OMNI-TILT

™

Vertical Antenna

Tilt Base

DXE-OMNITILT-1

DXE-OMNITILT-INS Revision 1b

© DX Engineering 2021

1200 Southeast Ave. - Tallmadge, OH 44278 USA

Phone: (800) 777-0703 - Tech Support and International: (330) 572-3200

Fax: (330) 572-3279 - E-mail: DXEngineering@DXEngineering.com

- 1 -

Introduction

The DX Engineering OMNI-TILT™ Vertical Antenna Tilt Base is a new design incorporating

features that make this Tilt Base a ‘must have’ for all types of vertical antennas.

The OMNI-TILT™ base is patterned on the same proven safe

technology as the patented DX Engineering SAF-T-TILT™ base and

the patented DXE-TB-3P tilt base that prevent the antenna from

falling when the fasteners are loosened. The user simply lifts the

OMNI-TILT™ base plate and this positive action disengages the

bolts from the top and allows the user to easily lower the antenna for

maintenance or if extreme weather is on the way.

Custom made from laser cut 1/8”

thick Stainless Steel for strength

and durability. All of the

hardware used in the OMNI-

TILT™ Base is Stainless Steel to

ensure long and dependable

service.

The DX Engineering OMNI-

TILT™ is safe to use and is available with a wide range of

optional mounting hardware to maximize the use of this tilt base

with all types of vertical antennas.

The OMNI-TILT™ was designed to be used with the Hustler

BTV series antennas and can be used with the Hy-Gain AVQ

series antennas which both use the optional DXE-TVA-HWK

Trap Vertical Mounting Hardware kit. Additionally, the OMNI-TILT™ may also be used with

other vertical antenna or mast mounting schemes depending on the mounting hardware chosen to

correspond to the diameter of pipe (1-1/4” to 2-1/2” diameter) being used.

Additional Material and Tools Needed but not Supplied:

JTL-12555 - Jet-Lube SS-30 Anti-Seize Lubricant or PTX-81343 - Permatex Anti-

Seize Lubricant. Used on the threads of Stainless Steel Hardware to prevent galling

(seizing) and aid in proper tightening.

DXE-TVA-HWK Trap Vertical Mounting Hardware Kit for BTV or AVQ series

antennas (included with the DXE-OMNITILT-1P ) (see text)

DXE-OTMC-250P Mounting Clamps to mount to a customer supplied ground mounted

pipe and for mounting a customer supplied antenna mast (see text)

Standard tools including wrenches, nut drivers, etc.

1/2” Nut Driver

7/16” Nut Driver or Open End Wench (for mounting pipe clamps)

1/2” Open End Wrench

- 2 -

There are three OMNI-TILT™ kits and one clamp kit available:

Part Number

Description

DXE-OMNITILT-1

OMNI-TILT™ Base with hardware

DXE-OMNITILT-1P

OMNI-TILT™ Base with hardware for Trap Vertical - includes one DXE-TVA-HWK

DXE-OMNITILT-2P

OMNI-TILT™ Base with hardware for Mast Mounted Vertical includes 2 DXE-OTMC-250P Clamp Kits

DXE-OTMC-250P

Double V-Clamp fits 1.25 to 2.5" OD, includes bolts

Basic Assembly

The following describes the basic assembly of the OMNI-TILT™ base. Fastening to a customer

supplied ground mounted pipe and antenna are described after this basic assembly.

