Page 1

Bulletin TE-UHH

3.038

[77.17 mm]

2.169

[55.09 mm]

8.508

[216.11 mm]

Model UHH - Universal Handheld Test Instrument

Specifications - Installation and Operating Instructions

Front View Side View

The Model UHH Universal Handheld Test Instrument is a highly versatile

instrument that offers the utmost flexibility and ease of user operation by having

the capacity to work with a variety of Dwyer Instruments, Inc. compatible sensing

modules and probes. Additional wired and wireless probes or modules are

instantly recognized by the UHH without any user reprogramming or alteration,

allowing seemless sensor addition, upgrade or replacement. See the Dwyer

Instruments, Inc. catalog or website www.dwyer-inst.com for available packages

and sensors. The Universal Handheld offers a slew of features that enable a

technician to quickly set up and intuitively navigate through their daily activities.

Data is stored via the internal memory or separate SD card in various auto or

manual logging operations. Logged files can be quickly transferred to a device

through a USB cable or by a portable SD card. The display can operate in standard

numerical meter mode, gauge mode with analog needle and bar graph, gauge

mode with additional pass/fail operation zones, and strip chart mode which

enables a simplified visual tracking of the process. The four button directional plus

enter button combined with the three soft key buttons aligning to corresponding

screen functions allow for quick navigation through the four main operation menus.

The rugged plastic case with protective thermo-plastic over-mold along with the

dust-shielding rubber caps permit the unit to handle abuse and properly withstand

dusty environments. The base UHH includes an integral molded compartment,

that securely holds wireless modules. The storage compartment offers convenient

transportation of a module with the base instrument during testing. A flexible hand

strap included with every UHH provides means for the base handheld to be safely

connected to a belt, pipe, ladder or similar structure freeing the user's hands to

focus on the sampling test. A 6-pin connector enables one wired probe at a time

to be plugged in to the base instrument without worry of becoming disconnected

during sampling. The rechargeable battery via the included USB cable provides

long term operation to last through several days work. At just under 10 oz, the

compact UHH base is lightweight. Included in the standard series kits is a soft

carrying case which secures the provided accessories and test probe. The ProSeries provides the addition of a rugged hard case with foam cut-outs that secures

existing as well as additional test sensors and accessories.

*Wireless Guidelines in Accordance with FCC:

Changes not expressly approved by Dwyer Instruments Inc. could void the user's

authority to operate the equipment.

This product complies with FCC OET Bulletin 65 radiation exposure limits set forth

for an uncontrolled environment.

Pursuant to FCC 15.21 of the FCC rules, changes not expressly approved by

Dwyer Instruments, Inc. might cause harmful interference and void the FCC

authorization to operate this product.

Canadian Government Guidelines:

Operation is subject to the following two conditions: (1) This device may not cause

harmful interference and (2) this device must accept any interference received,

including interference that may cause undesired operation.

INFORMATION TO THE USER

Power Output: 6 mW

Operating Frequency: 2.4 GHz

Operating Channel: 11

Operating Mode: IEEE 802.15.4, Zigbee, Direct Sequence Spread Spectrum

Data Rate: Up to 250 kbps

Intended Use: Industrial/commercial HVAC

Antenna Connection: Internal only, non-tunable

DWYER INSTRUMENTS, INC.

UHH SPECIFICATIONS

Languages: German, Spanish, Italian,

English, Portuguese.

Display: OLED, color 240 x 320.

Temperature Limits: 5 to 125°F (-15

to 51°C);

Note: When using wireless

function: 20 to 125°F (-6 to 51°C).

Battery Charging Limits: 32 to 113°F

(0 to 45°C).

Resolution: 1 FPM, 0.1 MPS, 0.1

3

CFM & M

Units Air Velocity: FPM, MPH, KN,

M/H, M/S K/H, FPS.

Units Flow: CFM, M

GPH, GPD, LPS, LPM, LPH.

