Page 1

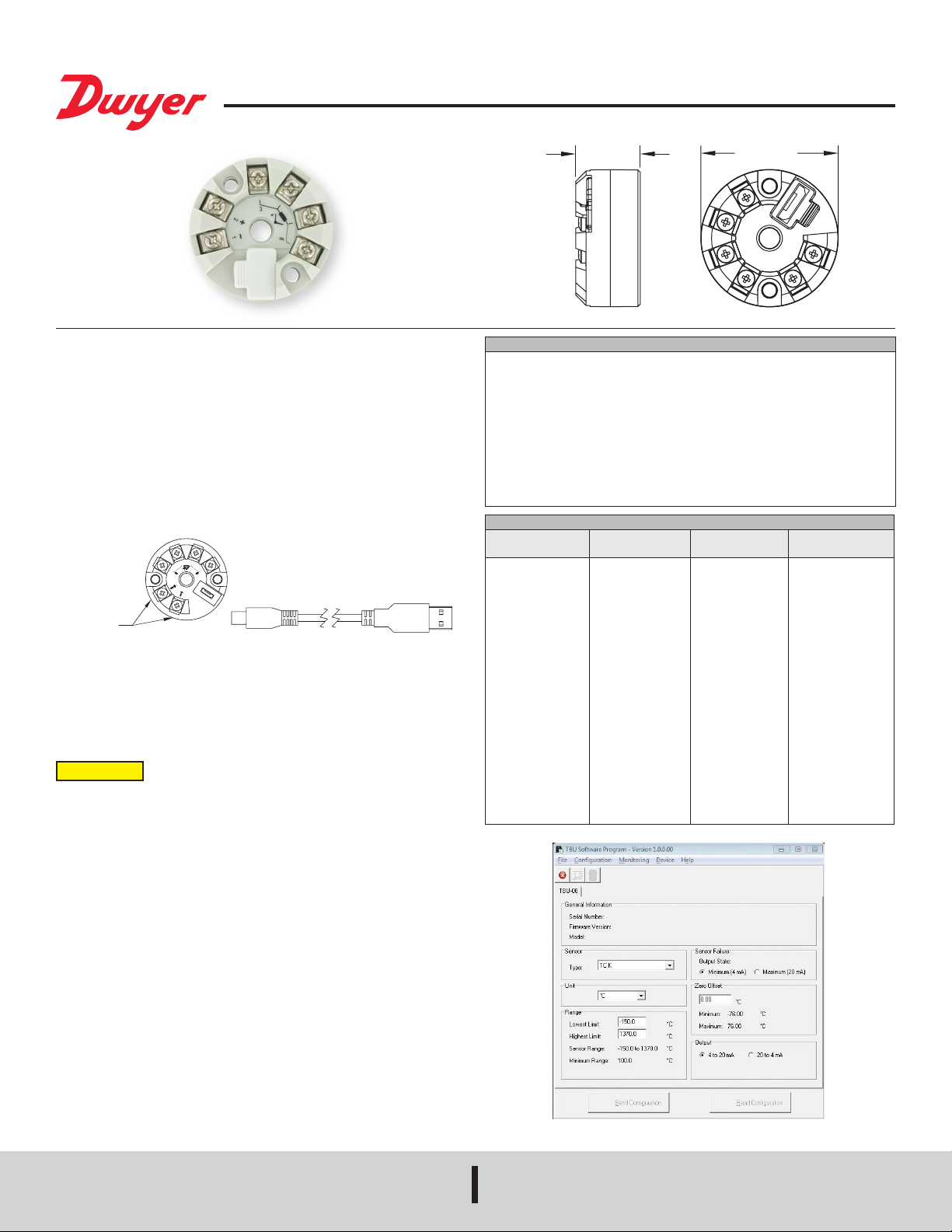

Model TBU-00 Temperature Transmitter

TO PC USB PORT

®

Specications - Installation and Operating Instructions

Bulletin T-TBU-00

The Model TBU-00 Temperature Transmitter is a high precision temperature

transmitter designed to easily mount in most temperature sensor instrument

enclosures. The universal input reduces inventory while the micro-USB port facilitates

easy conguration, and calibration in the lab or in the eld. The versatile TBU

model allows for selection and conguration of input type, measurement range, and

calibration. The output can be set as either direct 4 to 20 mA, or reverse 20 to 4 mA,

through easy to use conguration software.

