Page 1

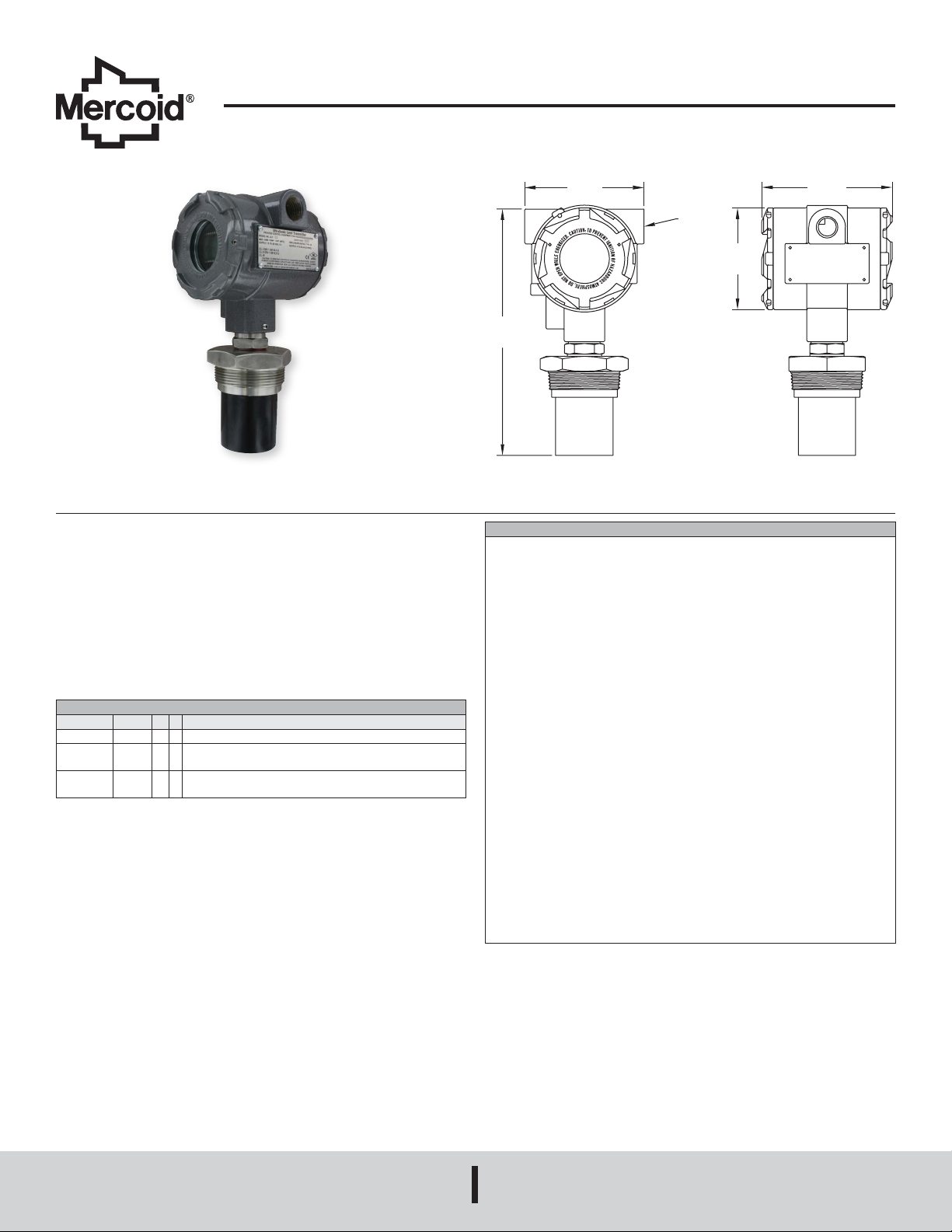

Series ULT Ultrasonic Level Transmitter

3 29/32

[204.79]

4 9/32

By Dwyer

Specications - Installation and Operating Instructions

Bulletin L-45

Series ULT Ultrasonic Level Transmitter provides reliable, accurate, noncontact

measurement of liquid levels. Ultrasonic non-contact technology offers no moving parts

to wear, jam, corrode, or get coated like contact technologies. Mapping software makes

effective measuring surface only a 3˝ diameter column. No concerns with ladders,

pipes, or other tank intrusions in the remaining sound cone. Unit is FM approved

explosion-proof making it ideal for use in hazardous locations. The ULT features easy

programming with 6 digit LCD display and simple menu structure. Output range is

adjustable with choices of inputting tank dimensions or just ll and empty the tank

while calibrating and it automatically scales to levels it senses. Window cover allows

early viewing of display. Failsafe output options and diagnostic capabilities makes the

ULT a good choice for critical applications.