Units Temperature: °F, °C.

Handle Enclosure: Thermoplastic

elastomer over polycarbonate.

Maximum Wireless Distance: 50’

(15 m)

Power Requirements: Rechargeable

lithium ion polymer via USB.

Weight: 10 oz (283 g).

Supplied With:

Agency Approval: CE, EN 1000-4-2,

EN 1000-4-3, EN 1000-4-4, EN 10004-5, EN 1000-4-6, EN 1000-4-11, EN

300 328, EN 300 328, EN 300 328,

EN 300 328, EN 300 328, EN 50371,

EN 300 328 with CE approved

charger, RoHS; Note: Intended to be

operated with power cables less than

3 m in length *FCC Compliance.

THERMO ANEMOMETER PROBE

SPECIFICATIONS

Service: Air velocity and temperature

of clean, dry air.

Temperature Limits:

Battery Charging Limits: 32 to 113°F

(0 to 45°C).

Range Air Velocity: 0 to 6000 FPM (0

to 30 m/s).

Accuracy Air Velocity: ±3% FS

within temperature range of 40 to 90°F

(4 to 32°C).

Range Volumetric Air Flow: 999,999

in selected flow units.

Range Temperature: -40 to 212°F

(-40 to 100°C).

Accuracy Temperature: ±0.5°F

(±0.28°C).

/HR; 0.1°F & °C; RH 0.1%.

3

/HR, M3/S, GPM,

AQTI: Soft case; USB cable/

charger; Hand strap;

AQTIP: Soft case; Hard case; USB

cable/charger; Hand strap, 2GB

SD card.

Process: -20 to 200°F

(-29 to 93°C);

Ambient: 5 to 125°F (-15 to 51°C).

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Power Requirements: Rechargeable

lithium ion polymer via USB. Wireless

probes only. Do not operate wireless

probes while connected to the battery

charger.

Handle Enclosure: Thermoplastic

elastomer over polycarbonate.

Probe Length: 8˝ (203 mm) insertion.

Cable Length: 28˝ (71 cm) retracted,

6 ft (183 cm) extended.

Supplied With: Wrist strap.

Agency Approval: CE, EN 1000-4-2,

EN 1000-4-3, EN 1000-4-4, EN 10004-5, EN 1000-4-6, EN 1000-4-11, EN

300 328, EN 300 328, EN 300 328,

EN 300 328, EN 300 328, EN 50371,

EN 300 328 with CE approved charger

RoHS; Note: Intended to be operated

with power cables less than 3 m in

length *FCC Compliance.

HUMIDITY/TEMPERATURE PROBE

SPECIFICATIONS

Service: Humidity and temperature

detection in clean air.

Temperature Limits:

Process: -40 to 176°F

(-40 to 80°C);

Ambient: 5 to 125°F (-15 to 51°C).

Battery Charging Limits: 32 to 113°F

(0 to 45°C).

Range Relative Humidity: 0 to 100%

(non-condensing).

Accuracy Relative Humidity: ±2%

FS over 10 to 90% @ 77°F (25°C).

Range Temperature: -20 to 140°F

(-28 to 60°C).

Accuracy Temperature: ±0.9°F @

72°F (±0.3°C @ 25°C).

Power Requirements: Rechargeable

lithium ion polymer via USB. Wireless

probes only. Do not operate wireless

probes while connected to the battery

charger.

Handle Enclosure: Thermoplastic

elastomer over polycarbonate.

Probe Length: 8˝ (203 mm) insertion.

Cable Length: 28˝ (71 cm) retracted,

6 ft (183 cm) extended.

Supplied With: Wrist strap.

Agency Approval: CE, EN 1000-4-2,

EN 1000-4-3, EN 1000-4-4, EN 10004-5, EN 1000-4-6, EN 1000-4-11, EN

300 328, EN 300 328, EN 300 328,

EN 300 328, EN 300 328, EN 50371,

EN 300 328 with CE approved

charger, RoHS; Note: Intended to be

operated with power cables less than

3 m in length *FCC Compliance.

