Page 1

HEXXAGONAL BEAM

Mark 2

DXE-HEXX-5TAP-2, DXE-HEXX-1TAP-2

DXE-HEXX-BEAM-MARK2-INS Rev. 2

© DX Engineering 2010

P.O. Box 1491 · Akron, OH 44309-1491 USA

Phone: (800) 777-0703 · Tech Support and International: (330) 572-3200

Fax: (330) 572-3279 · E-mail: DXEngineering@DXEngineering.com

Page 2

Table of Contents

Introduction 2

HEXXAGONAL BEAM Mark 2 Features 5

HEXXAGONAL BEAM Kits 5

Parts Lists

DXE-HEXX-1HBP - HEXX HUB (US Patent No. D605,184) 6

DXE-HEXX-1SCP-2 - HEXXAGONAL BEAM Spreader & Center Post 6

DXE-HEXX-5FFP HEXXAGONAL BEAM 5-Band Stainless Steel/Teflon® Rigid

Feeder System (patent pending)

6

DXE-HEXX-5WRP-2 - HEXXAGONAL BEAM 5-band Wire Element & Wire Guide 6

DXE-HEXX-1WRP-2 - HEXXAGONAL BEAM 1-band Wire Element & Wire Guide 7

Parts Required but not supplied 7

Tools Required 7

Manual Updates 7

HEXXAGONAL BEAM Construction 8

Hexxagonal Hub Assembly Instructions 9

Working with Fiberglass 10

Center Post Assembly 11

5-Band Stainless Steel/Teflon

®

Rigid Feeder System (patent pending) 13

Installing the Center Post Rope Hub 14

Installing the optional Feedline Current Choke 16

Spreader Assembly 17

Installing the Wire Elements 22

Installation on a Mast and Rotator 26

SWR Testing 27

Single Band Wire Element and Wire Guide Package Instructions 28

Optional Items 32

Technical Support 36

Warranty 36

Introduction

The DX Engineering HEXXAGONAL BEAM KITS provide a fast,

economical way to build the hottest new design of an antenna concept

that has been around since the 1980’s. HEXXAGONAL BEAM

component kits are available for an easy, step-by-step approach to

designing your own antenna or to upgrade an existing installation.

2

Page 3

The DX Engineering HEXXAGONAL BEAM Mark 2 Five Band Hexxagonal Beam Antenna

Package is a complete build-it-yourself system, including pre-assembled wire element kits,

assembled wire guide and rope attachment clamps and a revolutionary new Five-Band Stainless

Steel/Teflon

®

Rigid Feeder System (patent pending) which operates all bands, 20 thru 10 meters

with a single feedline. All hardware is high quality stainless steel. The

pre-cut wire elements are 14 gauge stranded copper with black PVC

insulation with special black wire guide tubes and ring terminals

factory assembled. The rope supplied is a double-braided

Dacron/Polyester, not weakened by decay or mildew and provides

excellent resistance to abrasion. The color sealed black polyester yarn

used in the braided jacket also protects the cord from damage due to

ultra-violet light. The fiberglass spreaders are measured and cut to

length with pre-cut slits on one end for proper tightening using the

stainless steel band clamps. Also included is the complete DX

Engineering Hexx Hub (patented). The cast aluminum Hexxagonal

Beam Hub provides a superior mounting platform with built-in vsaddle clamping channels and all stainless steel v-bolts and hardware

are included.

The DX Engineering HEXXAGONAL BEAM Mark 2 can offer gain

and front-to-back performance that exceeds your expectations for a

multi-band two element

beam, as its unique shape is

much smaller, better

balanced and has been

reported to receive less

noise than typical beams.

This lighter, easier to

handle antenna can be

rotated with a light duty

rotator, and it performs

well, even when it is not

mounted very high above

the ground. With the DX Engineering HEXXAGONAL BEAM

Mark 2 and kits you can build your antenna with a broadband,

u-shaped reflector for better coverage of the bands with low SWR.

This is only one of the dramatic improvements of the G3TXQ

broadband design over the "classic" dual-w hex beam antennas.

The Five Band Stainless Steel/Teflon® Rigid Feeder System is a

revolutionary breakthrough for Hexagonal Beam Antennas!

This new patent pending Stainless Steel/Teflon® Rigid Feeder System

eliminates vulnerable coaxial cable feedpoint sections - providing a

weatherproof, low-loss, high power balanced connection to all bands

for optimum antenna pattern control. This revolutionary Rigid Feeder

3

Page 4

attaches directly to the outside of the full-size 1-1/4" fiberglass Center Post. It is no longer

necessary to drill or slice up a center post - weakening it - to attach or protect older coaxial cable

feeders with homebrew or terminal strip connections.

The integral center insulators with the unique serpentine wire grip assure long, reliable

performance. The pre-assembled and tested Five Band Stainless Steel/Teflon® Rigid Feeder System

is also ideal for retrofitting to other, older hexagonal beam designs using the DX Engineering wire

element dimensions - or with your own hex antenna with appropriate testing and modifications.

At the center of the new HEXXAGONAL BEAM Mark 2 is the exclusive DX Engineering cast

aluminum HEXX Hub (US Patent No. D605,184). Specially designed and mechanically superior to

available home-made base plate designs, the HEXX Hub has integral V-saddles and Stainless Steel

V-Bolt hardware to firmly attach the fiberglass

spreaders in proper alignment without drilling or

crushing. The upper and lower mast mounts are

integrally cast into the hub, eliminating the need to find

separate mounting flanges, reducing assembly time,

improving mast alignment and providing a far stronger,

heavy duty attachment for the mast. For the rest of the

antenna frame, high quality stainless steel element

clamps rigidly hold the telescoping fiberglass sections

at the correct lengths without drilling holes. Exclusive

DX Engineering stainless steel element clamps with

studs provide secure attachment points for the Five Band Stainless Steel/Teflon® Rigid Feeder

System without drilling. The unique Floating Element Wire Guides allow independent movement of

the radiating wire elements and flexible fiberglass spreaders in the wind without creating breaking

stresses. These special Wire Guides are attached to the spreaders without drilling, for a stronger,

longer lasting antenna.

The DX Engineering HEXXAGONAL BEAM Mark 2 is a directional beam antenna made with

fiberglass spreaders and wire elements that looks like a very large inverted umbrella frame. Even at

22 feet wide and approximately 5 feet tall, it has a smaller turning radius than a two element 20

meter Yagi, and offers several enhanced operating characteristics. It may be mounted at the top of a

rotatable mast or directly into a light to medium duty rotator. This antenna is fed at the top of the

center post with a single 50 ohm feedline. This top fed feedline arrangement has been tested and

proven to function better than a bottom feedpoint connection.

