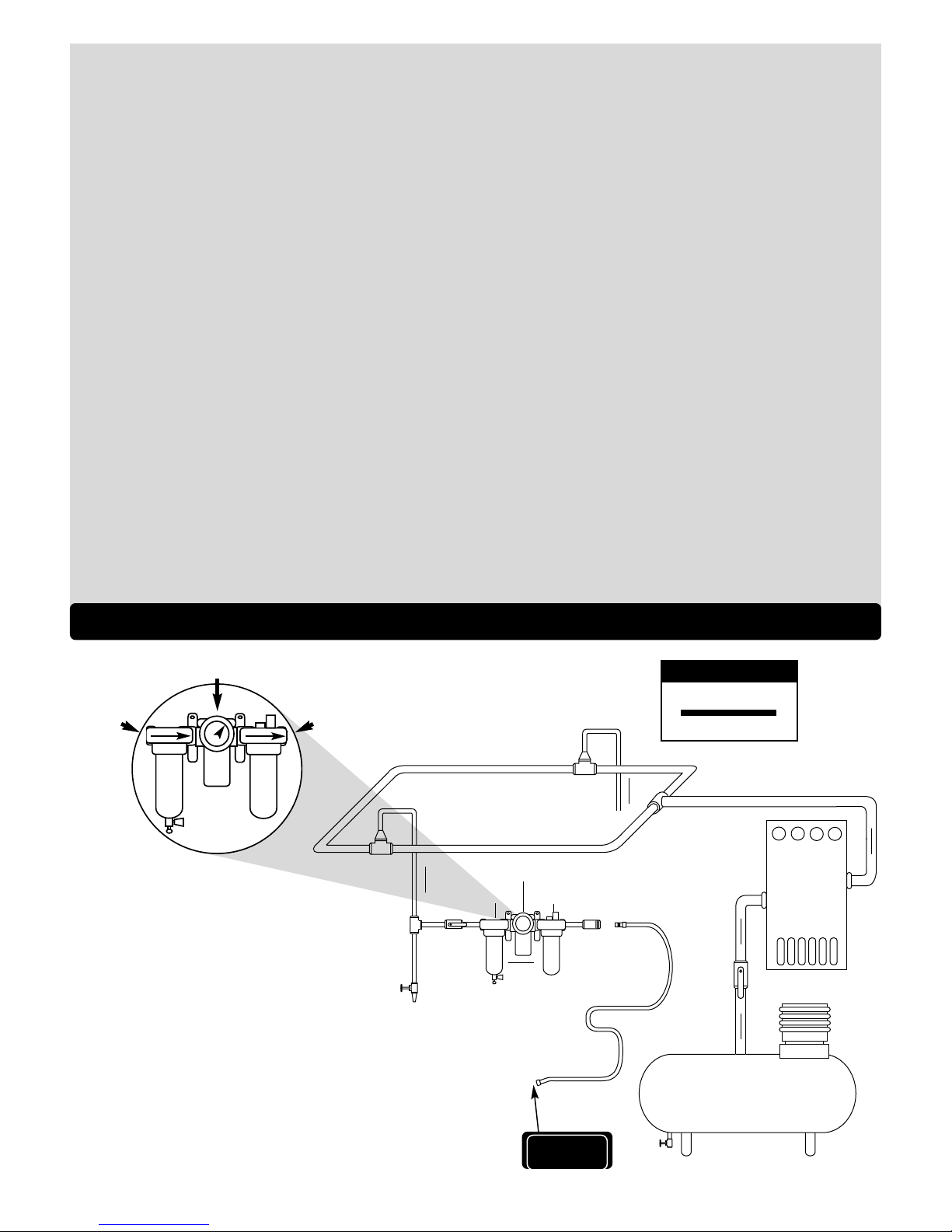

To Tool Station

Closed Loop Pipe System

(Sloped in the direction of air flow)

Ball

Valve

Ball

Valve

Filter

Regulator

Lubricator

Air Flow

Drain

Valve

Drain

Valve

Air Tool

Air Compressor

and Receiver

Drain

Valve

Air Hose

Air Flow

Refrigerated

Air Dryer

2

Filter

Regulator

Lubricator

90 PSIG

(6.2 Bar, g)

Air System

1 DROP/MIN.

20 SCFM

LUBRICATOR SETTING

•

Dynabrade Air Power Tools are designed to

operate at 90 PSIG (6.2 Bar/620 kPa) maximum

air pressure at the tool inlet, when the tool is

running. Use recommended regulator to control

air pressure.

