Page 1

Weatherproofing

Coaxial Cable

Connections

DXE-TECHTIP-WPCC Rev 3

© DX Engineering 2015

1200 Southeast Ave. - Tallmadge, OH 44278

Phone: (800) 777-0703 ∙ Tech Support and International: (330) 572-3200

Fax: (330) 572-3279 ∙ E-mail: DXEngineering@DXEngineering.com

Page 2

Weatherproofing Your Coaxial Cable Connections

This DX Engineering Tech-Tip will show you the preferred way to reliably weatherproof your

coaxial connections.

Over the years many different methods have been used to weatherproof coaxial cable connections.

Some worked, some did not. Once water or condensation enters your coaxial cable, it will ruin it, or

worse yet, cause shorting or high SWR conditions which could lead to permanent damage to your

transmitter.

One type of coaxial sealing material is a gummy tar like substance that you wrap around the coaxial

connection. This gummy substance works pretty good, except when you try to remove it for

maintenance or coaxial cable replacement, it can cause further problems. The gummy substance just

doesn't come off cleanly and small bits of it may remain in the threads of PL-259's or SO-239's.

These small bits of material are mini-insulators, and could cause intermittent operation.

The method described in this DX Engineering Tech-Tip uses a combination of two types of tape

which not only protect your coaxial connection, but also allow easy removal for future maintenance.

The two products, available from DX Engineering, used in this Tech-Tip are:

TES-2155 - 3M Temflex™ 2155 Rubber Splicing Tape.

Conformable self-fusing rubber electrical insulating tape. It is designed for low

voltage electrical insulating and moisture sealing applications. For outdoor use, it

should be protected from UV deterioration with an overwrap of TES-06132

TES-06132 - Scotch® Super 33+.

Highly conformable super stretchy tape for all weather applications. This tape

provides flexibility and easy handling for all around performance. It also combines

PVC backing with excellent electrical insulating properties to provide primary

electrical insulation for splices up to 600V and protective jacketing.

These tapes can be used indoors or outdoors. When used outdoors the temperature should be above

freezing, and if it's raining, keep the assembly you are wrapping covered and dry while applying the

tapes. Any airborne moisture such as fog, rain and snow may cause the tape to not stick properly, so

take adequate precautions to protect the assembly you are weatherproofing.

Additionally, the coaxial cable and connectors should be clean and free of any moisture, dirt or

other residues.

- 1 -

Page 3

1. The only tool you will need for this procedure is a pair of scissors. This example is using two

pieces of coaxial cable with PL-259 connectors that are joined together with a short UHF barrel

connector. This same method may be used on any connection you are weatherproofing.

2. Cut a piece of TES-2155 - 3M Temflex™ 2155 Rubber Splicing Tape long enough to complete

the job you are doing. If the length you

cut is too short, that's okay. You can add

more where needed and it will not

compromise the weatherproofing.

In this example a 15" length of the TES-

2155 - 3M Temflex™ 2155 Rubber

Splicing Tape was used to weatherproof

two PL-259's tightly connected together

with a short UHF barrel connector.

3. The TES-2155 - 3M Temflex™ 2155 Rubber Splicing Tape has a protective backing material

so the tape will not stick to itself when on the roll. As shown below, peel this protective

backing off of the length that you cut from the roll.