4

Page 5

HEXXAGONAL BEAM Features

The DX Engineering HEXXAGONAL BEAM Mark 2 design has a number of important

advantages over a yagi:

● Small turning radius - the HEXXAGONAL BEAM Mark 2 has a turning radius of 11'

● Gain - 5 dBi (3 dBd), depending on band - similar to 2 element Yagi, far exceeding

performance of multi-band mini-beams

● Front-to-Back - >20 dB, depending on band

● Balanced in the wind - Hexxagonal symmetry reduces torque on the rotor

● Light weight - fully assembled - less than 25 pounds

● Wind load - less than 5 square feet

● Can be turned with a light duty rotator - no need to spend big dollars

● Performs well at low heights - good results at 20 to 30 feet above ground

● Five Band gain and front-to-back - can meet or exceeds other small antennas

● Handles full legal limit power – no power restriction as on competing antennas

● Low Noise results - approaches performance of closed loop antennas

● Has full length pre-cut elements - no lossy coils or traps

● Five-Band Stainless Steel/Teflon

● Requires no matching network - direct single 50 ohm coax feed

● New, easier and faster assembly - fewer parts to speed completion of the antenna project

®

Rigid Feeder System (patent pending)

HEXXAGONAL BEAM Kits

DXE-HEXX-5TAP-2 - The DX Engineering HEXX BEAM Mark 2 - Five-Band Total Antenna

Package consists of these four kits:

DXE-HEXX-1HBP HEXXAGONAL BEAM Hub package (US Patent No. D605,184)

DXE-HEXX-1SCP-2 HEXXAGONAL BEAM Spreader & Center Post package

DXE-HEXX-5FFP HEXXAGONAL BEAM 5-Band Stainless Steel/Teflon

Feeder System (patent pending)

DXE-HEXX-5WRP-2 HEXXAGONAL BEAM 5-band Wire Element & Wire Guide

package

DXE-HEXX-1TAP-2 - The DX Engineering HEXX BEAM 1-Band Total Antenna Package

consists of these three kits:

DXE-HEXX-1HBP HEXXAGONAL BEAM Hub package (US Patent No. D605,184)

DXE-HEXX-1SCP-2 HEXXAGONAL BEAM Spreader & Center Post package

DXE-HEXX-1WRP-2 HEXXAGONAL BEAM 1-band Wire Element & Wire Guide

package

®

Rigid

5

Page 6

Parts Lists

DXE-HEXX-1HBP - HEXX HUB

Qty Description

1 Cast Aluminum Hexxagonal Hub (US Patent No. D605,184)

12 1.5" short Stainless Steel V-Bolt

12 1/4-20 Stainless Steel Hardware Kit for V-Bolts

6 1/4-20 Stainless Steel Hex Head Bolt 1.5" long

6 1/4-20 Stainless Steel Hex Nut

6 1/4-20 Stainless Steel Flat Washer

6 1/4-20 Stainless Steel Split Washer

DXE-HEXX-1SCP-2 - HEXXAGONAL BEAM Spreader & Center Post

Qty Description

1 Fiberglass Tube, Gray, 1.25" OD x 58" Long, .120 Wall (for the Center Post)

6 Fiberglass Tube, Gray, 1.00" OD x 58" Long, .120 Wall with slits

6 Fiberglass Tube, Gray, 0.75" OD x 43" Long, .120 Wall with slits

6 Fiberglass Tube, Gray, 0.75" OD x 5" Long, .120 Wall

6 Fiberglass Tube, Gray, 0.50" OD x 48" Long, .120 Wall

1 Tube, Antenna, Aluminum, 1.375" OD x 14" Long, Slit one end (for the Center Post)

6 DXE-ECL-10SS - Element Clamp for 1" and 1.125" OD tubing

6 DXE-ECL-060 - Element Clamp for .75" and smaller OD tubing

1 DXE-ECL-16SS - Element Clamp for 1.375" and 1.5" OD tubing

1 Vinyl End Cap, Black

2 STI-DBR-94-100 - Dacron/Polyester Rope, 100 Foot Roll

6 Spreader Rope Connection Assembly w/cushioned P-Clamps mounted on Stainless Steel Band Clamps

1 Center Post Rope Connection Assembly - includes the following parts:

1 DXE-MPH-1 Multi-Purpose Hub 1.5"

3 1/4-20 x 1.25" Stainless Steel Hex Head Bolt

DXE-HEXX-5FFP - HEXXAGONAL BEAM 5-Band Stainless Steel/Teflon®

Rigid Feeder System (patent pending)

Qty Description

1 Five Band Stainless Steel/Teflon® Rigid Feeder (patent pending)

1 Coaxial cable feedpoint pigtail

1 UHF Female-to-Female Adapter (dual SO-239 type)

DXE-HEXX-5WRP - HEXXAGONAL BEAM 5-band Wire & Wire Guide

Qty Description

15

12 Floating Wire Guides for 1/2" Spreader

18 Floating Wire Guides for 3/4" Spreader

3 1/4-20 Stainless Steel Nut

3 1/4-20 Stainless Steel Square Nut

3 1/4" Stainless Steel Split Washer

3 1/4" Stainless Steel Flat Washer, 18-8

2

1

20/17/15/12/10 Meter Wire Driven Element Sets - #14 Copper Stranded Wire with Black PVC

Insulation with Ring Terminals attached and Wire Guides installed

20/17/15/12/10 Meter Wire Reflector Element Sets - #14 Copper Stranded Wire with Black PVC

Insulation with Ring Terminals attached and Wire Guides installed

#10 hole, 16-14 Wire Gauge Ring Terminal (Spares for various bands and/or adjustment in element

lengths)

6

Page 7

DXE-HEXX-1WRP HEXXAGONAL BEAM 1-band Wire & Wire Guide

Qty Description

2

1

6

1 UHF Female-to-Female Adapter (dual SO-239 style)

1 Coax Wire Assembly, 10" with PL-259 and Ring Terminals

1 Single Band Feeder Insulator Clamp Assembly

6 Floating Wire Guides for 3/4" Spreader.

20 Meter Wire Driven Element - #14 Copper Stranded Wire with Black PVC

Insulation with Ring Terminals attached and Wire Guides installed

20 Meter Wire Reflector Element - #14 Copper Stranded Wire with Black

PVC Insulation with Ring Terminals attached and Wire Guides installed

#10 hole, 16-14 Wire Gauge Ring Terminal

(Spares for various bands and/or adjustment in element lengths)

Parts Required but not supplied

DXE-81343 - Anti-Seize, 1 oz. Squeeze Tube - or -

DXE-NSBT8 - Never-Seez, 8 oz. Brush Top - or -

DXE-NMCBT8 - Never-Seez, 8 oz. Brush Top, Mariner's Choice

The above products are limited to domestic UPS Ground shipping only

Note: Anti-Seize or Never Seez should be used to prevent

galling (seizing) of stainless steel hardware.

DXE-3M2155 - 3M Temflex™ 2155 Rubber Splicing Tape

DXE-33PLUS - Scotch® Super 33+ Tape

The DXE-FCC050-H05-A - Feedline Current Choke and the DXE-BMB-1P Balun Mounting

Kit for a .750 in. thru 1.50 in. Boom - are suggested options and this manual describes their

installation.

