Page 1

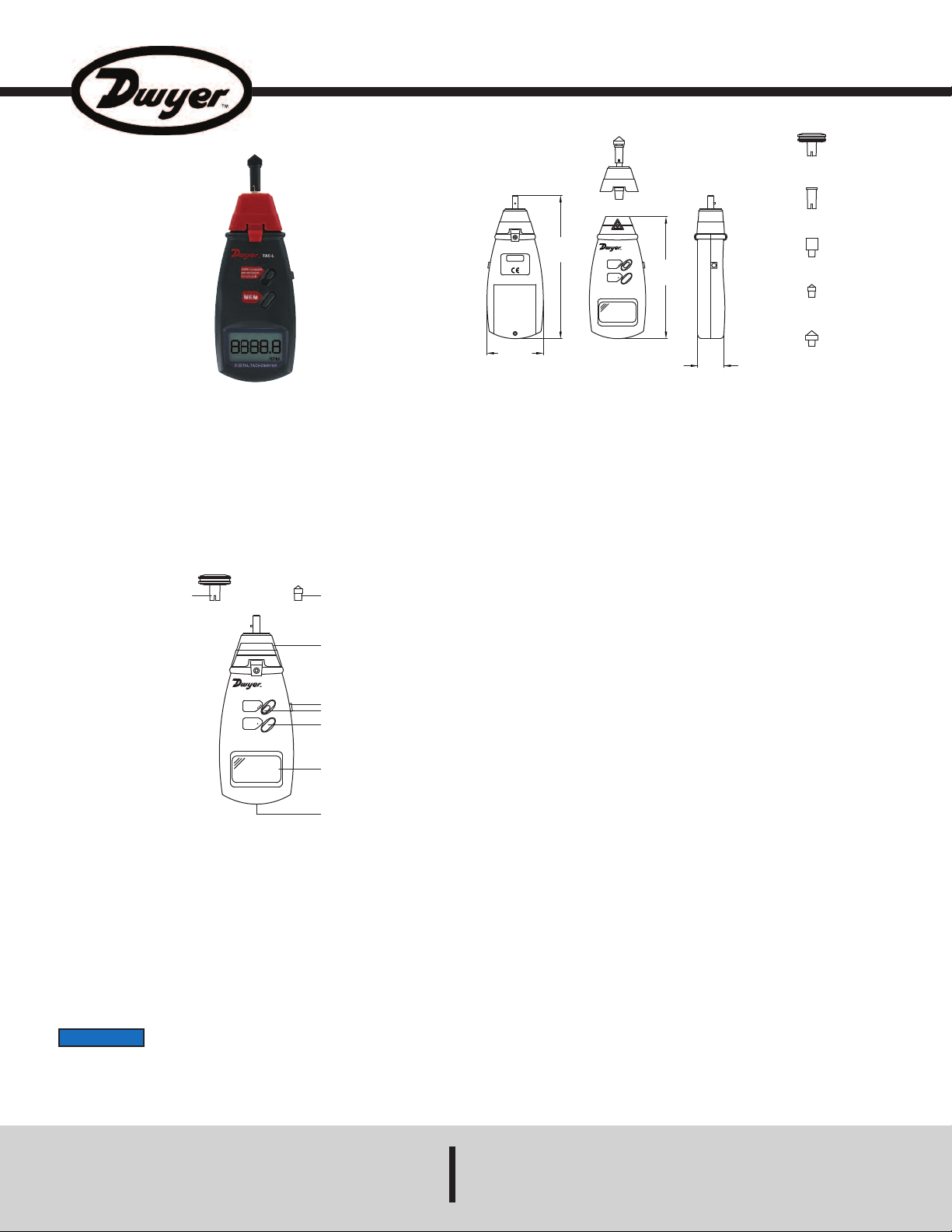

Model TAC-L Photo/Contact Digital Tachometer

m/min

rpm

rpm

MEM

c

ontact

contact

p

hoto

D

IGITAL TACHOMETER

T

AC-L

A

B

C

D

E

F

G

H

m

/min

r

pm

r

pm

MEM

c

ontact

c

ontact

p

hoto

DIGITAL TACHOMETER

TAC-L

7

-3/8

[

187.91]

2-7/8

[73.89]

6

-1/4

[

159.96]

1

-3/8

[

34.05]

R

PM ADAPTER FITTING

(

ATTACHED TO UNIT)

