Page 1

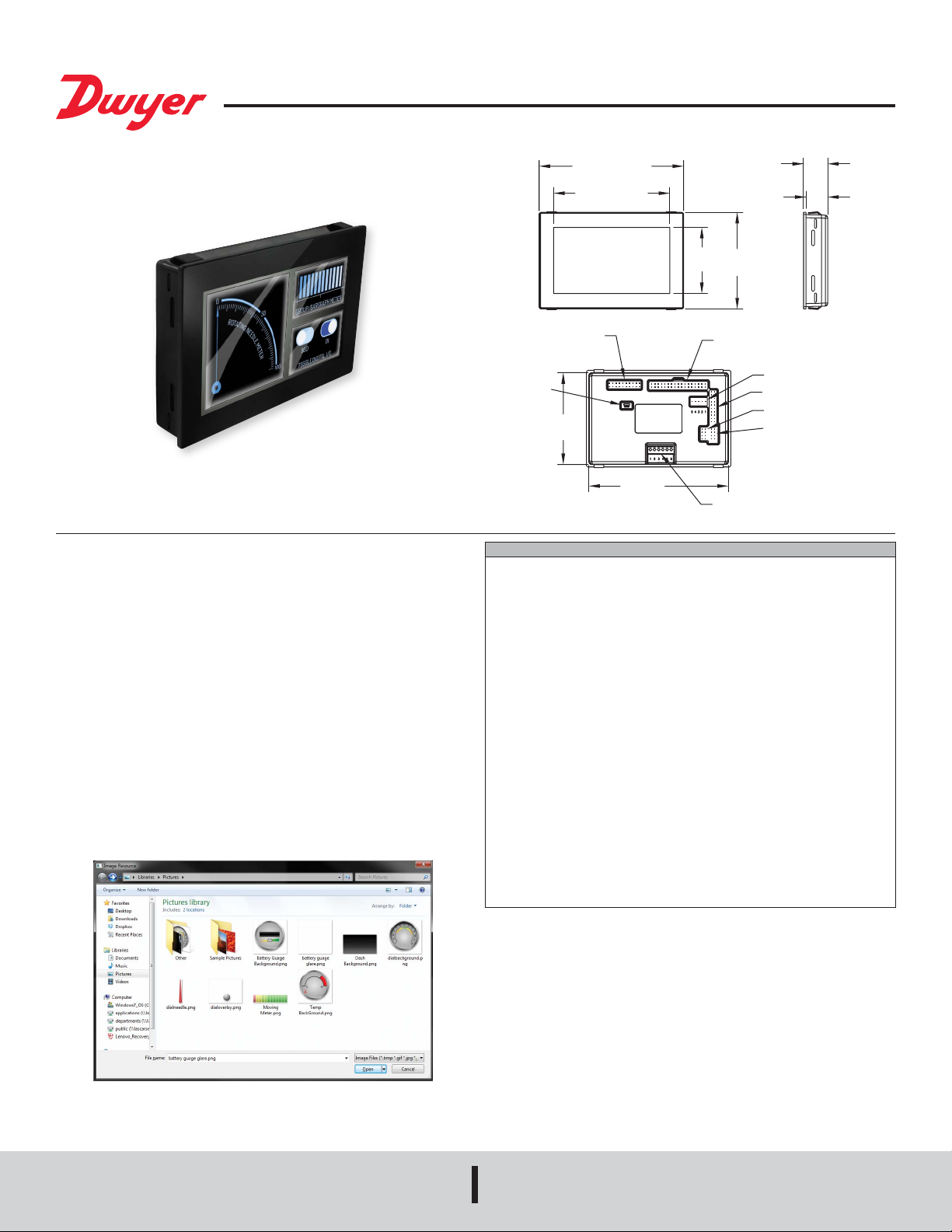

Series SPPM2 Graphical User Interface Panel Meter

25/32

MINI USB PO

ANSION I/O

POWER & ANALOG INPUTS

®

Specications - Installation and Operating Instructions

Bulletin PC-SPPM2

The SERIES SPPM2 Graphical User Interface Panel Meter is a congurable, full-color

4.3˝ (109 mm) touch screen display that can be used in a variety of applications.

By using the free Windows

can personalize the display to suit their needs. A development kit is also available,

which a development board with buttons, dials, LEDs, and screw terminals to test the

functionality of all inputs and outputs.