Tools Required

1/4", 5/16", 3/8" and 7/16" Deep Well Nut Drivers and/or Open End Wrenches

Tape Measure, 50 ft

Step Ladder, 6 ft. Use proper precautions for step ladder safety

Screwdriver

Pliers

Scissors

Lighter or flame source (to slightly melt the cut rope ends to keep them from fraying)

Use proper safety precautions for a lighter or flame producing item

Marking Pen or Pencil

Three foot Tripod and three foot mast pipe - To hold the antenna while under construction.

Manual Updates

Every effort is made to supply the latest manual revision with each product. Occasionally a manual

will be updated between the time your DX Engineering product is shipped and when you receive it.

Please check the DX Engineering web site (www.dxengineering.com) for the latest revision manual.

7

Page 8

HEXXAGONAL BEAM Construction

This manual for the DX Engineering HEXXAGONAL BEAM Mark 2 is written in sections for

the various assemblies. Each section of assembly instructions is titled with the HEXXAGONAL

BEAM Mark 2 kit name and model number for easy reference.

The typical build sequence is:

1. Assemble the patented HEXX HUB

2. Center Post assembly

3. 5-Band Stainless Steel/Teflon

4. Install the Center Post Rope Hub

5. Installation of the optional DXE-FCC050-H05-A Feedline Current Choke

6. Spreader assembly

7. Wire Element installation

8. Installation on a Mast and Rotator

9. SWR Testing

An outdoor area of about a minimum 30 foot square is required for assembly of this antenna.

The use of a three foot tripod and a three foot mast pipe makes construction of the antenna easier

(see Figure 1).

Figure 1 - Using a temporary tripod and mast for assembly at ground level

Sufficient space is required for the installation of the antenna on your mast or tower. The finished

antenna is approximately 22 feet in diameter.

®

Rigid Feeder System (patent pending) Installation

8

Page 9

Hexxagonal Hub Assembly Instructions

DXE-HEXX-1HBP - HEXXAGONAL HUB (US Patent No. D605,184) Parts List

Qty Description

1 Cast Aluminum Hexxagonal Hub (US Patent No. D605,184)

12 1.5" short Stainless Steel V-Bolt

12 1/4-20 Stainless Steel Hardware Kit for V-Bolts

6 1/4-20 Stainless Steel Hex Head Bolt, 1.5" long

6 1/4-20 Stainless Steel Hex Nut

6 1/4-20 Stainless Steel Flat Washer

6 1/4-20 Stainless Steel Split Washer

Insert the twelve Stainless Steel V-Bolts over the cast V-Saddles as shown in Figure 2.

Figure 2

Anti-Seize or Never Seez should be used to prevent galling (seizing) of stainless steel hardware.

Install a flat washer, a split washer and a 1/4-20 nut on each V-Bolt leg, snug the nuts partially.

Install six 1/4 -20 bolts, six flat washers, six split washers and six nuts, into the top and bottom castin flanges of the hub, as shown in Figure 3. These will be adjusted to fit the center post for the

HEXXAGONAL BEAM.

9

Page 10

Figure 3

The DX Engineering Hexxagonal Hub is now ready for use as the solid foundation for your

HEXXAGONAL BEAM Mark 2.

Working with Fiberglass

NOTE: Extra effort during production is accomplished to clean fiberglass dust from the

fiberglass parts. However, some fiberglass dust may remain. As a precaution, gloves,

a dust mask and eye protection should be worn when unpacking, handling and

cleaning (with a damp cloth) the fiberglass spreader tubes. This should be done

outdoors so fiberglass dust will not collect indoors.

10

Page 11

Center Post and Spreader Assembly Instructions

DXE-HEXX-1SCP-2 - HEXXAGONAL BEAM Spreader & Center Post Parts List

Qty Description

1 Fiberglass Tube, Gray, 1.25" OD x 58" Long, .120 Wall (for the Center Post)

6 Fiberglass Tube, Gray, 1.00" OD x 58" Long, .120 Wall with slits

6 Fiberglass Tube, Gray, 0.75" OD x 43" Long, .120 Wall with slits

6 Fiberglass Tube, Gray, 0.75" OD x 5" Long, .120 Wall

6 Fiberglass Tube, Gray, 0.50" OD x 48" Long, .120 Wall

1 Tube, Antenna, Aluminum, 1.375" OD x 14" Long, Slit one end (for the Center Post)

6 DXE-ECL-10SS - Element Clamp for 1" and 1.125" OD tubing

6 DXE-ECL-060 - Element Clamp for .75" and smaller OD tubing

1 DXE-ECL-16SS - Element Clamp for 1.375" and 1.5" OD tubing

1 Vinyl End Cap, Black

2 STI-DBR-94-100 - Dacron/Polyester Rope, 100 Foot Roll

6 Spreader Rope Connection Assemblies with cushioned p-clamps installed

1 Center Post Rope Connection Assembly - includes the following parts:

1 DXE-MPH-1 Multi-Purpose Hub 1.5"

3 1/4-20 x 1.25" Stainless Steel Hex Head Bolt

3 1/4-20 Stainless Steel Nut

3 1/4-20 Stainless Steel Square Nut

3 1/4" Stainless Steel Split Washer

3 1/4" Stainless Steel Flat Washer, 18-8

Center Post Assembly

Assemble the one 1-1/4" OD x 58" long fiberglass center post tube into

the one 1-3/8" x 14" long aluminum tube, with the slit end of the

aluminum tube oriented toward the middle of the center post. The other

end of the aluminum tube is aligned flush with the end of the fiberglass

center post. Secure the two parts together using the DXE-ECL-16SS

Element Clamp over the slits with a 3/8" spacing between the end of

the slit end of the aluminum tube to the element clamp as shown in

Figure 4.

Figure 4

11

Page 12

Insert the center post with aluminum tube sleeve into the Hexxagonal Hub. The height of the center

post should be 45" above the top of the Hexx Hub as shown in Figure 4.

Hand tighten the upper and lower mast mount hardware on the Hexxagonal Hub evenly, to

position the post exactly in the center of the hub. Make certain that the plane of the hub is

perpendicular to the post so the post and hub are concentrically spaced through the hub with the

mast mount hardware equally tightened. Tighten the mast mount bolts progressively, but carefully,

to maintain even spacing between the post and the hub upper and lower mast mounts as shown in

Figure 5.

The mast mount bolts should be tightened firmly to secure the hub, but not enough to dent

the aluminum tubing. Final position of these bolts is maintained by tightening the keeper nuts only

until the split washers are flat while keeping the mast mount bolts from turning further.

Once assembled, you can use a customer supplied 3 foot tube that will fit over the 1/38" OD

aluminum tube that sticks below the bottom of the Hexxagonal Hub and tripod as shown in Figure

4, to aid in assembling the antenna system at ground level.

Figure 5

If you are building the DX Engineering HEXXAGONAL BEAM 1-Band Total Antenna

Package - DXE-HEXX-1TAP-2, skip the section titled 5-Band Stainless Steel/Teflon®

Rigid Feeder System installation. Install the Rope Hub and Spreaders as described in the

sections titled Installing the Center Post Rope Hub and the Spreader Assembly. The

Single Feed system is described in the section titled: DXE-HEXX-1WRP-2 One-Band

Wire and Wire Guide Package (page 28).

