Page 1

SAFETY INSTRUCTIONS

Carefully Read all instructions before operating or servicing any Dynabrade

®

Abrasive Power Tool.

Products offered by Dynabrade are not to be modified, converted or otherwise altered from the original design without expressed written consent from Dynabrade, Inc.

Tool Intent: Vacuum Disc Sander is ideal for coatings removal in non-ferrous metal and non-spark applications.

Do Not use tool for anything other than its intended applications.

This power tool is not intended for use in potentially explosive atmospheres and is not insulated against contact with electrical power.

Training: Proper care, maintenance, and storage of your air tools will maximize their performance.

• Employer's Responsibility – Provide Vacuum Disc Sander operators with safety instructions and training for safe use of tools and accessories.

Accessory Selection:

• Use only 2" Locking-Type Sanding Discs.

• Abrasive/accessory RPM (speed) rating MUST be approved for AT LEAST the tool RPM rating.

• Before mounting an accessory, visually inspect for defects. Do not use defective accessories.

• Mount only recommended accessories. Reference Dynabrade catalog and this tool manual.

• DO NOT USE- grinding wheels or cut-off wheels.

Parts Page Reorder No. PD08•33

Effective July, 2008

2" Dia. Vacuum Disc Sanders

Air Tool Manual – Safety, Operation and Maintenance

51235 – 25,000 RPM, Self-Generated Vacuum

1" O.D. Port

2" (51mm) Discs Maximum

51236 – 25,000 RPM, Central Vacuum

1-1/4" I.D. Threaded Hose Cuff

2" (51mm) Discs Maximum

WARNING

Read and understand tool manual before

work starts to reduce risk of injury to

operator, visitors, and tool.

WARNING

Eye protection must be worn at all times,

eye protection to conform to ANSI Z87.1.

WARNING

Respiratory protection to be used when exposed to

contaminants that exceed the applicable threshold

limit values required by law.

WARNING

Air line hazard, pressurized supply lines and flexible

hoses can cause serious injury. Do not use damaged,

frayed or deteriorated air hoses and fittings.

SAVE THIS DOCUMENT, EDUCATE ALL PERSONNEL

SAFETY LEGEND

WARNIN

G

WARNING

Ear protection to be worn when exposure to sound,

exceeds the limits of applicable Federal, State or

local statues, ordinances and/or regulations.

Read and understand this tool manual before operating your air tool. Follow all safety rules for the protection of operating personnel

as well as adjacent areas. Always operate, inspect and maintain this tool in accordance with the American National Standards

Institute (ANSI) Safety Code for Portable Air Tools – B186.1. For additional safety information, refer to Safety Requirements for the

Use, Care and Protection of Abrasive Wheels – ANSI B7.1, Code of Federal Regulation – CFR 29 Part 1910, European Committee for

Standards (EN) Hand Held Non-Electric Power Tools – Safety Requirements and applicable State and Local Regulations.

WARNING

Some dust created by sanding, grinding, drilling, and other construction activities contain chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

WARNING

Practice safety requirements. Work alert,

have proper attire, and do not operate tools under

the influence of alcohol or drugs.

FIND THE MOST CURRENT OFFERING OF SUPPORT DOCUMENTS AND ACCESSORIES @ WWW.DYNABRADE.COM

Model 51236 Shown

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Page 2

To Tool Station

Closed Loop Pipe System

(Sloped in the direction of air flow)

Ball

Valve

Ball

Valve

Filter

Regulator

Lubricator

Air Flow

Drain

Valve

Drain

Valve

Air Compressor

and Receiver

Drain Valve

Air Hose

Air Flow

Refrigerated

Air Dryer

2

Filter

Regulator

Lubricator

90 PSIG

(6.2 Bar)

SAFETY INSTRUCTIONS CONT.

• Follow tool specifications before choosing size and type of accessory.

• Only use recommended fittings and air line sizes. Air supply hoses and air hose accessories must have a minimum working pressure of 150 PSIG (10 Bars, g) or 150 percent of the maximum pressure

produced in the system, whichever is higher. (See tool Machine Specifications table.)

