Page 1

Series ZV2 Two-Way Detachable Zone Valves

®

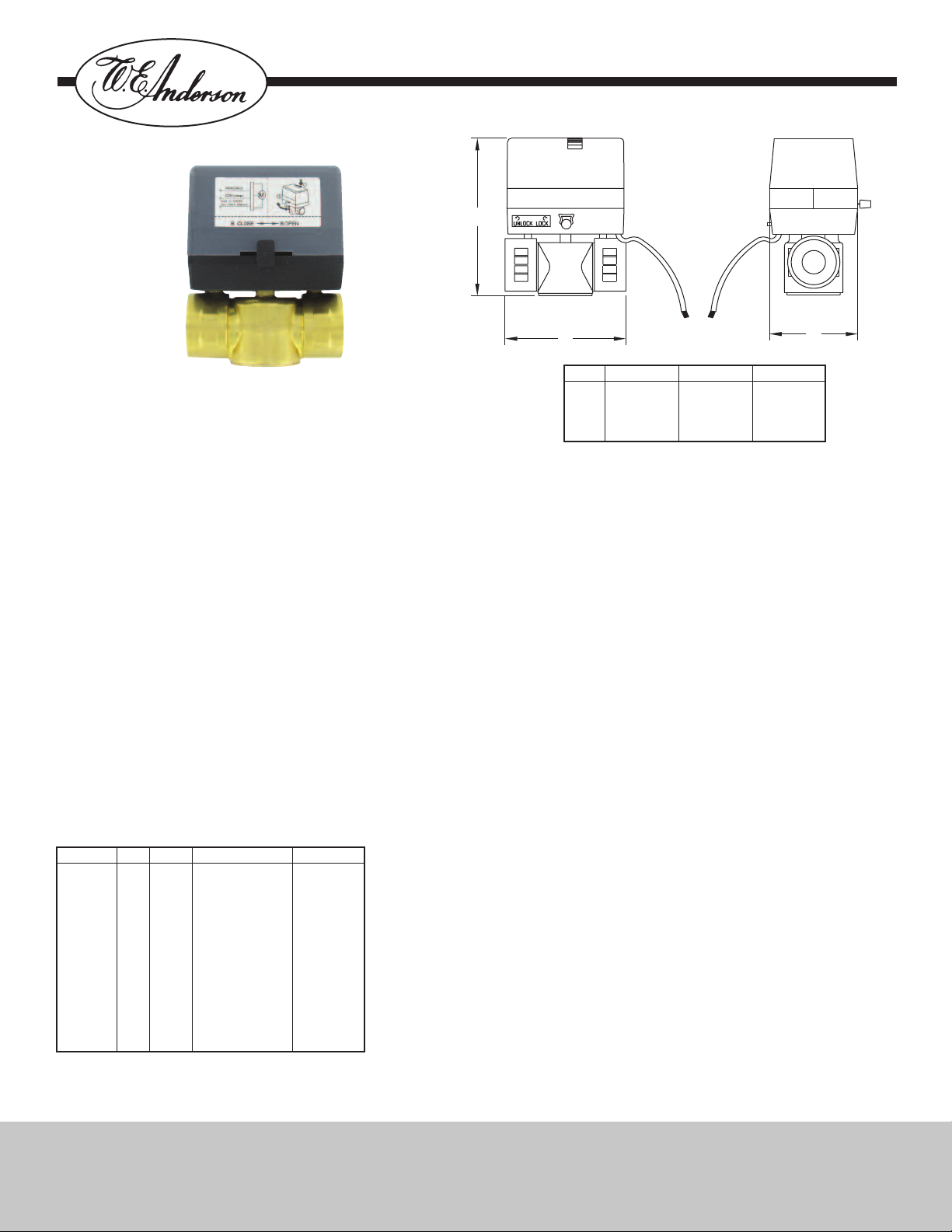

A

B

C

Specifications - Installation and Operating Instructions

Bulletin V-25

ZV2 Series Zone Valves are ideal for flow control in hot and cold

water HVAC systems. Zone valves are typically used in conjunction with

a thermostat to control room temperature. The ZV2 is electrically driven

to open and or close via a bidirectional motor. Units are available in 1/2˝,

3/4˝, 1˝, and 1-1/4˝ sizes with 24 or 120 VAC power supply. Easy to

install, these units are direct replacements for competitor units. Manual

override lever is easily accessible externally. Consult factory for 220 VAC

power supply, optional auxiliary switches, and BSP or sweat

connections.

