Page 1

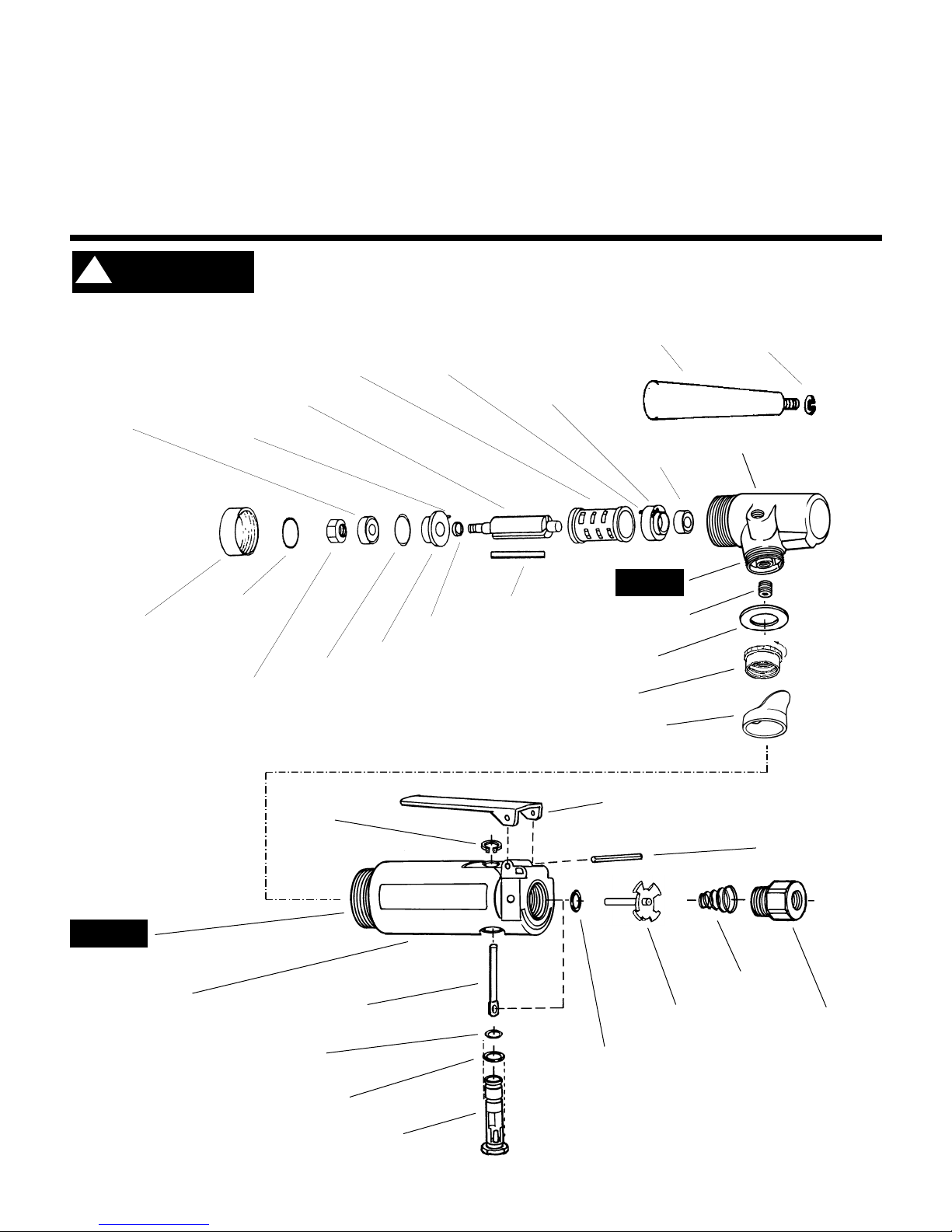

Parts Page Reorder No. PD94•47

Effective June, 1994

Model:

52700 — 18,000 RPM

Always operate, inspect and maintain this tool in accordance with the Safety Code for portable air tools

(ANSI B186.1) and any other applicable safety codes and regulations. Please refer to Dynabrade's

Warning/Safety Operating Instructions for more complete safety information.

.7 Hp/3" Gearless Depressed

Center Wheel Grinder

11535 Handle

01028 Cylinder

01185 Blade (4) (4/Pkg.)

55025 Rotor

01010 Spacer

01121 Shim (3/ Pkg.)

01007 Bearing

01708 Rotor Nut

95558 Retaining Ring

01738 Exhaust Cover

01744 Silencer

01008 Plate

01743 Bearing Plate

01009 Guide Pin

01009 Guide Pin

02649 Bearing

95042 Washer

See inside for Important Operating, Maintenance and Safety Instructions.