DOWNLOADING SOFTWARE

Customization software is available at www.dwyer-inst.com/SPPM2. To download,

follow these instructions:

1. To begin downloading, click “Run” when prompted.

2. When a security warning appears, click “Run” a second time.

3. As soon as the InstallShield Wizard screen appears, follow the on-screen

instructions.

4. When installation is complete, click “Finish” to quit the installer. The software can

now be used by clicking on the new icon on the desktop.

BUILDING AN APP

1. Open the software by double-clicking on the icon.

2. Connect the SPPM2 model to the PC using a mini-USB cable.

3. Gather any extra images to be used other than what is already included in the

app.

®

based Interface Panel Design Studio software, users

4-45/64 [119.30]

3-49/64 [95.84]

2-5/32

[54.66]

JTAG [FOR INTERNAL USE]

RT

2-63/64

[75.86]

4-17/32

[115.30]

SPECIFICATIONS

Inputs: Mini-USB, 6-line screw terminal analog, 4 x ±40 V, or 4 to 20 mA, 8 x digital

I/O.

Outputs: 4 x PWM, 2 x alarms (open collector).

Accuracy: ±0.05% ±0.1 mV (typ).

Resolution: 0.04 mV (max ) or 4 decimal places.

Power Supply: USB port or 5 to 30 VDC.

Current Consumption: 400 mA at 5 VDC.

Display: 4.3˝ (10.9 cm) TFT LCD with 262k colors.

Display Resolution: 480 x 272 pixels.

Sampling Rate: 10 samples/sec.

Temperature Limits: 32 to 104°F (0 to 40°C).

Warm Up: 15 sec.

Mounting: Panel mount.

Electrical Connection: Multi-pin DIL’s, 1 mini-USB, and 1 RS232.

Computer Requirements: Compatible with Windows

®

Windows

Weight: 6.7 oz (181 g).

Approvals: CE.

DEVELOPMENT BOARD SPECIFICATIONS

Inputs: 4 x ± 5 VDC.

Outputs: 8 x digital I/O’s, 4 x PWM outputs.

Serial Communication: RS232.

Power Supply: USB port or 5 to 30 VDC.

Weight: 19.7 oz (560 g).

10.

[19.93]

45/64

[17.93]

3-9/64

[79.82]

ALARMS, SERIAL INPUT & DIGITAL I/O

RS232 INTERFACE

ETHERNET & EXP

4-20mA CURRENT LOOP

CONFIGURATION

ANALOG INPUTS

®

7, Windows® 8, and

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Windows® is a registered trademark of Microsoft Corporation.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

