Page 1

F - UFM

UFM

Ultrasonic Flowmeter

User Manual

Issue 1.4 Page 1

Page 2

F - UFM

Table of Contents

1 General Description ........................................................................................................................ 4

2 How does it work? .......................................................................................................................... 5

3 User interface .................................................................................................................................. 6

3.1 Key switches ............................................................................................................................ 6

4 Installing the UFM ........................................................................................................................... 7

4.1 Preparation ............................................................................................................................. 8

4.2 Sensor separation ................................................................................................................... 8

4.3 Adaptors for small pipes ....................................................................................................... 10

4.4 Attaching the UFM to the pipe ............................................................................................. 11

4.5 UFM interface cable .............................................................................................................. 12

4.6 Connecting the UFM to the Supply ....................................................................................... 12

4.7 Pulse Output connection ...................................................................................................... 12

4.8 Current Output ...................................................................................................................... 13

4.9 Cable Screen .......................................................................................................................... 13

5 Powering up for the first time ....................................................................................................... 14

5.1 How to enter the Pipe ID ...................................................................................................... 15

5.2 Pulse output .......................................................................................................................... 16

5.2.1 Volumetric mode .......................................................................................................... 16

5.2.2 Frequency mode ........................................................................................................... 16

5.3 4-20 mA Current output........................................................................................................ 16

6 Subsequent Power-ON Sequence ................................................................................................. 17

7 Password Controlled Menus ......................................................................................................... 17

7.1 General procedure for changing menu settings ................................................................... 17

7.1.1 Selection menus ............................................................................................................ 17

7.1.2 Data entry menus .......................................................................................................... 18

7.2 User Password controlled menu structure ........................................................................... 18

8 Diagnostics Menu .......................................................................................................................... 23

9 Relocation of guide rail ................................................................................................................. 24

10 Appendix I – UFM Specification ................................................................................................ 25

11 Appendix II – Default values ..................................................................................................... 26

12 Appendix III – Error and Warning Messages ............................................................................. 27

Issue 1.4 Page 2

Page 3

F - UFM

12.1 System errors ........................................................................................................................ 27

12.2 Warnings ............................................................................................................................... 27

13 Maintenance/Repair ................................................................................................................. 28

14 Warranty /Return ...................................................................................................................... 28

Issue 1.4 Page 3

Page 4

F - UFM

1 General Description

The UFM is a fixed installation, clamp-on flowmeter that is easy to install and requires

minimum information to be entered by the user. Both the electronics and guide rail housings

form an integral unit that is attached to the pipe using the supplied jubilee clips. Power to the

unit is provided by an external 12 – 24 V ac/dc power supply. The UFM is intended to operate

on steel, copper and plastic pipes with OD’s in the range 0.98 inches (24.9 mm) to 4.62 inches

(117.4 mm).

Compact, rugged and reliable, the UFM has been designed to provide sustained performance

in industrial environments.

UFM standard features include:

2 line x 16 character LCD with backlight

4-key keypad

Isolated pulse output

4-20 mA current output

Simplified guide rail and transducer assembly

Continuous signal monitoring

Password protected menu operation for secure use

Operates from external 12 to 24 V ac/dc power supplies

Small pipe adaptors

Typical applications

Hot water metering and flow measurement

Flow measurement for heat metering

Chilled water metering and flow measurement

Potable water metering and flow measurement

Process water metering and flow measurement

Ultra pure water metering and flow measurement.