MODEL CHART

Example ULT 1 1 ULT-11

Series ULT Ultrasonic level transmitter

Range 1224.6´ (7.5 m)

Options 122˝ NPT male process with 1/2˝ NPT female conduit

32.8´ (10 m)

2˝ BSPT male process with M20 conduit

[99.21]

2X 1/2 NPT

ø3 21/64

[84.53]

8 1/16

SPECIFICATIONS

Service: Compatible uids. Not for use with powder and bulk solids.

Wetted Materials: Sensor: PVDF; Process connection: 303 SS.

Ranges: 24.6´ (7.5 m), 32.8´ (10 m).

Accuracy: ±0.2% of maximum range.

Resolution: 0.079˝ (2 mm).

Blind Zone: Under 8˝ (20 cm).

Beam Width: 3˝ (7.6 cm) diameter.

Temperature Limits: Ambient: -40 to 140°F (-40 to 60°C); Process: -4 to 140°F

(-20 to 60°C).

Temperature Compensation: -40 to 140°F (-40 to 60°C).

Pressure Limits: 30 psi (2 bar) up to 25°C (77°C). Above 25°C (77°F), rating

decreases 1.667 psi per 1°C increase. See pressure and temperature chart.

Power Requirement: 18-28 VDC (two-wire).

Output Signal: 4-20 mA or 20-4 mA (two-wire).

Max. Loop Resistance: 250 Ω at 24 VDC.

Electrical Connections: Screw terminal.

Conduit Connection: 1/2˝ NPT female (two) or M20.

Process Connection: 2˝ NPT male or BSPT.

Enclosure Rating: Weather-proof meets NEMA 4X, explosion-proof rated Class I,

Div. 1, Groups B, C, D; Class II/III, Div. 1, Groups E, F, G.

Mounting Orientation: Vertical.

Failsafe: On lost echo after 30 s, user selectable to 4, 20, 21, 22 mA or last signal.

Memory: Non-volatile.

Display: 6 character LCD.

Units: In, cm, ft, m, percent.

Memory: Non-volatile.

Programming: 4 button.

Weight: 4.0 lb (1.8 kg).

Agency Approvals: CE, FM.

[108.74]

MERCOID

A DIVISION OF

DWYER INSTRUMENTS, INC.

