Page 1

F

L

FULL OPEN

®

E

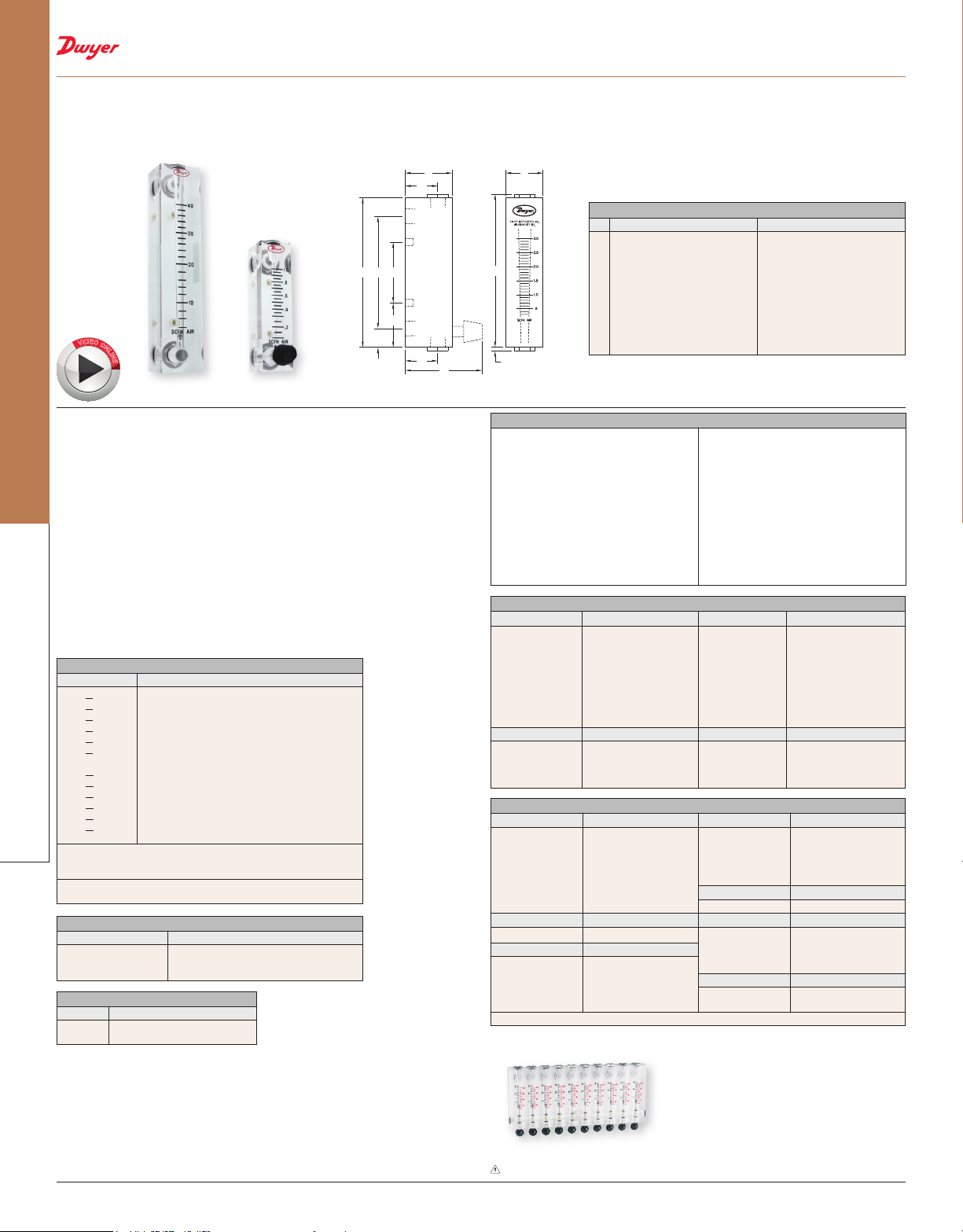

SERIES VF

VISI-FLOAT® ACRYLIC FLOWMETERS

FLOW

Hot-Stamped Scales, Multi-Angle Views of Flow

C

A

B

E

E

O

D

I

V

O

N

L

I

N

Model VFB Model VFA-SSV

D

M

DIMENSIONS - FLOWMETER

Model VFA Model VFB

A

4 [101.6]

B

3 [76.20]; 1/8 NPT conn.

C

K

M

I

N

1-5/8 [41.28]; 10-32 thd

D

1/2 [12.70]

E

1-3/16 [30.16]

F

1-1/4 [31.75]

I

2-1/16 [52.39]; Open

K

4-3/32 [104.0]

L

1 [25.40]

M

7/8 [22.23] ; 1/8 NPT

N

3/32 [2.381]

6-1/2 [165.1]

5-1/2 [139.7]; 1/8 NPT conn.

3-1/2 [88.90]; 10-32 thd

1/2 [12.70]

1-1/2 [38.10]

1-1/4 [31.75]

2-1/16 [52.39] ; Open

6-11/16 [169.9]

1-3/8 [34.93]

7/8 [22.23]; 1/8 NPT

3/32 [2.381]

The Series VF Visi-Float® Acrylic Flowmeters are a line of direct reading, precision

machined, clear acrylic body owmeters suitable for both gas and liquid applications.

