Page 1

1010

TEN YEARS

WHY GUY WITH SYNTHETIC ROPES?

WHY MASTRANT?

DESIGNED FOR GUYING·UV RESISTANCE·HIGH STRENGTH

·

LOW ELONGATION – NO STRETCH·WEATHER DURABILITY

WIDE RANGE OF ACCESSORIES AND ”MUST HAVES“ FOR ANTENNA WORK

·

·

·

HOW?

CHOOSE APPROPRIATE GUYROPE

CALCULATE LENGTHS·THINK ABOUT IT·DO IT·REGULARLY CHECK IT

·

ANNIVERSARY

WHERE WE CAN SUPPORT YOU

B

A

C

B

E

D

F

A

B

C

Page 2

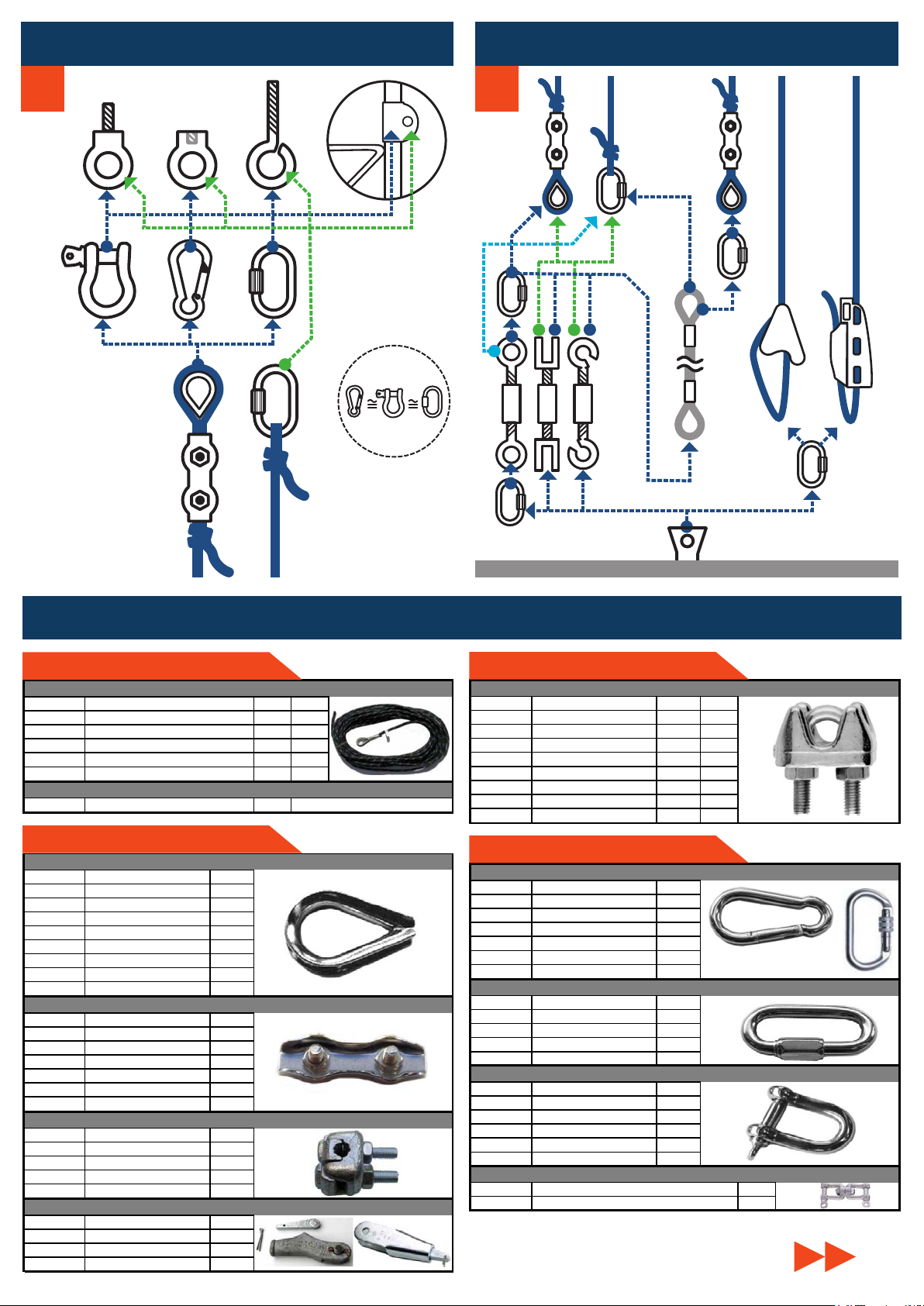

TYPICAL INSTALLATIONS + RECOMMENDED GUY ROPES

A

TYPE OF USE

LEVELS*

Wire antenna

suspension

conven-

tional

wire

antennas

tension

- heavy

160m ...

