Dwyer Instruments TUF-320 series, TUF-200 series, TUF-400 series, TUF-500 series, TUF-650 series Specifications-installation And Operating Instructions

...Page 1

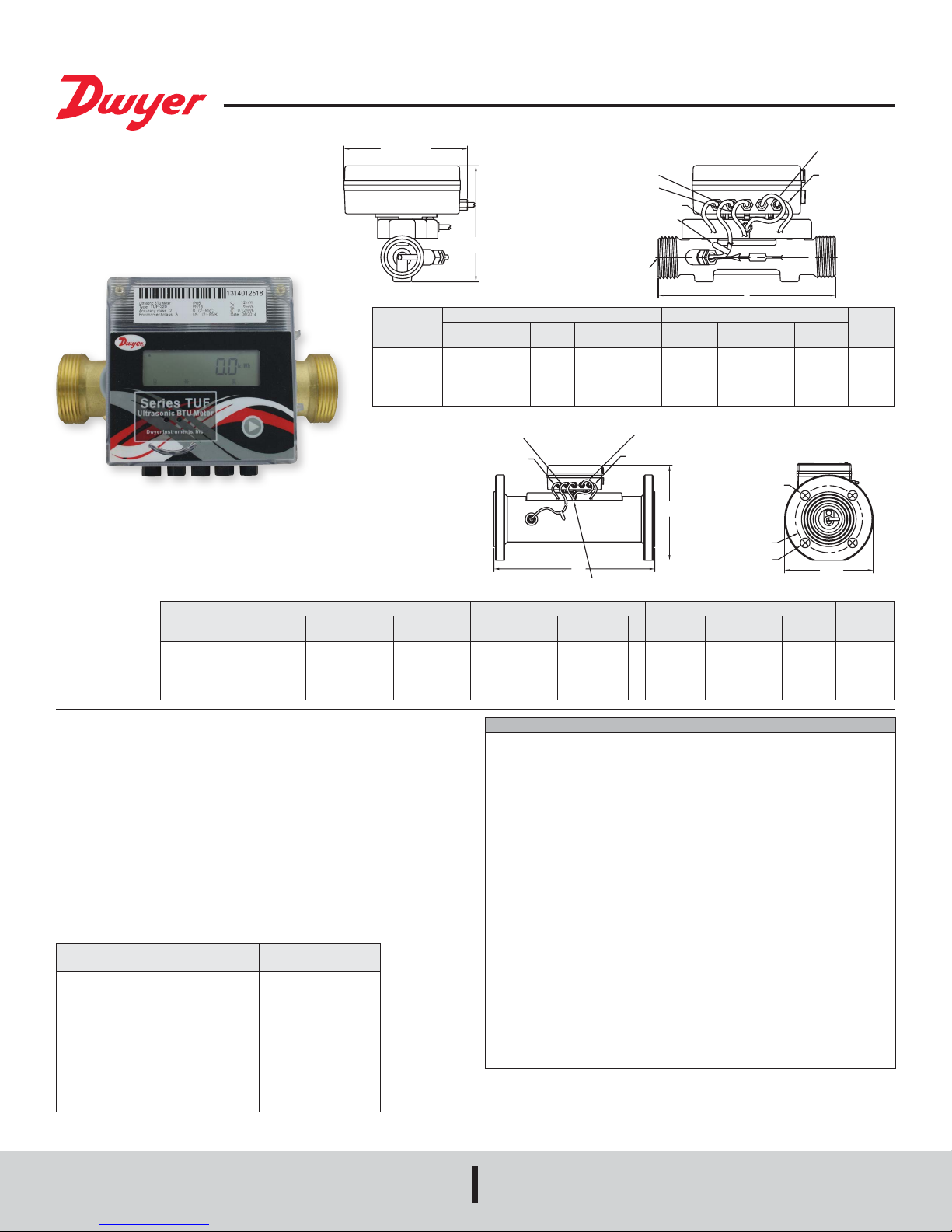

Series TUF Ultrasonic Energy Meter

4´ RETURN PIPE TEMP SENSOR

4-1/4

T

®

Specications - Installation and Operating Instructions

[108.00]

4´ FLOW PIPE TEMP SENSOR

4´ RETURN PIPE TEMP SENSOR

4´ 4-CORE WIRE

[2 COMMUNICATION, 2 POWER]