If you are building the DX Engineering HEXXAGONAL BEAM Mark 2

Five-Band Total Antenna Package - DXE-HEXX-5TAP-2 continue below.

12

Page 13

5-Band Stainless Steel/Teflon® Rigid Feeder System installation

Slide the entire 5-Band Stainless Steel/Teflon® Rigid Feeder System onto the

1-1/4" OD center post. Position the center of the 10 meter insulator 5" above

the patented Hexx Hub (DXE-HEXX-1HBP). Tighten the insulator clamps

after each of the insulators are aligned to face directly between the two

spreaders facing the front of the antenna. as shown in Figure 6.

Figure 6

Center Feed with Front of Beam

13

Page 14

Install the Coaxial Cable pigtail to the top (20 meter) feedpoint on the Five Band Stainless

Steel/Teflon® Rigid Feeder as shown in Figure 7. The Five Band Stainless Steel/Teflon® Rigid

Feeder is factory assembled with all hardware. You will have to remove and re-use some of the

nuts, washers and lock washers to install the pigtail. Later on you will also remove and re-use

hardware when installing the driven element wires.

Figure 7

14

Page 15

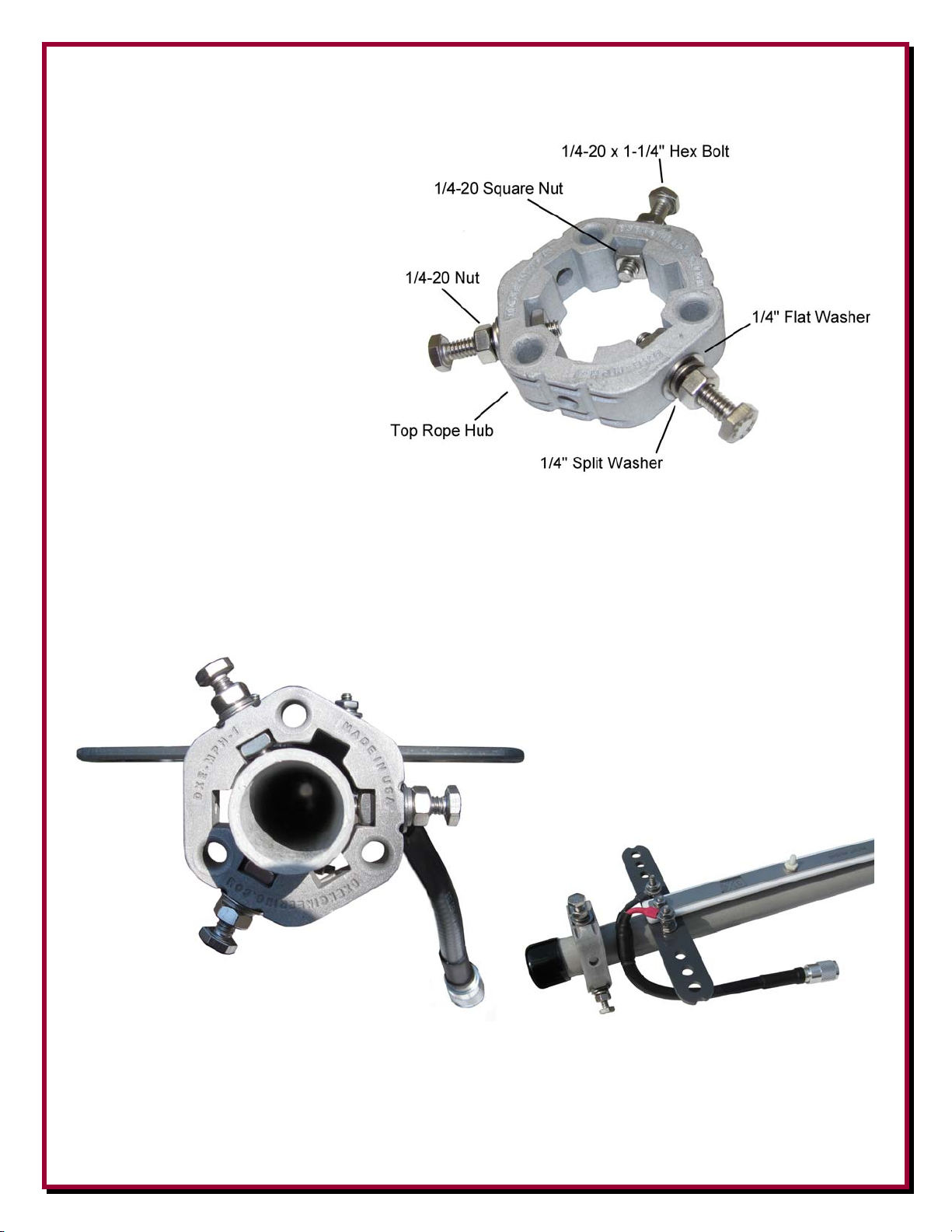

Installing the Center Post Rope Hub

Using Figure 8 as a reference,

assemble the center post rope

connection hub assembly with

hardware.

Figure 8

Install center post rope connection hub assembly, 1-1/2" from the top of the center post as shown

in Figure 9. Orient this hub so its vertical holes are facing between every other spreader. Tighten

the hub hardware carefully so the center post and the hub are concentric (space between the center

post and the interior of the hub is even). When tightened to the center post, lock the hex head bolts

in place by tightening the 1/4-20 hex nuts against the hub. Install the 1-1/4" black vinyl cap on the

top of the center post.

Figure 9

15

Page 16

Installing the optional Feedline Current Choke

Using the optional DXE-BMB-1P, attach the long aluminum strip to the

bottom of the optional DXE-FCC050-H05-A Feedline Current Choke.

Place the Feedline Current Choke on the Center Post using the two stainless

steel band clamps (included with the DXE-BMB-1P). One clamp is located

below the 20 meter feed point clamp and the lower band clamp is located

above the 17 meter element clamp as shown in Figure 10. Connect the

coaxial pigtail to the top of the Feedline Current Choke. If the optional

Feedline Current Choke is not installed, use the supplied UHF to UHF

adapter to connect your RG-213 (or equivalent) coaxial cable to the feedline

pigtail.

Figure 10

16

Page 17

Spreader Assembly

Locate the 25 fiberglass tubes. They are nested inside each other in the shipping box as shown in

Figure 11.

One 1-1/4" x 58" long fiberglass tube used for the center post assembly.

Six 1" OD x 58" long fiberglass tubes slit on one end for the spreaders.

Six 3/4" OD x 43" long fiberglass tubes slit on one end for the spreaders.

Six 1/2" OD x 48" long fiberglass tubes for the spreaders.

Six 3/4" OD x 5" long fiberglass tubes used to re-enforce the 1" OD tubes when

mounted in the Hexx Hub.

# Qty Fiberglass Tubes

1 1.25" OD x 58" Long

Figure 11 - Fiberglass Tubes

For ease of assembly and adjustment of the spreaders each element clamp tightening nut should be

under the spreader as you look down on the antenna.

