Dwyer Instruments Spirahelic 7000 Series Specifications-installation And Operating Instructions

Page 1

Series 7000 Spirahelic

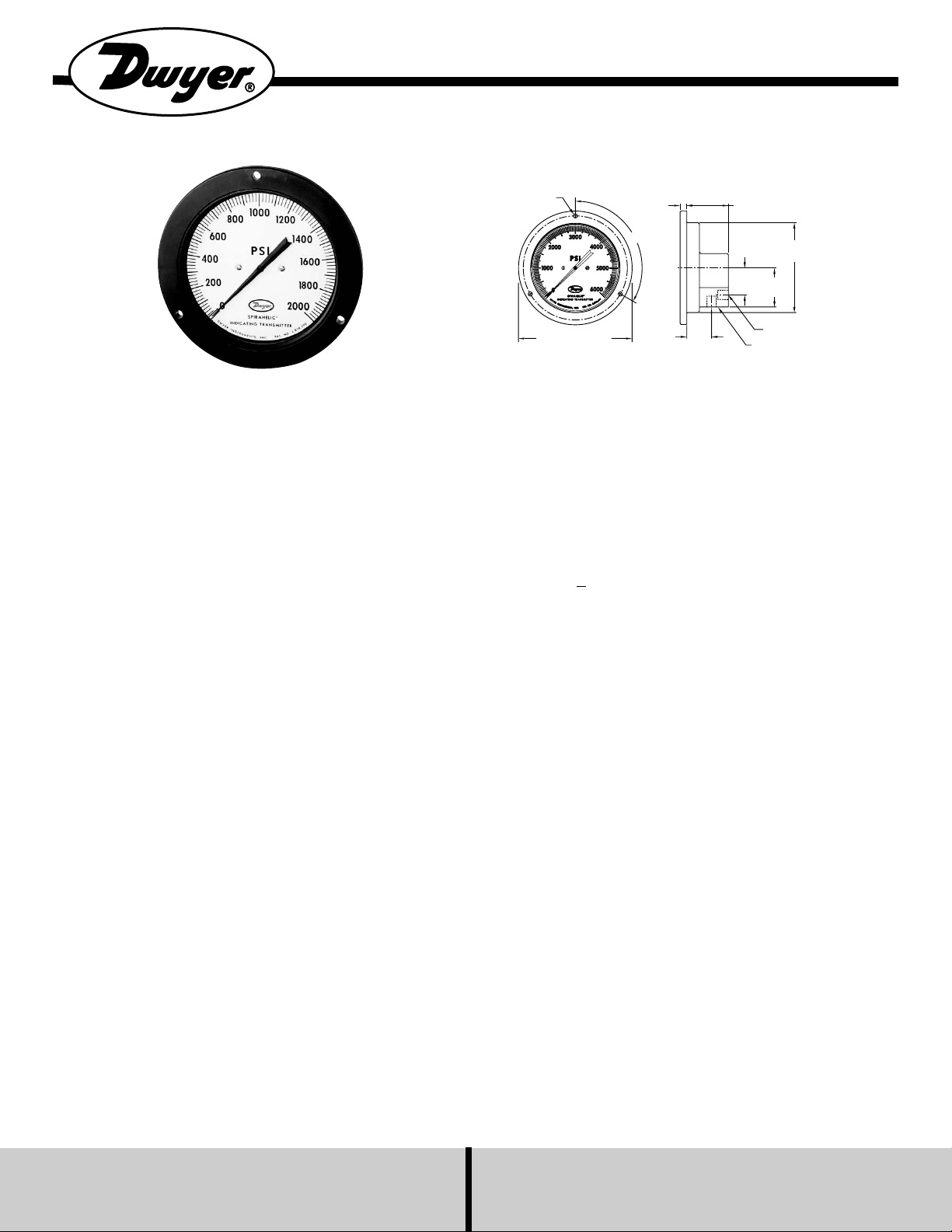

23/64

[9.13]

120° TYP

Ø5-7/8 [149.23]