Issue 1.4 Page 4

Page 5

F - UFM

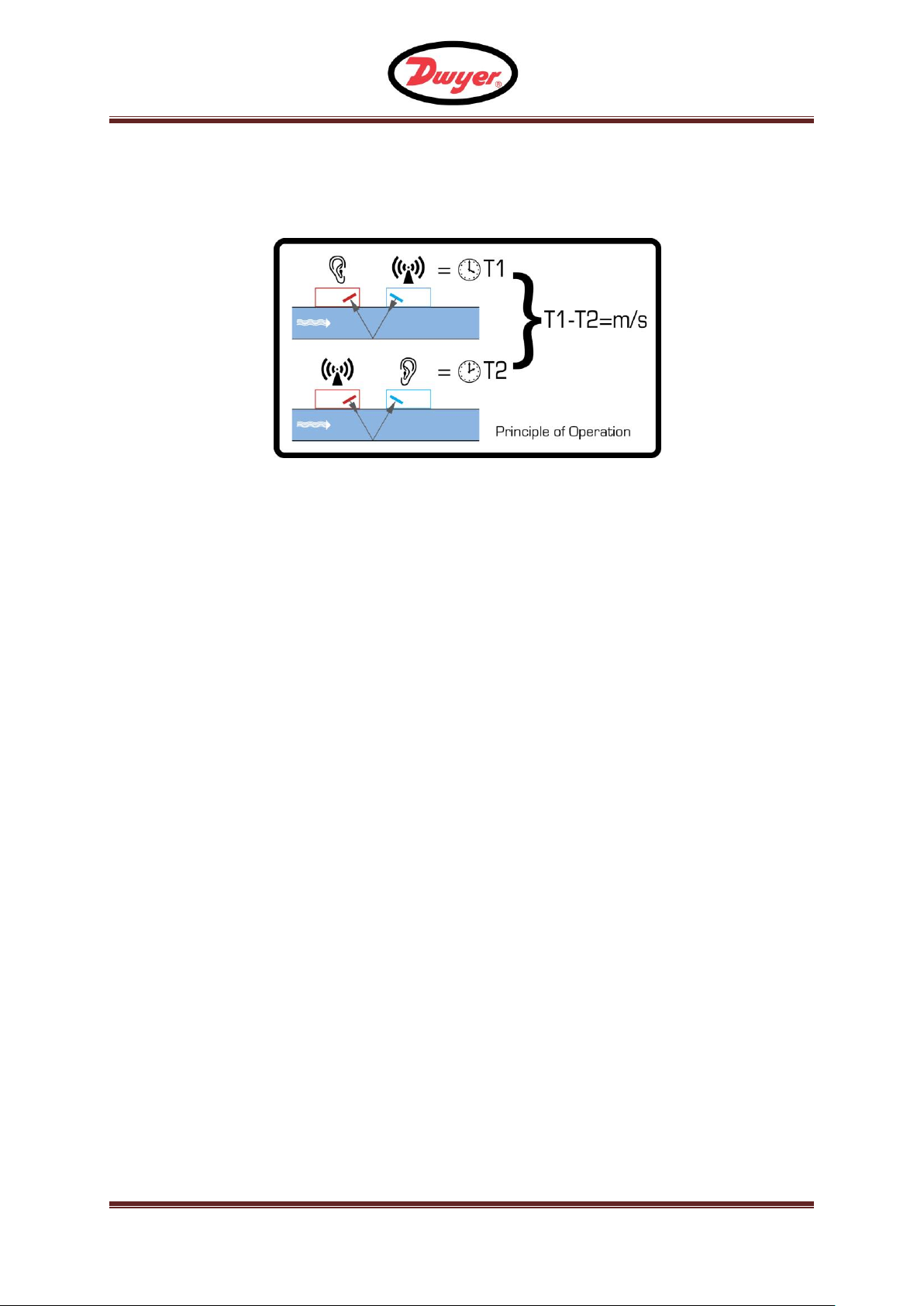

Figure 1 Principle of Transit-Time operation

2 How does it work?

The UFM is a clamp-on, ultrasonic flowmeter that uses a multiple slope transit time algorithm

to provide accurate flow measurements.

An ultrasonic beam of a given frequency is generated by applying a repetitive voltage pulse to

the transducer crystals. This transmission goes first from the Downstream transducer to the

Upstream transducer (red) as shown in the upper half of Figure 1. The transmission is then

made in the reverse direction, being sent from the Upstream transducer (red) to the

Downstream transducer (blue) as shown in the lower half of Figure 1. The speed at which the

ultrasound is transmitted through the liquid is accelerated slightly by the velocity of the liquid

through the pipe. The subsequent time difference T1 – T2 is directly proportional to the liquid

flow velocity.

Issue 1.4 Page 5

Page 6

F - UFM

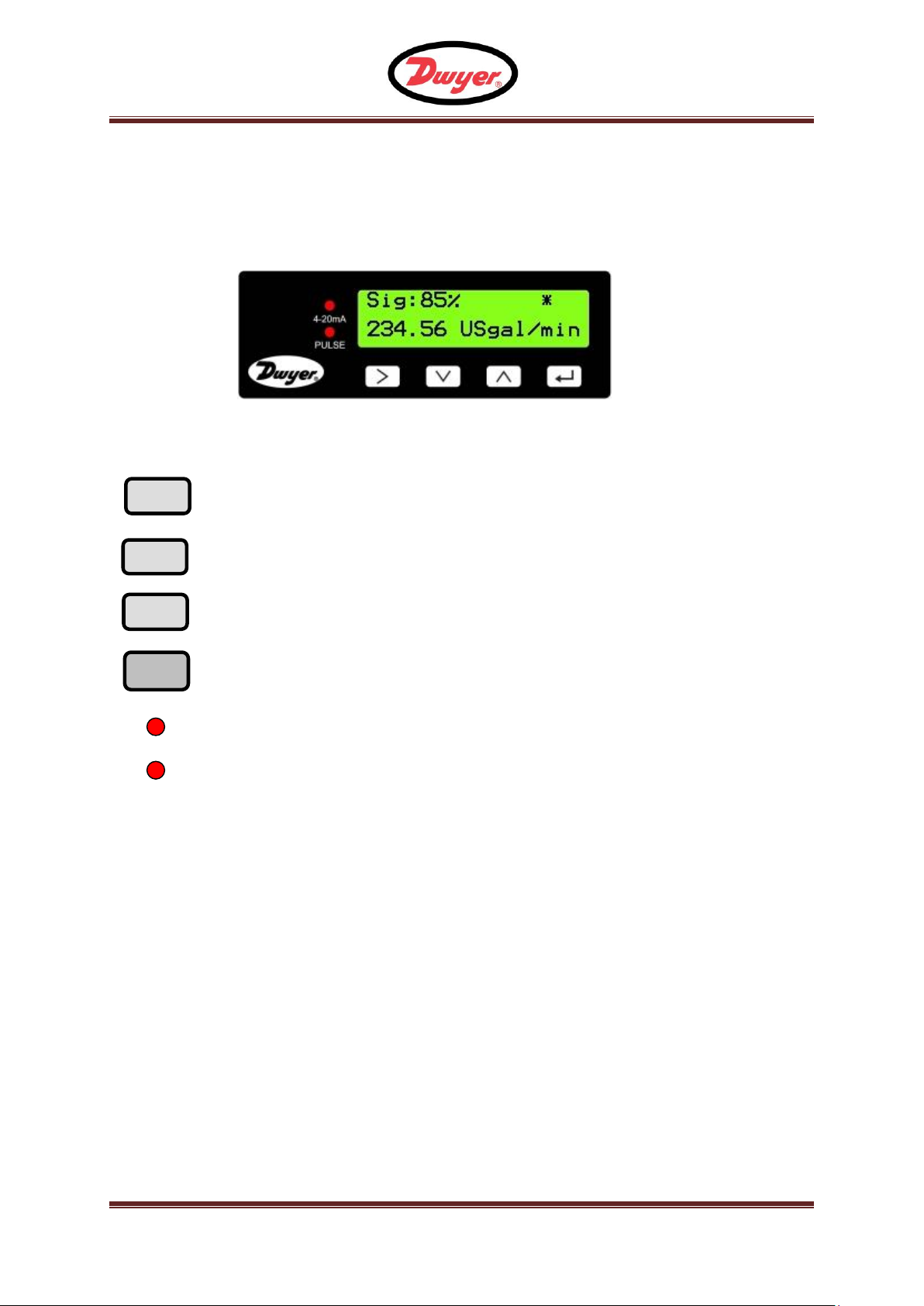

Figure 2 UFM User Interface

Selection key. Allows the user to select between options on the

display.

Used to increment the value of each digit in numeric entry fields.

Used to decrement the value of each digit in numeric entry fields.

Used to enter the selection displayed or terminate the data entry.

Pressing this key will take the user to another menu or to the Flow

Reading screen.