MASTRANT®P

2

(3/32“)

3

(1/8“)

4

(5/32“)

5

(3/16“)

6

1/4“)

8

10

12

14

(5/16“)

(3/8“)

(1/2“)

(9/16“)

STRETCH

2,4%

high

wire,

Vertical

antenna

Up to

70ft.,

1-3“

Up to

140ft.,

2-4“

2-3 3-5 2-3 3-5 2-3

Mast

25-100mm

Up to

30ft., 3

el. 3-B or

long VHF

Yagi

Up to

70ft., 5

el. Yagi

for 20m

Lattice tower

Up to

70ft., 7

el. tri-

3 stack of

bander

Up to

200ft.,

5 el. Yagi

20m

3-6 [lbs.]

STRETCH = ELONGATION: 2.4%, CORE = POLYESTER, COVER = POLYESTER

breaking strength (BS)

220

440

880

110 0

1870

2870

4190

4850

7060

70

130

260

330

560

860

1260

1460

2120

safe working load (SWL)

PRICE

(incl. tax)

Feets

330

100

17

n/a

25

37

54

n/a

90

n/a

114

n/a

152

n/a

204

n/a

259

n/a

Size of couplers

$

5

5

5

5

6

6

7

8

10

Turnbuckle

6

6

6

6

8

8

10

12

14

Carabiner Shackle Chain

CODE

1

5

0.07

P-2

9

0.10

P-3

15

0.15

P-4

0.21

P-5

P-6

0.36

0.41

P-8

10

0.55

0.74

0.94

P-10

P-12

P-14

HD

HD

5

5

5

6

5

6

5

8

6

6

7

8

-

10

MASTRANT®M

(2/32“)

1

(3/32“)

2

(1/8“)

3

(5/32“)

4

(3/16“)

5

1/4“)

6

(5/16“)

8

(3/8“)

10

(1/2“)

12

* LEVELS = NUMBER OF GUY ATTACHMENT POINTS. OTHER ASSUMPTIONS: WIND SPEED UP TO 100mph, DISTANCE BETWEEN ANCHOR POINT AND BASE OF MAST > 70% OF THE HEIGHT

EXTRA

STRONG

STRETCH

< 1,2%

STRETCH = ELONGATION: <1.2%, CORE = DYNEEMA® DM 20, COVER = POLYESTER

220

70

35

n/a

490

150

41

860

260

68

1980

600

136

n/a

2650

790

214

n/a

4080

1220

272

n/a

5730

1720

383

n/a

8490

2550

666

n/a

12130

3640

1098

n/a

15

25

0.13

0.15

0.25

0.49

0.78

0.99

1.39

2.42

4

M-1

M-2

M-3

M-4

M-5

M-6

M-8

M-10

M-12

10

HD

5

5

5

6

5

5

5

6

6

5

5

6

7

5

5

6

8

6

6

8

7

7

10

8

8

12

-

10

10

16

-

10

12

20

BASIC INSTRUCTIONS TO GUY WITH SYNTHETIC ROPES

WHEN PLANNING AN “ANCHORING SYSTEM” (GUY-ROPES WITH END TERMINATION, COUPLERS AND ANCHORAGE)

THERE ARE A NUMBER OF FACTS THAT HAVE TO BE TAKEN INTO ACCOUNT:

The stability of the system is

1

determined by its weakest link.

That is why it is no use combining

a rope of 5000 kg of strength with a

turnbuckle 500 kg strong.

Even the most excellent

2

synthetic rope is elastic

– when guyed it elongates. In

the layout of the tower and its

anchorage (even when xing

elements of the antennas) you have

to reckon with this characteristic

and always consider how the

elongation of the anchoring system

will affect the overall construction.

In certain cases it will be necessary

to use a stronger rope (with a

smaller absolute extensibility),

than for other constructions that

are not negatively affected by

the elongation of the anchors. A

problem occurs especially in such

a case, when the ground anchor

point is situated too close to the

tower base, or when dealing with a

lattice tower with low exibility.

The rope must be screened

3

against all kind of sharp edges.