Page 2

UHH FEATURE OUTLINE

SD MEMORY

CARD SLOT

SENSOR AND LOGGING

ICON LOCATION

MAIN MENUS

4 DIRECTIONAL ARROWS

WITH ON/OFF/ENTER BUTTON

ALLOW QUICK NAVIGATION

LED INDICATES CHARGING

STATUS AND DATA STORAGE

RED: INDICATES CHARGING.

NOTE: TURNS OFF WHEN

FULLY CHARGED.

GREEN: INDICATES A DATA

POINT STORAGE OR THAT

UNIT IS IN SLEEP MODE.

PROTECTIVE RUBBER CAPS

SIDE VIEW

INDUSTRIAL 6-PIN

PROBE CONNECTION

HAND STRAP

TOP CLIPS

BATTERY

INDICATOR

LARGE BACKLIT

COLOR OLED

3 SOFT KEYS CORRESPOND

TO APPLICABLE ON-SCREEN

FUNCTIONS

HAND STRAP BOTTOM CLIP

Module Storage

Compartment

USB CONNECTION FOR DATA

TRANSFER OR RECHARGING WITH

INTEGRAL PROTECTIVE RUBBER CAP

Page 3

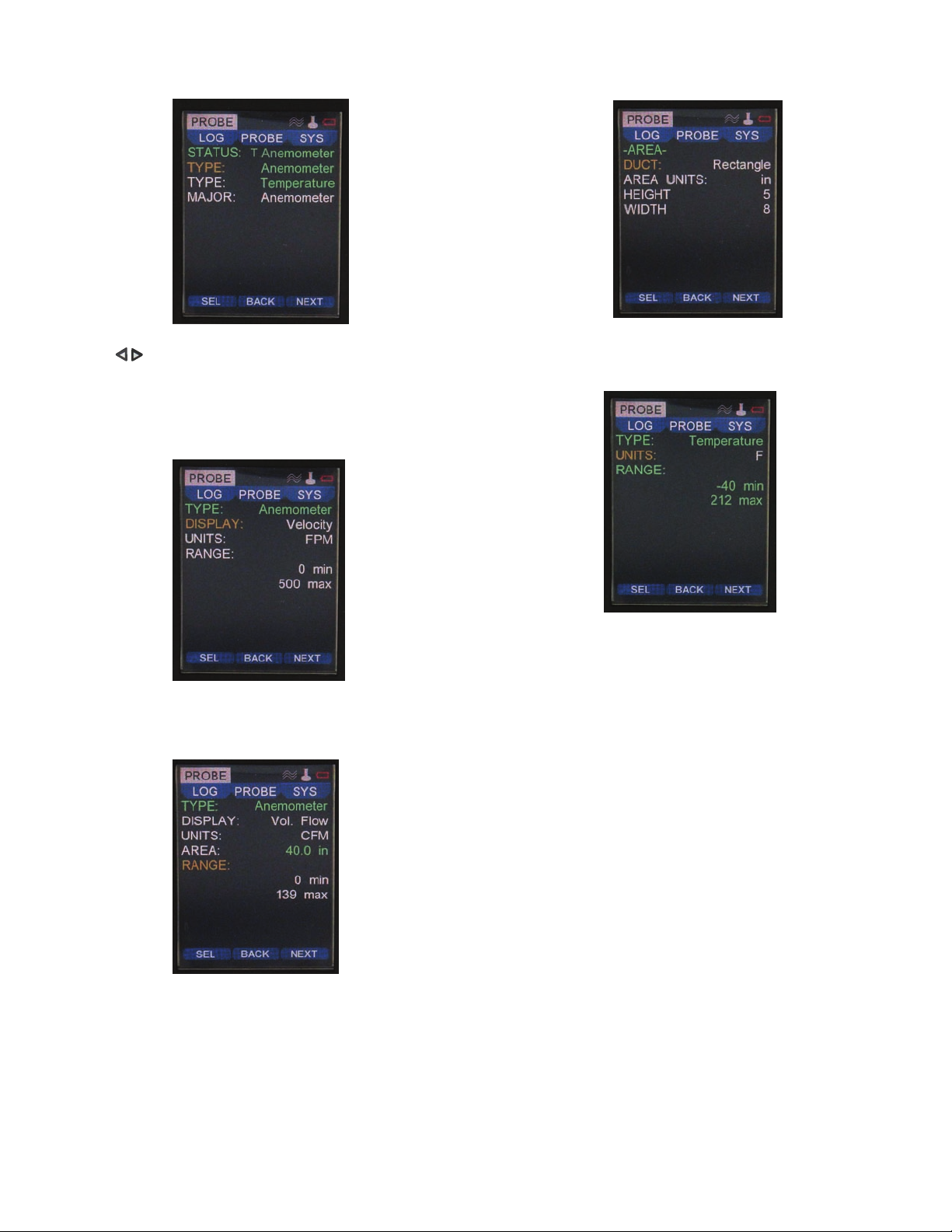

MENU SETUP

Probe Main Menu

Probe Menu

• Press the to scroll through the top main menus.

• When PROBE is highlighted, hit the enter key.

• The status of the probe connected will appear as well as the outputs being provided

to the UHH.

• Select the primary measurement of the home screen under the MAJOR setting.

• To alter the potential modes of the measurements scroll down to any of the TYPE

TYPE Sub-Menu Anemometer (Velocity Selected)

sub-menus to select and adjust.

• In this example, the Anemometer can be changed from either Velocity mode or

Vol. Flow mode.

• Change the engineering units to be displayed under the UNITS section.

Area Sub Menu (Vol. Flow Selected)

• If Vol. Flow is chosen, select the AREA category to adjust the DUCT style, the

AREA UNITS, HEIGHT and WIDTH dimensions.

TYPE Sub-Menu Temperature

• In this example, the Temperature range is set and cannot be changed as it is green

and unselectable, however the units may be adjusted.

TYPE Anemometer Sub-Menu (Vol. Flow Selected)

• Similarly to when Velocity is selected, applicable engineering units can be chosen