OPERATING INSTRUCTIONS

Warning: Always wear personal protective equipment. Operator of tool is responsible for the following: accepted eye, face, respiratory, hearing and body protection.

Caution: Hand, wrist and arm injury may result from repetitive work, motion and overexposure to vibration.

• Keep hand and clothing away from working end of the air tool.

• Working end of tool has a potential of cutting and severing.

Operation: Be sure that any loose clothing, hair and all jewelry is properly restrained.

• Secure inlet bushing on air tool with a wrench before attempting to install the air fitting to avoid damaging housing assembly.

• BEFORE MOUNTING A BACK-UP PAD, after all tool repairs and whenever a Vacuum Disc Sander is issued for use, check tool RPM (speed) with tachometer with air pressure set at 90

PSIG while the tool is running. If tool is operating at a higher speed than the RPM marked on the tool housing, or operating improperly, the tool must be serviced and corrected before use.

Caution: Tool RPM must never exceed abrasive/accessory RPM rating. Check accessory manufacturer for details on maximum operating speed or special mounting instructions.

• Disconnect air hose from tool when changing abrasive discs.

• Connect air tool to power source. Be careful NOT to depress throttle lever in the process. Do not expose air tool to inlet pressure above 90 PSIG or (6.2 Bars).

Caution: After installing the accessory, before testing or use and/or after assembling tool, the Vacuum Disc Sander must be started at a reduced speed to check for good balance. Gradually

increase tool speed. DO NOT USE if tool vibration is excessive. Correct cause, and retest to insure safe operation. Test tool at its free speed (RPM) in a protected area for at least one minute before

applying the tool to the work.

• Release throttle lever when air supply is interrupted.

• Make sure that work area is uncluttered, and visitors are at a safe range from the tools and debris.

• Air tools are not intended for use in explosive atmospheres and are not insulated for contact with electric power sources.

• Use a vise or clamping device to hold work piece firmly in place.

• Do not apply excessive force on tool or apply “rough” treatment to it.

• Always work with a firm footing, posture and proper lighting.

• Ensure that sparks and debris resulting from work does not create a hazard.

• USE ONLY ON NON-FERROUS MATERIALS.

• This tool has rear exhaust. Exhaust may contain lubricants, vane material, bearing grease, and other materials flushed thru the tool.

Warning: Sanding certain materials can create explosive dust. It is the employers responsibility to notify the user of acceptable dust levels.

• Sanding certain materials can cause sparks which can cause fires or explosions. It is the users responsibility to make sure the work area is free of flammable materials.

• Always use dust extraction or suppression systems which are suitable for the materials being processed.

Report to your supervisor any condition of the tool, accessories, or operation you consider unsafe.

Air System

1 DROP/MIN.

20 SCFM

LUBRICATOR SETTING

•

Dynabrade Air Power Tools are designed to

operate at 90 PSIG (6.2 Bar/620 kPa) maximum

air pressure at the tool inlet, when the tool is

running. Use recommended regulator to control

air pressure.

•

Ideally the air supply should be free of moisture.

To facilitate removing moisture from air supply, the

installation of a refrigerated air dryer after the

compressor and the use of drain valves at each

tool station is recommended.

➤

➤

➤

➤

➤

➤

90 PSIG MAX

(6.2 Bar)