Conguration

During the setup, the transmitter is powered by the USB, and does not require an

external power supply. See Figure 1. The transmitter setup can also be made by

connecting it to the loop using the loop power supply. There is no electrical insulation

between the transmitter and the communication port (interface), therefore do not

congure the transmitter when it is connected to the process.

PLUG A

POWERED

CURRENTS

LOOP

FACTORY SETTING AND CONFIGURATION

When the transmitter is used with the factory setting, no further action is required

and the transmitter is ready to be installed. Changes to the conguration are possible

through the TBU software, provided free of charge on the Dwyer website. The factory

setting for the TBU is for a Pt100 3-wire sensor with a range of 0 to 100°C with 0°C

zero correction and an output of 4 to 20 mA.

CAUTION

equipment is powered may result in equipment damage.

After these connections, the user must run the TBU software. See Figure 2 for software

screen.

TRANSMITTER USB CABLE

Figure 1: USB cable connections

The USB communication port (micro-USB) of the TBU-00 is not

electrically insulated from the transmitters input. Connection while

MICRO B

13/16 [20.5]

SPECIFICATIONS

Input: Thermocouples J, K, R, S, T, N, E, and B; 2, 3, or 4 wire Pt100 RTD, 2 or 3

wire Pt1000 RTD, 2 wire NTC thermistor, or 0 to 50 mV voltage.

Output: Linearized 4 to 20 mA, 2 wire or 20 to 4 mA loop powered.

Transmitter Type: 2, 3, or 4 wire.

Temperature Limits: -40°F to 185°F (-40 to 85°C).

Power Requirements: 10 to 35 VDC.

Accuracy: See chart below.

Temperature Drift: < ±0.16% / 25°C.

Response Time: 1.6 s, typical.

Weight: 1.4 oz (40 g).

Agency Approvals: CE.

ACCURACY CHART

Input Type

Voltage

Thermocouple J

Thermocouple K

Thermocouple R/S

Thermocouple T

Thermocouple N

Thermocouple E

Thermocouple B

Pt100/Pt1000 RTDs

NTC Thermistor

Max. Temperature

Range

0 to 50 mV

-148 to 1400°F

(-100 to 760°C)

-238 to 2498°F

(-150 to 1370°C)

-58 to 3200°F

(-50 to 1760°C)

-256 to 752°F

(-160 to 400°C)

-454 to 2372°F

(-270 to 1300°C)

-130 to 1328°F

(-90 to 720°C)

932 to 3308°F

(500 to 1820°C)

-328 to 1202°F

(-200 to 650°C)

-22 to 248°F

(-30 to 120°C)

1-23/32 [43.5]

Min. Temperature

Range Accuracy (Typical)

5 mV

212°F (100°C)

212°F (100°C)

752°F (400°C)

212°F (100°C)

212°F (100°C)

212°F (100°C)

752°F (400°C)

104°F (40°C)

104°F (40°C)

±0.1% FS

±0.1% FS

±0.1% FS

±0.1% FS

±0.1% FS

±0.1% FS

±0.1% FS

±0.1% FS

±0.13% FS

±0.3°C

The elds in the software screen pictured in Figure 2 mean:

1. General Information: This eld shows information that identies the transmitter.

This information could be sent to Dwyer Instruments when additional technical

assistance is requested.

2. Sensor: Select the type of sensor to be used.

3. Measuring Range: Sets the measurement range of the transmitter.

Lower Range Limit: Equivalent temperature for a current of 4 mA.

Upper Range Limit: Equivalent temperature for a current of 20 mA.

Sensor Range: The values chosen cannot exceed the range of the sensor.

Minimum Range: Do not set a lower band (span) than the minimum range indicated.

4. Sensor Failure: Establishes the output behavior when the transmitter indicates a

failure.