Insert a 3/4" OD x 5" long fiberglass reinforcement tube flush into the un-slit end of each of the six

1" OD x 58" long fiberglass sections. When the 1" OD is slid into the one of the six Hexxagonal

Hub V-Saddle channels, under the V- Bolts ensure the smaller 5" long tube inside stays at the end.

These short 5" pieces are being used to re-enforce the 1" tube under the V-Bolts.

Leave a space of about 1/2" to 3/4" between the upper mast mount surface of the hub and the end of

each 1" OD spreader section. The slits at the far end should be aligned horizontally , not vertically.

Ensuring the inside tube does not move, tighten the V-bolt nuts evenly until the lock washers are

flattened, without crushing the section as shown in Figure 12.

6 1.00" OD x 58" Long Slit One End

6 0.75" OD x 43" Long Slit One End

6 0.50" OD x 48" Long

6 0.75" OD x 5" Long

17

Page 18

Figure 12

Place one DXE-ECL-10SS on each slit end of the six 1" OD sections. Slide the 3/4" OD x 43" long

sections into the 1" sections and clamp them together, adjusting the 3/4" section to 39" in length as

shown in Figure 13.

Ensure the slit ends are horizontally aligned, not vertical. Position the element clamp about 1/4" to

3/8" away from the end of the section when tightening. Do not over-tighten which will damage the

element clamp. The clamp tightening screw should be on the bottom of the tube assembly.

Figure 13

18

Page 19

Slide the 1/2" OD x 48" long fiberglass section into the 3/4" fiberglass sections. Referring to

Figure 14 for each spreader, slide the three 3/4" wire element guides, the DXE-ECL-60 band

clamp, the two 1/2" wire element guides and the Rope Connection clamps as shown.

Figure 14

For each spreader, slide the 3/4" fiberglass section out of the 1" OD section to 39" as shown in

Figure 15. Tighten the DXE-ECL-10SS. Slide the 1/2" OD long fiberglass section out of the 3/4"

OD sections to 42" as shown in Figure 15 and tighten the DXE-ECL-60 clamp. Position the

element clamps about 1/4" to 3/8" away from the end of the section when tightening. Do not overtighten which will damage the element clamp. The clamp tightening screw should be on the bottom

of the tube assembly. When completed, the three long sections (or tubes) making up one spreader

will be 139" in length.

Figure 15

Place and tighten the wire guides as shown in Figure 16 on the spreaders positioned vertically (PClamp up with loop toward the Hexx Hub - center of the antenna). These assemblies may be moved

for final positioning on your antenna. Snug the band clamps in place and do not tighten.

Figure 16

19

Page 20

Tighten each spreader rope connection assembly 1/2 " from the end of each spreader and tighten

with the clamp stud and cushioned p-clamp are positioned vertically as shown in Figure 17.

Figure 17

The Dacron Polyester rope that came with the Spreader and Center Post Package may now be cut

into specific lengths for the antenna assembly. After cutting this type of rope, the end should be

slightly melted with a flame to prevent unraveling. The dimensions indicated include extra length

for knots. Upon completion of the antenna, excess rope may be trimmed and re-melted.

Cut seven pieces of spreader support rope 136" in length (11’4”).

Cut one piece of rope 72" in length (6’).

Cut one piece of rope 106" in length (8’ 10").

Cut 10 element spacer ropes (2 for each band) to the 'cut lengths' dimensions in Table 1.

Band

Element Spacer Ropes

Cut Length

Element Spacer Ropes

Tied Length

20 30" 23-1/2"

17 24" 18"

15 22" 15-1/2"

12 20" 13-1/4"

10 18" 11-3/4"

Table 1 - Element Spacer Ropes

Caution: Bowed fiberglass spreaders can cause injury if they are accidentally released.

Be sure helpers are not in the proximity of a bowed spreader during assembly.

20

Page 21

Attach the 136" spreader support ropes onto each spreader rope connection assembly, knotting

through and around the cushioned p-clamp.

Working with help, if possible, using the step ladder positioned near the center of the antenna. Pull

on the spreader support rope to bow the spreader up. The spreader support rope will be horizontal

when the spreader is moved into the final antenna position. See Figure 18. Knot the rope through

one of the three vertically aligned holes on the center post support rope attachment hub. Adjacent

spreaders share rope attachment holes on this hub.

Figure 18

Repeat this process on the spreader on ‘opposite’ sides of the antenna until all six spreaders are

secured in their final position. Each spreader end will be at the same horizontal height position as

the rope attachment hub on the center post.

The seventh 136" rope is strung

between the spreader rope attachment

clamps at the end of the spreaders

adjacent to the feeder insulator,

across the front of the beam. Secure

this rope into a horizontal position

without pulling these two spreader

ends together as shown in Figure 19.

Figure 19

Ropes previously installed from the

ends of each spreader to the center

rope hub are not shown in this picture

for clarity.

21

Page 22

Install the 72" and the 106" ropes across the front of the beam, tied around the spreaders where the

smaller fiberglass spreader section is clamped into the next larger section. Secure these ropes into a

horizontal position with out pulling the middle sections of the two spreaders together as shown in

Figure 19. These two spreaders will now remain straight when the wire elements are strung around

and tied and straightened into position with tension.

Installing the Wire Elements

The precut and assembled wire sets have the wire guide tubes and ring terminals installed. The wire

lengths are as shown in Table 2. Minor variations in these lengths will not adversely affect antenna

performance.

Band

20 17' 10-1/2" 33' 10"

17 13' 10-1/4" 26' 3"

15 11' 10" 22' 6"

12 9' 11-1/2" 19'

10 8' 8-3/4" 16' 8-3/4"

Table 2 - Driven Wire Elements and Reflector Wire Elements

Start with the 20 meter band. Thread one end of the two driven element wires (front of beam) with

the black tubes and ring terminals through the previously installed wire guide clamps, positioning

one of the black tubes through each clamp as shown. The tubes are -pre-installed on the wire sets.

Once the tubes are in place, tighten the p-clamp to hold the tubes perpendicular to it's spreader as

shown in Figure 20.

Figure 20 22

Driven Elements (2)

Wire Length

Reflector

Wire Length

22

Page 23

Connect the 20 meter Driven Element Wires to the Five Band Stainless Steel/Teflon® Rigid Feeder.

Hardware previously installed to hold the coaxial pigtail is removed and re-used. Refer to Figure 21

for the hardware sequence.

Hardware Loose

Hardware installed

Side View Viewed from front of antenna

Figure 21

23

Page 24

The 20 meter reflector (rear of beam) wire with black tubes and ring terminals is threaded through

the p-clamps used for the reflectors in the same manner as the driven element. Thread the wire and

black tubes through and position one tube in each p-clamp.

Note: Although not normally required, minor adjustment, or trimming of each wire driven element

and/or reflector element wire may be needed to minimize the SWR. Additional Ring Terminals are

supplied for this purpose.

Figure 22

Repeat the sequence to install the 17 meter driven element wires and the 17 meter reflector wire.