H

2X D

THREAD

Model

TUF-150-XX

TUF-200-XX

TUF-250-XX

TUF-320-XX

TUF-400-XX

Dimensions in [mm] Flow Rate GPM [LPM]

4-21/64 [110.00]

5-1/8 [130.00]

6-19/64 [160.00]

7-3/32 [180.00]

7-7/8 [200.00]

G3/4B

G1B

G11/4B

G11/2B

G2B

3-31/32 [101.00]

3-31/32 [101.00]

4-11/64 [106.00]

4-29/64 [113.00]

4-49/64 [121.00]

Max Flow

(Qs)

13 [50]

22 [83]

31 [117]

53 [200]

88 [333]

DNXX

L

Nominal Flow

Range (Qp)

6.6 [25]

11 [42]

15 [58]

26 [100]

44 [167]

Bulletin F-TUF

2.8´ WATER-IN

FLOW SENSOR

2.8´ WATER-OU

FLOW SENSOR

Min Flow

(Qi)

0.1 [0.5]

0.2 [0.8]

0.3 [1.2]

0.5 [2]

0.9 [3.3]

Weight

lb [kg]L D H

3.1 [1.4]

3.1 [1.4]

4.1 [1.8]

5.2 [2.3]

6.6 [3.0]

4´ FLOW PIPE TEMP SENSOR

[2 COMMUNICATION, 2 POWER]

Dimensions in [mm] Flow Rate GPM [LPM]

Model

TUF-500-XX

TUF-650-XX

TUF-800-XX

TUF-1000-XX

TUF-1250-XX

The Series TUF Tennant Ultrasonic BTU Flowmeter is a MID/EN1434 approved

highly accurate and stable energy meter. It utilizes ultrasonic technology to measure

heating and cooling energy consumption. The Series TUF incorporates a owmeter,

temperature meter, and a calculator into a single, compact unit. The size and lack of

moving parts means the Series TUF requires minimal maintenance. The 8-digit LED

display enables easy reading of the meter’s recorded values; including temperature,

ow-rate, energy consumption, etc. These features make it ideal for installation on

chillers, boilers, and individual apartment piping. With the optional couplings it is

capable of being used with either NPT or BSPT pipe sizes. It is the perfect meter for

tenant billing applications.

FEATURES

• Lower maintenance costs with local parameter display and no moving parts

• Serial communication output allows for easy transfer of data

• Flow and temperature monitor in one unit eliminates the need for multiple units

Model

TUF-150-XX

TUF-200-XX

TUF-250-XX

TUF-320-XX

TUF-400-XX

TUF-500-XX

TUF-650-XX

TUF-800-XX

TUF-1000-XX

TUF-1250-XX

Process

Connection

G-3/4

G1

G1-1/4

G1-1/2

G2

GB9119 Flange

GB9119 Flange

GB9119 Flange

GB9119 Flange

GB9119 Flange

7-7/8 [200]

7-7/8 [200]

8-55/64 [225]

9-27/32 [250]

9-27/32 [250]

Corresponding

Pipe Fitting

1/2˝ NPT or BSPT

3/4˝ NPT or BSPT

1˝ NPT or BSPT

1-1/4˝ NPT or BSPT

1-1/2˝ NPT or BSPT

2˝ DN 50 PN 16 Flange

2-1/2˝ DN 65 Flange

3˝ DN 80 Flange

4˝ DN 100 Flange

5˝ DN 125 Flange

6-1/2 [165.00]

7-9/32 [185.00]

7-7/8 [200.00]

8-21/32 [220.00]

9-27/32 [250.00]

9-27/32 [250]

10-7/16 [265]

11-1/32 [280]

12-13/64 [310]

12-63/64 [330]

2.8´ WATER-IN FLOW SENSOR

4´ 4-CORE WIRE

L

4-59/64 [125.00]

5-45/64 [145.00]

6-19/64 [160.00]

7-3/32 [180.00]

8-17/64 [210.00]

SPECIFICATIONS

Service: Clean, compatible liquids.

Wetted Materials: Brass and 316L SS.

Range: See chart.

Display: 8-digit LED.

Accuracy: BTU: EN1434/CJ128 Class 2; Flow: ±(2+(0.02 Qp / Q))%; Temperature:

0.18°F (±0.1°C).

Power Requirements: 24 VDC or 3.6 V ER26500 lithium metal battery, user

supplied and installed, battery acts as back-up if power is lost.