Minimum: Output current goes to < 3.6 mA (down-scale), typically used for

refrigeration.

Maximum: Output current goes to > 22.0 mA (up-scale), typically used for heating.

5. Zero Offset: Offset allowing for small deviations presented in the transmitter output.

6. Send Conguration: Once set, the setup will be uploaded to the transmitter.

7. Read Conguration: Reads the current setup in the connected transmitter.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Figure 2: Software screenshot

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

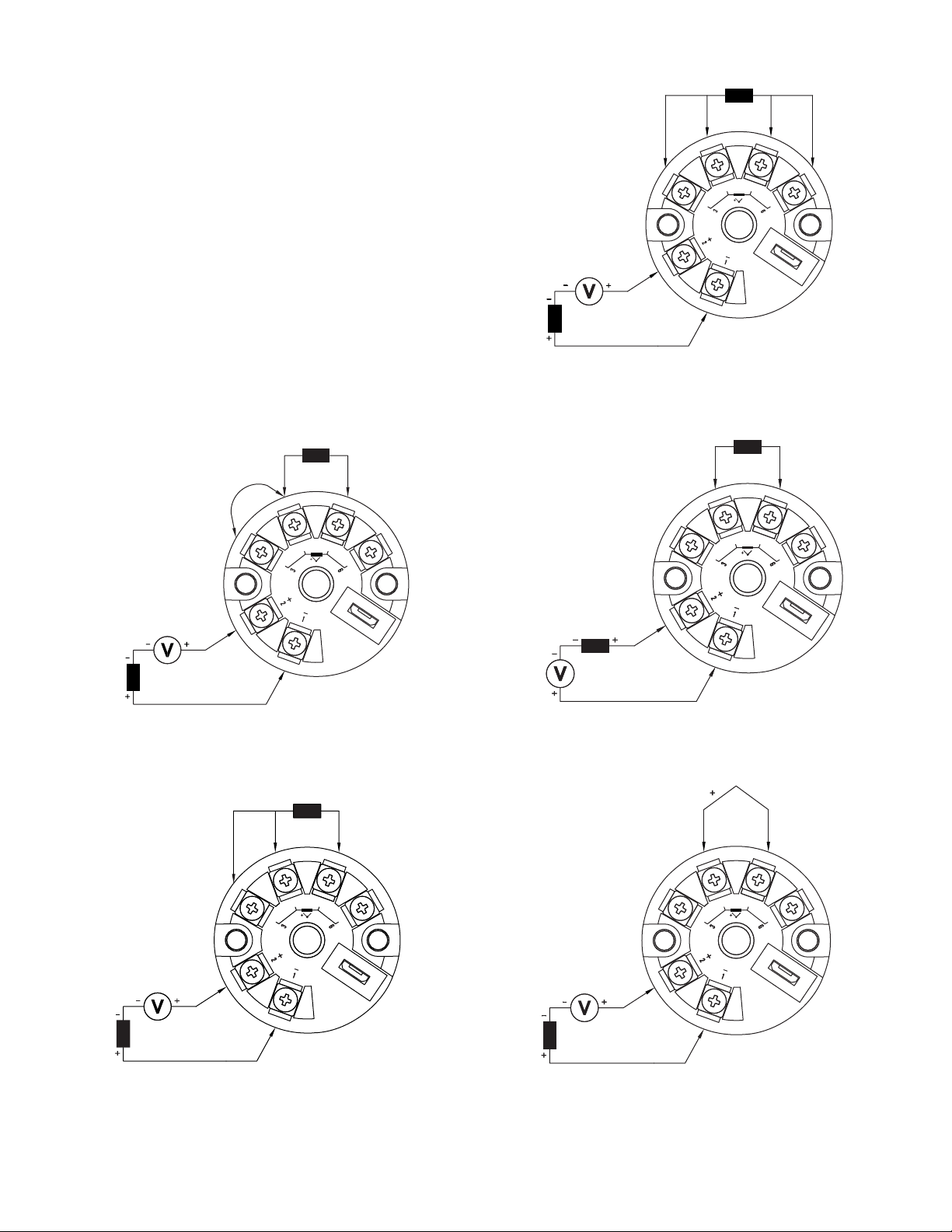

MECHANICAL INSTALLATION

Pt100 SENSOR

The TBU-00 transmitter is suitable to be installed in instrument enclosures. Vibrations,

moisture, extreme temperatures, electro-magnetic interference, high voltage, and

other interferences can permanently damage the unit, and could cause an error in the

measured value.