(3) Ø7/32 [5.56] MOUNTING

HOLES EQUALLY SPACED ON

A 5-3/8 [136.53] BOLT CIRCLE

2-5/32

[54.76]

1-9/32

[32.54]

1 [25.40] SQUARE

CONNECTION BLOCK

1/4 FEMALE NPT

PRESSURE CONNECTION

TYP 2 PLACES

1-13/32

[35.71]

2-1/32

[51.59]

Ø4-41/64

[117.8]

®

Pressure Indicating Transmitter

Specifications - Installation and Operating Instructions

Bulletin A-33-A

The Dwyer Series 7000 Spirahelic®Pressure

Indicating Transmitter provides local indication on a

large, easy-to-read analog scale while also converting that

pressure into a standard two wire 4-20 mA output signal.

Positive pressure of compatible gases or liquids is measured with 1/2% of full scale accuracy. The gage employs a

triple helix Bourdon tube movement with direct drive design

to reduce friction and mass for exceptional responsiveness,

repeatability and accuracy. Because there are no gears,

springs, linkages or other complicated mechanisms, wear is

practically eliminated. The electrical output signal is produced by a piezoresistive pressure sensor mounted on the

pressure block. The pressure block also includes an integral

filter plug to protect the gage interior from dirt and other

particulates. Safety is assured with a solid front case design

and a rear blowout hole.

INSTALLATION

1. Select a location free from excessive vibration where the

temperature limits of 20° to 120°F (-6.7° to 49°C) will not be

exceeded. The mounting surface should be vertical to

SPECIFICATIONS

GAGE SPECIFICATIONS

Service: Compatible gases & liquids

Wetted Materials: Inconel®X-750 Bourdon Tube, Type

316L SS connection.

Housing: Black polycarbonate case and clear acrylic

cover.

Accuracy: Grade 2A (0.5% F.S.).

Stability: + 1% F.S./yr.

Pressure Limit: 150% of full scale. Gage will maintain

its specifications for overpressures up to 150% maximum

range. Normal operation should be between 25% and

75% of full scale.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

Size: 4 -1/2˝ dial face (114.3 mm), Design conforms to

ASME B40.1.

Process Connections: Two 1/4˝ female NPT field selectable back or bottom connection.

Weight: 17.1 oz. (581 g).

match the position in which all standard gages are calibrated. Avoid locations in direct sunlight which may cause

accelerated discoloration of the clear acrylic lens or where

exposure to oil mist or other airborne vapors could likewise

result in lens damage. Make sure that the case relief area on

the rear is not obstructed. This hole is designed to direct

pressure rearward in the event of failure or the Bourdon tube

element. See complete safety recommendations in this bulletin.

2. Cut a 4.94˝ (125 mm) mounting hole and drill (3) 7/32˝

(5.56 mm) bolt holes on a 5.38˝ (137 mm) bolt circle as

shown in drawing above. Attach gage to panel with (3) 3/16˝

bolts of appropriate length.

TRANSMITTER SPECIFICATIONS

Accuracy: 0.5% F.S.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

Thermal Effect: ±0.025% F.S. /°F (0.045% F.S./C°).

Power Requirements: 10-35 VDC (2 wire).

Output Signal: 4-20 mA DC.

Zero & Span Adjustments: Externally accessible

potentiometers.

Loop Resistance: DC, 0-1250 ohms.

Current Consumption: DC, 38 mA max.

Electrical Connections: Screw Terminals.

Mounting Orientation: Vertical.

Agency Approvals: CE.

DWYER INSTRUMENTS, INC.