V

Λ

3 User interface

Figure 2 illustrates the UFM user interface comprising of :

One 2 line x 16 character LCD with backlight

Four tactile key switches

Two LED’s

3.1 Key switches

4-20 mA LED is illuminated when the 4-20 mA output is ON

Pulse LED is illuminated when the Pulse output is ON

Issue 1.4 Page 6

Page 7

F - UFM

Possible Air

Possible

sludge

Guide

rail

Uniform Flow Profile

Distorted Flow Profile

Flow

Flow

Valid transducer location

20 x Diameter

10 x Diameter

45°

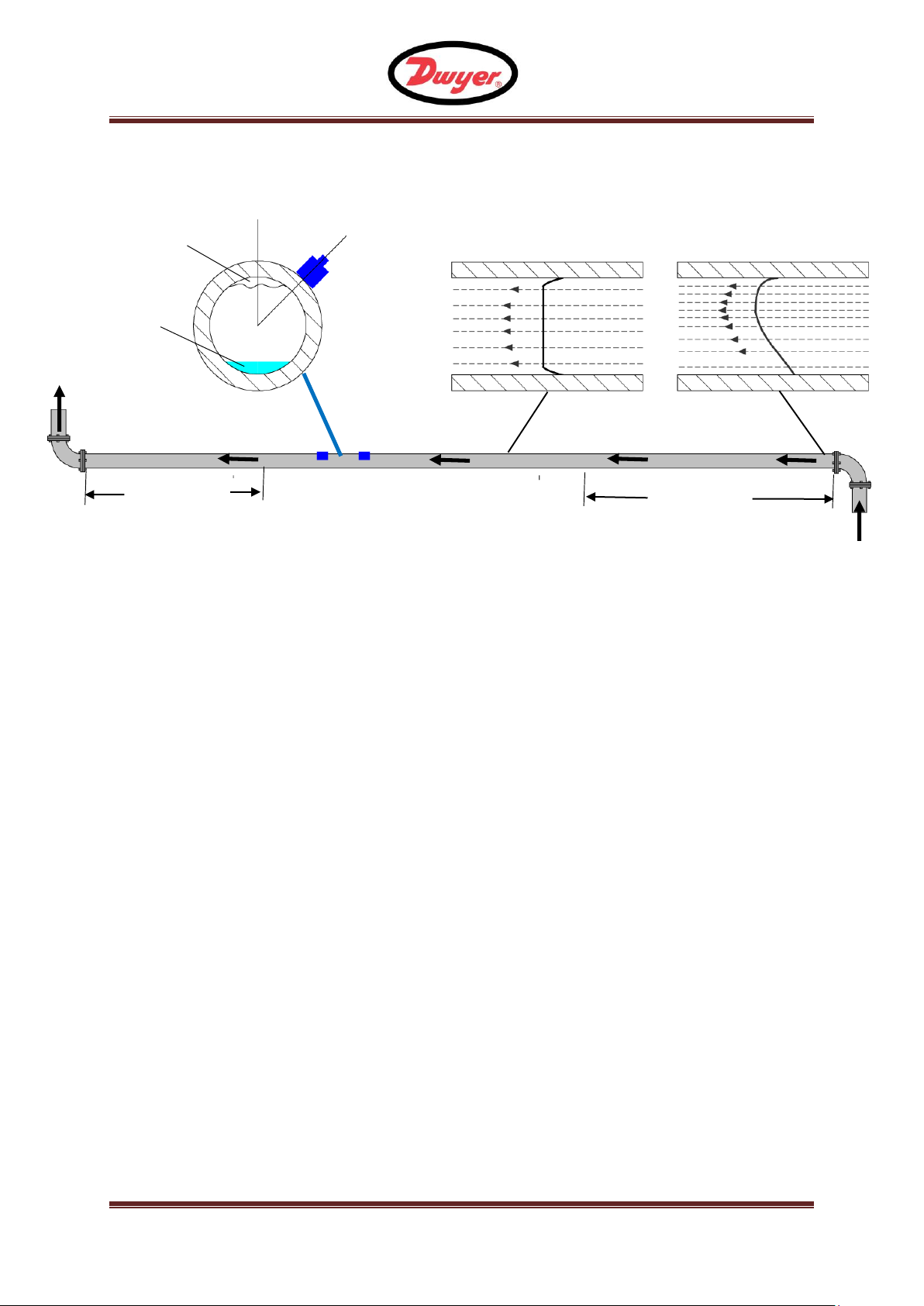

4 Installing the UFM

Figure 3 Location of Transducers

In many applications an even flow velocity profile over a full 360° is unattainable due to the

presence of air turbulence at the top of the flow and possibly sludge at the bottom of the pipe.

Experience has shown that the most consistently accurate results are achieved when the

transducer guide rails are mounted at 45° with respect to the top of the pipe.

The UFM equipment expects a uniform flow profile, as a distorted flow will produce

unpredictable measurement errors. Flow profile distortions can result from upstream

disturbance such as bends, tees, valves, pumps and other similar obstructions. To ensure a

uniform profile the transducers must be mounted far enough away from any cause of distortion

such that it no longer has an effect.

To obtain the most accurate results the condition of both the liquid and the pipe must be

suitable to allow ultrasound transmission along the predetermined path. It is important that

liquid flows uniformly within the length of pipe being monitored, and that the flow profile is not

distorted by any upstream or downstream obstructions. This is best achieved by ensuring

there is a straight length of pipe upstream of the transducers of at least 20 times the pipe

diameter, and 10 times the pipe diameter on the downstream side, as shown in Figure 3. Flow

measurements can be made on shorter lengths of straight pipe, down to 10 diameters

upstream and 5 diameters downstream, but when the transducers are mounted this close to

any obstruction the resulting errors can be unpredictable.

Key Point: Do not expect to obtain accurate results if the transducers are positioned close to

any obstruction that distorts the uniformity of the flow profile.