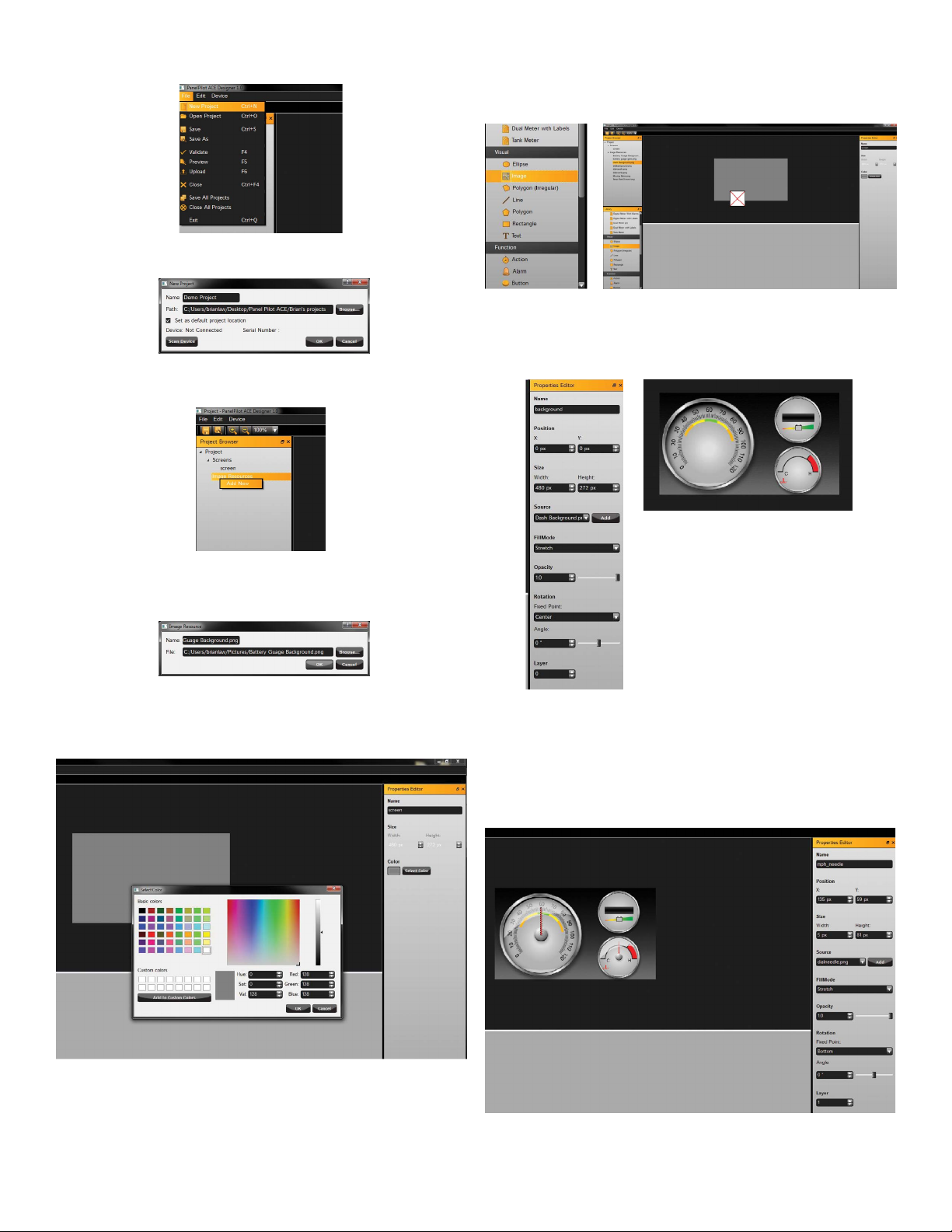

4. In the GUI software, choose “New Project”.

5. In the window that pops up, name it, choose where it will save, and press “OK”.

6. Bring the images in by right-clicking “Image Resources” and choosing “Add New”.

9. To use an image as the background: a) Choose “Image” under the library window

and drag it onto the gray box. b) Give the image an appropriate name and use the

appropriate size settings to ll the entire screen. c) Select the image background in

“Source”.

10. To add the meters: a) Add in meter images in the same way as mentioned in step

9. b) To resize the images, grab the corners or sides and stretch them to the

necessary size. c) Once nished, click on the individual meters and name them for

easy access later.

7. Navigate to the location where the pictures are stored and select the picture to

bring in. The image will now appear under image resources in the project browser.

8. To use a color as the background: a) Click on the gray box in the middle of the

screen where the display preview will be. b) Choose the background color in the

“Properties Editor” menu that appears on the right.

11. To add the needles for each display: a) Add in needle images as mentioned in

step 9. b) Position the bottom of the needle to be in the center of the dial. c) Set

the transform origin to the bottom center of the picture in the “Properties Editor”

menu on the right. (This is the xed point that will be the “hinge” that the dial turns

on.) d) Under “Rotation”, change the angle to check how the image will rotate and

verify it is moving in the expected way. (Make a note of the angles where the needle

needs to start and stop.)

Page 3

12. To add the battery gauge: a) Add the gauge photo as mentioned in step 9. b) Drop

the image into position and name it.

13. To make the dials move: a) Choose “rotating needle” under the function setting of

the library and drag it to the gray area to the right. b) Click on rotatingNeedle and

name it appropriately. c) The analogueInput will default to channel one. d) The

visual element is the picture of the needle. e) The angle range is where the needle

needs to start and stop. (Noted in step 11.)

16. To test the app, click File>Preview or press F5 to bring up the simulation window.

Inputs can be simulated in this screen to verify that everything is working properly.

17. Once satised with the simulation, click File>Upload or press F6 with the meter still

plugged in to send the app to the display.

14. Click on analogueInput and assign the wanted channel to control the mph_needle.

Here, also set the voltage range and what value that voltage range translates to on

the display. Follow the same instructions to add any other needle channels.