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

Bulletin A-33-A

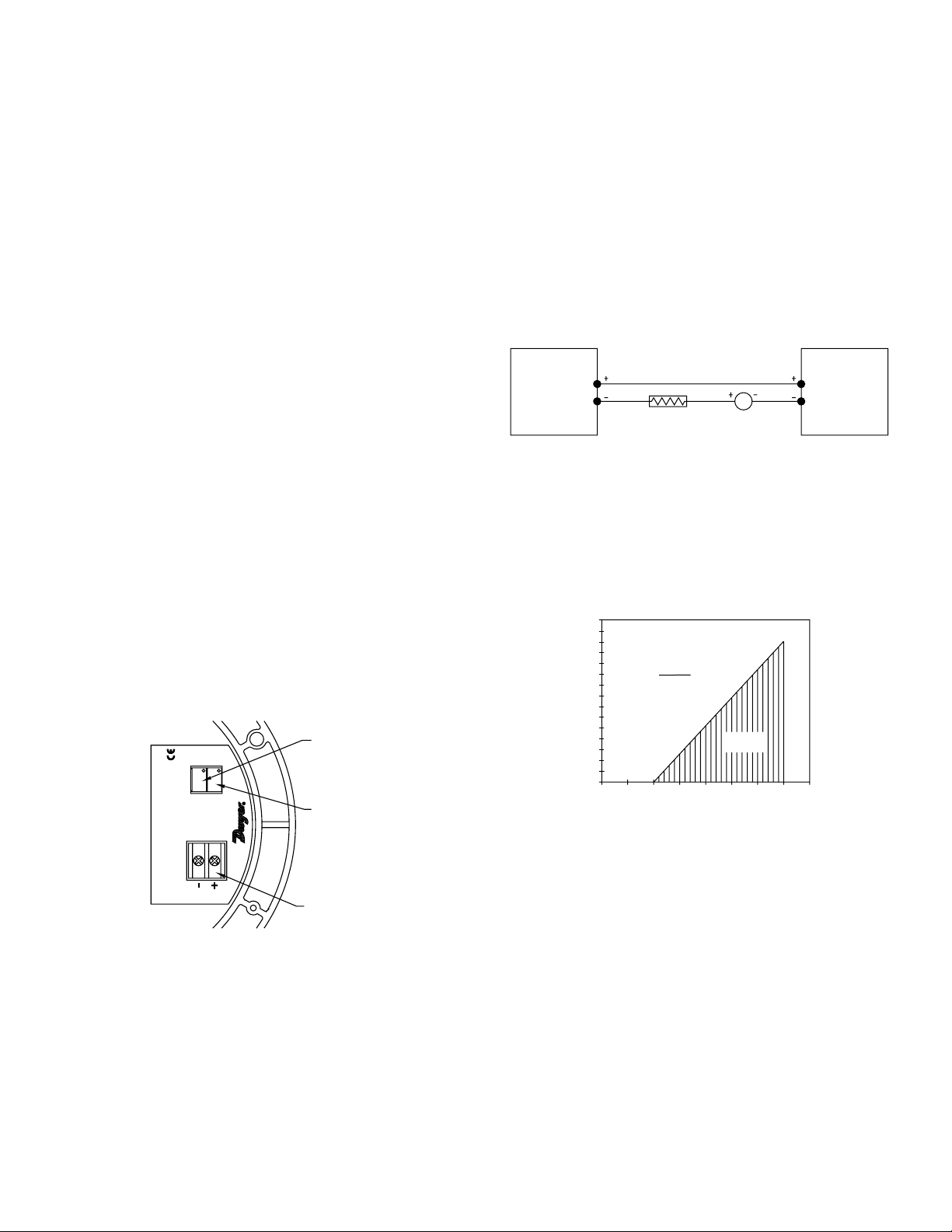

MAXIMUM VALUE (1300 OHMS)

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

50

0

5

10

15 20 25

30 35

40

OPERATING

REGION

RECEIVER RESISTANCE (OHMS)

R L MAX =

Vps-10.0

20mA DC

7000 SERIES

INDICATING

PRESSURE

TRANSMITTER

POWER

SUPPLY

10-35 VDC

mA

RECEIVER

page 2

3. Two 1/4˝ female NPT pressure connections are furnished

to allow a choice of vertical or horizontal piping. The unused

port should be plugged. Use a minimal amount of thread

sealant. Too much could block the internal pressure passage.

CAUTION: When installing fittings or pipe always us a second wrench on the 1˝ pressure block DO NOT allow torque

to be transmitted from block to the gage case.