Issue 1.4 Page 7

Page 8

F - UFM

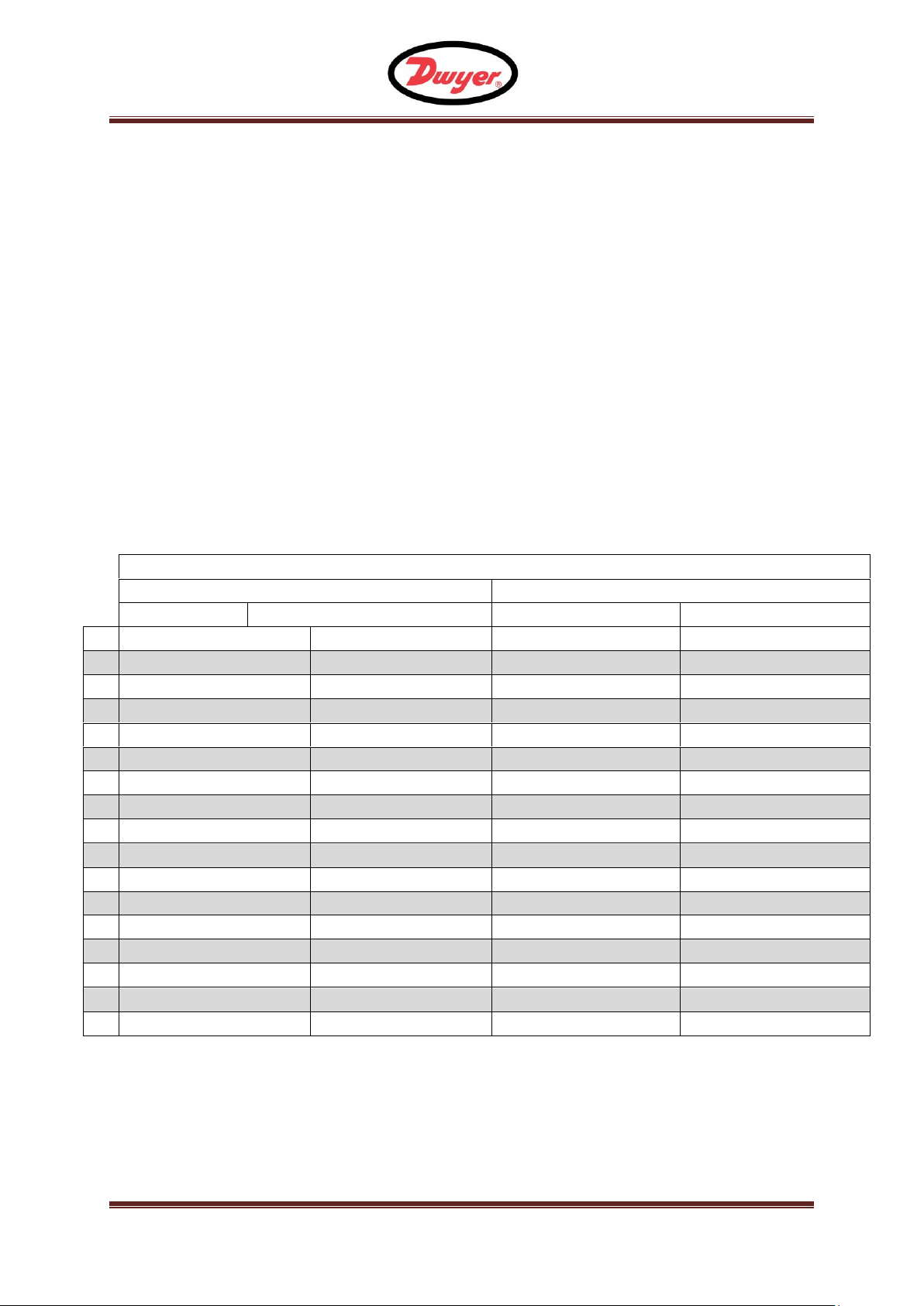

Pipe Material

Plastic & Copper

Steel

Minimum

Maximum

Minimum

Maximum

B1

0.98 inches (24.9 mm)

1.22 inches (31.0 mm)

A2

1.22 inches (31.0 mm)

1.50 inches (38.1 mm)

0.98 inches (24.9 mm)

1.18 inches (30.0 mm)

C1

1.50 inches (38.1 mm)

1.69 inches (42.9 mm)

1.18 inches (30.0 mm)

1.42 inches (36.1 mm)

B2

1.69 inches (42.9 mm)

1.97 inches (50.0 mm)

1.42 inches (36.1 mm)

1.69 inches (42.9 mm)

A3

1.97 inches (50.0 mm)

2.20 inches (55.9 mm)

1.69 inches (42.9 mm)

1.93 inches (49.0 mm)

C2

2.20 inches (55.9 mm)

2.44 inches (62.0 mm)

1.93 inches (49.0 mm)

2.17 inches ( 55.1 mm)

B3

2.44 inches (62.0 mm)

2.68 inches (68.1 mm)

2.17 inches ( 55.1 mm)

2.40 inches (61.0 mm)

D2

2.68 inches (68.1 mm)

2.91 inches (73.9 mm)

2.40 inches (61.0 mm)

2.64 inches (67.0 mm)

C3

2.91 inches (73.9 mm)

3.15 inches (80.0 mm)

2.64 inches (67.0 mm)

2.87 inches (72.9 mm)

E2

3.15 inches (80.0 mm)

3.39 inches (86.1 mm)

2.87 inches (72.9 mm)

3.11 inches (79.0 mm)

D3

3.39 inches (86.1 mm)

3.66 inches (93.0 mm)

3.11 inches (79.0 mm)

3.35 inches (85.1 mm)

C4

3.66 inches (93.0 mm)

3.90 inches (99.0 mm)

3.35 inches (85.1 mm)

3.58 inches (90.9 mm)

E3

3.90 inches (99.0 mm)

4.13 inches (104.9 mm)

3.58 inches (90.9 mm)

3.82 inches (97.0 mm)

D4

4.13 inches (104.9 mm)

4.37 inches (111.0 mm)

3.82 inches (97.0 mm)

4.06 inches (103.1 mm)

F3

4.37 inches (111.0 mm)

4.53 inches (115.0 mm)

4.06 inches (103.1 mm)

4.29 inches (109.0 mm)

E4

4.53 inches (115.0 mm)

4.62 inches (117.3 mm)

4.29 inches (109.0 mm)

4.53 inches (115.0 mm)

D5

4.53 inches (115.0 mm)

4.62 inches (117.3 mm)

Pipe OD range (inches)

4.1 Preparation

1. Before attaching the transducers first ensure that the proposed location satisfies the

distance requirements shown in Figure 3 otherwise the resulting accuracy of the flow readings

may be affected.