in the UNITS category for Vol. Flow.

• Note an area must be programmed.

Page 4

SYS Menu

VIEW Menu

SYS Main Menu

• Press the to scroll through the top main menus.

• When SYS is highlighted, push the enter key.

• The STATUS will show how many probes are connected at once.

• The WIRELESS feature may be turned on or off and the display CONTRAST

adjusted here as well.

• If desired, a RESTORE DEFAULT feature is available from this screen.

• Note: FILE displays remaining available memory. If INT is selected in the LOG

main menu the maximum memory is 4 mb. A 2 GB memory card is the maximum

memory the UHH can utilize if SD is selected.

Status Sub Menu

• If you select the STATUS sub menu you can view the firmware edition as well as

the type of probes connected to the unit.

VIEW METER Mode

• Press the to scroll through the top main menus.

• When VIEW is highlighted, select with the enter key.

• Several viewing modes are available on the home screen from the selections in

this menu.

• The default is METER which displays numerical values.

• The AVERAGE setting calculation is programmed in this menu.

• AVERAGE values may be altered from 5 to 60 seconds.

SETTINGS Sub Menu

• Click on the SETTINGS sub menu for language selection as well as the default

engineering units. The DATE and TIME can be entered, as well as power

management inactivity time delays for SLEEP and SHUTDOWN.

• The user can program in their name, an identification code or their company name

into the SETTINGS sub menu under OWNER.

Page 5

Home Displays Under Standard METER Mode

CURR View in the Home Screen

• On the home display, two values may be viewed at the same time if a sensor

offers.

• If two are present the reading at the top, or MAJOR reading, may be switched.