PNEUMATIC CALIBRATION TESTER

Use a dead weight tester or certified test gage with .125%

or better accuracy. The test gage range should be comparable to the range of the Spirahelic®Pressure Indicating

Transmitter being checked. Connect the lines from the two

instruments to a tee and the third line from the tee to a controllable source of pressure. Apply pressure slowly so pressure equalizes throughout the system. Compare readings, if

gage being tested is found to need calibration, return it,

freight prepaid to the factory.

ELECTRICAL CONNECTIONS

CAUTION: Do not exceed specified supply voltage ratings.

Permanent damage not covered by warranty will result. This

unit is not designed for 120 or 240 volt AC line operation.

Electrical connections to the Series 7000 Spirahelic

Pressure Indicating Transmitter are made at the rear of the

pressure gage. Feed stripped and tinned leads to the terminal block screws shown below, refer to Figure A for locations of the terminal block, span and zero adjustments.

2-Wire Operation - A external power supply delivering 1035 VDC with minimum current capability of 40 mA DC (per

transmitter), must be used to power the control loop. See

Figure B for connection of the power supply, transmitter,

and receiver. The range of the appropriate receiver load

resistance (RL) for the DC power supply voltage available is

expressed by the formula and graph in Figure C. Shielded

two wire cable is recommended for control loop wiring. if

grounding is required use negative side of control loop after

receiver see Figure B.

®

Fig. B

7000

SPIRAHELIC INDICATING TRANSMITTER

MODEL:

RANGE:

SPAN ADJUST

ZERO

SPAN

ZERO ADJUST

TERMINAL BLOCK

PRESSURE RANGING

Each standard Series 7000 Spirahelic

Fig. C

®

Pressure Indicating

Transmitter is factory calibrated to produce a 4 mA output

signal at zero pressure and a 20 mA signal at full scale. Use

Fig. A

the following procedure to check or adjust the output signal

calibration.

1. With the unit connected to its companion receiver and

power supply, an accurate milliammeter should be inserted in

series with the current loop. A controllable pressure source

capable of achieving the necessary full scale pressure

should be connected to the pressure port of the transmitter

and teed to an accurate pressure gage or manometer. The

instrument should be calibrated in the same position in

which it will be used. Vertical mounting is recommended.

Page 3

Bulletin A-33-A

page 3

2. Apply electrical power to the system and allow it to stabilize for 10 minutes.

3. With no pressure applied to the transmitter, adjust “Zero”

control so that loop current is 4 mA.

4. Apply full scale pressure and adjust “Span” control so

that loop current is 20 mA.

5. Relieve pressure and allow transmitter to stabilize to 2

minutes.

6. Zero and Span controls are slightly interactive so repeat

steps 3 through 5 until zero and full scale pressures consistently produce loop currents of 4 and 20 mA respectively.

7. Remove milliammeter from the current loop and proceed

with final installation of the transmitter and receiver.

WIRE LENGTH

The maximum length of wire connecting transmitter and

receiver is a function of wire size and receiver resistance.

Wiring should not contribute to more than 10% of receiver

resistance to total loop resistance. For extremely long runs

(over 1000 feet), choose receivers with higher resistance’s

to minimize size and cost of connecting leads. When the

wiring length is under 100 feet, lead wire as small as 22 awg

can be used.

MULTIPLE RECEIVER INSTALLATION

An advantage of the standard 4-20 mA DC output signal

provided by the 7000 Spirahelic®Pressure Indicating

Transmitter is that any number or receivers can be connected in series in the current loop. Thus, an A-701 digital readout, an analog panel meter, a chart recorder, process controlling equipment, or any combination of these devices can

be operated simultaneously. It is necessary only that each

be equipped with a standard 4-20 mA input and proper

polarity of the input connections be observed when inserting the device into the current loop. If any of the receiving

devices displays a negative or downscale reading this indicates that the signal input leads are reversed.