Air Tool

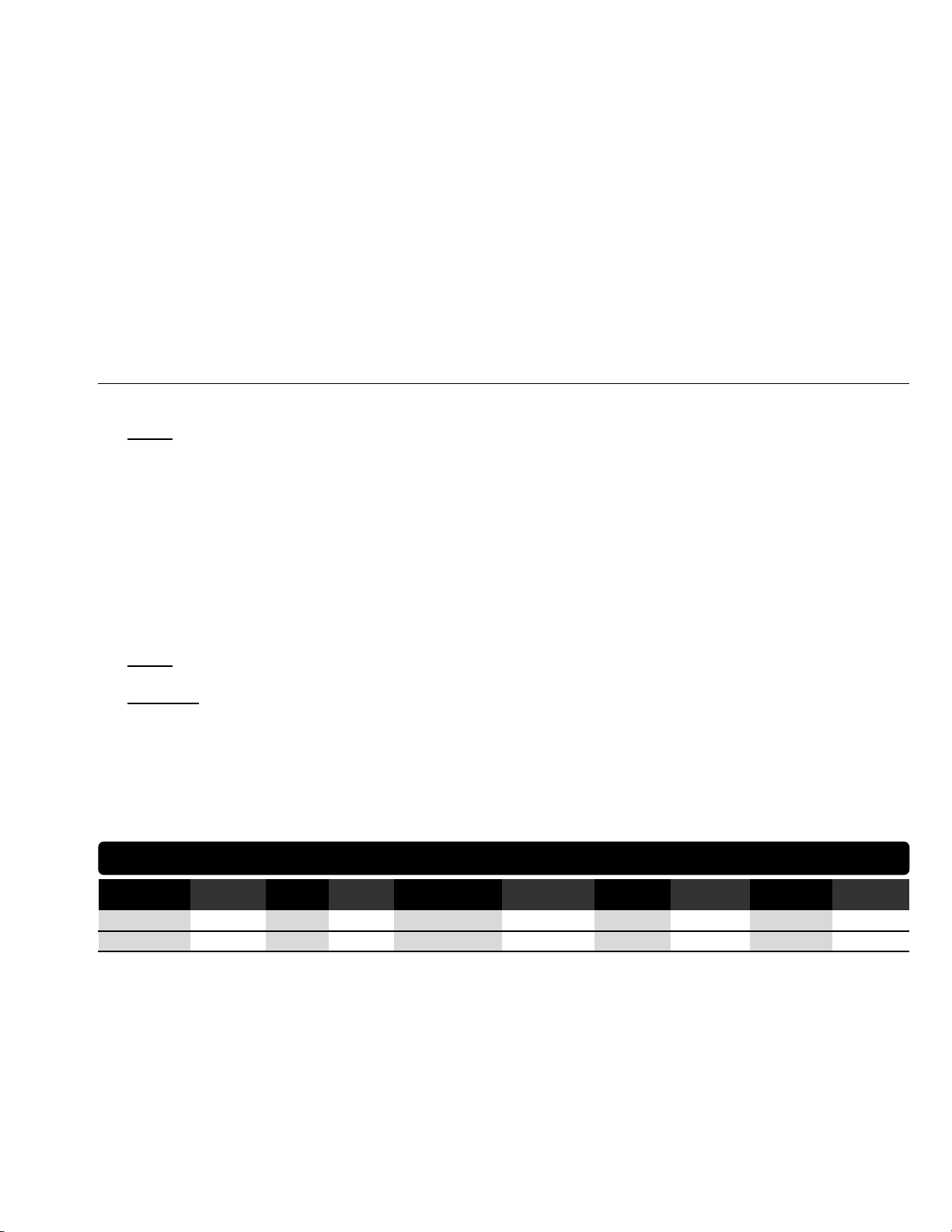

Back-Up Pad/Abrasive Mounting

• Disconnect air source from the tool.

• Secure spindle with wrench.

• Thread back-up pad onto spindle securely.

• Check mounting by rotating spindle, make certain abrasive disc is

concentrically mounted and back-up pad is not excessively warped.

Side View

Back-Up Pad

Spindle

Housing

Vacuum Port

Shroud

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Page 3

Maintenance Instructions

Important: To keep tool safe a preventative maintenance program is recommended whenever portable power tools are used. The program should include

inspection of air supply lines, air line pressure, proper lubrication and repair of tools. Refer to ANSI B186.1 for additional maintenance information.

•

Use only genuine Dynabrade replacement parts to insure quality. To order replacement parts, specify Model#, Serial# and RPM of your air tool.