See the Probe main menu for details.

• Press the soft key on the left aligned with the HOLD function to freeze the

reading at that instant. The RUN function will then appear on the left.

• To resume reading the live process press the left soft key aligned with the RUN

function.

AVG Home Screen

• To see the average reading instead of the current process reading press the soft

key in the middle aligned with the CURR function so that the AVG function is on

top. Press the soft key on the right aligned with the CLEAR function to reset the

average readings.

• See the VIEW main menu to adjust the average function time period.

Note: The current process reading will remain visible at the top of the display.

PEAK VALLEY Home Screen

• To view the peak and valley values, press the middle soft key one more time to

scroll from TOTAL to P/V.

• Hit the CLEAR soft key on the right to instantly reset the peak and valley values

and recalculate new peak and valley values.

Note: The current process reading will remain visible at the top of the display.

View GAUGE Mode

• Choose GAUGE mode to display a digital analog gauge like one similar to a

speedometer. The available range will be adjustable at the bottom of the screen.

• Adjust both the min and max for the associated values that will correspond to

the 0° value for min and the 180° value for the max or full scale reading.

Note: Some probes or modules may have selectable ranges that are programmed

in the PROBE menu under RANGE. You cannot go above this chosen full scale

RANGE in the GAUGE setting in the VIEW menu.

TOTAL Summation Home Screen

• To view the sum or total value, again press the middle soft key to scroll from AVG

to TOTAL.

Note: Only visible on certain probes.

• Hit the CLEAR soft key on the right to reset the total value back to zero and restart

the summation.

Note: The current process reading will remain visible at the top of the display.

Home View GAUGE Mode

• In this example, the min is zero and the max is 500. The live process value is

shown under the gauge dial.

• The mid point will always show at the 90° point on the gauge dial.

Page 6

View RANGE Mode

• An extension from the GAUGE mode is the RANGE mode.

• Select RANGE in the VIEW category.

• Two sets of min and max will appear listed as GAUGE and RANGE.

• The GAUGE settings are just as in the previous GAUGE view mode and show the

zero and full scale points of the dial.

• The RANGE low and high settings provide a different color green zone to appear

on the dial of the digital gauge. This two color band dial provides a quick

determination during a test if the reading is in the pass or fail zone.

Home View RANGE Mode

• In this example, the GAUGE has a min of 0 and a max of 500. The RANGE low

is 100 while the high is 400.

• A green zone on the dial corresponding to the RANGE low/high settings will

appear on the home screen.

Home View STRIP Mode

• Besides the time setting shown on the graph, you can program the graph to show

full scale of the range of the sensor, half scale where the top of the Y axis is half

of the full scale, or mid-scale where half the full scale value is displayed in the

middle of the Y axis.

LOG Main Menu

LOG Main Menu

• Press the to scroll through the top main menus.

• When LOG is highlighted, push the enter key.

• Here you can program the sampling rate of the logging. The sampling RATE may

be adjusted from 1 to 3600 seconds between recordings.

• The FILE FORMAT can be altered from CSV to a TSV downloadable file type.

• You can program the TRIGGER to be a manual trigger, a trigger begun by a

programmed event or a single trigger which manually logs a single point by the

push of a button.

• Select the LOG to START and STOP the logging function. The LED will flash

when the data sample is stored in any logging mode. A log status icon will also

appear at the top to acknowledge a logging session is active.

• After the log session has begun, the file name will appear on the FILE row.

• You may select under MEDIA to either store data logged files to an SD card if

one is inserted or to INT which is the internal memory.

• Select LOG FILES to view all saved files. See view of saved files section for more

details.

View STRIP Mode

• The fourth and final choice in the VIEW menu is STRIP. This option offers the user

a strip chart style graph with Y axis scaled with the selected major sensor setting

and an X axis showing the selected time.

• The x axis time may be adjusted from 10 to 3,600 seconds.

