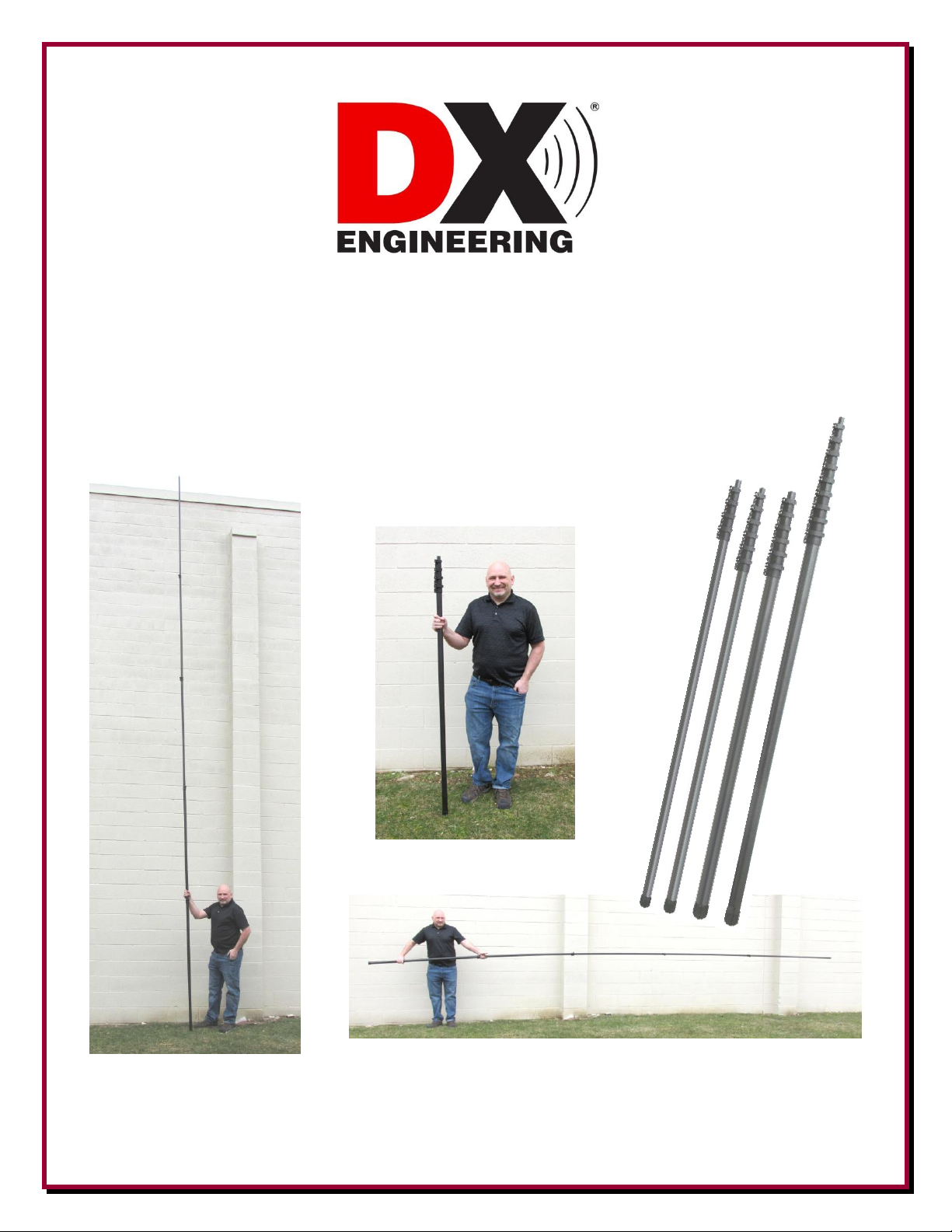

Telescoping Carbon Fiber

Tubing with Cam Lock Clamps

DXE-TCFP-24, DXE-TCFP-33, DXE-TCFP-33HD, DXE-TCFP-49

DXE-TCFP-INS-Rev 0

Model DXE-TCFP-24 shown

DX Engineering 2022

1200 Southeast Ave. - Tallmadge, OH 44278 USA

Phone: (800) 777-0703 Technical Support and International: (330) 572-3200

Fax: (330) 572-3279 E-mail: DXEngineering@DXEngineering.com

- 1 -

Introduction

Part Number

Description

Sections

Clamps

Overlap

Length

Bottom

Dia

Top

Dia

Extended

length

Closed

Length*

Weight

DXE-TCFP-24

Custom 24 foot carbon fiber mast

with clamps and end caps

5 sections

4 clamps

7”

1.4”

0.89”

24 Ft

5.8 Ft

3.75 Lbs

DXE-TCFP-33

Custom 33 foot carbon fiber mast

with clamps and end caps

7 sections

6 clamps

7”

1.67”

0.89”

33 Ft

5.8 Ft

5.4 Lbs

DXE-TCFP-33HD

Custom 33 foot heavy duty carbon

fiber mast with clamps and end caps

7 sections

6 clamps

7”

2.06”

1.27”

33 Ft

5.8 Ft

7.8 Lbs

DXE-TCFP-49

Custom 49 foot carbon fiber mast

with clamps and end caps

10 sections

9 clamps

7.9”

2.06”

0.89”

49 Ft

6.8 Ft

8.9 Lbs

DX Engineering Premier Telescoping Carbon Fiber Masts are the superior choice for portable antenna supports.

Custom made for DX Engineering with short sections that allow easy transport and shipping, these very highstrength carbon fiber masts are available in four extended length versions; 24 feet, 33 feet, Heavy-Duty 33 feet and

49 feet. The longest 49 foot model has a closed length of 81 inches; the other three models slide down to 69 inches.