The fabrication of the Visi-Float® Flowmeters is backed by over 60 years of experience

in acrylic instrument machining. This Series consists of 2˝ (51 mm) and 4˝ (102 mm)

scales with optional precision metering valves.

FEATURES/BENEFITS

• Bodies are cut and precision machined from solid, clear acrylic blocks allowing for

complete visual inspection

• White background allows for better visibility of the oat increasing reading accuracy

• Direct reading scales are hot stamped into the plastic eliminating the need for

troublesome conversions and increasing product operating life

• Precision machined tapered bore enables high repeatability

• Low installation costs with back or end connection options with metal mounting

inserts that can be supported directly by system piping

APPLICATIONS

• Medical equipment

• Laboratory equipment

• Air samplers

• Gas analyzers

• Pollution monitors

• Chemical injectors

• Cabinet purging

MODEL CHART

Model Description

VFA-X

VFA-X-SS

VFA-X-BV+

Flowmeters,

VFA-X-SSV+

VFA-X-EC

Variable Area & In-Line

VFA-X-EC-SS

VFB-X

VFB-X-SS

VFB-X-BV+

VFB-X-SSV+

VFB-X-EC

VFB-X-EC-SS

How To Order: Series—Range No. (“X”)—Valve—Option

Example: VFA-9-BV

(Series VFA with 20-200 SCFH air range & brass valve)

+Valve is designed for ow adjustment only, not intended to

be used as an open/shut-off valve.

Standard VFA

VFA with stainless metal wetted parts

VFA with brass valve

VFA with stainless steel valve

VFA with end connections

VFA with end connections and stainless

steel metal wetted parts

Standard VFB

VFB with stainless metal wetted parts

VFB with brass valve

VFB with stainless steel valve

VFB with end connections

VFB with end connections and stainless

steel metal wetted parts

OPTIONS

To order add sufx: Description

-NIST

-PF

-VIT

NIST traceable calibration certicate

Red ABS plastic pointer ag

Fluoroelastomer O-rings

ACCESSORIES

Model Description

RKA

RK-VFB

Regulator kit for Series VFA

Regulator kit for Series VFB

SPECIFICATIONS

Service: Compatible gases & liquids.

Wetted Materials: Body: Acrylic

plastic; O-ring: Buna-N (uoroelastomer

available); Metal parts: Nickel plated

brass standard, SS optional; Float:

SS, black glass, aluminum, K monel

depending on range.

Temperature & Pressure Limits:

Without valve: 100 psig (6.9 bar) @

150°F (65°C); 150 psig (10 bar) @ 100°F

(38°C); With valve: 100 psig (6.9 bar) @

120°F (48°C).

Accuracy: VFA = 5% of FS; VFB = 3%

of FS.

Process Connection: 1/8˝ female

NPT. VFB ranges 85 and 86 have 1/4˝

NPT back connections or 3/8˝ NPT end

connections. These ranges not available

with brass valves.

Scale Length: VFA 2˝ typical length;

VFB 4˝ typical length.

Mounting Orientation: Mount in vertical

position.

Weight: VFA: 4.0 to 4.8 oz (.11 to .14

kg); VFB: 7.2 to 8.8 oz (.20 to .25 kg).

Agency Approvals: Meets the technical

requirements of EU Directive 2011/65/

EU (RoHS II).

RANGE CHART - VFA 2˝ SCALE - POPULAR RANGES

Range No. SCFH Air Range No. LPM Air

1

2

3

4

5

6

7

8

9

.1 to 1

.2 to 2

.6 to 5

1 to 10

2 to 20

4 to 30

5 to 50

10 to 100

20 to 200

21

22

23

24

25

26

27

.06 to 0.5

.15 to 1

.6 to 5

1 to 10

3 to 25

6 to 50

10 to 100

Range No. CC/Min. Water Range No. GPH Water

32

33

34

6 to 50

10 to 100

20 to 200

41

42

43

44

.6 to 5

2 to 10

3 to 20

8 to 40

RANGE CHART - VFB 4˝ SCALE - POPULAR RANGES

Range No. SCFH Air Range No. LPM Air

50

91*

51*

52

53*

54*

55*

.3 to 3

1 to 10

2 to 20

4 to 40

10 to 100

10 to 150

20 to 200

65

66

67

68

69

.2 to 4

1 to 10

1 to 20

3 to 30

4 to 40

Range No. CC/Min. Water

82 2 to 30

Range No. SCFM Air Range No. GPH Water

90 .3 to 3 80*

Range No. CC/Min. Air

60 100 to 1000

83*

84

81

.5 to 12

1 to 20

6 to 40

6 to 60

Range No. GPM Water

85

86

.2 to 2

.6 to 5

*For dual range models in English and Metric add “D” to end of Range No.

OEM specials

Special owmeter designs can be supplied to meet a wide range of requirements and

specic applications. These include: on-off plunger and push-to-test valves, special

gas or uid calibration, special ranges, scales, name brand or other identication.

Pointer ags can be furnished for instant visual reference. For specic information,

please supply an outline of your requirements.

DWYER INSTRUMENTS, INC. | 248

Special multi-column Visi-Float® owmeters

Perfect for OEM applications, Visi-Float®

Flowmeters can be custom made with up to 10

columns in a single block of acrylic plastic.

Available with or without valves. Consult factory

for more information.

USA: California Proposition 65

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Loading...

Loading...