Remote Tuner Options

for the

DXE-MBVE-5A

Vertical Antenna

DXE-MBVE-5UGBRT3

for the

MFJ-993BRT 300 Watt Remote Tuner

DXE-MBVE-5UGBRT4

for the

MFJ-994BRT 600 Watt Remote Tuner

DXE-MBVE-5UGBRT3-4- INS-Revision 0b

Remote Tuner shown with additional optional parts

© DX Engineering 2017

1200 Southeast Ave. - Tallmadge, OH 44278 USA

Phone: (800) 777-0703 ∙ Tech Support and International: (330) 572-3200

Fax: (330) 572-3279 ∙ E-mail: DXEngineering@DXEngineering.com

Introduction

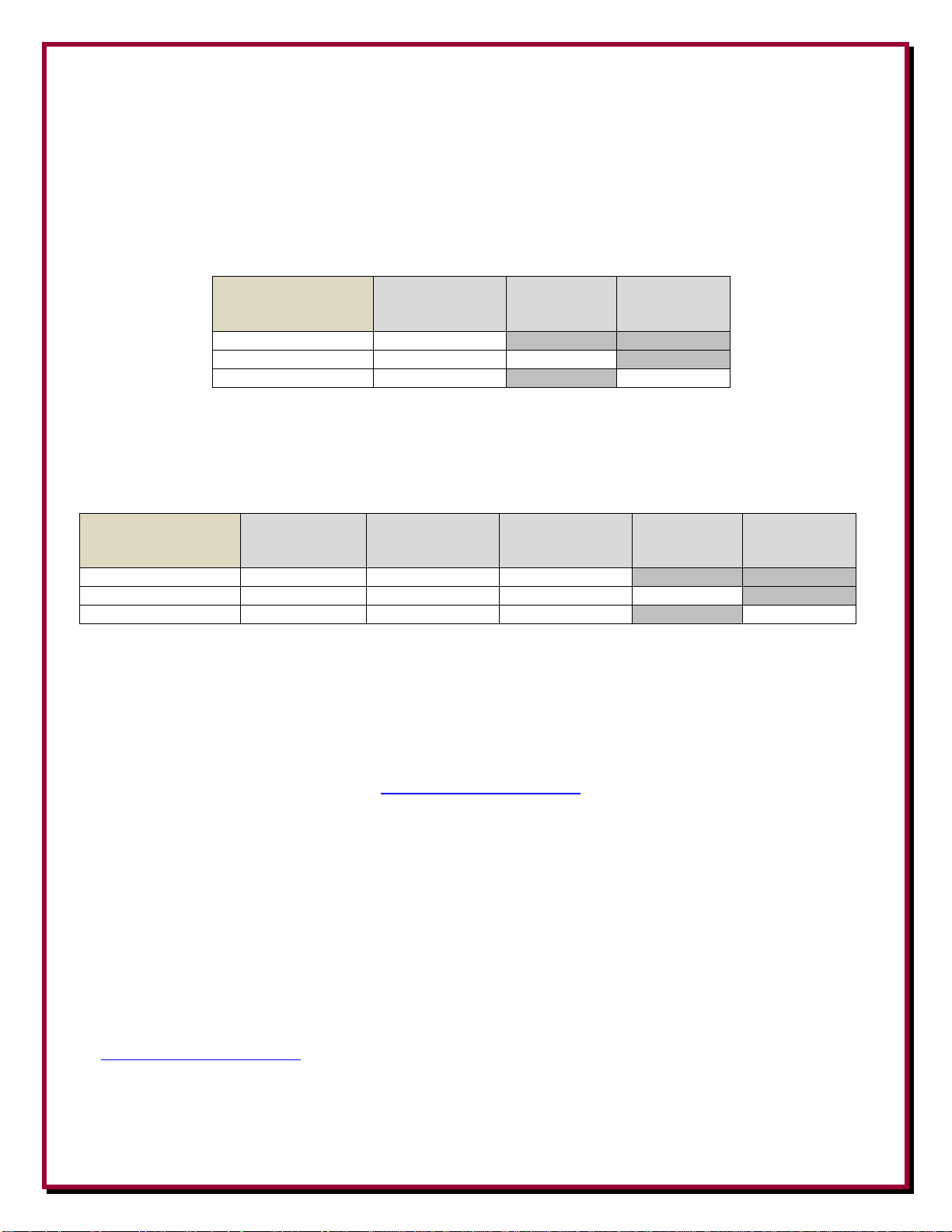

DX Engineering

Antenna Model

Numbers

MFJ-993/4BRT -

Brackets

MFJ-993BRT -

Tuner

300 Watt

MFJ-994BRT -

Tuner

600 Watt

DXE-MBVE-5AE-BRT

X

DXE-MBVE-5AEBRT3

X X

DXE-MBVE-5AEBRT4

X X

DX Engineering

Upgrade Model

Numbers

DXE-MBVE-THW

Hardware Kit

DXE-MBVE-5A-

UGHW

Hardware Kit

MFJ-993/4BRT -

Brackets

MFJ-993BRT -

Tuner

300 Watt

MFJ-994BRT -

Tuner

600 Watt

DXE-MBVE-5UG-BRT

X X X

DXE-MBVE-5UGBRT3

X X X X

DXE-MBVE-5UGBRT4

X X X X

This instruction manual describes three of the optional remote tuner upgrade packages available for

the DXE-MBVE-5A multi-band vertical antenna system.

There are 3 complete DXE-MBVE-5A antenna systems for use with either the MFJ-993BRT or

MFJ-994BRT Remote Tuner. These packages include the DXE-MBVE-5A antenna.

X = Included

There are two upgrade retrofit kits for existing DXE-MBVE-5/5A systems for use with either the

MFJ-993BRT or MFJ-994BRT Remote Tuner. There is also one upgrade kit that has the hardware

needed to mount the MFJ-998RT Remote Tuner that the customer already has.

X = Included

There are also options available for other MFJ remote tuners allowing operation at 200, 300, 600 or

1500 Watt power levels. See the DX Engineering web site for complete details.

A complete manual including the assembly of the DXE-MBVE-5A antenna system that also

includes the information in this manual is available from DX Engineering and can be downloaded

