Page 1

Universal Copper Grounding Clamp

DXE-UCGC-Z

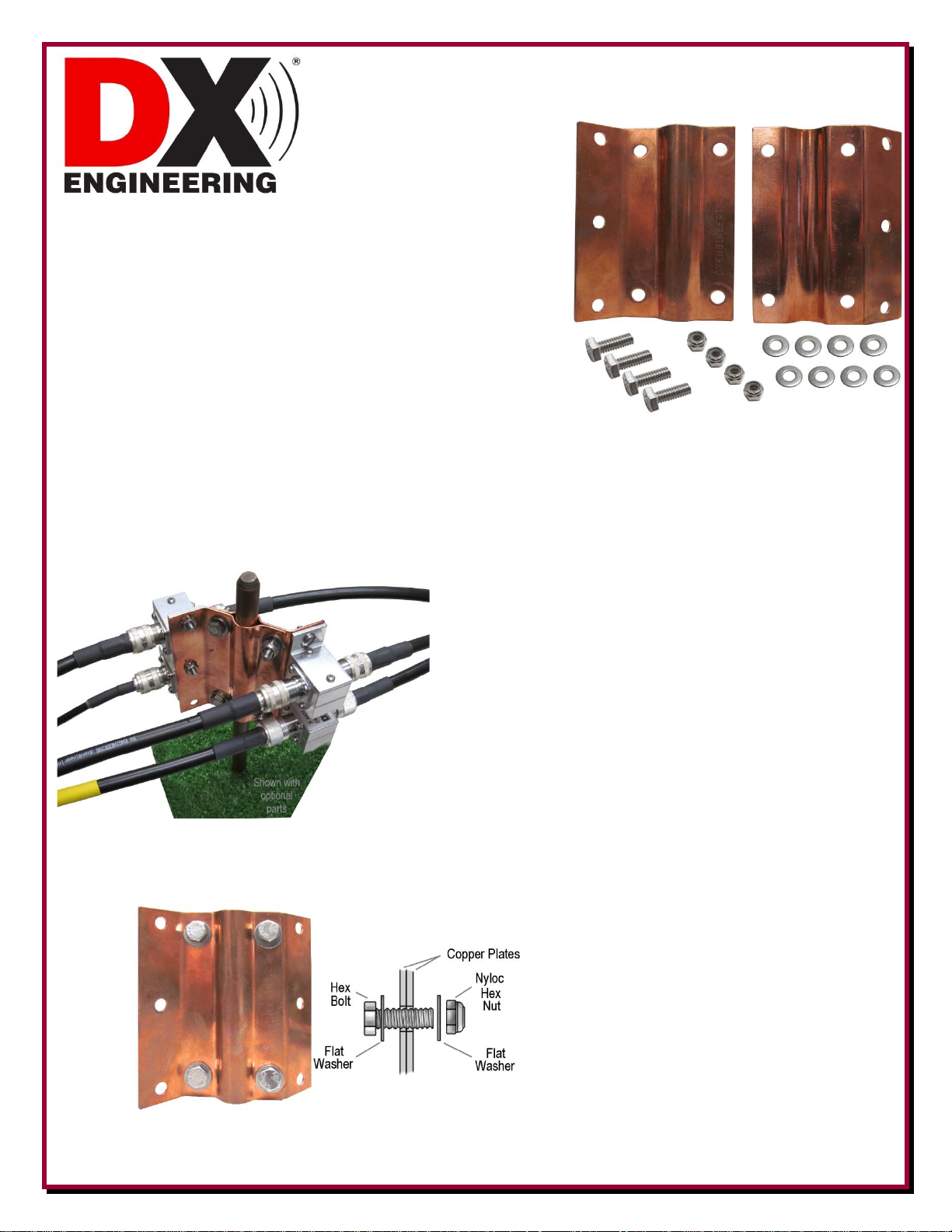

The DXE-UCGC-Z Universal Copper Grounding Clamp is

custom designed to provide a mounting platform for various

types of lightning protectors commonly used for Amateur

Radio. The “Z” design makes it easy to install and remove

coaxial cable connectors. Ideal for both permanent installations

and for temporary installations such as Field Day.

The DXE-UCGC-Z Features:

Made from 1/16” thick Copper Alloy 110 for maximum

conductivity with a “Z” bend for easier installation and

removal of coax connectors

Easy to assemble two-piece construction. Each plate is approximately 3-1/4” wide x 4-3/16” tall.

Fits common standard 5/8” through 3/4” diameter ground rods.

Using this copper clamp is faster and easier than building up the joint for an exothermic weld.

1/4” Stainless Steel hardware is included: Eight 1/4” Flat Washers, four 1/4”-20 Nyloc Hex Nuts and

four 1/4”-20 x 3/4” long Hex Head Bolts.

The DXE-UCGC-Z can easily mount up to six lightning

protectors. The photo shows two DX Engineering and

two PolyPhaser lightning protectors installed on a DXE-

UCGC-Z mounted to a 5/8” diameter ground rod. Other

lightning protection products can also be mounted, such

as the DXE-IS-RCT Control Line Protector and Alpha

Delta Lightning Protectors.