CYLINDRICAL CONTACT

ROTATIONAL FITTING

SMALL POINTED CONTACT

ROTATIONAL FITTING

L

ARGE POINTED CONTACT

R

OTATIONAL FITTINGS

(

ATTACHED TO UNIT)

SURFACE SPEED

RING ATTACHMENT

Installation and Operating Instructions

Bulletin TE-TAC-L

Model TAC-L Portable Digital Tachometer measures rotational speed

either by contacting a rotatable head to the shaft of the object, or using

photo sensor to detect the reflections from the laser. The laser target can

record from a distance of up to 20 inches and gives a more accurate

measurement than LED targeting. Model TAC-L includes a large LCD

with a backlight for use in dark areas. This tachometer is made of a

strong, lightweight ABS plastic housing, which is designed to comfortably

fit in the hand of the user. Supplied with this model are 3 contact rotational

heads, a contact surface wheel, and a protective carrying case.

PRODUCT OVERVIEW

Figure 1

A. Surface speed wheel B. Contact test device

C. Contact measuring device D. Measuring button

E. Function switch F. Memory button

G. Display H. Battery cover

SPECIFICATIONS:

Accuracy: ±(0.05% + 1 digit).

Display: Backlit LCD; 5 digits, 7 segments, 0.7˝ (1.8 cm) H.

Range:

Non-contact (RPM): 2.5 to 99,999 RPM;

Contact (RPM): 0.5 to 19,999 RPM;

Surface Speed (m/min): 0.05 to 1999.9 m/min.

Resolution:

Non-contact (RPM): 0.1 RPM (2.5 to 999.9 RPM),

1 RPM (1000 to 99,999 RPM);

Contact (RPM): 0.1 RPM (0.5 to 999.9 RPM),

1 RPM (1000 to 19,999 RPM);

Surface Speed (m/min): 0.01 m/min (0.05 to 99.99 m/min),

0.1 m/min (100.0 to 1999.9 m/min).

Non-contact Measuring Distance Range: 2 to 20˝ (5 to 50 cm).

Sampling Time: 0.8 s.

Temperature Limits: 32 to 122°F (0 to 50°C).

Power Requirements: (4) 1.5 V AA alkaline batteries, included, user

replaceable.

Weight: 1.37 lb (.620 kg).

NON-CONTACT MEASURING (RPM)

1. Apply a reflective mark to the object being measured.

2. Slide the function switch to “rpm photo” and remove the cap.

3. Depress the measuring button and align the visible light beam with the

applied target. Verify that the monitor indicator lights when the target

aligns with the beam.

NOTICE

an average distance apart on the object, then measure as above, giving a more

accurate measurement. The user then must divide the reading shown by the number

of reflective marks to find the true RPM.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

In the case of measuring low RPM values with the non-contact

laser, it is suggested that the user attach more reflective marks

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

CONTACT MEASURING (RPM)

1. Install the contact device, with the head piece that works best for the

object being measured.

OTICE

peed.

s

N

The large tapered and pillar rubber pieces are more suitable for

low speed. The small tapered piece is more suitable for high

2. Slide the function switch to “rpm contact.”

3. Lightly press the rpm adapter against the center hole of the rotating

shaft.

4. Depress the measuring button, being sure to keep the alignment

straight.