Power Consumption: 1 W.

Temperature Limits: Ambient: 41 to 131°F (5 to 55°C); Process: 36 to 203°F (2 to

95°C).

Humidity Limit: <93%.

Pressure Limits: 232 psi (16 bar) for DN15 to DN40; 362 psi (25 bar) for >DN50.

Pressure Drop: <1.5 psi (10 kPa).

Process Connection: See chart.

Serial Communications: Modbus

Enclosure Rating: IP65.

Enclosure Material: Plastic.

Repeatability: Flowmeter: 1%.

Electrical Connections: 3 ft (0.91 m) 4x0.2 mm2 cable with terminal block.

Flow Direction: Unidirectional.

Mounting Orientation: Horizontal or vertical.

Weight: See chart.

Agency Approvals: CE.

45/64 [18.00]

45/64 [18.00]

45/64 [18.00]

45/64 [18.00]

45/64 [18.00]

2.8´ WATER-OUT FLOW SENSOR

´N´ NO. OF HOLES

[SEE TABLE]

H

ØD1 B.C.

ØD2

Max Flow

(Qs)

4

132 [500]

4

220 [833]

8

352 [1333]

8

528 [2000]

8

881 [3333]

®

RTU or BACnet MSTP (selectable)**.

Nominal Flow

Range (Qp)

66 [250]

110 [417]

176 [667]

264 [1000]

440 [1667]

Min Flow

(Qi)

0.7 [2.5]

1.1 [4.2]

1.8 [6.7]

2.6 [10]

4.4 [17]

ØD

Weight

lb [kg]L ØD H ØD1 ØD2 N

30.8 [14]

30.2 [13.7]

37.5 [17]

41.8 [19]

57.3 [26]