An anti-seize compound such as JTL-12555 Jet Lube

SS-30 Pure Copper Anti-Seize must be used on the

threads to prevent galling or seizing of stainless steel

hardware. All connections must be generously coated

with a conductive joint compound to prevent

moisture penetration and enhance conductivity such as JTL-12555 Jet Lube SS-30 Pure Copper

Anti-Seize. DX Engineering’s DXE-CCK Copper Cleaning Kit contains the proper joint cleaning

compound, brush and cleaning pad to properly prepare the copper surfaces.

Choose your mounting scheme and position

the lightning protectors (in this example 2 DX

Engineering and 2 PolyPhaser lightning

protectors) where you want them.

Depending on the types and positions, the

four hex head 1/4”-20 bolts, eight flat washers

and four Nyloc nuts used to hold the two copper

plates together may be loosely installed. In this

example 3 of the hex bolts go in one

direction while the fourth one is reversed to

allow clearance for one of the PL-259 connectors. Use the mounting hardware that comes with the

Page 2

2

individual lightning protectors to attach them. The lightning protectors and copper clamp plates must be

thoroughly cleaned to remove any oxidation where surfaces mate to each other.

Once the position of the protectors is established and the four hex head bolts, eight flat washers and four

Nyloc nuts are installed, you can mount the DXE-UCGC-Z on your existing ground rod. Tighten the four

bolts evenly until the plates are flush to each other. Note: Some distortion of the copper plates may occur

while tightening.

Prior to attaching the lightning protectors, you may

want to install the proper coaxial cable lines to the

protectors and weather seal the PL-259 connectors

using 3M Temflex Rubber Tape with an overwrap

of 3M 33+ Vinyl Tape or 3M Super 88 Vinyl Tape.

Also, the lightning protector bodies are not

weatherproof and it is suggested to use the DX

engineering WK-1 Weatherproofing kit, or

completely tape the body of the protectors using the

same weatherproofing tapes as you used on the

connectors. Some users have also suggested

covering the entire assembly with a plastic food

container or plastic trash bin.

As with all electronic equipment, take proper safety considerations. For example: Do not install if there is

a storm anywhere in your area. Do not adjust or touch the grounding system equipment when there is a

storm anywhere in your area. Make sure all power is removed before making any adjustments or working

on any ground system or grounding components.

Technical Support

If you have questions about this product, or if you experience difficulties during the installation, contact

DX Engineering at (330) 572-3200. You can also e-mail us at:

DXEngineering@DXEngineering.com

For best service, please take a few minutes to review this instruction sheet before you call.

Warranty

All products manufactured by DX Engineering are warranted to be free from defects in material and workmanship for a period of one (1) year from date of shipment. DX

Engineering’s sole obligation under these warranties shall be to issue credit, repair or replace any item or part thereof which is proved to be other than as warranted; no allowance

shall be made for any labor charges of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such charges are authorized in advance by DX Engineering. If

DX Engineering’s products are claimed to be defective in material or workmanship, DX Engineering shall, upon prompt notice thereof, issue shipping instructions for return to DX

Engineering (transportation-charges prepaid by Buyer). Every such claim for breach of these warranties shall be deemed to be waived by Buyer unless made in writing. The above

warranties shall not extend to any products or parts thereof which have been subjected to any misuse or neglect, damaged by accident, rendered defective by reason of improper

installation, damaged from severe weather including floods, or abnormal environmental conditions such as prolonged exposure to corrosives or power surges, or by the performance

of repairs or alterations outside of our plant, and shall not apply to any goods or parts thereof furnished by Buyer or acquired from others at Buyer’s specifications. In addition, DX

Engineering’s warranties do not extend to other equipment and parts manufactured by others except to the extent of the original manufacturer’s warranty to DX Engineering. The

obligations under the foregoing warranties are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other remedies including

claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY OTHER WARRANTY WHATSOEVER, WHETHER EXPRESS, STATUTORY,

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME FOR DX ENGINEERING ANY

OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE FOREGOING.

©DX Engineering 2021

DX Engineering®, DXE®, DX Engineering, Inc.®, Hot Rodz®, Maxi-Core®, DX Engineering THUNDERBOLT®, DX Engineering Yagi Mechanical®, EZ-BUILD®, TELREX®,

Gorilla Grip® Stainless Steel Boom Clamps, Butternut®, SkyHawk™, SkyLark™, SecureMount™, OMNI-TILT™, RF-PRO-1B®, AFHD-4® are trademarks of PDS Electronics,

Inc. No license to use or reproduce any of these trademarks or other trademarks is given or implied. All other brands and product names are the trademarks of their respective owners.

Specifications subject to change without notice.

1200 Southeast Ave. - Tallmadge, OH 44278

Phone: (800) 777-0703 ∙ Tech Support and International: (330) 572-3200

Fax: (330) 572-3279 ∙ E-mail: DXEngineering@DXEngineering.com

DXE-UCGC-Z-INS Revision 0a

Loading...

Loading...