from the DX Engineering web site at www.DXEngineering.com

Additional Material Needed but not Supplied:

JTL-12555 Jet-Lube™ SS-30 Pure Copper Anti-Seize 12555 - To ensure good electrical

and RF connection for Aluminum Element Sections and also used on the threads of Stainless

Steel Hardware to prevent galling (seizing) and aid in proper tightening.

The assemblies or upgrades that use the extended base tube and new base tube insulator are

basically built the same as the standard DXE-MBVE-5A which is described in greater detail in the

DXE-MBVE-5A manual which is available on-line from the DX Engineering web site at

www.DXEngineering.com. The Saf-T-Tilt™ base and the aluminum vertical elements are all the

same for all of the DXE-MBVE-5A models. The only difference is the base tube length (Short Base

tube is 14”, Long Base Tube required for the remote tuners is 36”) new base tube insulator and

associated hardware.

- 1 -

Upgrade Hardware for the

SAF-T-Tilt™ Base Assembly Upgrade Hardware Kit

DXE-MBVE-5A-UGHW for the extended base tube option

Qty

Drawing

Ref.

Number

1/4”-20 x 3/4” long Hex Head Bolt, Stainless Steel

1 18

1/4”-20 x 2-3/4” long Hex Head Cap Screw, Stainless Steel

1

23

1/4”-20 x 3-1/4” long Hex Head Cap Screw, Stainless Steel

2

17

1/4” Flat Washer, Stainless Steel

11

19

1/4” Split Lock Washer, Stainless Steel

6

20

1/4" External Tooth Washer, Stainless Steel

3

21

1/4”-20 Hex Nut, Stainless Steel

6

22

1/4”-20 x 3” long Hex Head Cap Screw, Stainless Steel

2

25

1/2”-13 Hex Nut, Stainless Steel

1

11

1/2”-13 x 4-1/2” long, Hex Head Bolt, Stainless Steel

2

12

1/2” Flat Washer, Stainless Steel, Thick

1

13

1/2” External Tooth Washer, Stainless Steel

2

14

1/2” Split Lock Washer, Stainless Steel

1

15

1/2”-13 Flanged Nut, Stainless Steel

1

16

7” Wire, 14 ga PVC insulated, two 1/4” Ring Terminals

1

24

Extended Base Tube Drawing

This drawing shows

the Upgrade

Hardware Kit that

includes the associated

hardware.