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

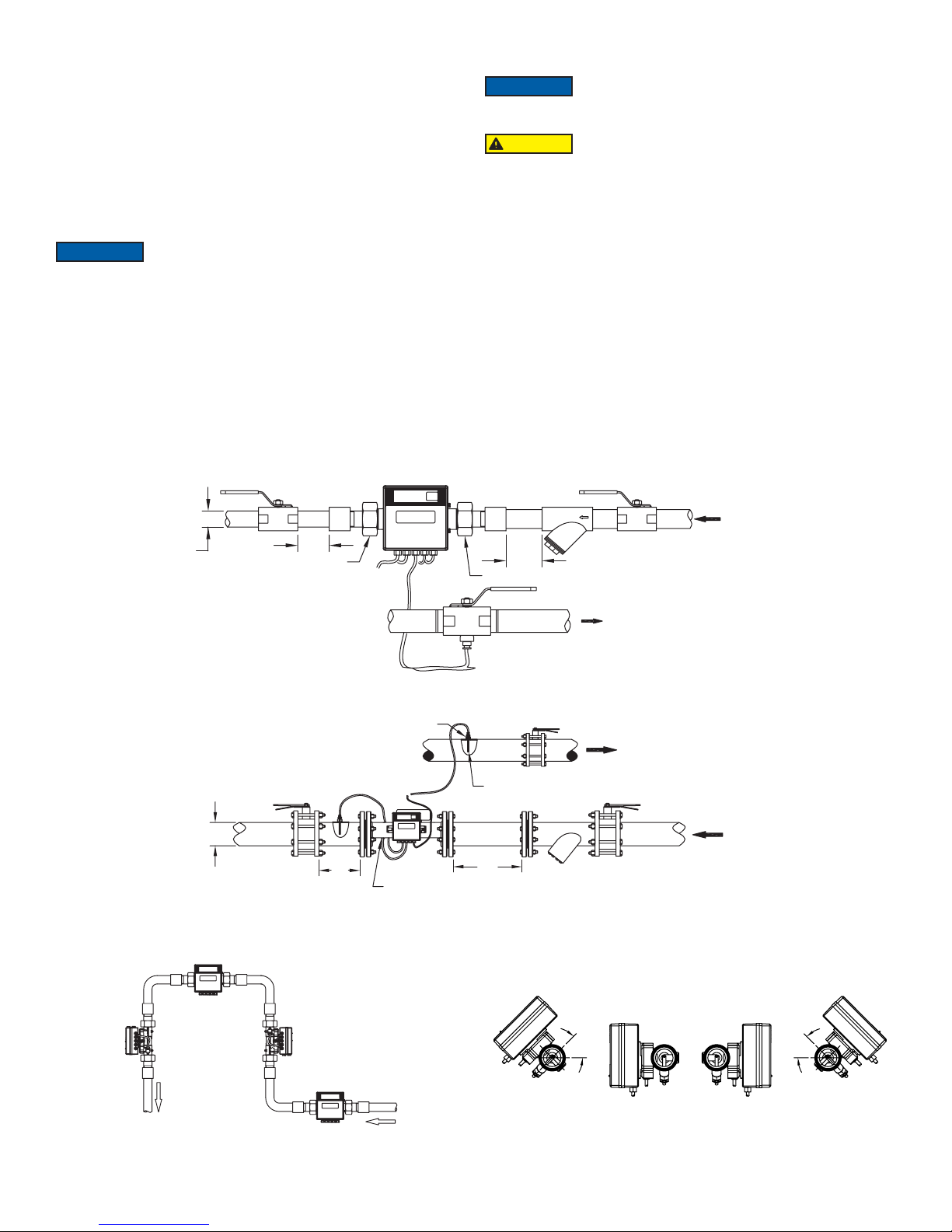

INSTALLATION INSTRUCTIONS

BALL

BALL

D

TEMPERATURE SENSOR

1. Install the meter as shown in either Figure 1 or Figure 2.

2. Mount the temperature sensor with the blue tag on the corresponding return pipe on

application. The sensor with the red tag has already been installed in the meter.

3. Flush the system in the proper direction until:

• No impurities remain in the lter and pipe.

• No water leaks when pressure is added to the system.

• The humidity inside the enclosure containing the meter does not exceed 93%.

4. After ushing for a period of time; close the ball valves on either side of the meter

and ush the impurities out of all lters.

*3.6 V ER26500 battery may be purchased separately to power display only.

INSTALLATION REQUIREMENTS

NOTICE

measuring accuracy.

1. Ensure that there is a 10 diameter straight run of pipe upstream and a 5 diameter

straight run of pipe downstream form the meter.

2. See the installation positions in Figure 3, in which A and B are the proper installation

positions, while C and D are the improper positions.

3. If the meter is installed on the horizontal pipe, it must be oriented at least 45° from

horizontal (see Figure 4). If the meter’s face is horizontal, then debris accumulation

can increase inaccuracies (see gure 5 for correct and incorrect orientations). There

is no special requirement when installing on the vertical pipe work.

4. Handle display with care. LCD display may damage with force.

Note: the meter can be installed on the return pipe or the supply pipe according to

user’s needs, but it should be selected in advance.

If the following requirements are not followed, then large air

particles and impurities in the pipe could inuence the meter’s

INSTALLATION NOTES

NOTICE

CAUTION

optional battery could cause the battery to explode and cause injury to people and

damage the meter.

1. Avoid tugging on the temperature probe’s cables.

2. Ensure the water is owing in the direction indicated by the arrow on the meter’s

body.

3. If several meters are installed on the same vertical pipe work, each meter should be

separated from the others to avoid pipe leakage or fallen debris that could affect the

other meters’ operation.

Do not directly weld the meter on to the pipe; the extreme heat

will damage the BTU meter’s internal elements.

Do not install the meter near a high temperature heat source

such as during electro gas welding. Doing so after installing an

STRAIGHT

JOINT

FILTER

PIPEPIPEPIPE PIPE PIPE

10D

UNION NUT

WATER RETURN

BALL

VALVE

BUTTERFLY

VALVE

RETURN WATER

TEMPERATURE

SENSOR

10D

BUTTERFLY

FILTER

VALVE

WATER SUPPLY

WATER RETURN

VALVE

WATER SUPPLY

STRAIGHT

VALVE

PIPE PIPE

D

5D

UNION NUT

BUTTERFLY

VALVE

JOINT

Figure 1: Installation Diagram for TUF-150/400

SENSOR

SLEEVE

5D

SUPPLY WATER

Figure 2: Installation Diagram for TUF-500/2000

Figure 3: Installation Positions

45° MIN.

45° MIN.

Figure 4: Mounting Rotation

Page 3

Yellow A+ (BACnet or Modbus)

Green B- (BACnet or Modbus)

Black- (24VDC or 24VAC)

Red+ (24VDC or 24VAC)

Temp Sensor In

Temp Sensor Out

Flow Sensor Out

Flow Sensor In

1. If meter is not in use during freezing conditions, drain all water from the connecting

pipe. Low temperatures will cause the water to freeze in the pipe and damage the

meter.