Pt100 SENSOR

4-WIRE

ELECTRICAL INSTALLATION

Recommended wire size: 26 AWG to 16 AWG (0.14 to 1.5 mm

2

).

Recommended terminal torque: 7.08 in-lbf (0.8 Nm).

RECOMMENDATIONS FOR INSTALLATION

Separate signal lines from facility power lines. The use of grounded conduit is

recommended.

The instrument must be powered from the instrumentation power supply circuit.

Transient suppression should be used with inductive loads such as contact coils and

solenoids.

ELECTRICAL CONNECTIONS

The gures below shows the electrical connections required. Terminals 3, 4, 5 and

6 are dedicated to the sensor connection. LOAD represents the 4 to 20 mA current

measuring device (indicator, controller, recorder, etc.).

Note: When using a Pt100Ω 2-wire RTD, terminals 3 and 4 must be interconnected,

according to Figure 3 below. The Pt100 wire length should be less than 12 in (30 cm)

to maintain the measurement error within specications (electrical resistance).

2-WIRE

JUMPER

LOAD

POWER

SUPPLY

Figure 5: Pt100 4-wire

NTC SENSOR

2-WIRE

TRANSMITTER

LOAD

LOAD

POWER

SUPPLY

POWER

SUPPLY

Figure 3: Pt100 2-wire

Pt100 SENSOR

3-WIRE

TRANSMITTER

TRANSMITTER

POWER

SUPPLY

LOAD

LOAD

POWER

SUPPLY

Figure 6: NTC 2-wire

THERMOCOUPLE

SENSOR

TRANSMITTER

TRANSMITTER

Figure 7: ThermocouplesFigure 4: Pt100 3-wire

Page 3

POWER

SUPPLY

0 to 50 mV

SUPPORT

This product contains no serviceable parts inside. For troubleshooting, visit our

frequently asked questions at www.dwyer-inst.com or contact our technical support

team at 1-800-872-9141.

MAINTENANCE/REPAIR

Upon nal installation of the Model TBU, no routine maintenance is required. The

Model TBU is not eld serviceable and is not possible to repair the unit. Field repair

should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

LOAD

Figure 8: Voltage (0 to 50 mV)

OPERATION

The sensor offset can be changed through the TBU-00 software. The USB cable may

be connected to the transmitter without causing any measurement errors. See item 5

Zero Offset on the rst page of this manual.

The user must choose the most suitable sensor and range to the process. The selected

range must not exceed the maximum range of measurement dened for the sensor

and should not be smaller than the minimum range for the same sensor.

Note: The transmitter accuracy is based on the maximum range of the sensor used,

even when a narrower range is programmed.

Example:

• The Pt100 sensor in the range 0 to 100°C and accuracy of 0.12%, the maximum

error will be 1.02°C (0.12% of 850 °C )

• The Pt100 sensor in the range of 500 to 600°C and accuracy of 0.19%, the maximum

error will be 1.61°C (0.19% of the 850°C )

Note: When the measurements are made at the transmitter, ensure the Pt100

excitation current required by the calibrator is compatible with the Pt100 excitation

current used in the transmitter: 0.8 mA.

SAFETY INFORMATION

Any control system design should take into account that any part of the system has the

potential to fail. This product is not a protection or safety device and its alarms are not

intended to protect against product failures. Independent safety devices should always

be provided if personnel or property are at risk.

TRANSMITTER

Product performance and specications may be affected by its environment and

installation. It’s the responsibility of the user to assure proper grounding, shielding,

cable routing, and electrical noise ltering are in accordance with local regulations,

EMC standards, and good installation practices.

Page 4

NOTES

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

Printed in U.S.A. 5/19 FR# 444508-00 Rev. 1©Copyright 2019 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...