The coaxial cable pigtail is only installed on the 20 meter

feed.

Repeat the sequence to install the 15 meter driven element

wires and the 15 meter reflector wire.

Repeat the sequence to install the 12 meter driven element

wires and the 12 meter reflector wire.

Repeat the sequence to install the 10 meter driven element

wires and the 10 meter reflector wire.

24

Page 25

Figure 23 is a side view for reference showing the wire elements installed.

Figure 23

Rope for the element spacers are installed for each band as shown in Figure 24. The cut and final

measurements are shown in Table 3.

Band

20 30" 23-1/2"

17 24" 18"

15 22" 15-1/2"

12 20" 13-1/4"

10 18" 11-3/4"

Element Spacer Ropes

Cut Length

Table 3

Element Spacer Ropes

Tied Length

Figure 24

Note: Although not normally required, minor adjustment, or trimming of a particular wire driven

element and/or reflector element wire may be needed to minimize the SWR. Additional information

on tuning is found in the section: "SWR Testing" at the end of these assembly instructions.

Additional Ring Terminals are supplied for this purpose.

25

Page 26

Final leveling and slight tension on the wires is accomplished by small, equal adjustments of the

wire guide stud clamp positions on the spreaders away from the center of the antenna. Too much

tension will distort the shape of the spreaders and slacken the other wire elements. This adjustment

process may take some time to get an acceptable balance between element tensions, but the goal is

to have all of the wires horizontal, evenly spaced, with only slight tension to prevent antenna wires

from moving toward and away from each other in gentle breezes. The unique feature of the

“floating wire guides” will allow all of the spreaders and wires to move independently in strong

winds without causing undue stress, and then return to their natural position.

Remember, having tight wires will not improve performance - only appearance. A little slack is

better than too tight. This will eliminate stretching of the element wires and unnecessary tension on

the wire ring terminals.

Perform final tightening of all spreader clamps, wire guide and rope attachment p-clamp hardware

and stud clamps. DO NOT over tighten these stainless steel element clamps. A modest tightening of

these small gear screws will accomplish sufficient hold.

If the optional Feedline Current Choke was not installed, connect a coaxial cable (RG-213 or

equivalent) feedline to the included dual female SO-239 (UHF to UHF) adapter installed at the end

of the pigtail. If the optional Feedline Current Choke is installed, connect your coaxial cable

feedline (RG-213 or equivalent) to the bottom of the Feedline Current Choke. Use electrical tape to

hold the coaxial cable to the center post.

Installation on a Mast and Rotator

The aluminum tube that holds the Fiberglass

Center Post is supplied with the Hexxagonal

Beam. This tube has an outside diameter of

1-3/8" and may be used directly into a

rotator. When mounting the completed

Hexxagonal Beam on the customer supplied

mast, use mast or tubing that has an inside

diameter of 1-3/8".

This mast could be 3 feet or 6 feet long

depending on your rotator specifications.

When using DX Engineering tubing, use

two pieces of .058" wall thickness tubes that

are 1-1/2" OD and 1-5/8" OD and nested

together to give you a thick wall mast that

the 1-3/8" tube will fit in.

Once mounted, the mast should be held to

the Hexxagonal Beam tube by drilling one

or two holes and pinning as shown in the

picture.

26

Page 27

Install your completed DX Engineering HEXXAGONAL BEAM Mark 2 with a rotator at a height

of at least 25 feet for very good results. The best overall results are realized with the antenna at 35

to 65 feet.

SWR Testing

The HEXXAGONAL BEAM Mark 2 should not require tuning. SWR may be checked when the

antenna is at least 8 feet above the ground, however SWR dips may not be under 2:1 or not in the

band. Once the antenna is elevated to operating position, SWR curves should dip below 1.5:1 within

each band, with much lower SWR likely near the low end or middle of the 20 and 15 meter bands,

and lowest SWR around 28.200 MHz in the 10 meter band, however the G3TXQ broadband version

provides low SWR over a wide frequency range. If any adjustments are desired, they should be

done incrementally and simultaneously with a small changes of driven and reflector element wire

lengths. Example: Tuning on 10 meters is done by trimming approximately 1/4" on each driven

element wire and approximately 1/2" on the end of the respective reflector wire. Extra Ring

Terminals are included in the kit to allow replacements as you trim the wire lengths. Once the

frequency of the lowest SWR may appear below the band, if the SWR is checked before the antenna

is elevated into appropriate position. Reasonable SWR should be the result on all bands after the

antenna is elevated.

Temporary accumulation of moisture or ice on the element spacer ropes has very little effect on

SWR.

Enjoy your high quality, DX Engineering HEXXAGONAL BEAM, which should offer years of

trouble free performance.

****************************************************************************

27

Page 28

Resume assembly from this point if you are building the 1-Band Total Antenna Package DXE-HEXX-1TAP

This kit is used to make one band HEXXAGONAL BEAM wire elements and attach them to our

unique floating element wire guides. The floating wire guides allow your spreaders to have

independent movement during windy conditions reducing stress and strain on the element wires and

spreaders.

Assembly of the Hexx Hub, Spreaders, Wire Gide Clamps, Rope Clamps and Rope Hub is identical

to the Five Band version. The difference being the Single Band has one feedpoint assembly that you

will locate on the center post at the desired height for a particular band. The wire element set

included is already measured and pre-assembled for 20 meters. If you desire a different band, the

wire elements will have to be trimmed accordingly. Extra ring terminals are included in this kit to

accomplish that task.

The HEXXAGONAL BEAM 1-band Coax Feeder is custom made from high quality coaxial cable.

The ring terminals are crimped, hand soldered and special weatherproof adhesive shrink tubing

installed for a long lasting precision feedline assembly. The coaxial cable center conductor

connection has red shrink tubing on the ring terminal.

Exclusive DX Engineering stainless steel band clamp with welded stud provides a secure

attachment for the driven element feedpoints without drilling. The high strength insulator features

serpentine wire grip and stainless steel hardware providing superior connections for trouble free

operation.

DXE-HEXX-1WRP-2 HEXXAGONAL BEAM 1-Band Wire Element & Wire Guide

Qty Description

2

1

6

20 Meter Wire Driven Element - #14 Copper Stranded Wire with Black PVC

Insulation with Ring Terminals attached and Wire Guides installed

20 Meter Wire Reflector Element - #14 Copper Stranded Wire with Black

PVC Insulation with Ring Terminals attached and Wire Guides installed

#10 hole, 16-14 Wire Gauge Ring Terminal

(Spares for various bands and/or adjustment in element lengths)

1 UHF Female-to-Female Adapter (dual SO-239 style)

1 Coax Wire Assembly, 10" with PL-259 and Ring Terminals

1 Single Band Feeder Insulator Clamp Assembly

60" Double-braided Dacron/Polyester rope

6 Floating Wire Guides for 3/4" Spreader.

28

Page 29

Choose the band you are constructing and install the Wire Guide as shown below on a typical spreader

positioned vertically. These assemblies may be moved for final positioning on your antenna. Snug them in

place and do not tighten.