Page 2

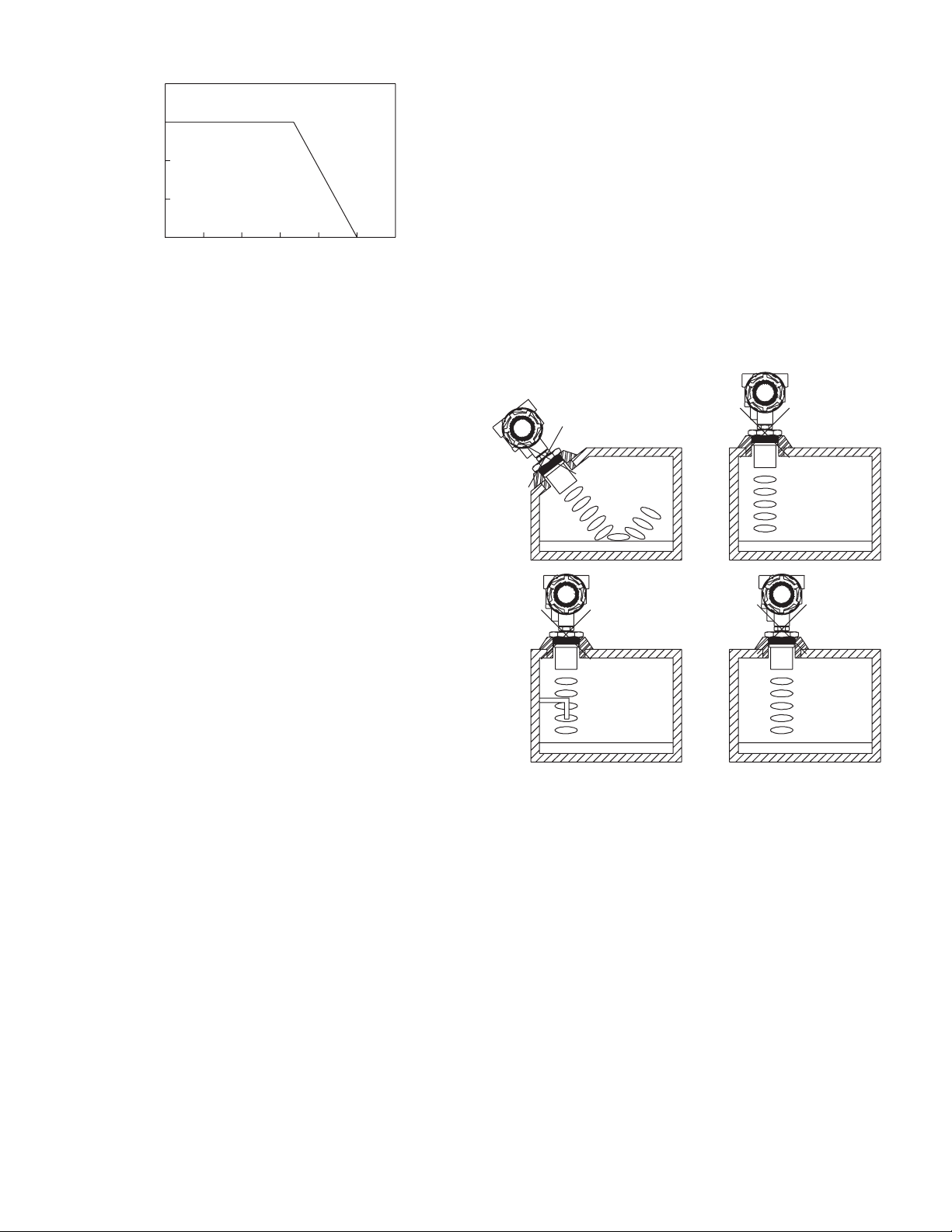

TEMPERATURE/PRESSURE DERATING

TEMPERATURE °C

OPERATING PRESSURE PSI

INSTALLATION

S

40

UNACCEPTABLE

30

20

ACCEPTABLE

10

RANGE

RANGE

Unpacking

Remove the ULT from the shipping carton and inspect for damage. If damage is found,

notify the carrier immediately.

Materials

The ULT may be used to detect level of a variety of materials. Since the sensing

technology is non-contact it is well suited for corrosive, coating, slurry, or sticky media.

The hazardous approval rating also makes the unit ideal for use with hazardous

rated applications. Please see the specications section for hazardous approval

classications.

0

-40 -20 0 20 40 60 80

OPERATING PRINCIPLE

Ultrasound is sound with a frequency greater than the upper limit of human hearing;

approximately 20 kilohertz. The ULT contains an ultrasonic transducer and a

temperature sensing element. The ultrasonic transducer transmits ultrasound wave

pulses through air directed towards the material of which the level is desired. The

ultrasound waves then reect off of the material as an echo and travel back to the

transducer. The level of the material is determined by the transit time of the ultrasound

wave pulse from the sensor to material and for the echo to come back to the sensor.

The speed of sound through air is sensitive to the air temperature. The ULT uses the

temperature sensing element to compensate for air temperature changes.

The ULT incorporates patented surface processing technology and adaptive signal

processing. Surface processing technology lters out all signal obstructions that may

be in the tank creating an effecting beam diameter of only 3˝ (7.6 cm). This beam

diameter is a straight column and not cone shaped like competitor units. Adaptive signal

processing continuously optimizes sensor power, output ltering, and environmental

noise rejection.

Mounting Location

• The process temperature and ambient temperature must be within the specied

limits.

• The probe must be located away from tank inlets or chutes where material may fall

on the probe during lling or emptying.

• The probe must be located at least 3˝ (7.6 cm) away from the tank side wall.

• The probe cannot be used in vacuum applications.

• The probe must be installed vertically and perpendicular to the media surface.

• Make sure the covers are accessible to allow for programming, wiring, and ability

to see the display.

