Page 1

Hyper 2 In-line Regulator

Product Guide

The ‘04 DYE Hyper 2 In-Line Regulator has been designed to meet the quickly changing demands of today’s top

players. The ‘04 Hyper In-line exceeds the requirements of every paint gun on the market today. With extremely consistent regulated

output pressure and an amazingly high rate of airflow, the ‘04 Hyper 2 In-Line virtually eliminates inconsistent velocity, as well as shoot

down due to inadequate air supply. The Hyper 2 In-Line has an easily fine-tuned range of adjustment, from 50psi to 450psi.

With the air inlet port located on a swivel at the bottom of the regulator, the Hyper 2 In-line is quickly installed onto

almost every gun, with nearly any cradle and air system configuration. The external pressure adjustment is easily accessed at the

bottom of the regulator with a standard 3/16” Allen wrench.

Installation and Adjustment

The Hyper 2 In-Line fits any standard ASA adapter. To install the Hyper 2 In-Line, simply thread on the desired air

fitting into the air inlet port on the side of the swivel sleeve. Use a thread sealant similar to Loctite.

After carefully connecting your air hose from your bottle or air system to the Hyper 2 In-Line you will need to adjust

the Hyper 2 reg to the recommended output pressure for your marker. The Hyper 2 In-Line is set by the factory to approximately

175psi.

The output pressure of the Hyper 2 In-Line is adjusted by turning the brass seat housing. The seat housing screw is

located up inside the bottom of the reg. A 3/16” Allen wrench will be needed for this operation. By turning the housing counter-

clockwise, you will increase the output pressure of the reg to the gun. By turning the housing screw clockwise, you will decrease the

output pressure of the reg.

After each adjustment of the output pressure of the Hyper 2 In-Line, you will need to cycle your marker a few times.

This will allow your marker and air system to stabilize at their new operating pressure. The Hyper 2 will need a break-in period of about

2,500 shots to let its seat form to the piston and reach its optimum performance.

Trouble Shooting

PROBLEM

No or poor air flow

Erratic velocity or shoot down

Output pressure creeps up

Air leaks from side vent hole.

Air leaks out bottom

of adjustment screw

POSSIBLE CAUSE

Check for blocked air passage in hose line or regulator. Adjustment screw may be screwed in too

far. Seat may have excessively deep piston groove cut into it. Replace if needed.

Piston or spring stack may be binding due to excessive dirt or lack of lubricant. Seat may be dirty

or damaged. Clean and grease reg. Inspect and replace damaged parts as needed.

Dirty seat or damaged piston face.

Clean and inspect; if either is damaged, replace.

Piston o-rings may be damaged. Inspect o-rings.

Replace if any visible nicks or cuts are found.

This is a safety bleed-off to help prevent over-pressurizing. De-gas the Hyper 2; be sure all air is

vented out of the reg. Supply air back to the regulator. The leak should stop. If the leak persists

replace the reg seat. Make sure there are no nicks or scratches on the raised ring at the bottom

of the seat-retaining cavity.

Page 2

Hyper 2 In-line Regulator

Maintenance and Repair

The Hyper 2 In-Line was designed to perform under the most extreme playing conditions, and built to hold up under

the abuse of even the roughest player. Even with this much durability built into the Hyper 2 In-Line, excessive dirt and debris can affect

its performance and increase the need for servicing. Some general maintenance must be performed to ensure optimum

performance.

1. Make sure the inlet and outlet ports and connecting fittings are free of all dirt and paint.

2. Examine all o-rings for nicks or cuts.

3. Carefully inspect the seat for excessive wear that might cause spiking and over-pressurizing.

4. Clean any accumulated dirt out of the air chambers and passages.

5. Keep the piston o-rings and spring pack well greased to allow smooth velocity adjustment and prevent

erratic velocity spikes and drop off.

6. Clean off all old grease that may be contaminated with dirt; reapply fresh grease to the piston and other necessary areas.