MAINTENANCE

Upon final installation of the Series 7000 Spirahelic

Pressure Indicating Transmitter and the companion receiver,

no routine maintenance is required. A periodic check of the

system calibration is recommended. The Series 7000

Spirahelic®Pressure Indicating Transmitter is not field serviceable and should be returned freight prepaid, to the factory (listed below) if repair is required (field repair should not

be attempted and may void warranty).

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

®

Page 4

The following material is excerpted from a standard

titled Gauges-Pressure Indicating Dial Type-

Elastic Element (ANSI/ASME B40.1-1985) as published by The American Society of Mechanical

Engineers, 345 East 47th St. New York, NY 10017.

This information is furnished to assist the user of Dwyer

®

Spirahelic

for the intended application and conditions.

4 SAFETY

4.1 Scope

mation to guide users, suppliers, and manufacturers

toward minimizing the hazards that could result from

misuse or misapplication of pressure gauges with elastic elements. The user should become familiar with all

sections of this Standard, as all aspects of safety cannot be covered in this Section. Consult the manufacturer or supplier for advice whenever there is uncertainty about the safe application of a pressure gauge.

4.2 General Discussion

ning and careful selection and installation of gauges

into a pressure system. The user should inform the

supplier of all conditions pertinent to the application

and environment so that the supplier can recommend

the most suitable gauge for the application.

pressure gauges has been excellent. Injury to personnel and damage to property have been minimal. In

most instances, the cause of failure has been misuse or

misapplication.

gauges is subjected to high internal stresses, and

applications exist where the possibility of catastrophic

failure is present. Pressure regulators, chemical

(diaphragm) seals, pulsation dampers or snubbers,

syphons, and other similar items, are available for the

use in these potentially hazardous systems. The hazard

potential increases at higher operating pressure.

tially hazardous and must be carefully evaluated:

atoms

flammable mixture or medium

dentally applied

could result in hazardous internal contamination or

where lower pressure gauges could be installed in

higher pressure systems

uids or gases)

media having known or uncertain corrosive effects or

known to be radioactive, random or unique destructive

phenomena can occur. In such cases the user should

always furnish the supplier or manufacturer with information relative to the application and solicit his advice

prior to installation of the gauge.

can cause pressure element failure with very violent

effects, even to the point of completely disintegrating or

melting the pressure gauge. Violent effects are also

produced when failure occurs due to:

heat sources

caused by heat sources such as fires

ed to produce violent effects.

are four basic modes of elastic element failure, as follows.

pressure induced stress generally occurs from the

inside to the outside along a highly stressed edge

radius, appearing as a small crack that propagates

along the edge radius. Such failures are usually more

critical with compressed gas media than with liquid

media.

slowly so case pressure buildup can be averted by providing pressure relief openings in the gauge case.

However, in high pressure elastic elements where the

yield strength approaches the ultimate strength of the

element material, fatigue failure may resemble explosive failure.

gages in properly evaluating their suitability

This Section of the Standard presents certain infor-

4.2.1 Adequate safety results from intelligent plan-

4.2.2 The history of safety with respect to m use of

4.2.3 The pressure sensing element in most

4.2.4 The following systems are considered poten-

(a) compressed gas systems

(b) oxygen systems

(c) systems containing hydrogen or free hydrogen

(d) corrosive fluid systems (gas and liquid)

(e) pressure systems containing any explosive or

(f) steam systems

(g) nonsteady pressure systems

(h) systems where high overpressure could be acci-

(i) systems wherein interchangeability of gauges

(j) systems containing radioactive or toxic fluids (liq-

(k) systems installed in a hazardous environment

4.2.5 When gauges are to be used in contact with

4.2.6 Fire and explosions within a pressure system

(a) hydrogen enbrittlement

(b) contamination of a compressed gas

(c) formation of acetylides

(d) weakening of soft solder joints by steam or other

(e) weakening of soft soldered or silver brazed joints

(f) corrosion

(g) fatigue

(h) mechanical shock

(i) excessive vibration

Failure in a compressed gas system can be expect-

4.2.7 Modes of Elastic Element Failure. There

4.2.7.1 Fatigue Failure. Fatigue failure caused by

Fatigue cracks usually release the media fluid

A restrictor placed in the gauge pressure inlet will

reduce pressure surges and restrict fluid flow into the

partially open Bourdon tube.