5-Band positions - Choose one

Mount the Single Band Insulator Center Feed Clamp Assembly on the vertical post in the position for the

chosen band. One end of the two Driven Element Wires is threaded through the wire guide clamps and

connected to the center feed. Route the wires through the center insulator in a serpentine manner as shown.

29

Page 30

Thread the other end of the two Driven Element Wires (front of beam) with the black tubes and ring terminals through

the previously installed Wire Guide Clamps, positioning one of the Black Tubes through the clamp as shown. Once the

tubes are in place, tighten the clamp to hold the tubes.

Depending on the band you are installing, the reflector and the

driven elements may be a different length than the supplied set

of elements which are cut for 20 meters and have the black tubes

and ring terminals installed.

For the other bands, you will have to trim the lengths and install

new ring terminal. There are 6 spare ring terminals included in this kit.

Band

Driven Elements (2)

Wire Length

Reflector

Wire Length

20 17' 10-1/2" 33' 10"

17 13' 10-1/4" 26' 3"

15 11' 10" 22' 6"

12 9' 11-1/2" 19'

10 8' 8-3/4" 16' 8-3/4"

Note: Although not normally required, minor adjustment, or

trimming of each wire driven element and/or reflector element

wire may be needed to minimize the SWR. Additional Ring

Terminals are supplied for this purpose.

The reflector (rear of beam) wires with black tubes and ring terminals are threaded through the clamps used for the

reflector in the same manner as the driven elements. Thread the wires & black tubes through and position one tube in

each clamp. Later, once all wire elements are in place you will tighten the clamps that hold the wire guides in place.

Using the 60" of rope included, cut two pieces to the length

required for the band you are building. Use the rope to

make and connect the elements together for the band

you have chosen as shown

Element

Band

20 30" 23-1/2"

17 24" 18"

15 22" 15-1/2"

12 20" 13-1/4"

10 18" 11-3/4"

Spacer Ropes

Cut Length

Element

Spacer Ropes

Tied Length

30

Page 31

NOTE: Creating a 2-band antenna by

adding a 1-Band Kit to a 1-band

HEXXAGONAL BEAM may require

special length jumpers and special

element dimensions which may vary from

the dimensions in this manual. The

process of creating a two-band antenna

has not been evaluated by DX

Engineering. The owner of the antenna

assumes the responsibility to make the

element and coax jumper lengths required

for a 2 band model.

31

Page 32

Optional Items

The DX Engineering HEXXAGONAL BEAM Kits and Total Antenna Packages are ideal for

either an experimenter or an operator. They are do not require advanced skills to assemble, but

they offer plenty of options for making your own design.

DXE-HEXX-5TAP-2 - The DX Engineering HEXX BEAM Mark 2 - Five-Band Total Antenna Package

consists of these four kits:

DXE-HEXX-1HBP HEXXAGONAL BEAM Hub package (US Patent No. D605,184)

DXE-HEXX-1SCP-2 HEXXAGONAL BEAM Spreader & Center Post package

DXE-HEXX-5FFP HEXXAGONAL BEAM 5-Band Stainless Steel/Teflon

Patent Pending

DXE-HEXX-5WRP-2 HEXXAGONAL BEAM 5-band Wire Element & Wire Guide package

DXE-HEXX-1TAP-2 - The DX Engineering HEXX BEAM 1-Band Total Antenna Package consists of

these three kits:

DXE-HEXX-1HBP HEXXAGONAL BEAM Hub package (US Patent No. D605,184)

DXE-HEXX-1SCP-2 HEXXAGONAL BEAM Spreader & Center Post package

DXE-HEXX-1WRP-2 HEXXAGONAL BEAM 1-band Wire Element & Wire Guide package

DXE-FCC050-H05-A - Feedline Current Choke, 2 kW, for Coaxially Fed 50 Ω Antennas - Aluminum Enclosure

The DXE-FCC050-H05-A Feedline Current Choke, using Maxi-Core® technology, prevents unwanted RFI by eliminating feedline

current and radiation in 50 , coaxially fed antenna systems. It provides excellent feedline decoupling and low loss performance

from 1 to 60 MHz and is power rated for 2 kW continuous, 5 kW intermittent. The FCC has significantly higher common mode

impedance and a larger effective core area than similar line isolators, including conventional enameled wire or bead baluns.

This results in:

Higher power handling with lower loss – more power to the antenna

Improved antenna bandwidth – easier on the radio

Reduced RFI – less interference to and from your radio

Compensation for a less than optimal ground system

While most common advice is to improve the station’s RF ground, the root of the problem is in the poor isolation of the

feedline from antenna currents. In other cases, as the coax feedline travels through the near-field of the antenna, the current

can be re-introduced to the feedline after the balun. If your SWR is already low and you wish to reduce feedline radiation

(RFI) and improve reception, an FCC is recommended. The DXE-FCC050-H05-A Feedline Current Choke is designed for

use with coaxially fed, 50 antennas of many varieties including verticals with elevated radials. It is rated at 2 kW.

DXE-BMB-1P - Balun Mounting Kit for a .750 in. thru 1.50 in. Boom

This handy Aluminum mounting bar and Stainless Steel hardware kit will allow you to mount your quality DX

Engineering Balun, Feed Line Current Choke, or Vertical Feedline Current Choke, directly to a .750 in. thru 1.50

in. boom or pipe.

Kits includes:

(1) Mounting Bracket

(1) Bracket Hardware Kit

(2) Boom Clamps

Bar Material: Aluminum

Bar Hardware and Element Clamp Material: Stainless Steel

Bar Dimensions: 10 x 1.00 x .125 (inches)

®

Rigid Feeder System

32

Page 33

DXE-81343, NSBT8 - Anti-Seize & Never-Seez

An Anti-seize compound MUST be used on any Stainless Steel nuts, bolts, clamps or other hardware to prevent galling and

thread seizure. Any of these products can be used for this purpose.

*DXE-81343 Anti-Seize, 1 oz. Squeeze Tube

*DXE-81464 Anti-Seize, 8.5 oz. Aerosol Can

*DXE-NSBT8 Never-Seez, 8 oz. Brush Top

*DXE-NMBT8 Never-Seez, 8 oz. Brush Top, Marine Grade

* These products are limited to domestic UPS Ground shipping only

DXE-3M2155 - 3M Temflex™ 2155 Rubber Splicing Tape.

Conformable self-fusing rubber electrical insulating tape. It is designed for low voltage electrical insulating and moisture

sealing applications. For outdoor use, it should be protected from UV deterioration with an overwrap of DXE-33PLUS

DXE-33PLUS - Scotch® Super 33+.

Highly conformable super stretchy tape for all weather applications. This tape provides flexibility and easy handling for

all around performance. It also combines PVC backing with excellent electrical insulating properties to provide primary

electrical insulation for splices up to 600V and protective jacketing.

MFJ HF/VHF Antenna/SWR/RF Analyzer w/ LCD, Counter & Meters - MFJ-259B

The MFJ-259B RF analyzer is a compact battery powered RF impedance analyzer. This unit combines four basic circuits;

a 1.8-170 MHz variable frequency oscillator, a frequency counter, a 50 ohm RF bridge, and an eight-bit micro-controller.