•

Ideally the air supply should be free of moisture.

To facilitate removing moisture from air supply, the

installation of a refrigerated air dryer after the

compressor and the use of drain valves at each

tool station is recommended.

➤

➤

➤

➤

➤

➤

90 PSIG MAX

(6.2 Bar, g)

Maintenance Instructions

Important:A preventative maintenance program is recommended whenever portable power tools are used.

•

Use only genuine Dynabrade replacement parts to insure quality. To order replacement parts, specify Model#, Serial# and RPM of your air tool.

•

It is strongly recommended that all Dynabrade rotary vane air tools be used with a Filter-Regulator-Lubricator to minimize the possibility of misuse due

to unclean air, wet air or insufficient lubrication. Dynabrade recommends the following: 11411 Air Filter-Regulator-Lubricator (FRL) – Provides accurate

air pressure regulation and two stage filtration of water contaminants. Operates 55 SCFM/1,558 LPM @ 90 PSIG (6.2 Bar, g) with 1/2" NPT female ports.

•

Dynabrade recommends one drop of air lube per minute for each 20 SCFM/566 LPM (example: if the tool specification states 40 SCFM/1133 LPM, set

the drip rate on the filter-lubricator to 2 drops per minute). Dynabrade Air Lube (P/N 95842: 1 pt 473 ml) is recommended.

Routine Preventative Maintenance: Check free speed of tool using a tachometer. This tool should be speed checked on a regular basis.

•

Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids, esters,

ketones, chlorinated hydrocarbons or nitro carbons.

•

DO NOT clean or maintain tools with chemicals that have a low flash point (example: WD-40

®

).

•

A Motor Tune-Up Kit (P/N 96236) is available which includes high wear and medium wear motor parts.

•

Air tool labels must be kept legible at all times, if not, reorder label(s) and replace. User is responsible for maintaining specification information i.e.:

Model #, S/N, and RPM. (See Assembly Breakdown)

•

Blow air supply hose out prior to initial use.

•

Visually inspect air hoses and fittings for frays, visible damage and signs of deterioration. Replace damaged or worn components.

•

Refer to Dynabrade's Warning/Safety Operating Instructions Tag (Reorder No. 95903) for safety information.

After maintenance is performed on tool, add a few drops of Dynabrade Air Lube (P/N 95842) to the air line and start the tool a few times to lubricate air motor.

Check for excessive tool vibration.

Handling and Storage:

•

Use of tool rests, hangers and/or balancers is recommended.

•

Protect tool inlet from debris (see Notice below).

•

DO NOT carry tool by air hose or near the tool throttle lever.

•

Protect abrasive accessories from exposure to water, solvents, high humidity, freezing temperature and extreme temperature changes.

•

Store accessories in protective racks or compartments to prevent damage.

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances.The failure of quality pneumatic motors

can most often be traced to an unclean air supply or the lack of lubrication.Air pressure easily forces dirt or water contained in the air supply into motor

bearings causing early failure.It often scores the cylinder walls and the rotor blades resulting in limited efficiency and power.Our warranty obligation is

contingent upon proper use of our tools and cannot apply to equipment which has been subjected to misuse such as unclean air, wet air or a lack of

lubrication during the use of this tool.

One Year Warranty

Following the reasonable assumption that any inherent defect which might prevail in a product will become apparent to the user within one year from the

date of purchase, all equipment of our manufacture is warranted against defects in workmanship and materials under normal use and service.We shall

repair or replace at our factory, any equipment or part thereof which shall, within one year after delivery to the original purchaser, indicate upon our

examination to have been defective.Our obligation is contingent upon proper use of Dynabrade tools in accordance with factory recommendations,

instructions and safety practices.It shall not apply to equipment which has been subject to misuse, negligence, accident or tampering in any way so as to

affect its normal performance.Normally wearable parts such as bearings, contact wheels, rotor blades, etc., are not covered under this warranty.