4.2.7.2 Overpressure Failure. Overpressure fail-

ure is caused by the application of internal pressure

greater than the rated limits of the elastic element and

can occur when a low pressure gauge is installed in a

high pressure port of system. The effects of overpressure failure, usually more critical in compressed gas

systems than in liquid filled systems, are unpredictable

and may cause parts to be propelled in any direction.

Cases with pressure relief openings will not always

retain expelled parts.

Placing a restrictor in the pressure gauge inlet will

not reduce the immediate effect of failure, but will help

control flow of escaping fluid following rupture and

reduce potential of secondary effects.

It is generally accepted that solid front cases with

pressure relief back will reduce the possibility of parts

being projected forward in the event of failure.

The window alone will not provide adequate protection against internal case pressure buildup, and can

be the most hazardous component.

4.2.7.3 Corrosion Failure. Corrosion failure

occurs when the elastic element has been weakened

through the attack by corrosive chemicals present in

either the media inside or the environment outside it.

Failure may occur as pinhole leakage through the elements walls or early fatigue failure due to stress cracking brought about by chemical deterioration or embrittlement of the material.

A chemical (diaphragm) seal should be considered

for use with pressure media that may have a corrosive

effect on the elastic element.

4.2.7.4 Explosive Failure. Explosive failure is

caused by the release of explosive energy generated

by a chemical reaction such as can result with adiabatic compression of oxygen occurs in the presence of

hydrocarbons. It is generally accepted that there is no

known means of predicting the magnitude or effects of

this type of failure. For this mode of failure, a solid wall

or partition between the elastic element and the window will not necessarily prevent parts being projected

forward.

4.2.8 Pressure Connection. See recommenda-

tions in para. 3.3.4.

4.3 Safety Recommendations.

4.3.1 Operating Pressure. The pressure gauge

selected should have a full scale pressure such that the

operating pressure occurs in the middle half (25 to

75%) of the scale. The full scale pressure of the gauge

selected should be approximately two times the intended operating pressure.

Should it be necessary for the operating pressure to

exceed 75% of full scale, contact the supplier for recommendations.

This does not apply to test, retarded, or suppressed scale gauges.

4.3.2 Use of Gauges Near Zero Pressure. The

use of gauges near zero pressure is not recommended

because the accuracy tolerance may be a large percentage of the applied pressure. If, for example, a

0/100 psi Grade B gauge is used to measure 6 psi, the

accuracy of measurement will be ±50% of the applied

pressure. In addition, the scale of a gauge is often laid

out with takeup, which can result in further inaccuracies when measuring pressures that are a small percentage of the gauge span.

For the same reasons, gauges should not be used

for the purpose of indicating that the pressure in a tank,

autoclave, or other similar unit has been completely

exhausted to atmospheric pressure. Depending on the

accuracy and the span of the gauge and the possibility that takeup is incorporated at the beginning of the

scale, hazardous pressure may remain in the tank even

though the gauge is indicating zero pressure. A venting

device must be used to completely reduce the pressure before unlocking covers, removing fittings, or performing other similar activities.

4.3.3 Compatibility With the Pressure Medium.

The elastic element is generally a thin walled member,

which of necessity operates under high stress conditions and must, therefore, be carefully selected for

compatibility with the pressure medium being measured. None of the common element materials is

impervious to every type of chemical attack. The

potential for corrosive attack is established by many

factors, including the concentration, temperature, and

contamination of the medium. The user should inform

the gauge supplier of the installation conditions so that

the appropriate element materials can be selected.

4.3.4 In addition to the factors discussed above,

the capability of a pressure element is influenced by the

design, materials, and fabrication of the joints between

its parts.

Common methods of joining are soft soldering, silver brazing, and welding. Joints can be affected by

temperature, stress, and corrosive media. Where application questions arise, these factors should be considered and discussed by the user and manufacturer.