For this reason it is necessary to

x the rope with a thimble or tie

it to a coupler with a very smooth

surface. Be aware of the fact that

inappropriate metallic materials

corrode and therefore their

surface roughens. Never should

you tie a rope to a concrete slope

or to a stone! If you do want to

use a stone, a rock or a concrete

slope as ground anchor point, we

recommend using a loop from steel

rope, which you can connect to the

guy rope with the help of a smooth

coupler.

A great danger for any

4

synthetic rope lies in friction

against any object on its path. This

can cause the rope to be seriously

damaged or cut through, and has

to be avoided at all cost. Even a

guy rope on a tower can move

enough to suffer friction damage

if it touches anything along its

length, so please locate your guys

carefully. Particularly to be avoided

are trees and tree branches. If you

are using a tree support for a wire

antenna you must ensure that no

part of the synthetic rope can get

close enough to the tree to risk

damage by rubbing. Always use

steel rope near or in a tree. You

could use a pulley on the end of

a steel rope to keep the synthetic

rope well clear.

The lower part of the

5

anchoring system should

consist of steel rope 2-4 meters

in length. This ensures that the

synthetic rope isn’t “chewed up”

by an animal or gets damaged by

some human activity (intentionally

or unintentionally).

Page 3

NP040x0 9.50 13.50

NP050x0 13.50 19.00

NP060x0 22.00 31.50

NP080x0 28.00 40.00

NP100x0 37.00 52.50

NP120x0 76.00

ZCI01 9.70

A: Guy ropes

5 mm (3/16"), BS: 500 kg (1100 lb)

6 mm (1/4"), BS: 850 kg (1870 lb)

8 mm (5/16"), BS: 1300 kg (2870 lb)

10 mm (3/8"), BS: 1900 kg (4190 lb)

Thimble fitted on one end.

4 mm (5/32"), BS: 400 kg (880 lb)

66 ft 99 ft

NP040x0 9.50 13.50

NP050x0 13.50 19.00

NP060x0 22.00 31.50

NP080x0 28.00 40.00

NP100x0 37.00 52.50

NP120x0 76.00

ZCI01 9.70

ATH02 2 mm (min.Ø 8 mm) 0.25

ATH03 3 mm (min.Ø 10 mm) 0.29

ATH04 4 mm (min.Ø 11 mm) 0.38

ATH05 5 mm (min.Ø 13 mm) 0.49

ATH06 6 mm (min.Ø 14 mm) 0.62

8 mm (min.Ø 18 mm)

10 mm (min.Ø 24 mm)

12 mm (min.Ø 30 mm)

14 mm (min.Ø 32 mm)

ADC02 2 mm (M4, wrench 7) 1.20

ADC03 3 mm (M4, wrench 7) 1.40

ADC04 4 mm (M5, wrench 8) 1.60

ADC05 5 mm (M5, wrench 8) 2.60

ADC06 6 mm (M6, wrench 10) 3.70

ADC08 8 mm (M8, wrench 13) 5.60

ADC10 10 mm (M10, wr.17) 10.30

APC06 6 mm (5-8 mm, M6) 2.30

APC08 8 mm (8-10 mm, M6) 3.10

APC10 10 mm (10-12, M8) 4.50

APC12 12 mm (12-14, M10) 5.80

APC16 16 mm (14-18, M12) 7.80

AWC06 wedge socket 5-6.5 mm 15.00

AWC08 wedge socket 6-8 mm 31.00

AWC11 wedge socket 9-11 mm 29.00

AWC14

wedge socket 12-14

32.00

suitable for cutting ropes

Cutting synthetic ropes

A: Guy ropes

5 mm (3/16"), BS: 500 kg (1100 lb)

6 mm (1/4"), BS: 850 kg (1870 lb)

8 mm (5/16"), BS: 1300 kg (2870 lb)

10 mm (3/8"), BS: 1900 kg (4190 lb)

12 mm (1/2"), BS: 2200 kg (4850 lb)

Thimble fitted on one end.

4 mm (5/32"), BS: 400 kg (880 lb)