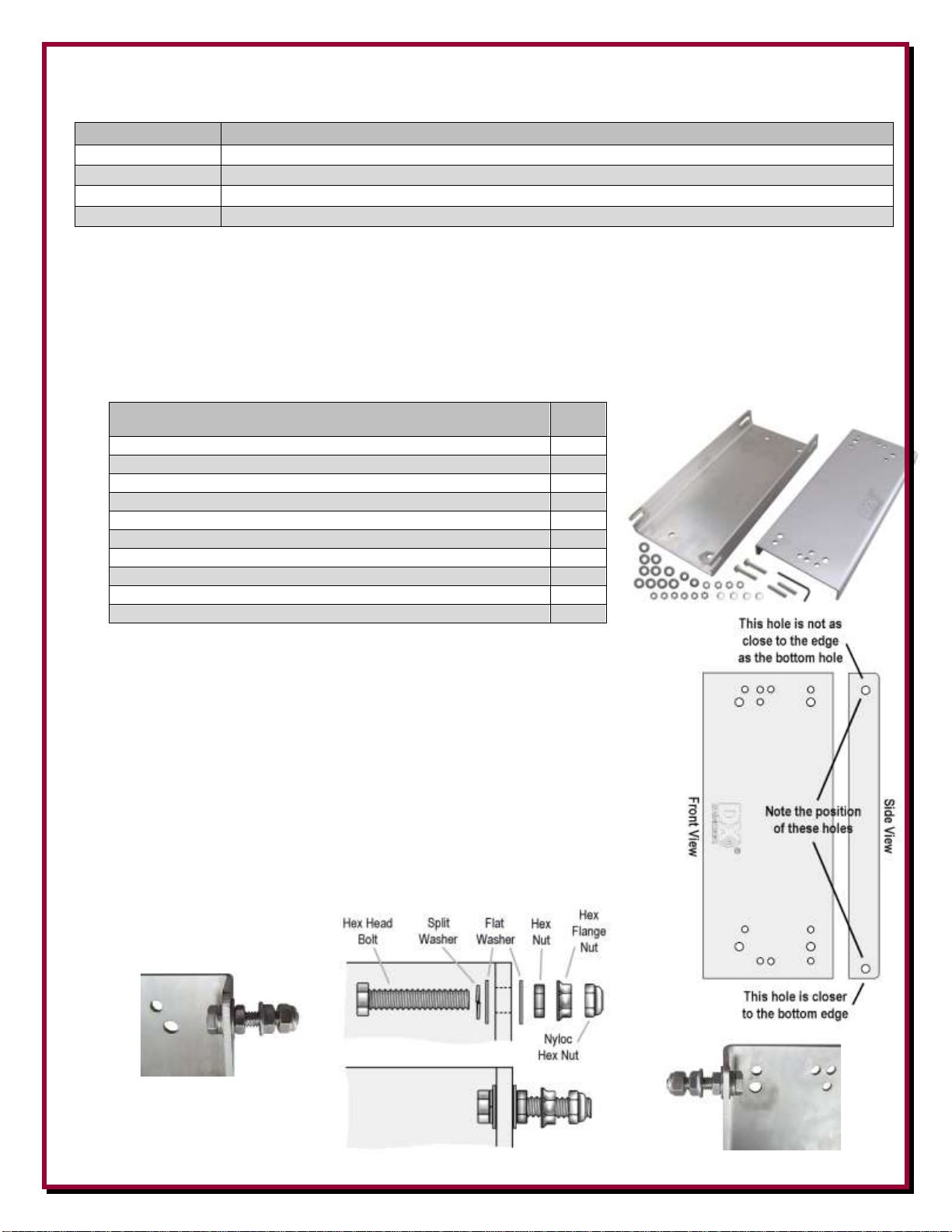

DXE-OMNI-TILT™ Base with Hardware Parts List

DXE-OMNITILT-1 OMNI-TILT™ Base with Hardware

Qty

OMNI-TILT™ Tilt Base, Front, Stainless Steel with DX logo

1

OMNI-TILT™ Tilt Base, Rear, Stainless Steel

1

5/32” Hex Wrench, 2-1/2” long

1

5/16”-18 Hex Serrated Flange Nut, Stainless Steel

2

5/16”-18 Nyloc Hex Nut, Stainless Steel

4

5/16”-18 Hex Nut, Thin, Stainless Steel

6

5/16”-18 x 1.5” long Hex Head Cap Screw, Full Thread

2

5/16-18 x 1.5” long Set Screw, Stainless Steel, Full Thread

2

5/16” Washer, Flat, Stainless Steel

10

5/16” Washer, Split Lock, Stainless Steel

4

1. Note the front and rear plates have a variety of holes which will be explained.

The front plate has mounting holes in the sides used for the tilting

process and these holes are not located in identical positions.

Take care to position the front plate properly before starting to mount

the hardware. Refer to the drawing for reference.

2. Install the upper hardware as shown. Do not tighten the flange hex

nut or the Nyloc hex nut at this time. Use Jet-Lube SS-30 Anti-Seize

(part number JTL-12555 or PTX-81343) on all stainless steel parts to

avoid galling. Even good stainless steel parts will freeze up if anti-seize

is not used.

- 3 -

3. Position the rear plate and the front plate together as shown below.

Rear Plate Front Plate

(Has DX logo)

4. Install a flat washer and hex nut onto one of the set screws as show.

Note: position these parts on the opposite end of the set screw that

has the hex wrench opening. Do the same for the second set screw.