This unit makes a wide variety of useful antenna or impedance measurements, including coaxial cable loss and distance to

an open or short. Primarily designed for analyzing 50 ohm antenna and transmission line systems, the MFJ-259B also

measures RF impedances between a few ohms and several hundred ohms. It also functions as a signal source and

frequency counter. The frequency range of impedance measurement is 1.8 to 170 MHz, in six overlapping bands. Requires

10 AA size batteries for portable operation (not furnished). See "Suggested Parts" above for AC adapter and accessories.

RG-8/U Foam Coax Assemblies

These DX Engineering cable assemblies use high quality Belden 8214/RG-8/U Foam dielectric coaxial cable and

include Silver Teflon PL-259 (UHF) connectors installed at each end. RG-8/U cable is protected by a PVC jacket

and is normally recommended for indoor applications - or protected areas where ultraviolet contamination is

unlikely to occur. When comparison shopping, note that RG-8/U is no longer a government MIL-spec cable leaving it open to interpretation by many manufacturers. When in doubt, use RG-213/U with a non-contaminating

PVC jacket for longest life in most outdoor applications. The coax has a flexible 11 gauge stranded copper center, foamed Poly

dielectric, 97% coverage bare copper shield and a black PVC jacket. The PL-259 connector is silver plated with a silver plated center

conductor. Connectors are soldered rather than crimped and an adhesive lined shrink tubing is used to form a weather-resistant bond

between the connector body and the coax. Each assembly is then 100% Hi-Pot tested to guarantee a quality cable assembly you can

count on.

Custom Lengths Available, Call DX Engineering for Details

Part # Part Name

DXE-CBC-008U002 Coax Cable, RG-8/U, UHF connectors, 2 feet for BTV DCF kit

DXE-CBC-008U003 Coax Cable, RG-8/U, UHF connectors, 3 feet

DXE-CBC-008U006 Coax Cable, RG-8/U, UHF connectors, 6 feet

DXE-CBC-008U012 Coax Cable, RG-8/U, UHF connectors, 12 feet

33

Page 34

RG-213/U Coax Assemblies

These DX Engineering cable assemblies use high quality Belden 8267/RG-213/U coaxial cable and include

Silver/Teflon PL-259 (UHF) or male N connectors installed at each end. RG-213/U cable is protected by a noncontaminating PVC jacket and is normally recommended for both indoor and outdoor applications. The UV

stabilized jacket assures long life where ultraviolet contamination is a concern. Covered by a government MIL-spec

(MIL-C-17, M17/163-00001), you can always be sure of getting the highest quality cable. The coax has a flexible 13

gauge stranded copper center, Poly dielectric, 96% coverage bare copper shield and a non –contaminating PVC jacket. The PL-259

connector is Silver/Teflon with a silver plated center conductor. The N connector is Silver/Teflon with a gold center conductor.

Connectors are soldered rather than crimped and an adhesive lined shrink tubing is used to form a weather-resistant bond between the

connector body and the coax. Each assembly is then 100% Hi-Pot tested to guarantee a quality cable assembly you can count on.

Custom Lengths Available, Call DX Engineering for Details

Part # Part Name

DXE-CBC-213U3 Coax Cable Assembly, RG-213/U Coax, with PL-259 Connectors, 3ft.

DXE-CBC-213U6 Coax Cable Assembly, RG-213/U Coax, PL-259 Connectors at each end, 6ft.

DXE-CBC-213U12 Coax Cable Assembly, RG-213/U Coax, with PL-259 Connectors, 12ft.

DXE-CBC-213U25 Coax Assembly, RG-213/U Coax, WITH PL-259 Connectors, 25ft.

50 Ohm Coax Cable Prep Tools

The UT-8213 simplifies the preparation of RG-8 or RG-213 coax to accept PL-259 UHF style or 2-piece Type N

connectors. The UT-808X is specifically designed for stripping RG-8X/Belden 9258 cable. The CNL-911 cutters have

specially designed blades to cut the cable without crushing it - leaving the end cleanly cut and ready for stripping and

connector assembly. The UT-80P or UT-80N allow mechanical assembly of the PL-259 or 2-piece Type N connector

body to the cable without shredding it with pliers. All DX Engineering Cable Prep Tools are designed and selected to

provide better results, with greater ease of use.

Part # Part Name

DXE-UT-8213 Coax Cable Stripper for RG-213, RG-8, 9913F7, LMR-400 etc.

DXE-UT-808X Coax Cable Stripper for RG-8X, Belden 9258, LMR-240

DXE-UT-RB-HD Premium Replacement Blades for DX Engineering and Cablematic Strippers

DXE-UT-80P Connector Assembly Tool for PL-259/RG-213-size Cable

DXE-CNL-911 Coax Cable Cutter

DXE-170M Precision Shear Side Cutters

34

Page 35

Notes:

35

Page 36

Technical Support

If you have questions about this product, or if you experience difficulties during the installation,

contact DX Engineering at (330) 572-3200. You can also e-mail us at:

DXEngineering@DXEngineering.com

For best service, please take a few minutes to review this manual before you call.

Warranty

All products manufactured by DX Engineering are warranted to be free from defects in material and workmanship for a

period of one (1) year from date of shipment. DX Engineering’s sole obligation under these warranties shall be to issue

credit, repair or replace any item or part thereof which is proved to be other than as warranted; no allowance shall be

made for any labor charges of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such

charges are authorized in advance by DX Engineering. If DX Engineering’s products are claimed to be defective in

material or workmanship, DX Engineering shall, upon prompt notice thereof, issue shipping instructions for return to

DX Engineering (transportation-charges prepaid by Buyer). Every such claim for breach of these warranties shall be

deemed to be waived by Buyer unless made in writing. The above warranties shall not extend to any products or parts

thereof which have been subjected to any misuse or neglect, damaged by accident, rendered defective by reason of

improper installation, damaged from severe weather including floods, or abnormal environmental conditions such as

prolonged exposure to corrosives or power surges, or by the performance of repairs or alterations outside of our plant,

and shall not apply to any goods or parts thereof furnished by Buyer or acquired from others at Buyer’s specifications.

In addition, DX Engineering’s warranties do not extend to other equipment and parts manufactured by others except to

the extent of the original manufacturer’s warranty to DX Engineering. The obligations under the foregoing warranties

are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other

remedies including claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY

OTHER WARRANTY WHATSOEVER, WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME

FOR DX ENGINEERING ANY OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE

FOREGOING.

©DX Engineering 2010

DX Engineering®, DXE®, Hot Rodz™, Maxi-Core™, THUNDERBOLT™, Antenna Designer™, Yagi Mechanical™,

and Gorilla Grip™ Stainless Steel Boom Clamps, are trademarks of PDS Electronics, Inc. No license to use or

reproduce any of these trademarks or other trademarks is given or implied. All other brands and product names are the

trademarks of their respective owners.

Specifications subject to change without notice.

36

Loading...

Loading...