2. Prepare the pipe by degreasing it and removing any loose material or flaking paint in order

to obtain the best possible surface. A smooth contact between pipe surface and the face of

the transducers is an important factor in achieving a good ultrasound signal strength and

therefore maximum accuracy.

4.2 Sensor separation

The sensor must be positioned at the correct distance for the pipe size and type they will be

used on. The table shown in Figure 4 gives the separation code for a given pipe material and

outside diameter. This code will be displayed whenever the pipe inside diameter and material

are prompted for.

Issue 1.4 Page 8

Figure 4 Separation Table

Page 9

F - UFM

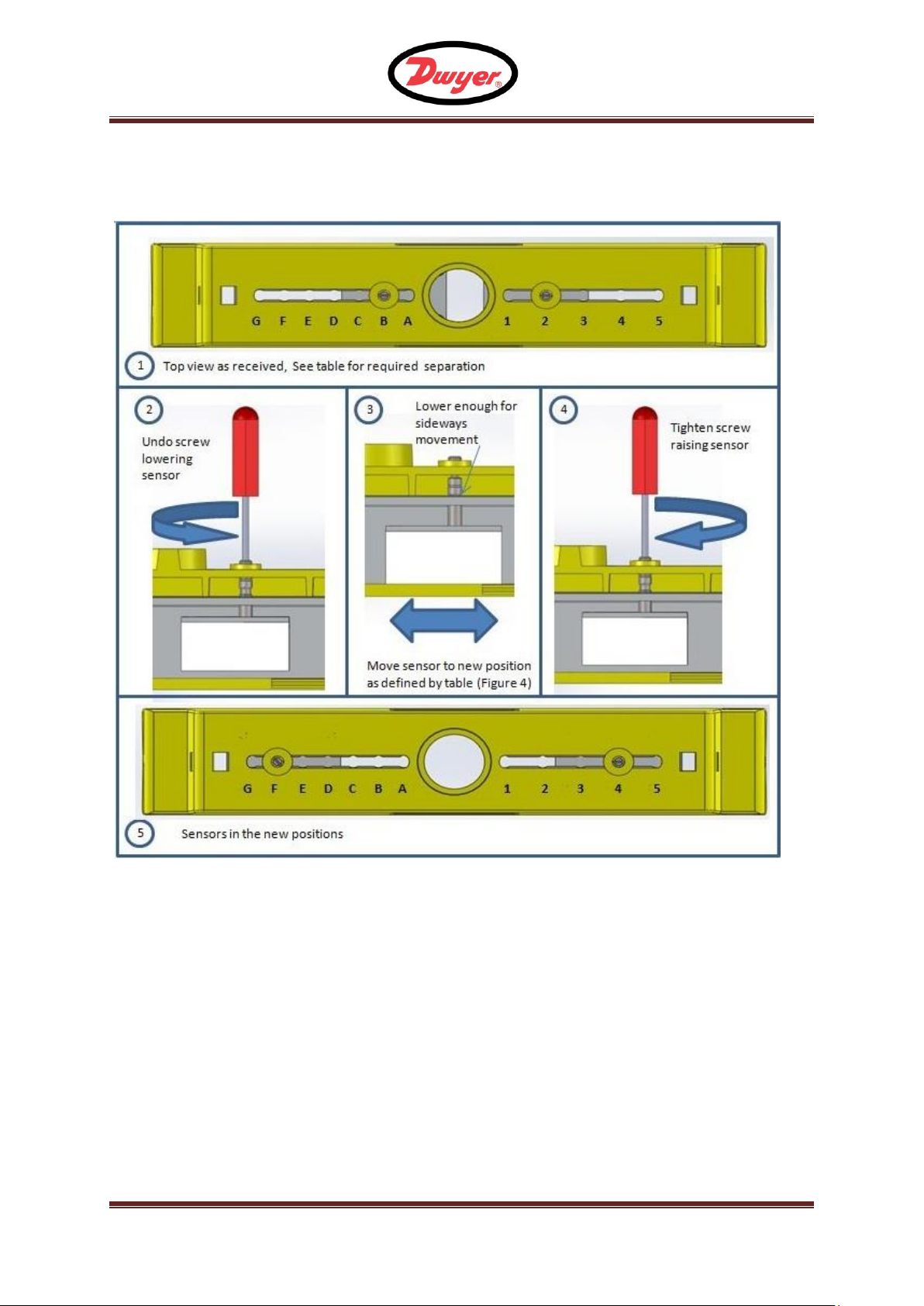

The diagram in figure 5 shows how to adjust the separation of the sensors

Figure 5 Separation Setting

Issue 1.4 Page 9

Page 10

F - UFM

Less than 1.6 inches (40.6 mm) outside diameter

1.6 to 2.4 inches (40.6 to 61 mm) outside diameter

Greater than 2.4 inches (61.0 mm) outside diameter

4.3 Adaptors for small pipes

Figure 6 Pipe Adaptors

Adaptors are supplied for use on small pipes. The diagrams in figure 6 show how these are fitted

around the pipe. The top pipe adaptor clips into the ends of the guide rail.

Issue 1.4 Page 10

Page 11

F - UFM

The grease provided in the syringe is applied to the

center of the sensors as shown above.

Clamp guide rail and sensor assembly to pipe,

using the supplied banding, and release sensor

locking screws.

Connect power and sensors to the electronics

assembly. Sensor leads can be connected either

way round.

4.4 Attaching the UFM to the pipe

Follow the five steps shown in Figure 7 below to attach the UFM to the pipe.

Click electronic assembly onto guide rails and sensor assembly

Figure 7 Simple Steps to Attaching the UFM on the Pipe

The locking screws and washers should be kept in case it is necessary to change the location of the

guide rail and sensors. See the relocation instructions in section 9 for the procedure to do this.

Issue 1.4 Page 11

Page 12

F - UFM

Power

Pulse

4-20 mA

Figure 8 UFM Interface Cable

12/24 V Input (+)

12/24 V Return (-)

Pulse Output

Pulse Return

4-20 mA Output (+) (Polar Sensitive)

4-20 mA Return (-) (Polar Sensitive)

Un-insulated screen

4.5 UFM interface cable

The UFM interface cable supplied is a 6-core cable and is shown in Figure 8.