DO NOT INSTALL AT

AN ANGLE RELATIVE

TO THE LIQUID

DO NOT INSTALL

WITH OBJECTS

IN THE BEAM

DO NOT INSTALL

WITHIN THREE INCHE

OF TANK SIDE WALL

DO NOT INSTALL

IN APPLICATIONS

WITH VACUUM

VACUUM

Figure 1: Unsuitable mounting locations

Page 3

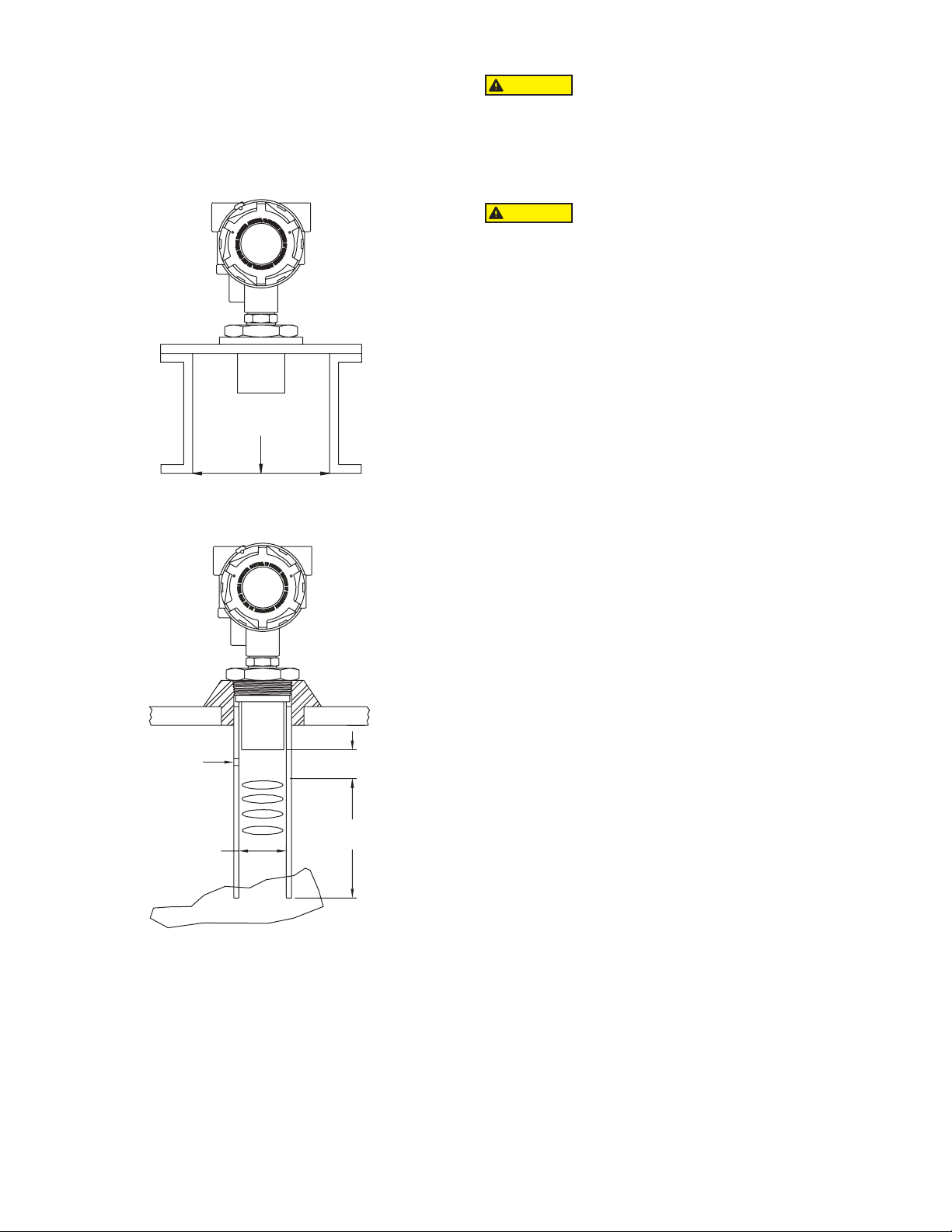

MOUNTING FITTING

VENTILL

LIQUID LEVEL

DIAMETER

RISER

Fittings should be selected that minimize the installation height of the transmitter so

that mounting hardware does not interfere with the acoustic signal. If the installation

does require a riser then the transmitter may be elevated up to 12˝ (30 cm) in a 6˝ (15

cm) diameter riser, 8˝ (20 cm) in a 4˝ (10 cm) diameter riser, and 3˝ (7.6 cm) in a 2˝ (5

cm) diameter riser, see Figure 2. A stand pipe may be used to dampen turbulence or

separate surface foam. Use a minimum 3˝ diameter pipe and cut to the desired length

of the transmitter span with a 45° notch at the bottom. A ventillation hole needs to be

created at the top of the pipe within the 8˝ (20 cm) blind zone, see Figure 3.