Page 7

• If the trigger has been selected to be Manual from the LOG main menu, the

LOG TRIGGER Menu

screen will show the three following selections.

• You can change the ending of the log to be either a manual end under STOP, or

you can set the STOP to end after a duration.

• If DURATION is chosen the programmed duration determines how long the log

session will last. It may be set from 1 to 1,440 minutes.

LOG TRIGGER Event Menu

• If the TRIGGER has been selected to be Event from the LOG main menu, the

screen will appear as shown.

• LEVELS provides initiation points where the trigger will begin a log operation.

• The auto trigger EVENT settings can begin INSIDE or OUTSIDE the LEVELS

trigger band.

• Setting a PRE-TRIG setting to anything other than 0 will provide data recorded to

the file for that time period prior to the event trigger initiation.

• POST-TRIG sets the duration after the auto trigger event of the log session.

• If the MIN UPDATE is set to anything other than 0, a data point will be captured

at the time of the MIN UPDATE even if the TRIGGER threshold has not been

reached.

• The PRE-TRIG and POST-TRIG can be adjusted from 0 to 86,400 seconds, while

the MIN UPDATE can be set from 0 to 60 minutes.

File names can be scrolled through and their data viewed by selecting VIEW.

VIEW of Saved Files

Calculated statistics of the data from a file are viewable such as average or peak

and valley by selecting STAT. A file may be deleted by hitting DELETE. To exit this

screen and return to the previous, press the left arrow key.

VIEW of Saved File

The following will appear after hitting VIEW from the saved files list. Numerical

order value in the saved group along with its file name and format, the DATE, TIME

of that data point and the MAJOR and MINOR data values recorded. To scroll

through each data point's information within a file, press the navigation keys.

Any data point may be deleted in their respective file by pressing DEL.

Home View If Single Trigger Chosen

If Single is chosen, no other parameters are necessary to be programmed. This

mode will allow with the right soft key located under STORE a single data point to

be entered into a file. Each subsequent data point will continue to be stored in that

same file until the NEW soft key is pressed. After NEW is pressed, the next set of

data points will be stored in a new file.

STAT (Statistics) of a Saved File

After selecting STAT from the saved file list screen you will see statistics for all data

within the respective file. Total, Average, Peak and Valley will be visible for both

Major and Minor parameters.

Note: If there are many stored data points on a file, some time may elapse before

the statistics shown above appear.