The polarity of the wires is as follows:

The un-insulated wire is the connection to the screen of the cable and should be earthed for full

immunity to electrical noise.

4.6 Connecting the UFM to the Supply

The UFM will operate within the voltage range 12 – 24 V ac/dc. Connect the external power

supply to the Brown and Blue wires of the six core cable. For full compliance with EMC

regulation a 12 V supply is recommended for domestic and light industrial applications.

4.7 Pulse Output connection

The isolated pulse output is provided by a SPNO MOSFET relay which has a maximum load

current of 500 mA and maximum load voltage of 48 V ac. The relay also provides 2500 V

isolation.

The pulse output is available at the White and Green wires. Electrically this is a volt free

contact closure.

Issue 1.4 Page 12

Page 13

F - UFM

4.8 Current Output

The isolated 4-20 mA is a current source and can drive into a maximum load of 620 Ω.

The 4-20 mA current output is available at the Red and Black wires. The polarities are shown

in Figure 8.

The alarm current due to a flow outside the range specified or due to a loss of signal is set at

3.5 mA.

4.9 Cable Screen

For full immunity to electrical interference the screen of the cable should be connected to

Earth.

Issue 1.4 Page 13

Page 14

F - UFM

5 Powering up for the first time

Powering up for the first time will initiate the sequence shown in Figure 9:

Figure 9 Powering the Unit Up

1. The startup screen is displayed for 5 seconds

2. The user enters the pipe ID and then the material by scrolling through the available list.

(refer to section 5.1)

3. The UFM checks for a valid signal

4. If a valid signal is found, signal strength and flow magnitude are displayed. The direction of

flow when powered up will be set as that for positive flow. The current output and pulse output

will relate to the flow in this direction. If the flow is reversed then the flow rate will still be

displayed but the activity indication will change from an asterisk to an exclamation mark. No

pulses will be generated, and the current will go to the 3.5 mA alarm state if the flow is

reversed.

Issue 1.4 Page 14

Page 15

F - UFM

Press the

key to increment the inches digit (1.964) in the sequence 0, 1. Press once

to increment digit, or hold key down to automatically scroll between 0 and

4.

Press the

key to decrement the inches digit in the sequence 4 to 0. Press once to

decrement digit, or hold key down to automatically scroll between 4 and

0.

Press the

key to move to the 0.1 inch digit (1.964). The 0.1 inch digit should now

blink.

Increment the 0.1 inch digit in the sequence 0,1,2,3,4,5,6,7,8,9,0 using

the

key. Press once to increment digit or hold down to scroll

through the numeric sequence. Decrement the 0.1 inch digit in the

sequence 9,8,7,6,5,4,3,2,1,0,9 using the key. Press once to

increment digit or hold down to scroll through the numeric sequence.

Press the

key to move to the 0.01 inch and 0.001 inch digits. The selected digit

should now blink. Increment or decrement the digit in an identical manner

to the 0.1 inch digit described above.

Press the

Use

Press the

key to enter the Pipe ID numerical value, and move to the next screen.

and

keys to scroll through the pipe materials.

To select the material and complete the setup

procedure.

V

Figure 10 Enter Pipe ID Screen (Metric)

V

Pipe material

Plastic

V

5.1 How to enter the Pipe ID

Figure 10 shows the Enter Pipe ID screen after an initial power up.

Initially, the inches digit (1.964) will blink.

Issue 1.4 Page 15

Page 16

F - UFM

If any of the parameters need to be changed from the default values, for example different

units are required, then the menu system must be activated via the password (see section 7).

5.2 Pulse output

Pulse output can be set up to operate in two modes, namely volumetric and frequency.

5.2.1 Volumetric mode

In Volumetric mode, each pulse output represents a measured volume of 10 gallons (default

value). In Volumetric mode, with the Vol per Pulse set to 1 and the pulse width set to 25 ms,

the maximum number of pulses that can be output (without storage) is 1/(0.025*2) = 20 pulses

per second. If the flow rate in the pipe is such that more than 20 pulses per second are

generated, a Pulse Overflow error may eventually occur if the stored number of pulses

exceeds 1000. To avoid this, set the Vol per Pulse to 100 gallons.

5.2.2 Frequency mode

In Frequency mode, the pulse output frequency is proportional to the flow rate within a

specified frequency range of 0 – 200 Hz.

5.3 4-20 mA Current output

The default 4-20 mA output setting will be ON, and the 4-20 mA LED on the keypad will be

illuminated. The default flow for 20 mA output will be automatically set depending on the pipe

size. The default flow for 4 mA is 0. This can be changed, see section 7.

If the flow reading is greater than that set as the 20 mA value, or there is negative flow, or no

flow signal can be detected, then an alarm current of 3.5 mA will generated.

Note: The 4-20 mA current output is factory calibrated.

Issue 1.4 Page 16

Page 17

F - UFM

Figure 11 Flow Units menu

6 Subsequent Power-ON Sequence

If the power supply is cycled OFF then ON after the pipe ID has been entered, all subsequent

start-ups will use the same configuration as was previously entered. If the configuration needs

to be changed for any reason, the user can make use of the password-controlled menu as

described in section 7.

7 Password Controlled Menus

The password controlled menu allows the user some flexibility to change the default settings:

User Password (71360):

Change the dimensions from mm to inches or vice-versa.

Change from Flow to Velocity Measurement

Change the system units liters/m3 or Impgal/USgal

Change the flow units l/s, l/min or gal/s, gal/min or USgals/s, USgals/min

Change the default value for Flow at Maximum Current

Change the default setting for Flow at Minimum Current

Change the Pulse Output type

Change the Pulse output parameters

Press the to get to the screen prompting for the password, which is entered using the

method shown in 7.1.2. To exit the password controlled menu navigate to the Exit screen and

press . To exit the password entry screen without entering a password wait until the flow

screen is displayed.

7.1 General procedure for changing menu settings

7.1.1 Selection menus

When a password controlled menu is selected the procedure for changing the default setting

is the same for all menus. For example, consider the Flow Units menu shown in Figure 11.