5. Release the measuring button when the display reading stabilizes.

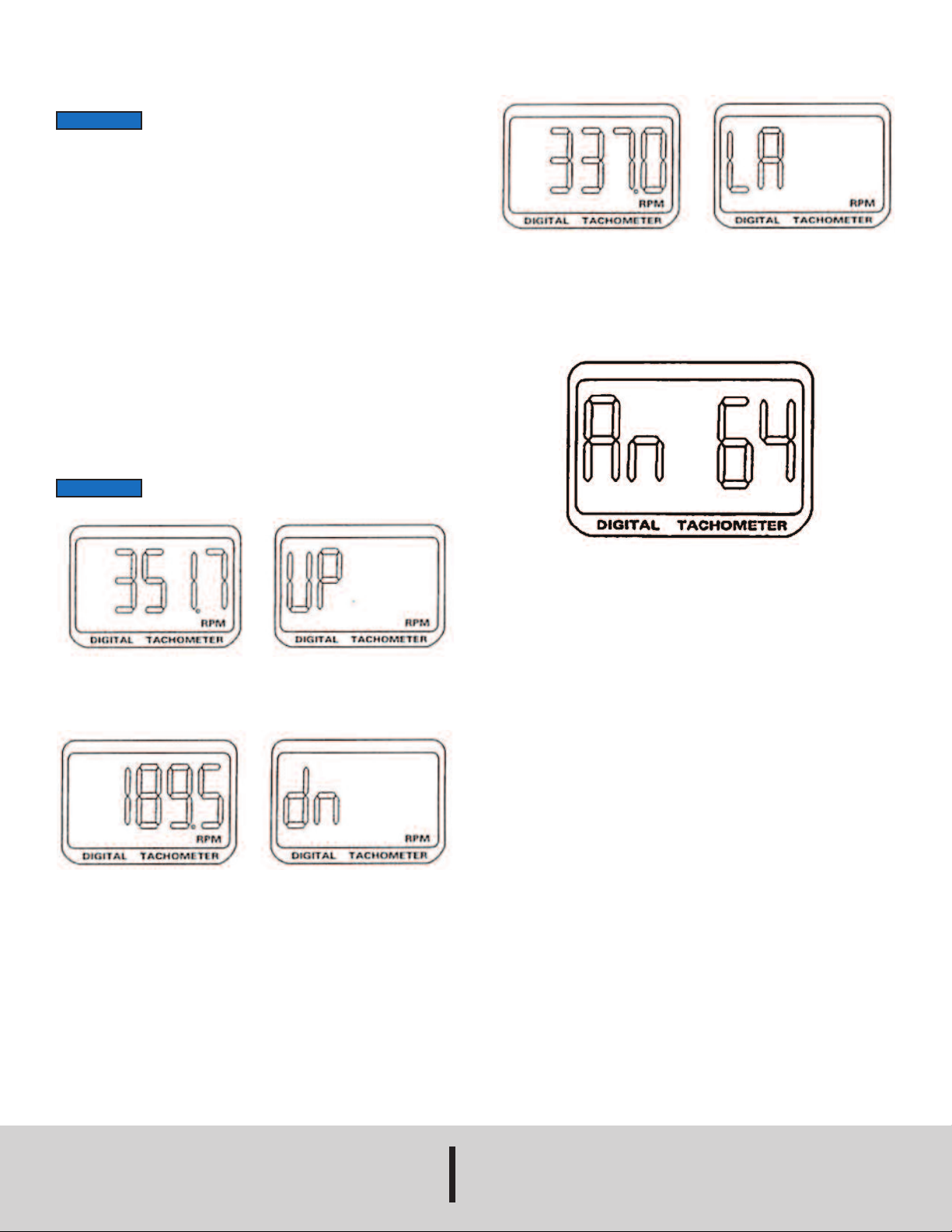

The third time the button is pressed, the last recorded value is shown,

alternated with “LA.” See Fig. 4.

Figure 4

SURFACE SPEED MEASURING (M/MIN)

1. Install the surface speed ring attachment.

2. Slide the function switch “m/min contact.”

3. Lightly press the speed ring to the object being measured.

4. Depress the measuring button, being sure to keep the alignment

straight.

5. Release the measuring button when the display reading stabilizes.

MEMORY

The memory button is able to recall the records from the last time the

measuring button was pressed. Press and hold the memory button each

time. The first time the button is pressed, the maximum recorded value is

shown, alternated with “UP.” See Fig. 2.

OTICE

N

Recorded data is reset every time the measuring button is

ressed.

p

Figure 2

The second time the button is pressed, the minimum recorded value is

shown, alternated with “DN.” See Fig. 3.

The fourth time the button is pressed, there will be a countdown from 20

to 1. After this, the display will show “An **.” The number that is displayed

after “An” is the number of seconds that the tachometer was recording for

during the last session. In the case of Figure 5, the tachometer recorded

for 64 seconds.

Figure 5

Each time the button is pressed after that, it will show the recorded value

for each second it was recording. After having gone through all of the

values, pressing the button will start from the beginning with the

maximum measurement.

REPLACING THE BATTERIES

When the batteries need to be replaced, the battery icon will appear in the

bottom left corner of the display. To replace the batteries, slide the battery

cover off of the tachometer and remove the 4 batteries. Install the new

batteries in the same position as the previous ones.

MAINTENANCE/REPAIR

Upon final installation of the Model TAC-L, no routine maintenance is

required besides changing the batteries. The Model TAC-L is not field

serviceable and should be returned if repair is needed. Field repair

should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our

Figure 3

website. Contact customer service to receive a Return Goods

Authorization number before shipping the product back for repair. Be

sure to include a brief description of the problem plus any additional

application notes.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 12/13 FR# R6-444140-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...