*Optional 01462 Safety lock

lever assembly available.

01739 Motor Housing

01558 Collar

01461 Lock Nut

01437 Plug

LEFT HAND

THREADS

RIGHT HAND

THREADS

01548 Gasket

*

01448 Throttle Lever

12132 Pin

01494 Inlet Bushing

01468 Spring

01472 Tip Valve

01449 Valve Stem

01020 O-Ring

01024 O-Ring

01464 Seal

01469 Regulator

01892 Valve Body

!

WARNING

Page 2

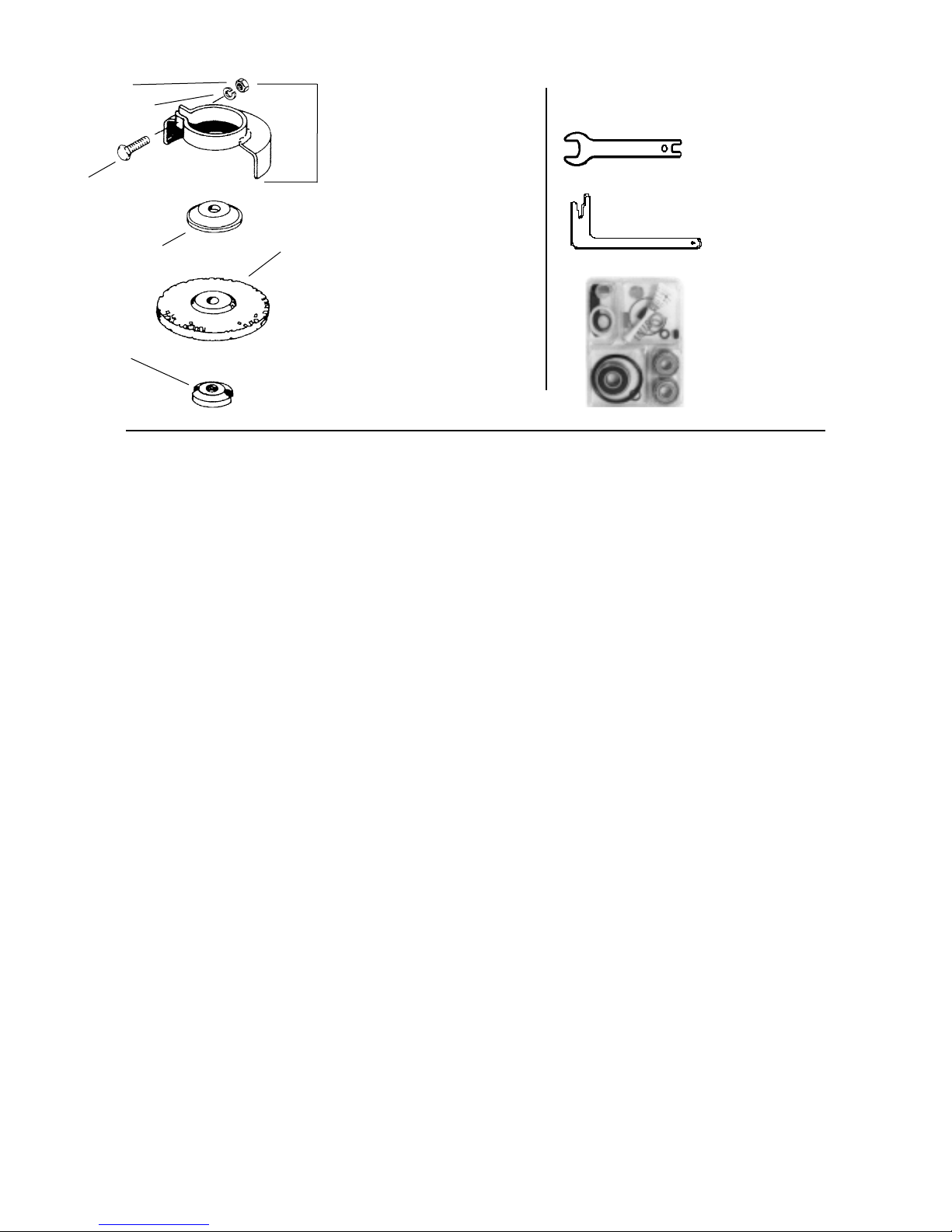

Wheel Guard Assembly

Wrenches

95281 19 mm wrench

Important Operating, Maintenance and Safety Instructions

Carefully read all instructions before operating or servicing this or any Dynabrade® Abrasive Power Tool.