The default value ‘USgal/m’ will blink to indicate that this is the current setting. To change to

‘USgal/h’, press the key. Now the ‘USgal/h’ units will blink to indicate that this is now the

selected units. Press the key to confirm the change.

Issue 1.4 Page 17

Page 18

F - UFM

Press the

key twice to select the hundreds unit (01000.0) which will now blink

Press the

Press the key twice to increment the hundreds unit from 0 to 2

(01200.0)

Press the

key once to select the tens unit (01200.0) which will now blink

Press the

key five times to increment the tens unit from 0 to 5 (01250.0)

Press the

key once to select units (01250.0) which will now blink

Press the

key twice to decrement the units from 0 to 8 (01258.0)

Press the

key to confirm the change

Figure 12 Example of a Data entry screen

V

7.1.2 Data entry menus

Menus containing a numeric value can be altered using the following procedure. For example,

consider changing the Flow at maximum current from the default setting 1000 gallons as

indicated in Figure 12. to 1258 gallons.

All numeric data menus can be changed in this way.

7.2 User Password controlled menu structure

Ensure that the instrument is in Flow Reading mode then press the key to go to the user

password menu. Enter 71360 using the procedure explained in section 7.1.2. to enter the

password.

The flow chart shown in Figure 13 shows the user password menu structure. To skip over any

menu item that should remain unchanged, simply press the key.

Issue 1.4 Page 18

Page 19

F - UFM

Sig: 87% *

1245 USgal/min

Enter Password:

*****

71360 MENU

Invalid & OR No

input for 10 seconds

User Menu:

Pulse Output

User Menu:

Current Output

User Menu:

Calibration

User Menu:

Setup

User Menu:

Totals

Checking Signals

******

Sig: 87% *

1245 USgal/min

Setup Menu

Totalizer Menu

Pulse Output Menu

Current Output Menu

User Menu:

Exit

v v v

v

v

Calibration Menu

v

Issue 1.4 Page 19

Figure 13 Main Menu

Page 20

F - UFM

Select Dimensions:

mm | inches

Enter Pipe ID:

050.0 mm

Enter Pipe ID:

2.000 inches

Select Reading:

Flow | Vel

Select Reading:

Flow | Vel

System Units:

liters | m3

System Units:

Impgal | USgal

Flow Units

m3/min | m3/hr

Flow Units

l/min | l/s

Flow Units

gal/min | gal/hr

Flow Units

USgal/min | USgal/hr

Range 20 – 110mm

050.0 mm

SETUP MENU

Inches &

Invalid

range

&

mm &

Invalid range

&

Valid &

Valid &

Vel & (m/s)

m3 &

Flow &

Liters &

Valid &

Flow &

Impgal &

USgal &

Vel &

(ft/s)

Range 0.79 – 4.33

2.000 inches

Pipe material

Plastic

Set Separation

B 2

Issue 1.4 Page 20

Figure 14 Setup Menu

Page 21

F - UFM

Select Pulse:

ON | OFF

Volume per Pulse:

10.0 gal

Pulse Width

25 ms

PULSE OUTPUT MENU

Valid &

Valid &

On &

Volume &

Max Pulse Freq:

200

Max Flow @ Freq:

9999.0

Valid &

Valid &

Off &

Invalid &

Valid &

Freq &

Pulse Type:

VOLUME | FREQ

Range 3 - 99

25 ms

Range 1 – 200

200

Invalid &

Valid &

Test mode, press V or Λ to

generate a pulse

Select Totals

ON|OFF

On &

Reset + Total

NO |YES

Off &

TOTALIZER MENU

Valid &

Figure 15 Pulse Output & Totalizer Menus

Issue 1.4 Page 21

Page 22

F - UFM

Select 4-20 mA:

ON | OFF

Flow @ 20mA

1000.0

Flow @ 4mA

0000.0

OFF &

ON &

CURRENT OUTPUT MENU

Valid &

Valid &

Damping Time [s]:

20

Zero Cut-off:

0.10 m/s

Zero Offset

0.000 USgal/min

Range 0.00 – 0.50

0.10 m/s

Done

Zero Offset:

Averaging…9

^ To Clear

v To Set

Valid &

Invalid &

Calibrat. Factor:

1.000

Range 0.500–1.500

1.000

CALIBRATION MENU

Invalid &

Valid &

Set Zero cut-off to

0.00 before using

Zero Offset and

restore to 0.05 or

more afterwards

If the Total is turned on then the display will alternate between the flow reading and the total.

Either display can be held for 30 seconds by pressing the key.

Issue 1.4 Page 22

Figure 16 Current Output & Calibration Menus

Page 23

F - UFM

V

The Estimated TA (Time of Arrival) and Actual TA show the

theoretical and measured transit times. These values should

be within several per cent of each other.

The gain on line one is an indicator of the signal strength. A

good signal should have a gain of between 600 to 970. The

number in parentheses is the switch setting and should be x1.

The second line shows the current time differential between

the upstream and downstream signals.

Line 1: Software version

Line 2: Serial number.

If the Frequency pulse option is enabled this screen displays

the current pulse output frequency. This is proportional to the

flow rate.

Press

To exit the Diagnostics menu

Please note the key board is less responsive in

the Diagnostics Menu and longer key presses

are required.

Sig: 87% *

1245 USgal/min

Est.TA 85.64

Act .TA 86.77

Gain 845 (x1)

DT 125 ns

Rev: 05.00.001

S/N: 12547 11/13

Pulse Frequency

124

>

>

>

v

Pipe Material

Plastic

The Selected pipe material

Figure 17 Diagnostics Menu

>

Separation

D-4

The separation setting based on the pipe material and inside

diameter.

>

8 Diagnostics Menu

The diagnostics menu provides some additional information about the flowmeter and its setup. The

menu can be accessed by pressing the key from the main flow-reading screen. The menu shown

below describes the various diagnostics items.

DIAGNOSTICS MENU

Issue 1.4 Page 23

Page 24

F - UFM

9 Relocation of guide rail

If it is necessary to relocated the guide rail and sensor assembly use the following procedure

1. Remove complete assembly from the pipe

2. Insert a small screwdriver in the hole at the end of the guide rail moulding and lever

up the clip holding the electronics assembly by pressing down on the screwdriver as

shown in figure 18.