- 2 -

Page 4

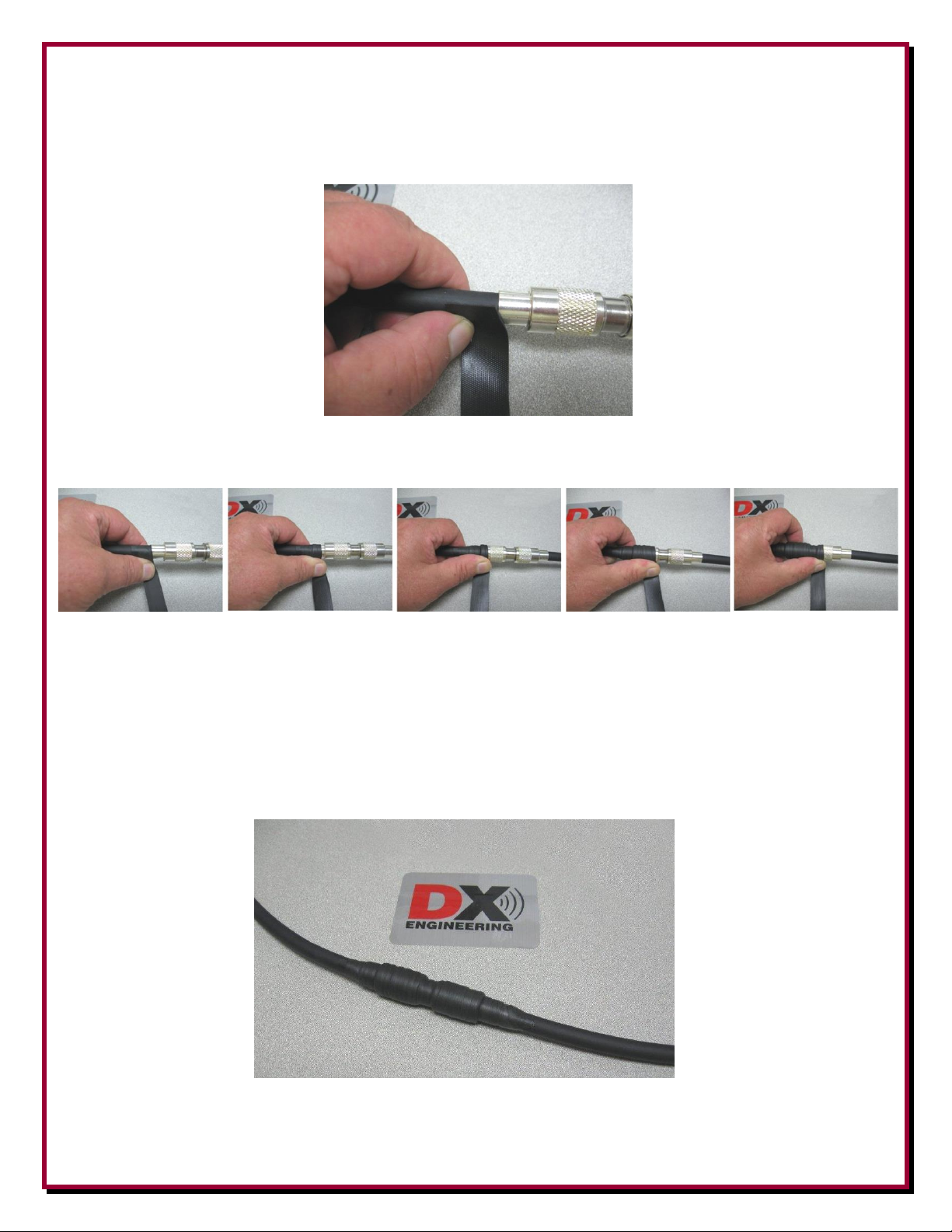

4. Starting at one end, hold the end of the cut length of TES-2155 - 3M Temflex™ 2155 Rubber

Splicing Tape in place about one inch before the end of the PL-259 and stretch it out until the

width of the tape is about 50% as shown below.

Starting

Stretched while overlapping wraps

5. While keeping the TES-2155 - 3M Temflex™ 2155 Rubber Splicing Tape stretched, wrap the

tape around the assembly and overlap the previous wrap by about 50%. Keep going until the

complete assembly is covered, and go an extra inch beyond.

If the length you cut is too short for the entire assembly, that's okay. You can add more starting

where the one piece ended and then continue on in the same manner described above.

This completes the first layer wrap. TES-2155 - 3M Temflex™ 2155 Rubber Splicing Tape

requires an added wrap of TES-06132 - Scotch® Super 33+ tape for UV protection.

- 3 -

Page 5

6. Starting about one inch before the

previously installed 3M Temflex™ 2155

Rubber Splicing Tape start a wrap of the

TES-06132 - Scotch® Super 33+ tape.

While wrapping, over lap the previous

wrap by about 50%. Use firm pressure

while wrapping to ensure the tape is on

flat and there are no wrinkles or open

spots.

Keep wrapping the Scotch® Super 33+

tape until you are about an inch past the

end of the previously installed 3M

Temflex™ 2155 Rubber Splicing Tape.

Using these quality products and this method, the completed weatherproofing will be complete

and reliable.

- 4 -

Page 6

Removal of Weatherproofing

There comes a time when you have to separate the previously weatherproofed coaxial cable

connections for maintenance or some other reason. This is when you will be glad you used the

above method to put on the weatherproofing!

1. Carefully cut the weatherproofing as shown. Be careful not to cut the coaxial cable, or your

fingers. Peel the weatherproofing off and the assembly will look like new.

Looking at the removed weatherproofing, you can see the TES-2155 - 3M Temflex™ 2155 Rubber

Splicing Tape conformed to your assembly and fully protected the assembly when it had been

properly applied as described in this Tech-Tip.

- 5 -

Page 7

Technical Support

If you have questions about this product, or if you experience difficulties during the installation, contact DX

Engineering at (330) 572-3200. You can also e-mail us at:

DXEngineering@DXEngineering.com

Warranty

All products manufactured by DX Engineering are warranted to be free from defects in material and workmanship for a

period of one (1) year from date of shipment. DX Engineering’s sole obligation under these warranties shall be to issue

credit, repair or replace any item or part thereof which is proved to be other than as warranted; no allowance shall be

made for any labor charges of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such

charges are authorized in advance by DX Engineering. If DX Engineering’s products are claimed to be defective in

material or workmanship, DX Engineering shall, upon prompt notice thereof, issue shipping instructions for return to

DX Engineering (transportation-charges prepaid by Buyer). Every such claim for breach of these warranties shall be

deemed to be waived by Buyer unless made in writing. The above warranties shall not extend to any products or parts

thereof which have been subjected to any misuse or neglect, damaged by accident, rendered defective by reason of

improper installation, damaged from severe weather including floods, or abnormal environmental conditions such as

prolonged exposure to corrosives or power surges, or by the performance of repairs or alterations outside of our plant,

and shall not apply to any goods or parts thereof furnished by Buyer or acquired from others at Buyer’s specifications.

In addition, DX Engineering’s warranties do not extend to other equipment and parts manufactured by others except to

the extent of the original manufacturer’s warranty to DX Engineering. The obligations under the foregoing warranties

are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other

remedies including claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY

OTHER WARRANTY WHATSOEVER, WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME

FOR DX ENGINEERING ANY OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE

FOREGOING.

©DX Engineering 2015

DX Engineering®, DXE®, DX Engineering, Inc. ®, Hot Rodz®, Maxi-Core®, DX Engineering THUNDERBOLT®, DX

Engineering Yagi Mechanical®, EZ-BUILD®, TELREX®, Gorilla Grip® Stainless Steel Boom Clamps, Butternut®,

SkyHawk™, SkyLark™, SecureMount™ are trademarks of PDS Electronics, Inc. No license to use or reproduce any of

these trademarks or other trademarks is given or implied. All other brands and product names are the trademarks of their

respective owners.

Specifications subject to change without notice.

- 6 -

Loading...

Loading...