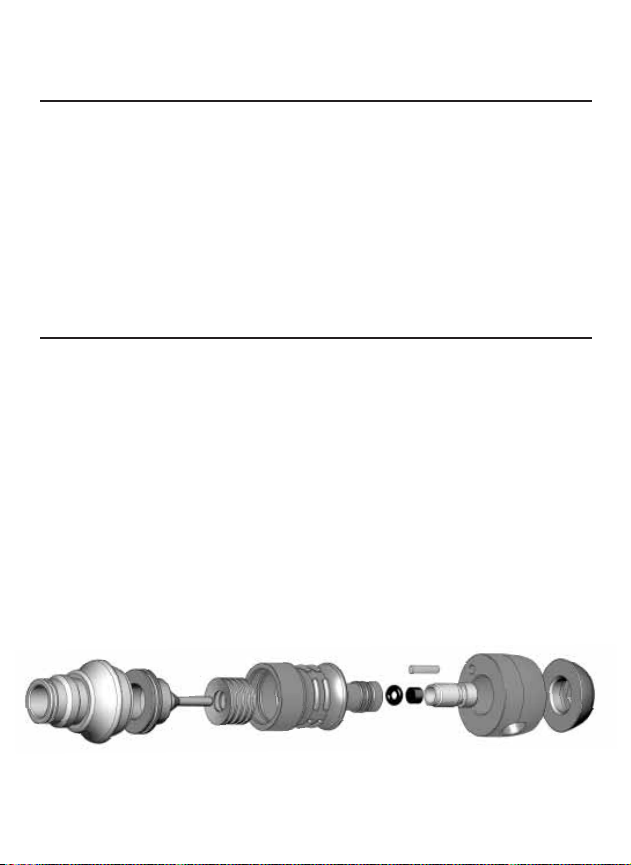

7. Be sure to reassemble the internal components in the proper order and direction.

8. See diagram for assistance.

Disassembly

Disassembly of the Hyper 2 In-Line is easily done with a 3/8” and a 5/16” Allen wrench.

1. Remove all air from your gun and Hyper 2 In-Line Regulator and remove reg from gun.

2. Lock the 3/8” Allen wrench into the top of the Hyper 2 In-Line. Using the 5/16”Allen wrench, unscrew the bottom retaining cap

from the main body.

3. Once the bottom-retaining cap is removed, you will be able to unscrew the seat housing from the reg body. Use a 3/16” Allen

wrench. With the seat housing extracted from the reg body, inspect the seat for dirt and/or visible damage. The seat should be

free of dirt, nicks, and cuts. There will be a recessed ring on the face of the seat. This is normal wear from the piston face sealing

against the seat.

4. Once the bottom-retaining cap has been removed from the reg, the swivel sleeve will pull off the reg with only little

resistance due to

o-rings dragging. Keep the swivel post o-rings well greased to insure smooth turning of the swivel.

5. To access the piston and spring pack, you will need to remove the top cap. Use the 3/8” Allen wrench. The piston and spring pack

will then be accessible from the top of the main reg body. Inspect the piston o-ring and make sure the spring pack is assembled

correctly. The spring pack is comprised of nine (9) shims. Be sure the shims alternate direction when stacked. Look closely at the

face of the piston that makes contact with the seat. Make sure it has no major nicks or scratches on it.

6. When installing the spring and piston you must take special care to make sure that the #007 o-ring is fully seated down

into the main reg body. You must make sure to keep the #007 o-ring seated in place when the piston is pressed in.

10637 Scripps Summit Ct. San Diego, CA 92131

Copyright ©2003 DYE Precision, Inc. The stylized “dye” logo and the “sphere” logo are either registered

trademarks, trademarks, or design trademarks of DYE Precision, Inc.

DYE Precision, Inc.

P 858-536-5183 F 858-536-5191

www.dyeprecision.com

Loading...

Loading...