15. To add bar graph ll graphics, drag in the “ll meter” function and another

analogueInput and follow the directions above.

Page 4

MOUNTING

1. Punch out a rectangular hole in the panel of the enclosure 4.6˝ x 3.07˝ (117 x 78

mm).

2. For panels between 0.04˝ and 0.12˝ (1 and 3 mm) in thickness, use the integral

clips to attach the SPPM2 to the panel.

3. For panels between 0.01˝ and 0.15˝ (0.5 an 4 mm) in thickness, place the gasket

around the bezel of the display, slide the display through the front hole in the panel,

and attach the mounting clip from the rear, as shown in Figure 1.

Figure 1

WIRING

19

20

PL5

USB

1

2

33

34

TBLK1

123456

Figure 2

PL4

PL7

54321

1

PL8

7

1

2

1

2

PL6

21

22

2

1

2

PL11

878

TBLK1: POWER & ANALOG INPUTS

PIN Number Function

1

2

3

4

5

6

PL4: ALARMS, SERIAL INPUT, & DIGITAL I/O

PIN Number Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

PL5: PROGRAMMING INTERFACE (JTAG)

PIN Number Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Supply Voltage (V+)

0 V

Analog Input 4 (IN4)

Analog Input 3 (IN3)

Analog Input 2 (IN2)

Analog Input 1 (IN1)

0 V

Supply Voltage (V+)

Alarm 1 (ALM1)

Alarm 2 (ALM2)

I2C0 SCL

I2C0 SDA

SPI SS1

SPI MOSI

SPI MISO

SPI SCK

Digital I/O Channel 1 (DIG1)

Digital I/O Channel 2 (DIG2)

Digital I/O Channel 3 (DIG3)

Digital I/O Channel 4 (DIG4)

Digital I/O Channel 5 (DIG5)

Digital I/O Channel 6 (DIG6)

Digital I/O Channel 7 (DIG7)

Digital I/O Channel 8 (DIG8)

PWM Channel 1 (PWM1)

PWM Channel 2 (PWM2)

PWM Channel 3 (PWM3)

PWM Channel 4 (PWM4)

DUART TX (for internal use)

DUART TX (for internal use)

USB D+

USB DI2C1 SDA (for internal use)

I2C1 SCL (for internal use)

+5 V Output Voltage

High Speed ADC

+3 V3 Output Voltage

0 V

Shorted together to enable rmware upgrade

Shorted together to enable rmware upgrade

+3 V3 Output Voltage

N/C (no connection)

JTAG_TRST

OV

JTAG_TDI

0V

JTAG_TMS

0V

JTAG_TCK

0V

JTAG_RTCK

0V

JTAG_TDO

0V

n_reset

0V

N/C

0V

0V via a 47 kΩ resistor

0V

Page 5

PL6: ETHERNET & EXPANSION I/O

PIN Number Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

PL7: RS232 INTERFACE

PIN Number Function

1

2

3

4

5

PL8: 4-20 mA CURRENT LOOP MEASUREMENT

PIN Number Function

1-2

3-4

5-6

7-8

PL11: ANALOG INPUTS

PIN Number Function

1

2

3

4

5

6

7

8

ENT CLK

ENT MDC

ENT MDIO

ENT RXD0

ENT RXD1

ENT RX EN

ENT TXD0

ENT TXD1

ENT TX EN

Digital I/O 9 (expansion)

Digital I/O 10 (expansion)

Digital I/O 11 (expansion)

Digital I/O 12 (expansion)

Digital I/O 13 (expansion)

Digital I/O 14 (expansion)

Digital I/O 15 (expansion)

Digital I/O 16 (expansion)

Digital I/O 17 (expansion)

+5 V

0 V

External Module Hardware ID

External Module Hardware ID

TX

RTS

RX

CTS

0 V

4-20 mA Current Loop Measurement (IN1) when shorted

4-20 mA Current Loop Measurement (IN1) when shorted

4-20 mA Current Loop Measurement (IN1) when shorted

4-20 mA Current Loop Measurement (IN1) when shorted

Analog Input 1 (IN1)

0 V

Analog Input 2 (IN2)

0 V

Analog Input 3 (IN3)

0 V

Analog Input 4 (IN4)

0 V

SUPPLY VOLTAGE

Supply to the display module can be connected to either the screw terminals (TBLK1),

pins (PL4), or the mini-USB connector. (Note: For best results, ensure the power

supply is free from electrical noise.