Warning: Hand, wrist and arm injury may result from repetitive work motion and overexposure to vibration.

Important: All Dynabrade air tools must be used with a Filter-Regulator-Lubricator to maintain all warranties.

Operating Instructions:

Warning: Eye, face and body protection must be worn while operating power tools. Failure to do so may result in serious injury or

death. Follow safety procedures posted in workplace.

1. With power source disconnected from tool, securely fasten abrasive/accessory on tool.

2. Connect power source to tool. Be careful not to depress throttle lever in the process.

3. Check tool speed with tachometer. If tool is operating at a higher speed than the RPM marked on the tool or operating

improperly, the tool should be serviced to correct the cause before use.

Maintenance Instructions:

Products offered by Dynabrade should not be converted or otherwise altered from original design without

expressed written consent from Dynabrade, Inc.

1. Check tool speed regularly with a tachometer. If tool is operating at a higher speed than the RPM marked on the tool, the tool

should be serviced to correct the cause before use.

2. Some silencers on air tools may clog with use. Clean and replace as required.

3. All Dynabrade air motors should be lubricated with two drops of Dynabrade Air Lube (P/N 95842: 1pt. 473ml.) e v ery four hours of use.

4. An air line filter-regulator-lubricator must be used with this air tool to maintain all warranties. Dynabrade recommends the

following: 11289 Air Line Filter-Regulator-Lubricator — Provides accurate air pressure regulation, two-stage filtration of water

contaminants and micro-mist lubrication of pneumatic components. Operates 28 CFM @ 90 PSI has 3/8" NPT female ports.

Safety Instructions:

• Important: User of tool is responsible for following accepted safety codes such as those published by the American National

Standards Institute (ANSI).

• Never mount bonded grinding wheels.

• Operate machine for one minute before application to workpiece to determine if machine is working properly and safely before

work begins.

• Always use proper guards. Make sure guards are in proper position, secure and in good repair.

• Always disconnect power supply before changing abrasive or making machine adjustments.

• Inspect abrasives for damage or defects prior to installation on tools.

• Please refer to Dynabrade’s Warning/Safety Oper ating Instructions Tag (Reorder No. 95903) for more complete safety information.

• Warning: Hand, wrist and arm injury may result from repetitive work, motion and overexposure to vibration.

Important Safety Information

1) Always use eye, face and body protection.

2) Always use wheel guard.

3) For safe use of this tool, always comply

with OSHA, ANSI Standards B7.1 and B186.1.

Warning: Do Not Remove Wheel Guard.

95186 Nut

95179 Screw

95167 Washer

50227 Wheel Guard Assembly

Includes:

95167 Washer

95179 Screw

95186 Nut

50091 Front

Wheel Flange

Depressed Center Wheel (not included)

Note: Use only Type 27 Reinforced

Depressed Center Wheels.

50093 Back-Up

Wheel Flange

95270 Wrench

96045 Tune-Up Kit

Includes assorted parts to help

maintain motor in tip-top shape.

2

Page 3

Important: Manufactures warranty is void if tool is disassembled before warranty expires.

To Disassemble:

1. Secure air tool in vise using 52996 Repair Collar or padded jaws.

2. Remove grinding wheel, flanging and wheel guard.

3. With a 1-1/2" open-end wrench, remove exhaust co ver b y turning counter-clockwise.

4. Pull motor assembly from housing.

5. Reposition motor housing in vise so inlet bushing is facing upwards.

6. Unscrew 01494 Inlet Bushing turning counter-clockwise.

7. Using needle nose pliers, remove 01448 Spring, 01472 Tip Valve and 01464 Seal.

8. Resecure housing in vise so throttle lever and 12132 Pin are accessible.

9. Using a 2.5mm diameter drift pin and a hammer, tap 12132 Pin out from housing and remove throttle lever.

10. Remove 95558 Retaining Ring and push 01469 Speed Regulator from Housing.

Optional: To disassemble valve body from motor housing, peel back 01558 Collar to expose 01462 Lock Nut. Unscrew lock

nut/valve body from housing (left hand threads).

Motor Disassembly:

1. Remove 01708 Rotor Nut from rotor shaft by inserting 3/16" hex wrench through rotor nut and into rotor shaft.

Twist rotor nut from shaft.