•

It is strongly recommended that all Dynabrade rotary vane air tools be used with a Filter-Regulator-Lubricator to minimize the possibility of misuse due

to unclean air, wet air or insufficient lubrication. Dynabrade recommends the following: 10681 Air Line Filter-Regulator-Lubricator — Provides accurate air

pressure regulation, two-stage filtration of water contaminants and micro-mist lubrication of pneumatic components.

•

Dynabrade recommends one drop of air lube per minute for each 20 SCFM (example: if the tool specification states 40 SCFM, set the drip rate on the

filter-lubricator to 2 drops per minute). Dynabrade Air Lube (P/N 95842: 1 pt 473 ml) is recommended.

Routine Preventative Maintenance:

•

Check free speed of tool regularly using a tachometer and after repair and maintenance. Remove abrasive and back-up pad before testing.

•

Inspect back-up pad regularly for nicks, cuts, sharp edges, flatness and runout. Replace damaged or worn back-up pad with genuine

Dynabrade back-up pad.

•

Inspect shroud for wear or damage. Shrouds that are severely worn or subject to a disc breakage must be replaced.

•

Inspect accessories before mounting. Do not mount accessories that are damaged or cracked.

•

Check accessory - speed rating. Rating on accessory must be greater than the tool speed marked on the housing.

•

If accessory breakage occurs, investigate to determine the cause and correct before issuing tool for work.

•

Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids, ester,

ketone, chlorinated hydrocarbons or nitro carbons.

•

DO NOT clean or maintain tools with chemicals that have a low flash point (example: WD-40

®

).

•

A Motor Tune-Up Kit (P/N 96049) is available which includes high wear and medium wear motor parts.

•

Air tool labels must be kept legible at all times, if not, reorder label(s) and replace. User is responsible for maintaining specification information i.e.:

Model #, S/N, and RPM. (See Assembly Breakdown)

•

Blow air supply hose out prior to initial use.

•

Visually inspect air hoses and fittings for frays, visible damage and signs of deterioration. Replace damaged or worn components.

•

Refer to Dynabrade's Warning/Safety Operating Instructions Tag (Reorder No. 95903) for safety information.

After maintenance is performed on tool, add a few drops of Dynabrade Air Lube (P/N 95842) to the air line and start the tool a few times to lubricate air motor.

Check for tool vibration before mounting abrasive wheel accessory.

Handling and Storage:

•

Use of tool rests, hangers and/or balancers is recommended.

•

Protect tool inlet from debris (see Notice below).

•

DO NOT carry tool by air hose or near the tool throttle lever.

•

Protect tool from exposure to water, solvents, high humidity, freezing temperature and extreme temperature changes.

•

DO NOT USE accessories that have been dropped or show signs of cracks, nicks or other defects.

•

Store accessories in protective racks or compartments to prevent damage.

•

Store abrasive discs prior to use at 40-50% relative humidity and 60-80˚F (15-27˚C) to reduce curling.

Machine Specifications

3

Model Motor Motor Sound Maximum Air Flow Spindle Air Pressure Weight Length Height

Number hp (W) RPM Level SCFM (LPM) Thread PSIG (Bars) Pound (kg) Inch (mm) Inch (mm)

51235 .4 (276) 25,000 92 dB(A) 20 (566) 1/4"-20 male 90 (6.2) 1.4 (.6) 9-3/4 (249) 3-7/8 (98)

51236 .4 (276) 25,000 81 dB(A) 20 (566) 1/4"-20 male 90 (6.2) 1.7 (.7) 10-1/4 (261) 3-7/8 (98)

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose I.D. 1/4" (6mm)

Sound Level is the pressure measurement according to the method outlined in ISO regulation ISO-15744.

Warning: Ear protection to be worn when exposure to sound exceeds the limits of applicable Federal, State or local statutes, ordinances and/or regulations.