Supply Voltage Screw Terminals (TBLK1) PIN (PL4)

V+

0 V

MEASURING AN ANALOG VOLTAGE

An analog voltage can be connected to either the screw terminals (TBLK1) or pins

(PL11).

Analog

Input

IN1

1

0 V

2

IN2

0 V

3

IN3

0 V

4

IN4

0 V

To minimize offsets, it is best practice to connect the analog grounds directly to the

meter pins (PL11) or screw terminals (TBLK1). The SPPM2 uses a programmable gain

amplier (PGA) together with a 16-bit analog to digital converter (ADC) for its analog

voltage measurements. The PGA is automatically set when the analog range of a

channel is input into the design software.

The table below shows the maximum resolution of the SPPM2’s analog measurements

across a number of voltage ranges

Analog Input Resolution

±1.25 V

±2.5 V

±5 V

±10 V

±20 V

±40 V

MEASURING A 4-20 mA CURRENT

The 4-20 mA signal should be connected as for “Measuring an Analog Voltage”, but

a jumper link should be placed across pins PL8 for each analog channel being used.

Analog Voltage Jumper Link (PL8)

IN1

IN2

IN3

IN4

Scaling: The sense resistors used are 110Ω. Therefore, in software scaling, 4 mA

equates to 0.44 V and 20 mA equates to 2.2 V. (Note: Transmitter terminals + or – must

be isolated from the power supply.).

1

2

Screw Terminals

(TBLK1)

6

2

5

2

4

2

3

2

0.04 mV

0.08 mV

0.16 mV

0.33 mV

0.66 mV

1.3 mV

1 & 2

3 & 4

5 & 6

7 & 8

PIN

(PL11)

1

2

3

4

5

6

7

8

2

1

Page 6

DRIVING AN ALARM OUTPUT

V+

OV

v+

The alarm outputs are open-collector. When an alarm is active, the output can sink as

much as 10 mA. Alarm outputs are connected via PL4.

Alarm Output PIN (PL4)

ALM1

ALM2

3

4

SPPM2

USING PWM OUTPUT

If the SPPM2 is congured to have a PWM output, it can be used to drive a buzzer

or produce a simple digital-to-analog converter. The PWM outputs are connected via

PL4.

PWM Output PIN (PL4)

PWM1

PWM2

PWM3

PWM4

19

20

21

22

R> V+-VLED

3.3

0.8

3.3

0.4

-

-

<10mA

R

15

16

17

18

V

V

V

V

mA

mA

ALM1

Figure 3: Driving an LED using Alarm Output

SPPM2

<10mA

ALM1

Figure 4: Driving a Relay using Alarm Output

USING DIGITAL INPUT/OUTPUT PINS

Digital inputs/outputs are connected via PL4.

Digital I/O PIN (PL4) Digital I/O PIN (PL4)

DIG1

DIG2

DIG3

DIG4

The characteristics of the digital I/O pins are as follows:

Parameter Min Max Unit

Input Voltage (High)

Input Voltage (Low)

Output Voltage (High)

Output Voltage (Low)

Output Source Current

Output Sink Current

11

12

13

14

DIG5

DIG6

DIG7

DIG8

2

0

2.6

0

-11.4

9.0

10mA

The characteristics of the PWM output pins are as follows:

Parameter Min Max Unit

LED

Voltage

Output Source Current (PWM)

Output Sink Current (PWM)

Figure 6: Using PWM Output to Convert Digital to Analog

SPPM2

Figure 7: Using PWM Output to Drive a Buzzer

MAINTENANCE/REPAIR

Upon nal installation of the Series SPPM2 Graphical User Interface Panel Meter, no

routine maintenance is required. The Series SPPM2 is not eld serviceable and is not

possible to repair the unit. Field repair should not be attempted and may void warranty.

SPPM2

PWM

PWM

0

-9.5

7.7

3.3

-

-

V

mA

mA

R

OV

R

OV

SPPM2

VDD 3.3V

1kΩ to 10k

DIG1

Figure 5: Generating a Digital Input with a Push Button

©Copyright 2017 Dwyer Instruments, Inc. Printed in U.S.A. 11/17 FR# 444322-00 Rev.1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...