Surpassing the competition and standard fiberglass, these ultra-portable lightweight telescopic carbon fiber tubing

masts feature lever-action clamps that provide excellent grip of the tubing’s black UV resistant surfaces. Clamps are

removable for placement of optional guy rings, and the lever grip is adjustable, both with the included 3mm Allen

wrench. Each different size clamp mounts securely on the lower tube and allows fast and easy telescopic mast raising

and lowering with its integral locking lever that secures the next smaller tube in place. These clamps are the type

that are mounted on the lower tube and allow fast telescopic mast raising and lowering with the integral locking lever

that secures the smaller tube in place. These are the ultimate quality carbon fiber masts for portable and temporary

antenna supports. Wherever you go and however you get there, DX Engineering Premier Telescoping Carbon Fiber

Masts are the best choice for your next portable antenna adventure.

Kits Available

There are four Carbon Fiber Tubing Kits available:

Mast Material – Carbon Fiber, Black. Color is Red in the Overlap area

*Closed Length – With clamps installed in place

Includes 3mm Hex Allen Wrench for clamp installation and adjustment

Bottom Vinyl cap with hole included

Top Vinyl Cap included: 0.875” on the 24, 22, 33 Foot models and 1.25” on the 33HD model

Bottom View (end caps installed) Top View (Clamps removed)