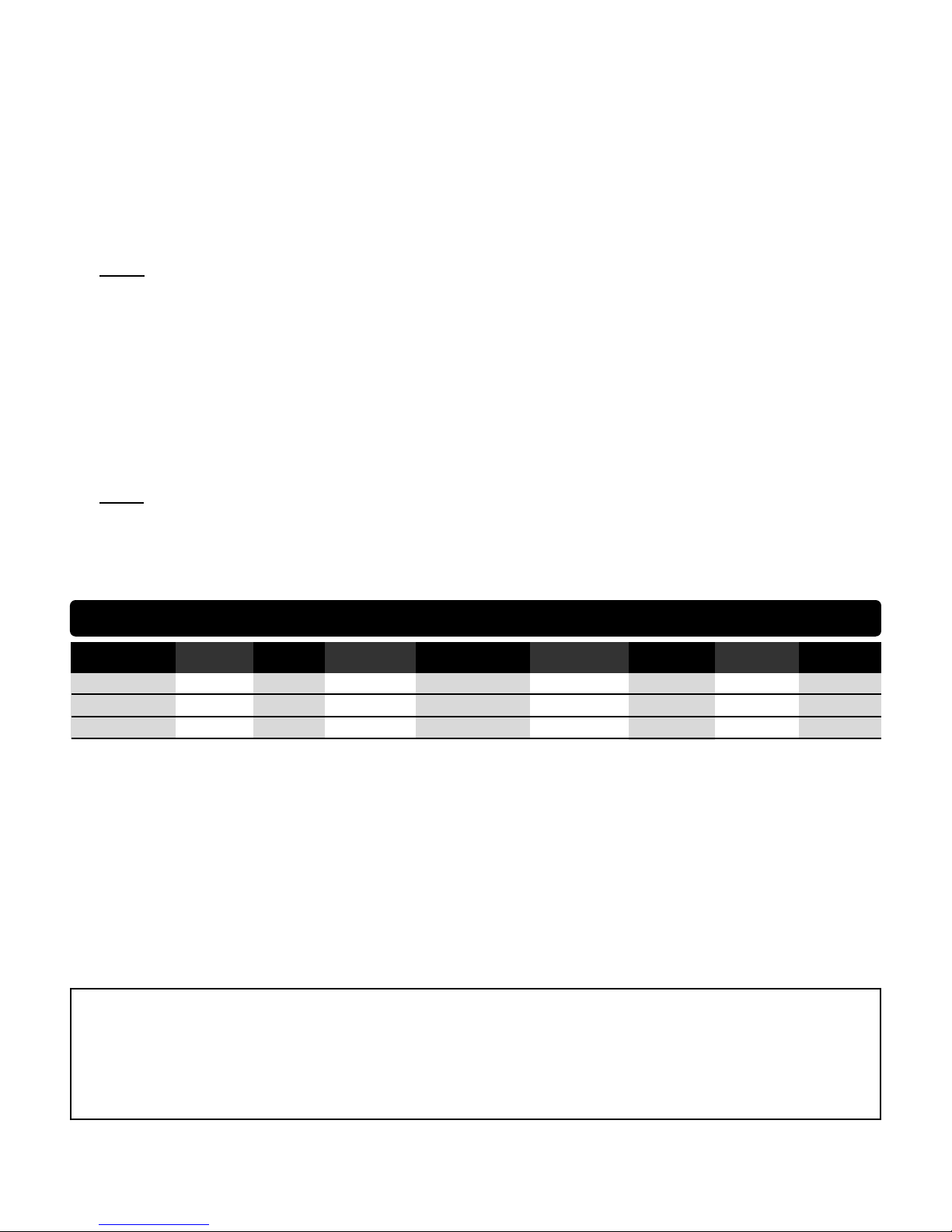

Machine Specifications

3

Model Motor Motor Sound Air Flow Rate Air Pressure Weight Length Height

Number hp (W) RPM Level SCFM (LPM) PSIG (Bars) Pound (kg) Inch (mm) Inch (mm)

10800/10810 .15 (118) 13,000 65 dB(A) 20 (566) 90 (6.2) 1.6 (.7) 9 (229) 3-3/4 (95)

10820/10821 .15 (118) 13,000 65 dB(A) 20 (566) 90 (6.2) 1.6 (.7) 11-3/4 (298) 4 (102)

10880 .15 (118) 13,000 65 dB(A) 20 (566) 90 (6.2) 1.6 (.7) 9 (229) 3-3/4 (95)

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose Size 1/4" (6 mm)

Sound Level is the pressure measurement according to the method outlined in ISO regulation ISO-15744

Loading...

Loading...