5. Position the front and rear plates together and insert the set screws as shown below.

6. Using one of the Nyloc hex nuts as a measuring tool, adjust both of the set screws inward so

when the Nyloc hex nut is installed and tightened during a later step, there will be

approximately three exposed threads sticking out. Using a 1/2” open end wrench helps to hold

the hex nut in place while you turn the set screw.

- 4 -

7. Install a flat washer, split washer and hex nut as shown. Tighten these

parts using a 1/2” open end wrench and the supplied 5/32” Allen

Wrench. Note that the parts are tightened together on the front plate as

shown.

Hardware in place

Allen Wrench and 1/2” open end wrench

Hardware tightened in place

8. Place a flat washer over the set screws (ensure you are using anti-seize – Permatex Anti-Seize

Lubricant or Jet-Lube-SS-30 ). Finger tighten the Nyloc Nuts.

- 5 -

9. Using the supplied Allen Wrench and a customer supplied 1/2” open end wrench, tighten the

Nyloc hex nuts. Note that when tightening the Nyloc Nuts in place, you DO NOT want

them completely tightened. The Allen wrench used in combination with the open end wrench

as shown will not loosen the previously installed hardware.

When installed, you want to be able to tilt the plate, thus you need a slight gap as shown

below.

Using the Allen wrench and 1/2” hex wrench

Parts in place

Reference Drawing

- 6 -

10. Once the hardware is properly installed, you can tilt the front and rear plates of the OMNI-

TILT™ base together. Note the bottom has an elongated hole so you lift the front plate in place

over the rear plate and drop it into position. The following pictures show the completed basic

assembly.

- 7 -

Installing the OMNI-TILT™ Tilt Base Ground Mounting Pipe

The following is a suggested 2” OD mounting pipe installation. You may want a heavier and/or

longer ground mounted pipe depending on your soil conditions and the type of antenna mast

being used with the OMNI-TILT™ base. Refer to your antenna’s manual for possible

suggestions. The OMNI-TILT™ DXE-OTMC-250P Double V-Clamp fits pipes from 1.25” to 2.5”

in diameter. DX Engineering also has the DXE-VGMT-2CG Steel tubing for ground mount

antennas made from high strength Chromoly: 2 inch OD x .25 wall thickness x 5 foot 4 inch

length.

Wooden Post

The OMNI-TILT™ Tilt Base can be installed to a customer supplied wooden post or to a ground

mounted antenna mounting pipe. Since there are multiple considerations in mounting to a wooded

post, the customer will have to decide what hardware to use.

Ground Mounted Pipe

Use a customer supplied thick-walled galvanized steel mounting pipe at least 4

feet long. This will allow approximately 2 feet or more to be below ground and

20 inches above ground. A thick-walled steel pipe 1-3/4" OD to 2" OD

maximum is recommended with a minimum thickness of 1/8" (1/4" preferred)

should be used. A standard 1-1/2" galvanized water pipe (with its 1.9" OD)

will work for this application and can usually be found at your local home

building supply store. DX Engineering also has the DXE-VGMT-2CG

Steel tubing for ground mount antennas made from high strength

Chromoly: 2 inch OD x .25 wall thickness x 5 foot 4 inch length. For

permanent mounting, use a post-hole digger to make the hole deep enough to

accommodate at least 2 feet of pipe and a couple inches of gravel at the bottom

for drainage. Set the mounting pipe on the gravel, use the pre-mix concrete to

fill around the pipe, adding water and mixing as you fill or mix the concrete

first, then pour in the hole (depends on the type of quick concrete you

purchase). Fill the hole until the concrete is level with the ground around it.

Use a level on the mounting pipe as you fill the hole to be sure it is vertically straight. Allow to set

overnight or per the concrete manufacturer’s recommendations. Your location, landscape and

ground conditions may require different mounting solutions in order to have the steel

mounting pipe and the vertical antenna in a secure position. A black vinyl cap (DXE-VC-2000

for 2” pipe) can be used to cap the top of the mounting pipe to prevent water and debris from

getting into the pipe.

Note: Galvanized steel, rather than aluminum, is much more suitable for mounting in concrete.

Aluminum will quickly corrode due to incompatibility with the materials used to make

concrete.