ZV2 models come in floating or modulating input types. Floating units

are controlled directly from the thermostat and modulation units accept

either a 4 to 20 mA or 0 to 10 VDC input. Modulating models include a

motor time out feature that automatically turns off the motor after the full

stroke of the valve to increase motor life. Featured in the ZV2 is a

detachable actuator that is easily removable by a turn key allowing the

valve body to be installed without the actuator. Actuator housing is

constructed of fire resistant plastic.

Features:

• Manual override lever

• Removable actuator

• Motor time out for controllers that do not automatically turn off their

signal after the full stroke of the valve

A [in (mm)]

Size

4.53 (115)

1/2˝

4.53 (115)

3/4˝

4.61 (117)

1˝

5.16 (131)

1-1/4˝

SPECIFICATIONS

Service: Compatible fluids.

Body: 2-way, normally closed.

Line Size: 1/2˝ to 1-1/4˝.

End Connections: Female NPT (optional BSP, sweat connections).

Pressure Limits: Maximum: 300 psi (20.7 bar); Close-off: 43 psi (2.96

bar).

Temperature Limits: Ambient: 32 to 104°F (0 to 40°C); Process: 37 to

201°F (3 to 94°C).

Wetted Materials: Brass, stainless steel, NBR.

Flow Characteristic: Quick opening.

Input: Floating: 3-wire, Modulating: 0 to 10 VDC or 4 to 20 mA (24

VAC power only).

Power Requirements: 120 VAC or 24 VAC, ±10%, 50/60 Hz. (Optional

220 VAC).

Power Consumption: Floating: 2.5 VA; Modulating: 3.5 VA.

Electrical Connection: 18 AWG jacketed, 9˝ (228 mm) long.

Cycle Time: Opening time: 50 to 65 seconds.

Enclosure Rating: General purpose.

Housing Material: PVC and polycarbonate.

B [in (mm)]

3.15 (80)

3.50 (89)

3.66 (93)

4.13 (105)

C [in (mm)]

2.64 (67)

2.64 (67)

2.64 (67)

2.64 (67)

Model

ZV20212

ZV20214

ZV20224

ZV20312

ZV20314

ZV20324

ZV20412

ZV20414

ZV20424

ZV20512

ZV20514

ZV20524

Cv

3.8

3.8

3.8

3.8

3.8

3.8

8.0

8.0

8.0

11.7

11.7

11.7

Size

1/2˝

1/2˝

1/2˝

3/4˝

3/4˝

3/4˝

1˝

1˝

1˝

1-1/4˝

1-1/4˝

1-1/4˝

Supply Voltage

120 VAC

24 VAC

24 VAC

120 VAC

24 VAC

24 VAC

120 VAC

24 VAC

24 VAC

120 VAC

24 VAC

24 VAC

W.E. ANDERSON DIV., DWYER

INSTRUMENTS, INC.

Input

Floating

Floating

Modulating

Floating

Floating

Modulating

Floating

Floating

Modulating

Floating

Floating

Modulating

Page 2

Instructions for Operation and Use

1. Assembly and disassembly of the actuator and valve body fit the

square axis of the valve body with the square hole in the actuator and

insert (make sure that another axis will not touch the actuator). Rotate

the actuator or valve body, make another axis of the valve body aim at

the corresponding hole in the actuator. Use a little force to press the

actuator. Turn the locking key clockwise to lock the actuator into place.

The assembly of the actuator and valve body is finished. When

disassembling, turn the locking key counterclockwise, and use a little

force to pull out the actuator in the opposite direction used during

assembly.

2. 2-way valves are installed as Figure 2 and 3 shows. For high building,

pressure–reducing valve should be installed on branch pipe at ground

floor.

3. Note: When the valve is mounted on a horizontal pipe, the angle must

be positioned less than 85° (see Figure 4). When the valve is mounted

on a vertical pipe, prevent from dripping.

4. Manual operating lever: The valve is unlocked when you press the

manual operating button. Moving the manual lever can make the valve

return. When releasing the button, the valve will be locked again

automatically.

5. When installing a 2-way valve, the flow direction is from end “B” to “A”.

For a normal-open valve, it is from end “A” to “B”. In both situations, the

valve closing direction is opposite.

Electronic Card Setting Diagram

MAINTENANCE

Upon final installation of the Series ZV2 Two-Way Detachable Zone

Valves, no routine maintenance is required. A periodic check of the

system calibration is recommended. The Series ZV2 is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant application notes.

Contact customer service to receive a return good authorization number

before shipping.

Fig. 4

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 9/14 FR # R3-443459-20 Rev. 3

W.E. ANDERSON DIV., DWYER

INSTRUMENTS, INC.

Loading...

Loading...