Terminated guy ropes Mastrant-P

B, C: Terminating

Soldering iron

66 ft 99 ft

NP040x0 9.50 13.50

NP050x0 13.50 19.00

NP060x0 22.00 31.50

NP080x0 28.00 40.00

NP100x0 37.00 52.50

NP120x0 76.00

ZCI01 9.70

ATH02 2 mm (min.Ø 8 mm) 0.25

ATH03 3 mm (min.Ø 10 mm) 0.29

ATH04 4 mm (min.Ø 11 mm) 0.38

ATH05 5 mm (min.Ø 13 mm) 0.49

ATH06 6 mm (min.Ø 14 mm) 0.62

ATH08 8 mm (min.Ø 18 mm) 1.03

ATH10 10 mm (min.Ø 24 mm) 1.60

ATH12 12 mm (min.Ø 30 mm) 1.90

ATH14 14 mm (min.Ø 32 mm) 2.60

ADC02 2 mm (M4, wrench 7) 1.20

ADC03 3 mm (M4, wrench 7) 1.40

ADC04 4 mm (M5, wrench 8) 1.60

ADC05 5 mm (M5, wrench 8) 2.60

ADC06 6 mm (M6, wrench 10) 3.70

ADC08 8 mm (M8, wrench 13) 5.60

ADC10 10 mm (M10, wr.17) 10.30

APC06 6 mm (5-8 mm, M6) 2.30

APC08 8 mm (8-10 mm, M6) 3.10

APC10 10 mm (10-12, M8) 4.50

APC12 12 mm (12-14, M10) 5.80

APC16 16 mm (14-18, M12) 7.80

AWC06 wedge socket 5-6.5 mm 15.00

AWC08 wedge socket 6-8 mm 31.00

AWC11 wedge socket 9-11 mm 29.00

AWC14

wedge socket 12-14

32.00

ASC12 12 mm (M10) 7.00 1.80

ASC13 13 mm (M10) 8.20

suitable for cutting ropes

Wedge sockets (galvanised)

Fist-grips (galvanised)

Cutting synthetic ropes

Thimbles (stainless)

A: Guy ropes

5 mm (3/16"), BS: 500 kg (1100 lb)

6 mm (1/4"), BS: 850 kg (1870 lb)

8 mm (5/16"), BS: 1300 kg (2870 lb)

10 mm (3/8"), BS: 1900 kg (4190 lb)

12 mm (1/2"), BS: 2200 kg (4850 lb)

Thimble fitted on one end.

4 mm (5/32"), BS: 400 kg (880 lb)

Terminated guy ropes Mastrant-P

B, C: Terminating

Soldering iron

Duplex wire rope clips (stainless)

AHO05 5 mm (BS: 570 daN) 1.40

AHO06 6 mm (BS: 670 daN) 1.60

AHO07 7 mm (BS: 750 daN) 2.60

AHO08 8 mm (BS: 870 daN) 3.30

AHO10 10 mm (BS: 1150 daN) 5.60

A7AZ11 25 kN, screw lock 9.10

ASE05 5 mm, 10x17 mm hole 2.00

ASE06 6 mm, 12x21 mm hole 2.40

ASE07 7 mm, 14x24 mm hole 2.70

ASE08 8 mm, 16x28 mm hole 3.00

ASE10 10 mm, 19x35 mm hole 5.80

ASE12 12 mm, 23x41 mm hole 8.20

ASW01 5.70

ASW02 10.10

swivel 1300 kg, stainless

swivel 2500 kg, stainless

B, C: Coupling

TERMINATION AND COUPLING

TENSIONING & ATTACHING

B

C

GUY ROPES

A:

Terminated guy ropes Mastrant-P

Cutting synthetic ropes

B,C:

Thimbles (stainless)

ATH08

ATH10

ATH12

ATH14

Duplex wire rope clips (stainless)

12 mm (1/2"), BS: 2200 kg (4850 lb)

Soldering iron

TERMINATING

”JEWELRY FOR YOUR TOWER“

TERMINATING

COUPLING

1.03

1.60

1.90

2.60

66 ft 99 ft

suitable for cutting ropes

B,C:

Bull-dog grips

ASC02 2 mm (M3) 1.40

ASC03 3 mm (M3) 1.60

ASC04 4 mm (M4) 1.70

ASC05 5 mm (M5) 1.90 0.33

ASC06 6 mm (M6) 2.10 0.41

ASC08 8 mm (M6) 2.50 0.78

ASC10 10 mm (M8) 3.70 1.03

B,C:

Spring hooks - Carabiners (stainless)

A7AZ11T 25 kN, twist lock 20.00

Chain quick-acting couplers (stainless)

ACC05 5 mm, max.opn.6.5 mm 2.00

ACC06 6 mm, max.opn.7.5 mm 2.80

ACC07 7 mm, max.opn.8.5 mm 3.70

ACC08 8 mm, max.opn.9.5 mm 4.50

ACC10 10 mm, max.opn.12 7.80

Shackles (stainless)

S.s. Galv.

(Stainless / Galvanised)

Fist-grips (galvanised)

Wedge sockets (galvanised)

Swivels (stainless)

Loading...

Loading...