Optional Radial Plate to Mounting Pipe

Install the optional patented DXE-RADP-3 Radial Plate on the 2" OD customer supplied mounting

pipe using the DXE-SSVC-2P V-Bolt Saddle Clamp as shown. The standard 1-1/2" galvanized

water pipe (with its 1.9" OD) is just fine for this application and can usually be found at your local

- 8 -

home building supply store. Mount the Radial Plate so you have approximately 1" of space between

the bottom of the plate and the ground level. This will allow easy access to install the radial wire

hardware. The DXE-RADP-3 Radial Plate comes with 20 sets of stainless steel hardware for

mounting the radial wires. Additional hardware kits are available from DX Engineering: DXE-

RADP-1HWK contains 20 sets of Radial Plate Hardware.

NOTE: If a larger diameter mounting

pipe is used (up to 2.5” OD) the

Optional Radial Plate will need a

larger clamp (DXE-SSVC-3P).

Optional DXE-RADP-3 Radial Plate Installation on customer supplied ground mounting pipe

Attaching the optional Ground Radial Wires to the Radial Plate

Using the 20 sets of supplied 1/4" stainless steel hardware (Bolt, Star Washer, Flat Washer, Split

Washer, Nut) connect the optional ground radial wires to the DXE-RADP-3 Radial Plate as shown

below. Additional hardware kits are available from DX Engineering: DXE-RADP-1HWK

contains 20 sets of Radial Plate Hardware.

There are optional DX Engineering Radial Wire Kits available. DXE-RADW-500K/BD contains a

500 foot spool of 14 gauge copper stranded wire with relaxed black PVC insulation, 20 Terminal

Lugs and 100 Steel or Biodegradable Lawn Staples. The DXE-RADW-1000K/BD Radial Wire Kit

contains a 1,000 foot spool of 14 gauge copper stranded wire with relaxed black PVC insulation, 40

Terminal Lugs and 200 Steel or Biodegradable Lawn Staples. RADW-20RT, -32RT or -65RT

contain 20 each radial wires with 1/4" terminal attached. These kits come in 20 Ft, 32 Ft, or 65 Ft

lengths. See these and other options available listed at the

end of this manual.

Depending on the number of radial wires used, space them

out evenly around the Radial Plate like the spokes on a

wheel. The Radial Plate will accommodate up to 60 radial

wires (60 laser drilled holes), or up to 120 radials if doubled

up.

Radial Wire Hardware Installation Radial Wire Pattern

- 9 -

Mounting the OMNI-TILT™ to the Ground Mounted Pipe

Two DXE-OTMC-250P Mounting Clamp Kits are used to mount the OMNI-TILT™ Tilt Base to

the ground mounted mounting pipe.

DXE-OTMC-250P (Qty 2 are required) Mounting Clamps

2 - DXE-OTMC-250P Mounting Clamps with Hardware Kits

For mounting to a 1-1/4” to 2-1/2” Dia. Mounting pipe

(----- Parts list and picture show 2 clamp kits ----)

Qty

1-1/4” x 2-1/2” Saddle Clamp, Stainless Steel

4

5/16”-18 x 4-1/2” long Hex Head Bolt, Full Thread, Stainless Steel

4

5/16” Washer, Flat, Stainless Steel

8

5/16” Washer, Split Lock, Stainless Steel

4

5/16”-18 Hex Nut, Stainless Steel

4

1. Using the hardware supplied, attach the OMNI-TILT™ Tilt Base to the ground mounted

mounting pipe as shown. Slightly tighten the upper and lower clamps in place just enough to

hold the OMNI-TILT™ base. Once the antenna base is mounted, up or down positioning

adjustment can be made which ensures the tilting action does not interfere with the optional

radial plate. When placement is where you want it, tighten the hardware (do not overtighten).

- 10 -

Mounting a Hustler BTV Series Vertical Antenna

to the OMNI-TILT™ Tilt Base

DXE-OMNITILT-1P

1. Mounting the Hustler BTV Series antenna to the OMNI-TILT™ Tilt Base requires installation

of four hex head bolts, Flat, Split Lock washers and Hex Nuts.

DXE-TVA-HWK Parts List

DXE-TVA-HWK Mounting Hardware Kit

For Trap Verticals (Hustler BTV series, Hy-Gain AVQ series)

Qty

1/4”-20 x 1” long Hex Bolt, Stainless Steel

4

1/4” Washer, Split Lock, Stainless Steel

4

1/4” Washer, Flat, Stainless Steel

4

1/4”-20 Hex Nut, Stainless Steel,

8

2. Position the BTV Base on the OMNI-TILT™ base. Align the Hustler BTV base with the

DXE-TVA-HWK mounting hardware and installed

the antenna base to the OMNI-TILT™ base as shown.