3. Repeat 2 on the other end and then pull off the electronics unit.

Figure 18

4. Disconnect the sensors

5. Remove the original grease from the sensors

6. Push the sensor blocks into the guide rail so that the washers and locking screws

can be refitted.

7. Place a bead of grease down the center of the sensor block using the syringe

provided. See illustration on fitting the guide rail to the pipe for recommended bead

size.

8. Follow the original procedure for installing the guide rail on the pipe.

Issue 1.4 Page 24

Page 25

F - UFM

General

Measuring Technique

Transit time

Measurement channels

1

Timing Resolution

±50 ps

Turn down ratio

200:1

Flow velocity range

0.1 to 10 m/s

Applicable Fluid types

Clean water with < 3% by volume of particulate content.

Accuracy

±3% of flow reading for flow rate >0.3 m/s

Repeatability

±0.5% of measured value

Selectable units

Velocity: m/s, ft/s

Flow Rate:l/s, l/min, gal/s, gal/min, USgal/s, USgal/min,

m3/min, m3/hr

Volume: liters, m3, gals, USgals

Languages supported

English only

Power input

12 – 24 V ac or dc

Power consumption

7 VA maximum

Cable

5 m screened 6 core

Pulse Output

Output

Opto-isolated MOSFET volt free normally open contact.

Isolation

2500V

Pulse width

Default value 25 ms; programmable range 3 – 99 ms

Pulse repetition rate

Up to 166 pulses/sec (depending on pulse width)

Frequency mode

200 Hz maximum

Maximum load voltage/current

48V AC / 500mA

Current Output

Output

4 – 20 mA

Resolution

0.1% of full scale

Maximum load

620 Ω

Isolation

1500 V opto-isolated

Alarm current

3.5 mA

Enclosure

Material

Plastic Polycarbonate

Fixing

Pipe mountable

Degree of Protection

IP54

Flammability Rating

UL94 V-0

Dimensions

10 inches x 2 inches x 3.6 inches (electronics + guide rail)

Weight

1.1 lb

Environmental

Pipe temperature

32°F to 185°F (0°C to 85°C)

Operating temperature (Electronics)

32°F to 122°F (0°C to 50°C )

10 Appendix I – UFM Specification

Table 1 lists the UFM Product Specification.

Issue 1.4 Page 25

Page 26

F - UFM

Storage temperature

14°F to 140 °F (-10°C to 60°C)

Humidity

90% RH at 122°F Max

Display

LCD

2 line x 16 characters

Viewing angle

Min 30°, Max 40°

Active area

3.27 inches (W) x 0.74 inches(H)

Keypad

Format

4 key tactile feedback membrane keypad

Parameter

Default Value

Dimensions

mm

Flow Rate

l/min

Pipe size

50 (mm)

4-20 mA

On, 4-20 mA selected

Flow at Max Current

Equivalent to 2m/s

Flow at Min Current

0

Pulse Output

On

Volume per Pulse

10 liters

Pulse Width

25 ms

Damping

20 seconds

Calibration Factor

1.000

Zero Cut-off

0.10 m/s

Zero Offset

0.000 l/min

Parameter

Default Value

Dimensions

inches

Flow Rate

USgal/min

Pipe size

2 (inches)

4-20 mA

On, 4-20 mA selected

Flow at Max Current

Equivalent to 6.5 ft/s

Flow at Min Current

0

Pulse Output

On

Volume per Pulse

10 US gallons

Pulse Width

25 ms

Damping

20 seconds

Calibration Factor

1.000

Zero Cut-off

0.10 m/s ( 0.3 ft/s)

Zero Offset

0.000 gal/min

11 Appendix II – Default values

The settings will be configured at the factory for either metric or imperial units. Table 2 lists

the metric default values.

Table 2 System Default Values

Table 3 lists the default values when Imperial dimensions are selected.

Table 3 System Default Values

Issue 1.4 Page 26

Page 27

F - UFM

Range 0.79 – 4.33

0.000 inches

Range 0 - 99999

0000.0

Range 1 - 200

200Hz

12 Appendix III – Error and Warning Messages

12.1 System errors

There are three possible ‘System Error’ messages that can be displayed. They are:

1. Poor Signal. The unit is unable to detect a signal from one or both transducers. If this

message persists the sensors will need to be relocated.

2. Pulse Overflow. The value for the ‘Vol per pulse’ is set too low. Increase the Vol per

Pulse setting in the password-controlled menu.

3. No BBME: This indicates a unit failure. Reset the unit by turning the power on and off.

Contact Dwyer Instruments, Inc. if the problem persists.

12.2 Warnings

These generally advise the user that the data entered is out of the specified range.

1. When an invalid Pipe ID is entered, the warning message shown below is displayed,

prompting the user to enter a value between 0.79 and 4.33 inches.

2. When the 4-20 mA current output is turned ON, the Flow at Maximum and Minimum current

can be changed under password control. The valid range is 0 – 99999.0 If an invalid value is

entered the following warning message is displayed:

3. When programming a Frequency Pulse output the frequency is limited to the range 1 to 200

Hz. If an invalid value is entered then the following warning message is displayed.

Issue 1.4 Page 27

Page 28

F - UFM

Range 3 - 99

00ms

Range 0.00 – 0.50

0.00

Range 0.50 – 1.50

0.000

4. When programming a Volume Pulse output the pulse width is limited to the range 3 to 99

ms. If an invalid value is entered then the following warning message is displayed.

5. When programming the Zero Cut -off this is limited to the range 0.000 to 0.500 m/s. If an

invalid value is entered then the following warning message is displayed.

6. When programming the Calibration Factor this is limited to the range 0.5 to 1.5. If an invalid

value is entered then the following warning message is displayed.

13 Maintenance/Repair

Upon final installation of the model UFM, no routine maintenance is required. The model UFM

is not field serviceable and should be returned if repair is needed. Field repair should not be

attempted and may void warranty.

14 Warranty /Return

Refer to “Terms and Conditions of Sale” in our catalog or on our website. Contact customer

service to receive a Return Goods Authorization number before shipping you product back for

repair. Be sure to include a brief description of the problem plus any relevant application notes.

Issue 1.4 Page 28

Loading...

Loading...