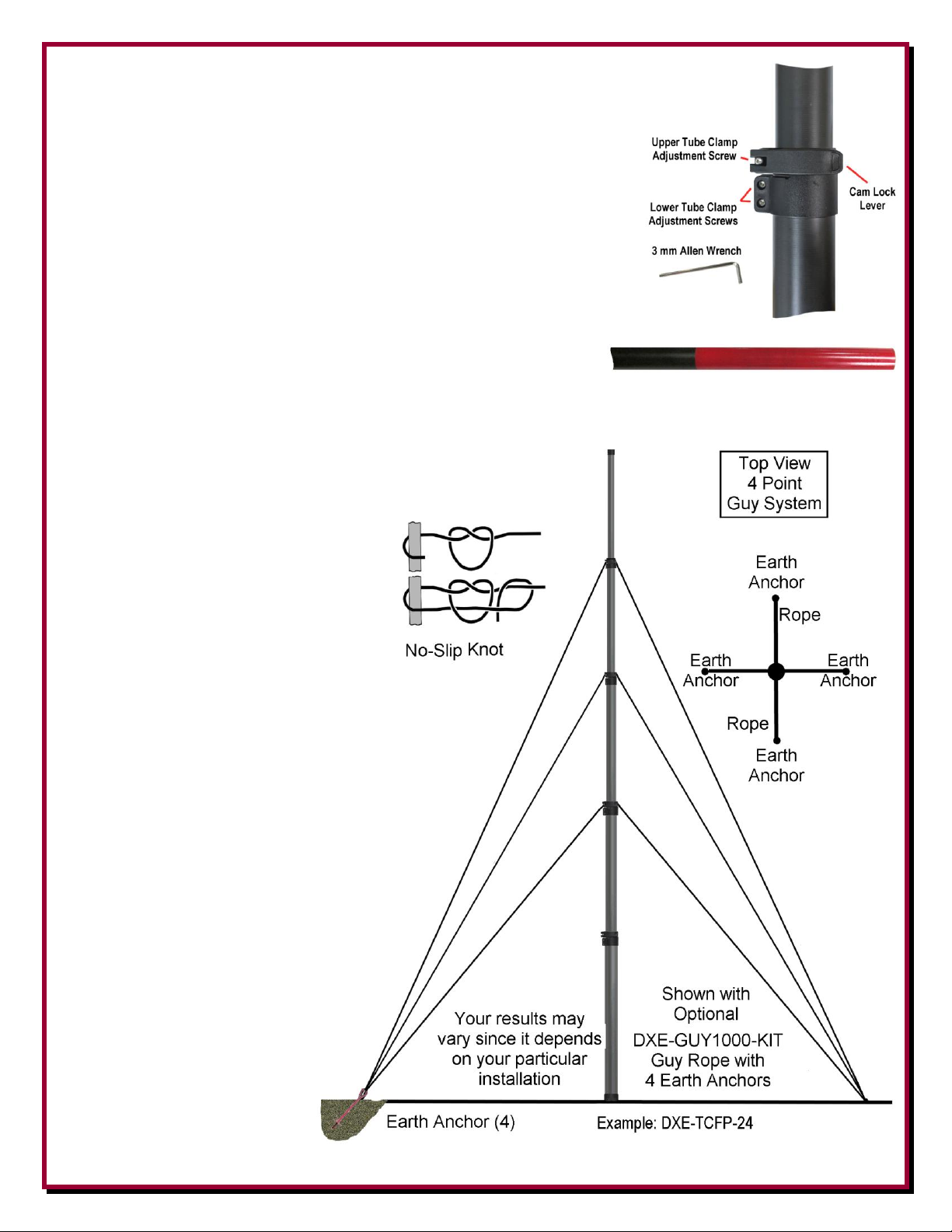

3 mm Allen wrench

Top Cap

- 2 -

Adjusting the cam lock clamps is accomplished using the appropriate size carbon

fiber tube and the included 3 mm Allen wrench. Once adjusted, they should work

as expected and not need adjusting every time they are used.

Use the included 3 mm Allen wrench to tighten the lower tube socket head cap

screws so the clamp is tight to the bottom tube. Open the cam lock lever and

adjust the upper socket head cap screw until the clamp is snug to the tube, then

loosen the upper socket head cap screw (on the cam lock clamp lever) one turn.

Close the cam lock clamp lever. The cam lock clamp should be set, if not, readjust as needed. Once this is set, you should not have to re-adjust for future use.

Repeat the procedure above for the other tubes and cam lock clamps as needed.

The minimum overlap is set by the tube kit. Each nested tube has a red area

and will not allow further telescoping outward. You can overlap more if

needed or if you want to reduce the height of the tube kit you are working with. When the clamps are installed

and adjusted properly, the mast will stop when the red portion is reached.