Install the flat washers, split washers and hex nuts and

tighten in place.

- 11 -

- 12 -

Mounting Other Vertical Antennas to the OMNI-TILT™ Tilt Base

DXE-OMNITILT-1P

Hy-Gain: DX88, AV-18VS, 12AVQ, 14AVQ, 18AVQ

vertical antenna to the OMNI-TILT™ Tilt Base

When mounting one of the above listed Hy-Gain vertical antennas, the procedure is exactly the

same as the Hustler BTV series. The only difference is the Hy-Gain base mounting holes are

spaced differently than the Hustler BTV series on the OMNI-TILT™ Base.

Typical Hy-Gain Base

- 13 -

Mounting methods for other vertical antennas to

the OMNI-TILT™ Tilt Base

Cushcraft R-8 will require a customer supplied 1-1/2” water pipe (1.90” OD)

approximately 8 feet long. The water pipe is installed on the OMNI-TILT™ base using

two DXE-OTMC-250P clamp kits.

Hy-Gain AV-620 or AV-640 will require a customer supplied 2” water pipe (2.38” OD)

approximately 8 feet long. The water pipe is installed on the OMNI-TILT™ base using

two DXE-OTMC-250P clamp kits.

MFJ-1796 will require a customer supplied 1-1/2” water pipe (1.90” OD) approximately 8

feet long. The water pipe is installed on the OMNI-TILT™ base using two DXE-OTMC250P clamp kits.

MFJ-1798 will require a customer supplied 2” water pipe (2.38” OD) approximately 8 feet

long. The water pipe is installed on the OMNI-TILT™ base using two DXE-OTMC-250P

clamp kits.

The above listed antennas use a clamping scheme that is common and is described below

DXE-OMNITILT-2P includes the DXE-OMNITILT-1 and

two DXE-OTMC-250P Clamp Kits

Two DXE-OTMC-250P Mounting Clamp Kits are used to mount the water pipe that will hold the

vertical antenna (see listing above) to the OMNI-TILT™ base.

DXE-OTMC-250P (Qty 2 are required) Mounting Clamps

2 - DXE-OTMC-250P Mounting Clamps with Hardware Kits

For mounting to a 1-1/2” to 2” Water Pipe

(Parts list and picture show 2 clamp kits)

Qty

1-1/4” x 2-1/2” Saddle Clamp, Stainless Steel

4

5/16”-18 x 4-1/2” long Hex Head Bolt, Full Thread, Stainless Steel

4

5/16” Washer, Flat, Stainless Steel

8

5/16” Washer, Split Lock, Stainless Steel

4

5/16”-18 Hex Nut, Stainless Steel

4

1. Using the mounting clamp hardware, attach the customer supplied water pipe (as described in

the previous antenna list) to the OMNI-TILT™ base as shown.

2. When the mounting pipe is attached to the OMNI-TILT™ base, the antenna is mounted to the

mounting pipe per the antenna manufacturer’s instructions.

- 14 -

- 15 -

Manual Updates

Every effort is made to supply the latest manual revision with each product. Occasionally a manual

will be updated between the time your DX Engineering product is shipped and when you receive it.

The OMNI-TILT™ tilt base is capable of mounting a wide variety of vertical antennas and

masts. As new mounting schemes are tested, this manual will be revised to include the latest

information.

Please check the DX Engineering web site (www.dxengineering.com) for the latest revision manual.

The following drawing shows the laser cut hole pattern in the OMNI-TILT™ base (front plate).

The various hole spacing can accommodate a wide variety of vertical antenna bases and clamps for

different mounting schemes.

- 15 -

- 16 -

Tilt Action

The OMNI-TILT™ is easy and safe to operate.

1. To tilt downward loosen the top Nyloc Nuts to allow the Flanged Nuts to be loosened

approximately 1/2 to 1 turn.

2. Grasp the antenna base (or mounting pipe) that is bolted to the OMNI-TILT™ base and lift

until the upper bolts on the front plate are out of the grooved area on the tilt base rear plate.

3. Slightly tilt until the front plate can be set downward into its resting place.

4. Carefully walk the antenna (or antenna and mounting mast) downward.

5. Use of a chair or saw horse to support the antenna so it remains level or protruding parts of the

antenna do not hit the ground when tilted down is suggested.

Reverse the above step to raise the antenna (or antenna and mounting mast).