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Page 4

23 N•m

T

O

1

45

44

46

41

42

39

40

41

47

48

49

51

39

50

44

45

46

52

A

8

23 N•m

T

O

1

A

8

Index Key

No. Part # Description

1 51344 Pad

2 52742 Shroud

3 97326 Clamp

4 01560 Exhaust Cover

5 01580 Felt Seal

6 97180 Vac. Hose Cuff (1")

(Conductive)

7 01546 7˚ Housing

8 01548 Gasket

9 01558 Collar

10 01461 Lock Nut

11 95523 O-Ring

12 01470 Insert

13 50133 Adapter

14 02649 Bearing

15 54543 Shim

16 54544 Shim

17 54551 Shim

18 01478 Bearing Plate

19 01479 Spacer

20 50767 Pin (2)

21 01392 Rotor

22 01480 Blade (4/pkg.)

23 01476 Cylinder

24 02676 Bearing Plate

25 02696 Bearing

26 02679 Shield

27 02228 Housing - Mdl: 51235

02229 Housing - Mdl: 51236

28 01469 Speed Regulator Assy.

29 01024 O-Ring

30 95730 O-Ring

31 01464 Seal

32 01472 Tip Valve

33 01468 Spring

34 01564 Air Control Ring

35 95558 Retaining Ring

36 01449 Valve Stem

37 01462 Safety-Lock Lever

38 12132 Pin

39 96584 Vac. Hose - Gray

(Non-Conductive)

31938 Vac. Hose - Black

(Conductive)

40 95438 O-Ring

41 95711 Retaining Ring

42 95601 Hose Cuff - Gray

(Non-Conductive)

43 94532 Vacuum Adapter

44 95375 O-Ring

45 94526 Spacer

46 94523 Inlet Adapter

47 94521 Muffler Base

48 94528 Silencer

49 97161 Vacuum Hose Retainer

50 94522 Muffler Cap

51 31907 Vac. Hose Cuff (1-1/4")

52 94519 Muffler Assembly

A

8

O

1

4

5

8

7

9

10

11

12

14

13

15

17

19

21

18

20

16

22

23

24

25

26

20

27

31

29

30

32

34

33

28

35

36

A

8

34 N•m

T

Adhesive: A4= Loctite #680

A

8

= Loctite #567

Torque: N•m x 8.85 = In. - lbs.

Oil: O

1

= Air Lube

W

Wicking: W

1

= Gear Oil

O

A

T

KEY

3

2

1

6

38

37

Left Hand

Threads

Right Hand

Threads

2 " Dia. Vacuum Disc Sanders

Complete Assembly

4

Models:

51235, 51236

96076 12mm Wrench

Shaded Index numbers represent parts

included in 53207 Vacuum Assembly.

Model: 51235

Model: 51236

40

43

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Page 5

5

Disassembly/Assembly Instructions

Important: Manufacturer’s warranty is void if tool is disassembled before warranty expires

Notice: Dynabrade strongly recommends the use of their 52296 Repair Collar (sold separately) during assembly/disassembly activities. Failure to

use this collar will highly increase the risk of damage to the valve body of this tool. Please refer to parts breakdown for part identification.

To Disassemble:

1. Disconnect tool from power source.

2. Secure air tool in vise using 52296 Repair Collar.

3. Remove 51344 Back-Up Pad. Take off 52742 Shroud by unscrewing 97326 Clamp.

4. With an adjustable pin wrench or 50971 Lock Ring Tool, remove 01560 Exhaust Cover by turning counter-clockwise.

5. Pull motor assembly from housing.

6. Reposition motor housing in vise so inlet bushing is facing upwards.

7. Remove 94523 Inlet Bushing and muffler assembly from valve body housing. Using needle nose pliers, remove spring, tip valve and seal.

8. Remove 95711 Retaining Ring from inlet adapter and disassemble muffler assembly.

9. Using a 2.5mm diameter drift pin and a hammer, tap 12132 Pin out from housing and remove throttle lever.

10. Remove 95558 Retaining Ring and push 01469 Speed Regulator from housing.

Motor Disassembly:

1. Remove 50133 Adapter from rotor shaft by inserting 3mm hex wrench through adapter and into rotor shaft. Twist adapter from shaft.