4.3.5 Some special applications require that the pressure element assembly have a high degree of leakage

integrity. Special arrangement should be made

between manufacturer and used to assure that the

allowable leakage rate is not exceeded.

4.3.6 Cases

4.3.6.1 Cases, Solid Front. It is generally

accepted that a solid front case per para. 3.3.1 will

reduce the possibility of parts being projected forward

in the event of elastic element assembly failure. An

exception is explosive failure of the elastic element

assembly.

4.3.6.2 Cases, Liquid Filled. It has been gener-

al practice to use glycerine or silicone filling liquids.

However, these fluids may not be suitable for all applications. They should be avoided where strong oxidizing agents including, but not limited to, oxygen, chlorine, nitric acid, and hydrogen peroxide are involved. In

the presence of oxidizing agents, potential hazard can

result from chemical reaction, ignition, or explosion.

Completely fluorinated or chlorinated fluids, or both,

may be more suitable for such applications.

The user shall furnish detailed information relative to

the application of gauges having liquid filled cases and

solicit the advice of the gauge supplier prior to installation.

Consideration should also be given to the instantaneous hydraulic effect that may be created by one of

the modes of failure outlined in para. 4.2.7. The

hydraulic effect due to pressure element failure could

cause the window to be projected forward even when

a case having a solid front is employed.

4.3.7 Restrictor. Placing a restrictor between the

pressure connection and the elastic element will not

reduce the immediate effect of failure, but will help control flow of escaping fluid following rupture and reduce

the potential of secondary effects.

4.3.8 Specific Service Conditions

4.3.8.1 Specific applications for pressure gauges

exist where hazards are known. In many instances,

requirements for design, construction, and use of

gauges for these applications are specified by state or

federal agencies or Underwriters Laboratories, Inc.

Some of these specific service gauges are listed below.

The list is not intended to include all types, and the user

should always advise the supplier of all application

details.

4.3.8.2 Acetylene Gauges. A gauge designed

to indicate acetylene pressure. It shall be constructed

using materials that are compatible with commercially

available acetylene. The gauge may bear the inscrip-

indicate ammonia pressure and to withstand the corrosive effects of ammonia. The gauge may bear the

inscription AMMONIA on the dial. It may also include

the equivalent saturation temperature scale markings

on the dial.

indicate the pressure of corrosive or high viscosity fluids, or both. The primary material(s) in contact with the

pressure medium may be identified on the dial. It may

be equipped with a chemical (diaphragm) seal, pulsation damper, or pressure relief device, or a combination. These devices help to minimize potential damage

to personnel and property in the event of gauge failure.

They may, however, also reduce accuracy of sensitivity,

or both.

indicate oxygen pressure. Cleanliness shall comply with

Level IV (see Section 5). The dial shall be clearly

marked with a universal symbol and/or USE NO OIL in

red color (see para. 6.1.2.1).

4.4 Reuse of Pressure Gauges

moved from one application to another. Should it be

necessary, however, the following must be considered.

quences of incompatibility can range from contamination to explosive failure. For example, moving an oil service gauge to oxygen service can result in explosive

failure.

involve pressure pulsation that has expended most of

the gauge life, resulting in early fatigue in the second

installation.

ment assembly in the first installation may be sufficient

to cause early failure in the second installation.

gauge, all guidelines covered in the Standard relative to

application of gauges should be followed in the same

manner as when a new gauge is selected.

tion ACETYLENE on the dial.

4.3.8.3 Ammonia Gauge. A gauge designed to

4.3.8.4 Chemical Gauge. A gauge designed to

4.3.8.5 Oxygen Gauge. A gauge designed to

It is not recommended that pressure gauges be

4.4.1 Chemical Compatibility. The conse-

4.4.2 Partial Fatigue. The first installation may

4.4.3 Corrosion. Corrosion of the pressure ele-

4.4.4 Other Considerations. When reusing a

©Copyright 2003 Dwyer Instruments, Inc. Printed in U.S.A. 4/03 FR# 17-440819-00 Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...