Once raised and the front plate is in the grooved area and fully seated, tighten the flanged nuts.

The Nyloc nuts can then be tightened against the flanged nuts to prevent them from loosening from

wind vibration.

The bottom set screws and nuts can remain slightly loose as described in the assembly instructions.

Notes: Heavy antennas or antennas using an approximately 8 foot water pipe mount attached

to the OMNI-TILT™ may require help when walking the antenna down or up.

Ensure you have adequate room for tilting and you are not near any power lines

or other obstructions.

The use of Anti-Seize on all stainless steel hardware is required to avoid having

the hardware freeze up (galling).

- 17 -

Optional Tilt Base Wing Nut Knobs

DX Engineering has optional Tilt Base Wing Nut Knobs - DXE-AOK-OT1194 - allow for the toolless, quick release of the DX Engineering DXE-OMNI-TILT™ base.

They are perfect for lowering the antenna for tuning or daily stealth operation.

To install them, simply remove the existing hex nuts and thread on the wing nut knobs.

DXE-AOK-OT1194

- 18 -

Guying a Vertical Antenna System

Guying of any vertical antenna is always recommended for stability. If your area encounters severe

wind velocities or icing conditions, simple guying will reduce the possibility of failure. Using the

DXE-GUY kits, you can install one, two or three level guy ropes. The drawing below shows an

example of dual level guying. Guy ropes should be tightened just enough to permit the antenna to

swing a few inches. The ends of the ropes are tied to the earth anchors that are screwed into the

ground at about the same angle as the ropes will be. The ropes are tied just above a band clamp at

the height desired. When using the OMNI-TILT™ base, position the guy ropes as shown below in

the overhead view. This will make it easy to raise or lower the antenna and only one guy rope needs

to be loosened. The other guy ropes will help guide the antenna on the way up.

- 19 -

Technical Support

If you have questions about this product, or if you experience difficulties during the installation,

contact DX Engineering at (330) 572-3200. You can also e-mail us at:

DXEngineering@DXEngineering.com

For best service, please take a few minutes to review this manual before you call.

Manual Updates

Every effort is made to supply the latest manual revision with each product. Occasionally a manual

will be updated between the time your DX Engineering product is shipped and when you receive it.

Please check the DX Engineering web site (www.dxengineering.com) for the latest revision manual.

Warranty

All products manufactured by DX Engineering are warranted to be free from defects in material and workmanship for a

period of one (1) year from date of shipment. DX Engineering’s sole obligation under these warranties shall be to issue

credit, repair or replace any item or part thereof which is proved to be other than as warranted; no allowance shall be

made for any labor charges of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such

charges are authorized in advance by DX Engineering. If DX Engineering’s products are claimed to be defective in

material or workmanship, DX Engineering shall, upon prompt notice thereof, issue shipping instructions for return to

DX Engineering (transportation-charges prepaid by Buyer). Every such claim for breach of these warranties shall be

deemed to be waived by Buyer unless made in writing. The above warranties shall not extend to any products or parts

thereof which have been subjected to any misuse or neglect, damaged by accident, rendered defective by reason of

improper installation, damaged from severe weather including floods, or abnormal environmental conditions such as

prolonged exposure to corrosives or power surges, or by the performance of repairs or alterations outside of our plant,

and shall not apply to any goods or parts thereof furnished by Buyer or acquired from others at Buyer’s specifications.

In addition, DX Engineering’s warranties do not extend to other equipment and parts manufactured by others except to

the extent of the original manufacturer’s warranty to DX Engineering. The obligations under the foregoing warranties

are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other

remedies including claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY

OTHER WARRANTY WHATSOEVER, WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME

FOR DX ENGINEERING ANY OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE

FOREGOING.

©DX Engineering 2021

DX Engineering®, DXE®, DX Engineering, Inc.®, Hot Rodz®, Maxi-Core®, DX Engineering THUNDERBOLT®, DX

Engineering Yagi Mechanical®, EZ-BUILD®, TELREX®, Gorilla Grip® Stainless Steel Boom Clamps, Butternut®,

SkyHawk™, SkyLark™, SecureMount™, OMNI-TILT™, RF-PRO-1B®, AFHD-4® are trademarks of PDS Electronics,

Inc. No license to use or reproduce any of these trademarks or other trademarks is given or implied. All other brands

and product names are the trademarks of their respective owners.

Specifications subject to change without notice.

Loading...

Loading...