2. Remove 01478 Front Bearing Plate, cylinder, blades (4) and 01479 Spacer from rotor. Note: 02649 Bearing is a slip fitinto 01478 Front Bearing Plate.

3. Press rotor from 02673 Rear Bearing Plate. Press 02696 Bearing from rear bearing plate. (96210 Bearing Removal Press Tool is available.)

Motor Disassembly Complete.

Motor Assembly:

Important: Be sure parts are clean and in good repair before assembling.

1. Place 01594 Rotor in padded vise with threaded spindle facing upwards.

2. Slip 01479 Spacer onto rotor.

3. Place a .002" shim into 01478 Front Bearing Plate as an initial spacing (Note: 54529 Shim Pack contains .001" and .002" shims) and slip 02649

Bearing into plate.

4. Install bearing/bearing plate assembly onto rotor.

5. Tighten 50133 Adapter onto rotor (torque to 17 N•m/150 in. - lbs.).

6. Check clearance between rotor and bearing plate by using a .001" feeler gauge. Clearance should be at .001" to .0015". Adjust clearance by repeating

steps 1-5 with different shim if necessary.

7. Once proper rotor/gap clearance is achieved, install well lubricated 01480 Blades (4) into rotor slots. Dynabrade Air Lube P/N 95842 is

recommended for lubrication.

8. Install cylinder over rotor. Be sure air inlet holes of cylinder face away from front bearing plate and that the pin in the front bearing plate aligns correctly

with the pin-hole in the cylinder.

9. Press against outer race of 02696 Rear Bearing and install into 02673 Rear Bearing Plate (96242 Bearing Press Tool available). Press bearing/bearing

plate assembly onto rotor. Be sure that pin and air inlet holes line-up with pin slot and air inlet holes in cylinder.

Important: Fit must be snug between bearing plates and cylinder. A loose fit will not achieve the proper preload of motorbearings. If too tight, rotor will

not turn freely. Rotor must then be lightly tapped at press fit end so it will turn freely while stillmaintaining a snug fit.

10. Secure motor housing in vise using 52296 Repair Collar with motor cavity facing upwards.

11. Install motor assembly into housing. Be sure motor drops all the way into housing.

12. Insert 01580 Silencer into 01560 Exhaust Cover and install onto motor housing. Apply #567 Loctite (or equivalent) to housing threads.

Torque to 28 N•m/250 in. - lbs.

13. Motor adjustment must now be checked. With motor housing still mounted in vise, pull end of rotor and twist (10-15 lbs. force), rotor should

turn freely without drag. If drag or rub is felt, then increase preload or remove shim. Also, push end of rotor and twist (10-15 lbs. force), rotor

should turn freely without drag. If drag or rub is felt, then deload or add shim.

14. Place 52742 Shroud onto housing and fasten 97326 Clamp.

15. Install 51344 Pad and abrasive.

Motor Assembly Complete.

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Page 6

Disassembly/Assembly Instructions - (continued)

Valve Body Assembly:

1. Insert 01469 Speed Regulator with valve stem and o-rings installed, into housing, secure with 95558 Retaining Ring.

2. Place seal into housing. Using tweezers or needle nose pliers, place the tip valve into the housing so that the pin goes into the valve stem hole of

regulator assembly.

3. Place 01468 Spring into housing with small end towards valve assembly.

4. Assemble muffler assembly. Slip 94523 Inlet Adapter through muffler assembly and secure with 95711 Retaining Ring.

5. Install air control ring into valve body housing.

6. Apply #567 Loctite PST Pipe Sealant (or equivalent) to threads of inlet bushing and install muffler assembly onto valve body (torque 23.0 N•m/200 in. lbs.).

7. Install throttle lever and 12132 Pin. Remove from vise.

Tool Assembly Complete. Please allow 30 minutes for adhesives to cure before operating tool.