2. Remove 01008 Front Bearing Plate, cylinder, blades (4) and 01010 Spacer from rotor. Note: 01007 Bearing,01008 Front

Bearing Plate and 01010 Spacer are a slip fit onto rotor.

3. Press rotor from 01743 Rear Bearing Plate. Press 02649 Bearing from bearing plate.

Motor disassembly is complete.

Motor Reassembly (Be sure parts are clean and in good repair before reassembly):

1. Place rotor in padded vise with threaded spindle facing upwards.

2. Slip 01010 Spacer onto rotor.

3. Place a .002" shim into 01008 Front Bearing Plate as an initial spacing (Note: 01121 Shim Pak contains .001" and .002"

shims) and slip 01007 Bearing into plate.

4. Install Bearing/Bearing Plate assembly onto rotor.

5. Tighten 01708 Rotor Nut onto rotor (torque to 150 in. lbs.).

6. Check clearance between rotor and bearing plate by using a .001" feeler gauge. Clearance should be at .001" to .0015".

Adjust clearance by repeating steps 1-5 with different shim if necessary.

7. Once proper rotor/gap clearance is achieved, install well lubricated 01185 Blades (4) into rotor slots. Dynabrade air lube P/N

95842 is recommended for lubrication.

8. Install cylinder over rotor. Be sure air inlet holes of cylinder face away from bearing plate.

9. Press 02649 Rear Bearing into 01743 Rear Bearing Plate. Press bearing/bearing plate assembly onto rotor . Be sure that pin and air

inlet holes line-up with pin slot and air inlet holes in cylinder. Important: Fit must be snug between bearing plates and cylinder. If too

tight, rotor will not turn freely. Rotor must then be lightly tapped at press fit end so it will turn freely while still maintaining a

snug fit. A loose fit will not achieve the proper preload of motor bearings.

10. Secure motor housing in padded vise so motor cavity faces upwards.

11. Install motor assembly into housing. Be sure motor drops all the way into housing.

12. Insert 01744 Silencer into exhaust cover and install onto motor housing (torque 150 in. lbs.).

13. Motor adjustment must now be checked. With motor housing still mounted in vise, pull end of rotor and twist (10-15 lbs. force),

rotor should turn freely without drag. If drag or rub is felt, then increase preload or remove shim. Also, push end of rotor and

twist (10-15 lbs. force), rotor should turn freely without drag. If drag or rub is felt, then deload or add shim.

Valve Stem/Body Reassembly:

1. Insert 01469 Speed Regulator Assembly into valve body. Secure with 95558 Retaining Ring.

2. Secure valve body in vise using 52996 Repair Collar or padded jaws with air inlet facing upwards and throttle lever accessible.

3. Insert 01464 Seal into housing.

4. Line-up the hole in the 01449 Valve Stem with the hole in the housing (looking past brass bushing). Using needle nose pliers,

insert 01472 Tip Valve so that the metal pin passes through the hole in the valve stem.

5. Install 01468 Spring (small end first).

6. Apply 1 drop of #271 Loctite (or equivalent) to threads of 01494 Inlet Bushing and install into valve body (torque 34.0 N•m 300 lbs. in.).

7. Install throttle lever and 12132 Pin. Remove valve body from vise.

Tool Assembly is complete. Please allow 30 minutes for adhesives to cure before operating tool.

Important: Motor should now be tested for proper operation at 90 PSI. If motor does not operate properly or operates at a higher

RPM than marked on the tool, the tool should be serviced to correct the cause before use.

Note: Throttle lever is preset at the factory at an 11:00 o’clock position.

Loctite is a registered trademark of 3M Company.

Service/Repair Instructions — .7 Hp/3" Gearless Depressed Center Wheel Grinder

Please refer to parts breakdown for part identification.

3

Page 4

DYNABRADE

®

DYNABRADE, INC., 8989 Sheridan Drive • Clarence, New York 14031-1490 • Telephone: (716) 631-0100 • Fax: 716-631-2073 • International Fax: 71-231-2524

DYNABRADE EUROPE s.a.r .l., Zone Artisanale • L-5485 Wormeldange—Haut, Luxembourg • Telephone: 352 76 84 94 • Fax: 352 76 84 95

©DYNABRADE, INC., 1994 PRINTED IN USA

Toll Free (U.S.A.) 1-800-828-7333

Toll Free (Can.) 1-800-344-1488

Loading...

Loading...