2. This device is intended to be used with clean water. While dirty water will not

damage the meter, it will cause errors in the reading.

3. A lter should be mounted near the meter and cleaned regularly.

4. If the heat exchanging system is operating normally, but the instantaneous ow-rate

of the heat meter reduces signicantly, then there is too much dirt in the lter. This

will narrow the pipe and reduce the ow. Cleaning the lter will x the problem.

5. To protect the meter and avoid damage from harsh conditions, it is recommended

that the meter be encased in an enclosure.

6. Primary Address: rst 2 digits of Manufacturer ID

7. Secondary Address: later 8 digits of Manufacturer ID

8. Company Code: BAS (08 33)

• Version: 54

DISPLAY

1. Switching Between Information

Holding down the button for > 1s will switch the sections from curren information ▲,

to monthly information ▲▲, and then to other information ▲▲▲. Once in the

desired section, pressing the key will switch the information shown for the given

section.

2. Display Units

Energy is displayed in kW•h, power is displayed in kW, ow volume is displayed as

3

, and ow-rate is displayed in m3/h.

m

3. Display Details

a. “Monthly Reading Date” is displayed as “Pd= XX”, in which XX is the end date of

the current month’s energy summation. The factory default value is 31, meaning

that the monthly recording period ends at midnight on the 31st day of the month. At

this time the current month’s cumulated energy will be stored and the system will

begin to record the next month’s energy.

b. The meter can store and display the recordings from the past 18 months.

c. The units for “Sum of Working Time” (hours) is displayed as h.

d. “Software and Protocol Editions” are displayed as “UEr.X.X X.X”. The rst X.X is

the software edition code and the second X.X is the communication protocol edition

code.

e. “Leaving-factory serial number” is the meter’s identication number, which is the

same as the one in the external label. This serial number is a unique number set by

the factory; it is also the secondary address in M-BUS system.

f. Battery Voltage displays “UCC=X.XX” (the default unit is Volts). When the battery’s

voltage capacity is lower than 2.9±0.1 V, “ ” will appear on the display. This

symbol will not appear if no battery is installed.

g. If there are any unresolved errors, the start date will display as normal but the end

date will display “00-00-00”, and then the error message will be displayed.

4. LCD Display Data:

• Cooling energy

• Heat energy

• Volume

• Operating time

• Flow temperature

• Return temperature

• Temperature difference

• Power

• Volume ow

• Recorded date

• Recorded energy

• Recorded volume

Error Message Table

Error

Messages Explanation

IN—CLOSE

IN—OPEN

OU—CLOSE

OU—OPEN

FL-OPEN

Temperature sensor of water supply is in closed state

Temperature sensor of water supply is in open state

Temperature sensor of return water is in closed state

Temperature sensor of return water is in open state

Flow sensor failure. (Could be caused by air in the meter, the

absence of water, or water owing in the wrong direction)

COD=XXXX

There is an error in malfunction record. “XXXX” is the error code

Low Battery*

*Battery Not Included

Page 4

4. Display Menus

Press button

Press button

Press button

Press button

Press button

Press button

Press button

Current Information Monthly Information Other Information

Hold button

Sum of cooling

energy

Sum of heating

energy

Power

Sum of flow rate

Flow velocity

Forward temperature

Return temperature

Temperature

difference

Press button

Press button

Press button

Press button

Press button

Press button

Monthly reading

date

Current date

Sum of monthly

energy

History reading

date 1

History reading

energy 1

Sum of flow rate 1

History reading

date 2

History reading

energy 2

Press button

Press button

Press button

Press button

Press button

Press button

Press button

Press button

Hold button

Current: Year,

month, date

Current: Hour,

minute, second

Sum of current

working time

LCD segment test

Protocol version

Primary address

Secondary address

Sum of flow rate 2

-History reading date 2

-History reading energy 2

-Sum of flow rate 2

Press button

-Error 4 message

-Error 4 beginning time

-Error 4 ending time

Battery voltage

Error 1 message

Error 1 beginning

time

Error 1 ending time

Press button

Press button

Press button

Press button

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

©Copyright 2018 Dwyer Instruments, Inc. Printed in U.S.A. 9/18 FR# 444246-50 Rev. 3

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...