Important: Before operating, place 2-3 drops of Dynabrade Air Lube (P/N 95842) directly into air inlet with throttle lever depressed. Operate tool for 30 seconds

to determine if tool is operating properly and to allow lubricating oils to properly penetrate motor. Motor should now be tested for proper operation at 90 PSIG. If

motor does not operate properly or operates at a higher RPM than marked on the tool, the tool should be serviced to correct the cause before use.

6

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality pneumatic motors can

most often be traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water contained in the air supply into motor bearings

causing early failure. It often scores the cylinder walls and the rotor blades resulting in limited efficiency and power. Our warranty obligation is contingent upon

proper use of our tools and cannot apply to equipment which has been subjected to misuse such as unclean air, wet air or a lack of lubrication during the use

of this tool.

Loctite®is a registered trademark of Loctite Corp.

Lifetime Warranty

All Dynabrade portable pneumatic power tools are rigorously inspected and performance tested in our factory before shipping to our customers. If a Dynabrade tool

develops a performance problem and an inherent defect is found during normal use and service, Dynabrade will warrant this tool against defects in workmanship and

materials for the lifetime of the tool. Upon examination and review at our factory, Dynabrade shall confirm that the tool qualifies for warranty status, and will repair or

replace the tool at no charge to the customer. Normally wearable parts and products are NOT covered under this warranty. Uncovered items include bearings, contact

wheels, rotor blades, regulators, valve stems, levers, shrouds, guards, O-rings, seals, gaskets and other wearable parts. Dynabrade’s warranty policy is contingent upon

proper use of our tools in accordance with factory recommendations, instructions and safety practices. It shall not apply to equipment that has been subjected to misuse,

negligence, accident or tampering in any way so as to affect its normal performance. To activate lifetime warranty, customer must register each tool at

www.dynabrade.com. Dynabrade will not honor lifetime warranty on unregistered tools. A one-year warranty will be honored on all unregistered portable pneumatic power

tools. Lifetime warranty applies only to portable pneumatic tools manufactured by Dynabrade, Inc. in the USA. Lifetime warranty applies only to the original tool owner;

warranty is non-transferable.

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Page 7

This service chart is published as a guide to expectant life of component parts. The replacement levels are based on average tool

usage over one year. Dynabrade Inc. considers one year usage to be 1,000 hours.

Parts Common to all Models:

Preventative Maintenance Schedule

For 2" Dia. Vacuum Disc Sander Models

Index Part Description Number High Wear Medium Wear Low Wear Non-Wear

# Number Required 100% 70% 30% 10%

1 51344 Pad 1 X

2 52742 Shroud 1 X

3 97326 Clamp 1 X

4 01560 Exhaust Cover 1 X

5 01580 Felt Seal 1 T

6 97180 Vacuum Hose Cuff 1 X

7 01546 7˚ Housing 1 X

8 01548 Gasket 1 X

9 01558 Collar 1 X

10 01461 Lock Nut 1 X

11 95523 O-Ring 1 X

12 01470 Insert 1 X

13 50133 Lock Nut 1 X

14 02649 Bearing 1 T

15 54543 Shim 1 T

16 54544 Shim 1 T

17 54551 Shim 1 T

18 01478 Bearing Plate 1 X

19 01479 Spacer 1 X

20 50767 Pin 2 X

21 01392 Rotor 1 X

22 01480 Blade (4/pkg.) 1 T

23 01476 Cylinder 1 X

24 02676 Bearing Plate 1 X

25 02696 Bearing 1 T

26 02679 Shield

1 T

27

See Note Housing 1 X

28 01469 Speed Regulator Assy. 1 T

29 01024 O-Ring 1 D

30 95730 O-Ring 1 D

31 01464 Seal 1 T

32 01472 Tip Valve 1 T

33 01468 Spring 1 T

34 01564 Air Control Ring 1 L

35 95558 Retaining Ring 1 T

36 01449 Valve Stem 1 T

37 01462 Throttle Lever 1 X

38 12132 Pin 1 T

39

See Note Vac. Hose 1 X

40 95438 O-Ring 1 D

41 95711 Retaining Ring 1 T

42 95601 Vacuum Hose Cuff 1 X

43 94532 Vacuum Adapter 1 X

44 95375 O-Ring 1 L

45 94526 Spacer 1 L

46 94523 Inlet Adapter 1 X

47 94521 Muffler Base 1 X

48 94528 Silencer 1 T

49 97161 Vacuum Hose Retainer 1 X

50 94522 Muffler Cap 1 X

51 31907 Vacuum Hose Cuff 1 X

96049 – Motor Tune-Up Kit

LEGEND

T Included in Tune-Up Kit

X Type of wear, no other

comments apply.

L Easily lost. Care during

assembly/disassembly.

D Easily damaged during

assembly/disassembly.

R Replace each time tool is

disassembled.

7

Note:

Please see page 4 for specific part number.

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Page 8

DYNABRADE

®

DYNABRADE, INC.,

8989 Sheridan Drive •Clarence, NY 14031-1419 •Phone: (716) 631-0100 •Fax: 716-631-2073 •International Fax: 716-631-2524

DYNABRADE EUROPE S.àr.l.,

Zone Artisanale •L-5485 Wormeldange—Haut, Luxembourg •Telephone: 352 76 84 94 1 •Fax: 352 76 84 95 1

© DYNABRADE, INC., 2008 PRINTED IN USA

Visit Our Web Site: www.dynabrade.com Email: Customer.Service@Dynabrade.com

Optional Accessories

Dynabrade Air Lube

•

Formulated for pneumatic equipment.

•

Absorbs up to 10% of its weight in water.

•

Prevents rust and formation of sludge.

•

Keeps pneumatic tools operating longer

with greater power and less down time.

95842: 1pt. (473 ml)

95843: 1gal. (3.8 L)

Composite-Style Coupler

•

Lightweight 1.4 oz. (.05 Kg), non-marring

composite material.

•

Easy connect/disconnect by single

push-button action.

•

Shock-proof, low-vibration, crush-resistant.

94960: 1/4" Female NPT

94980: 1/4" Male NPT

95675 Male Plug

•

Provides up to twice the air flow

compared to standard plug design.

•

Plug has “ported” design to prevent

“starving” of the air tool.

Open-End Wrench

96076 – 12mm

Dynaswivel

®

•

Swivels 360° at two locations which allows an

air hose to drop straight to the floor, no matter

how the tool is held.

94300 1/4" NPT.

52296 Repair Collar

•

Specially designed collar for use in vise to

prevent damage to valve body of tool

during disassembly/assembly.

Portable Vacuum Systems

•

Dynabrade offers a wide assortment of

vacuuming options to choose from. To

help make your selection please request

the most current portable vacuum

systems literature form your local

representative or by searching our

web site.

FIND THE MOST CURRENT OFFERING OF SUPPORT DOCUMENTS AND ACCESSORIES @ WWW.DYNABRADE.COM

96049 Motor Tune-Up Kit

•

Includes assorted parts to help maintain

and repair motor.

01392 Drop-In Motor - 25,000RPM

•

Allows quick and easy replacement.

No motor adjustments needed.

Reference Contact Information

1. American National Standards

Institute – ANSI

25 West 43

rd

Street

Forth Floor

New York, NY 10036

Tel: 1 (212) 642-4900

Fax: 1 (212) 398-0023

3. Power Tool Institute, Inc.

P.O. Box 818

Yachata, Oregon 97498-0818

Tel: 1 (503) 547-3185

Fax: 1 (503) 547-3539

4. European Committee for Standardization

Rue de Stassart 36

B - 1050 Brussels, Belgium

2. Government Printing Office – GPO

Superintendent of Documents

Attn. New Orders

P.O. Box 371954

Pittsburgh, PA 15250-7954

Tel: 1 (202) 512-1803

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Loading...

Loading...