For existing systems,

the new hardware is

supplied with the

upgrade kits to make

installation easier.

NOTE: The Upgrade

Kits also include an

extended (36”) Base

Tube and a new

Drilled Insulator

- 2 -

DXE-MBVE-THW Parts Listing

DXE-MBVE-THW Mounting Hardware Kit

For the MFJ-993BRT/MFJ-994BRT Tuner mounting option

Qty

U-Bolt, Stainless Steel, 2.5”, 4” long, 5/16”-18 threads

2

Aluminum Saddle, V-Block

2

5/16”-18 Hex Nut, Stainless Steel

9

5/16”-18 x 5/8” long, Hex Head Cap Bolt, Stainless Steel

1

5/16” Washer, Flat, Stainless Steel

9

5/16” Washer, External Tooth, Stainless Steel

5

5/16” Washer, Split Lock, Stainless Steel

9

2” Element Clamp with Threaded Stud, Stainless Steel

1

10-24, Hex Nut, Stainless Steel

1

#10 Washer, Split Lock, Stainless Steel

1

#10 Washer, Flat, Stainless Steel, Thick

2

#10 Washer, External Tooth, Stainless Steel

1

3” Wire Assembly, 12 ga, Black Insulated, two ring terminals

1

10” Wire Assembly, 12 ga, Black Insulated, two #10 ring terminals

1

Installing the MFJ-993BRT or MFJ-994BRT option

1. Install the short ground wire in the corner hole

on the tuner mounting flange using the 5/16”-18

Hex Nut, 5/16”-18 x 5/8” long Hex Head Cap

Bolt, 5/16” Flat Washer, 5/16” External Tooth

Washer, 5/16” Split Lock Washer and 3” Wire

Assembly. The other end of the short 3” tuner

wire goes to the tuner ground wing nut

connection on the tuner as shown.

2. Position one of the tuner mounting aluminum V-saddle

clamps 3/4” below the top of the thick wall tube as

shown. Refer to the photos on Page 36 for the positioning

of the clamps in as compared to the antenna base.

Use two 5/16”-18 Hex Nuts, two 5/16” Flat Washers, two

5/16” Split Lock Washers and one 5/16”-18 x 4” long UBolt. Do not over tighten the U-Bolt Hex Nuts which can

break or bend the aluminum V-saddle clamp. Evenly

tighten each side of the U-bolt until the split lock washer

is seated properly.

- 3 -

3. Loosely mount the bottom aluminum saddle clamp

assembly approximately 13-1/4” below the previously

(upper) mounted saddle clamp using the same hardware

described for the upper clamp. Ensure both clamps are

facing the same direction.

(This installation method works well since the MFJ

tuner mounting flanges can be in slightly different

positions on the tuners.)

4. Place on 5/16” External Tooth Washer on each leg of the upper saddle clamp U-bolt and then

position the MFJ-993BRT or MFJ-994BRT tuner in place on the upper U-bolt that protrudes

from the saddle clamp. Once in place, loosely install the two 5/16” Flat Washers, two 5/16” Split

Lock Washers and two 5/16”-18 Hex Nuts to hold the tuner in place on the upper clamp as

shown. You want the tuner to be able to move a bit for final positioning.

5. Position the lower saddle clamp (with the external tooth

washers on each leg) so the U-bolt will pass through the

bottom mounting flange on the tuner as shown. Once the

tuner is positioned in place and straight - use the two 5/16”

Flat Washers, two 5/16” Split Lock Washers and two 5/16”18 Hex Nuts to hold the bottom of the tuner in place.

Tighten all of the tuner mounting hardware (top and

bottom).