Guying of vertical tubing is

strongly recommended for

stability. A multi-level, four

point guying scheme provides

the best mechanical advantage to

prevent wind stress, regardless

of direction.

As an example, the suggested

guying scheme for a 24 foot

assembly is shown. Your guying

may use less than three levels.

Four points are still suggested

Guy rings may also be used.

Your results and requirements

may vary since it depends on the

length (height) of your particular

installation. Guying of vertical

tubing is strongly recommended

for stability.

- 3 -

WARNING!

INSTALLATION OF ANY MAST NEAR POWER LINES IS DANGEROUS

Warning: Do not locate the mast near overhead power lines or other electric light or power circuits, or where it can

come into contact with such circuits. When installing the mast, take extreme care not to come into contact with such

circuits because they may cause serious injury or death. Don't assume that wires are telephone or TV cable lines:

check with your electric utility for advice. Although overhead power lines may appear to be insulated, often these

coverings are intended only to protect metal wires from weather conditions and may not protect you from electric

shock. Keep your distance! Remember the 10-foot rule: When carrying and using ladders and other long tools, keep

them at least 10 feet away from all overhead lines - including any lines from the power pole.

Manual Updates

Every effort is made to supply the latest manual revision with each product. Occasionally a manual will be updated between the

time your DX Engineering product is shipped and when you receive it. Please check the DX Engineering web site

(www.dxengineering.com) for the latest revision manual.

Technical Support

If you have questions about this product, or if you experience difficulties during the installation, contact DX Engineering at

(330) 572-3200. You can also e-mail us at: DXEngineering@DXEngineering.com

For best service, please take a few minutes to review this manual before you call.

Warranty

All products manufactured by DX Engineering are warranted to be free from defects in material and workmanship for a period

of one (1) year from date of shipment. DX Engineering’s sole obligation under these warranties shall be to issue credit, repair or

replace any item or part thereof which is proved to be other than as warranted; no allowance shall be made for any labor charges

of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such charges are authorized in advance by

DX Engineering. If DX Engineering’s products are claimed to be defective in material or workmanship, DX Engineering shall,

upon prompt notice thereof, issue shipping instructions for return to DX Engineering (transportation-charges prepaid by Buyer).

Every such claim for breach of these warranties shall be deemed to be waived by Buyer unless made in writing. The above

warranties shall not extend to any products or parts thereof which have been subjected to any misuse or neglect, damaged by

accident, rendered defective by reason of improper installation, damaged from severe weather including floods, or abnormal

environmental conditions such as prolonged exposure to corrosives or power surges, or by the performance of repairs or

alterations outside of our plant, and shall not apply to any goods or parts thereof furnished by Buyer or acquired from others at

Buyer’s specifications. In addition, DX Engineering’s warranties do not extend to other equipment and pa rts manufactured by

others except to the extent of the original manufacturer’s warranty to DX Engineering. The obligations under the foregoing

warranties are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other

remedies including claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY OTHER

WARRANTY WHATSOEVER, WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME FOR DX ENGINEERING

ANY OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE FOREGOING.

©DX Engineering 2022

DX Engineering®, DXE®, DX Engineering, Inc.®, Hot Rodz®, Maxi-Core®, DX Engineering THUNDERBOLT®, DX

Engineering Yagi Mechanical®, EZ-BUILD®, TELREX®, Gorilla Grip® Stainless Steel Boom Clamps, Butternut

SkyLark™, SecureMount™, OMNI-TILT™, RF-PRO-1B®, AFHD-4® are trademarks of PDS Electronics, Inc. No license to use

or reproduce any of these trademarks or other trademarks is given or implied. All other brands and product names are the

trademarks of their respective owners.

Specifications subject to change without notice.

®

, SkyHawk™,

- 4 -

Loading...

Loading...