Page 8

ACCESSORIES

Model

AP1

RP1

AP2

RP2

160-F

UHH-STRAP

UHH-ICHRG

UHH-CBL

UHH-SD

Description

Thermo anemometer air velocity & temperature probe with coiled

cable

Thermo hygrometer & temperature probe with coiled cable

Wireless thermo anemometer air velocity & temperature probe

Wireless thermo hygrometer humidity & temperature probe

20˝ straight pitot

UHH hand strap

UHH charger with international adapters

USB cable

2GB SD card

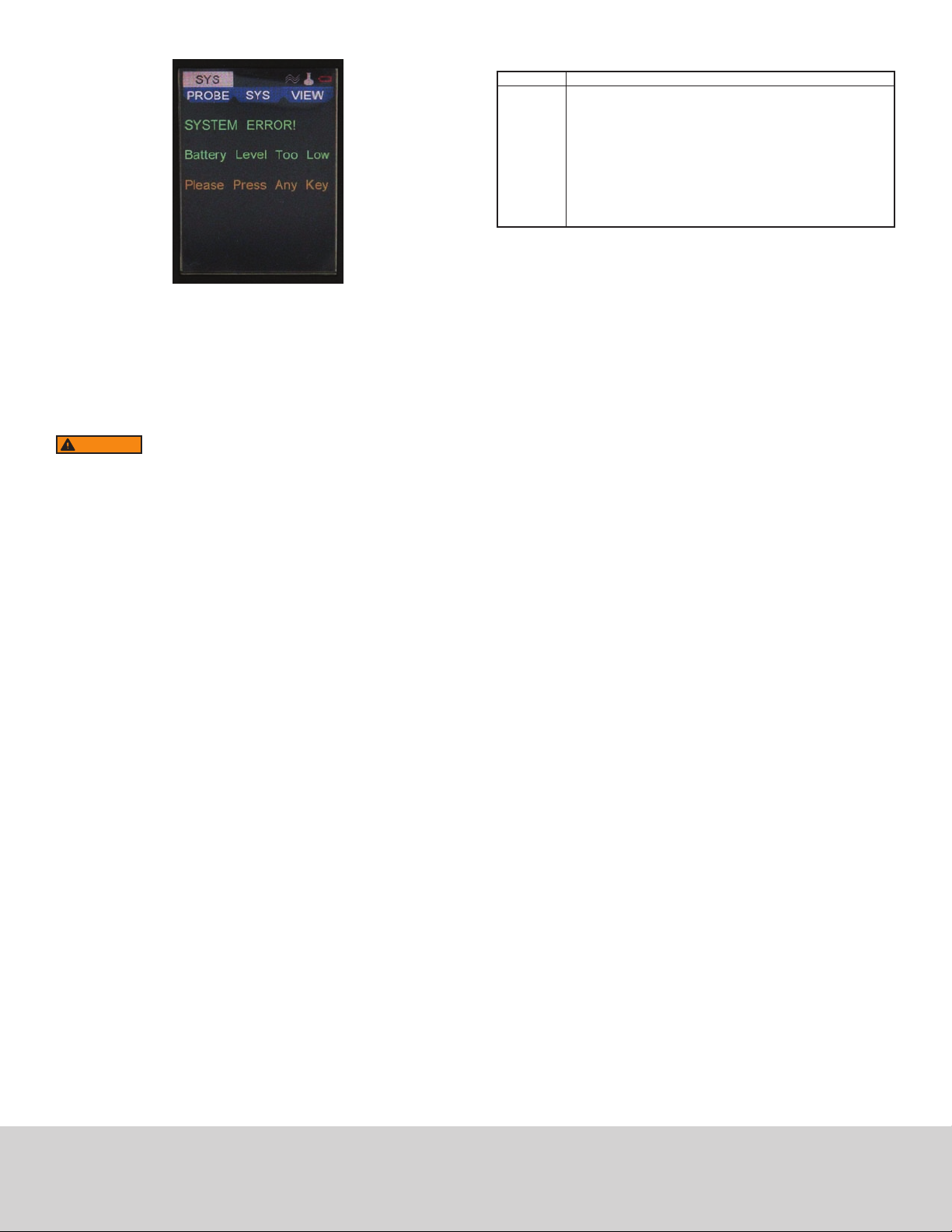

Low Battery Warning

The low battery level screen will appear when the UHH detects its charge to be

nearing an end. The lithium ion polymer battery is expected to provide

approximately 1000 full charge cycles over its lifespan. After the battery can no

longer provide a sufficient charge, please return to Dwyer Instruments Inc. for a

replacement.

Note: It is recommended on the initial usages to fully charge and use until the low

battery level screen appears before a second power charge. This will enable the

battery icon to properly calculate and display the battery charge level.

WARNING

Instruments, Inc. approved charging device in a well ventilated area away from any

flammable materials or gases. Do not incinerate. Only charge between 32 to 113°F

(0 to 45°C).

MAINTENANCE/REPAIR

Upon final installation of the Series UHH, no routine maintenance is required. The

Series UHH is not field serviceable and should be returned if repair is needed (field

repair should not be attempted and may void warranty).

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem

plus any additional application notes.

Lithium ion polymer batteries are very volatile and can cause a

fire if punctured or severly damaged. Only use a Dwyer

Low Battery Warning

©Copyright 2011 Dwyer Instruments, Inc. Printed in U.S.A. 8/11 FR# 02-443875-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...