- 4 -

6. When the upper antenna parts are mounted to the base assembly (see previous installation

instructions), install the Studded Band Clamp on the first element just above the black insulator

with the stud facing the side nearest the tuner connections. Install the 10” long tuner wire on the

studded band clamp using the #10 hardware as shown. The other end of the 10” wire is

connected to the tuner output wing nut connection on the tuner as shown.

The feedline coaxial cable connects from the Antenna Tuner to the Bias-T in the radio room.

Two views showing the

MFJ-993BRT or MFJ-994BRT

installed on the

DXE-MBVE-5A antenna

- 5 -

Bias Tee Information

The MFJ-4117 Bias Tee is included with the MFJ Remote Tuner. Since the

coaxial cable is supplying the DC voltage to the remote tuner (injected in the

coaxial cable by the Bias Tee), the coaxial cable used must have a good DC

path. Lightning protectors that block DC cannot be used.

Follow the instructions provided by MFJ for both the Tuner and the Bias

Tee.

Make certain the coaxial cables are properly connected to the Bias "T" as shown. Ensure the

ON/OFF switch on the Bias "T" is turned ON when using the system.

NOTE: Review the MFJ Remote IntelliTuner™ manual for a detailed

explanation of the Remote IntelliTuner™ and the Bias Tee operation.

Installing the Bias Tee incorrectly may cause damage to your radio.

- 6 -

Technical Support

If you have questions about this product, or if you experience difficulties during the installation,

contact DX Engineering at (330) 572-3200. You can also e-mail us at:

DXEngineering@DXEngineering.com

For best service, please take a few minutes to review this manual before you call.

Manual Updates

Every effort is made to supply the latest manual revision with each product. Occasionally a manual

will be updated between the time your DX Engineering product is shipped and when you receive it.

Please check the DX Engineering web site (www.dxengineering.com) for the latest revision manual.

Warranty

All products manufactured by DX Engineering are warranted to be free from defects in material and workmanship for a

period of one (1) year from date of shipment. DX Engineering’s sole obligation under these warranties shall be to issue

credit, repair or replace any item or part thereof which is proved to be other than as warranted; no allowance shall be

made for any labor charges of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such

charges are authorized in advance by DX Engineering. If DX Engineering’s products are claimed to be defective in

material or workmanship, DX Engineering shall, upon prompt notice thereof, issue shipping instructions for return to

DX Engineering (transportation-charges prepaid by Buyer). Every such claim for breach of these warranties shall be

deemed to be waived by Buyer unless made in writing. The above warranties shall not extend to any products or parts

thereof which have been subjected to any misuse or neglect, damaged by accident, rendered defective by reason of

improper installation, damaged from severe weather including floods, or abnormal environmental conditions such as

prolonged exposure to corrosives or power surges, or by the performance of repairs or alterations outside of our plant,

and shall not apply to any goods or parts thereof furnished by Buyer or acquired from others at Buyer’s specifications.

In addition, DX Engineering’s warranties do not extend to other equipment and parts manufactured by others except to

the extent of the original manufacturer’s warranty to DX Engineering. The obligations under the foregoing warranties

are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other

remedies including claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY

OTHER WARRANTY WHATSOEVER, WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME

FOR DX ENGINEERING ANY OBLIGATION OR LIABILITY NOT STRICTLY IN ACCORDANCE WITH THE

FOREGOING.

©DX Engineering 2017

DX Engineering®, DXE®, DX Engineering, Inc.®, Hot Rodz®, Maxi-Core®, DX Engineering THUNDERBOLT®, DX

Engineering Yagi Mechanical®, EZ-BUILD®, TELREX®, Gorilla Grip® Stainless Steel Boom Clamps, Butternut®,

SkyHawk™, SkyLark™, SecureMount™, OMNI-TILT™, RF-PRO-1B®, AFHD-4® are trademarks of PDS Electronics,

Inc. No license to use or reproduce any of these trademarks or other trademarks is given or implied. All other brands

and product names are the trademarks of their respective owners.

Specifications subject to change without notice.

- 7 -

Loading...

Loading...