HEIGHT

INNER

ELECTRICAL CONNECTION

CAUTION

designed for AC voltage operation.

Note: Installation must be made in accordance with local codes and regulations. When

shing wire through the conduit connection do not allow the wire to touch or press on

components on the boards. Damage to the circuitry may result. Make sure that the

wire is routed so it will not interfere with the calibration switches.

CAUTION

within 18˝ (45.7 cm) of conduit entry. Disconnect power before opening, servicing,

programming, installing, or removing.

The ULT provides two 1/2˝ NPT female ports for conduit connection. The conduit

connection must be made such that condensation is not allowed to enter the sensor

housing. If necessary install a conduit breather drain in a separate conduit body to

prevent buildup of moisture. If nonmetallic conduit is used the protective ground may

be connected to the internal ground connection screw.

The ULT transmitter is designed as a two wire 4-20 mA device. Connection to the

board is through a two pin terminal block. The circuitry is polarized so the positive must

be connected to terminal 1 and the negative must be connected to terminal number

2. It is recommended that shielded twisted pair wire be used if the potential exists

for interference from external noise sources. Ground the shield at the case using the

internal ground screw and leave the other end of the shield open. Do not use the shield

as one of the current loop conductors.

Do not exceed the specied supply voltage rating. Permanent

damage not covered by the warranty may result. This unit is not

Hazardous Area Use: Plug any unused conduit openings.

Plug must engage a minimum of 5 threads. Use a conduit seal

Figure 2: Riser mounting

ATION HOLE

Ø3 [76.20] MINIMUM

Figure 3: Stand pipe mounting

BLIND ZONE

8 [203.20]

OPERATIONAL

RANGE

LOWEST

Page 4

Power Supply

The transmitter requires a minimum of 18 Volts DC at its connection for proper operation,

and a maximum of 28 Volts. Choose a power supply with a voltage and current rating

sufcient to meet this power specication under all operational conditions. If the supply

is unregulated, make sure that the output voltage remains within the required voltage

range under all power line conditions. Ripple on the supply should not exceed 100 mV.

Loop Resistance

The maximum allowable loop resistance is dependent on the power supply voltage.

The maximum loop voltage drop must not reduce the transmitter voltage below the 18

Volt minimum. The maximum loop resistance can be calculated using the following

equation:

PS - 18.0

V

R

MAX =

20 mA

PS is the power supply voltage.

Where V

24 VDC

SETUP & CALIBRATION

Four buttons are provided for all setup and calibration operations. All settings are

stored in nonvolatile memory so they will not be lost if the power is removed.

INDEX

ENTER

UP

DOWN

Figure 5: Display and programming buttons

KEY FUNCTIONS

INDEX

Pressing the INDEX button advances the display to the next menu item.

ENTER

Pressing the ENTER button for approximately two seconds will end operating mode

and enter programing mode. In programming mode press the ENTER button will store

the value of menu items once they are changed to a new value.

UP

Pressing the UP button increments a value in programming.

Figure 4: Electrical wiring diagram

DOWN

Pressing the DOWN button decrements a value in programming.

UP & INDEX

Pressing the UP and INDEX simultaneously will allow faster increments in a value for

programming.

DOWN & INDEX

Pressing the DOWN and INDEX simultaneously will allow faster decrements in a value

for programming.

Page 5

MENU SELECTIONS

The transmitter has two modes: operating and programming. In the normal operating

mode the transmitter will display the liquid height. The unit comes factory calibrated

with the output defaulted to 4 mA equal to the maximum range and 20 mA equal to

the minimum range of the transmitter model. In the programming mode the transmitter

will display the programming menus and choices. When in the programming mode

the transmitter will hold the last current value. The value will not change until the

transmitter is returned to operating mode via RUN in the menu structure.

To enter the programming mode press and hold the ENTER button for approximately

5 seconds. Once in programming mode there are the following top menu selections:

DISPLAY, TANK, OUTPUT, TARGET CAL, VALUES, HELP, and RUN. Pressing the

INDEX button will increment to the next top menu and pressing the ENTER button will

enter the menu for programming changes.

DISPLAY MENU

Press INDEX to advance to the next menu time. Press ENTER to retain the value.

MEASURE

Sets the transmitter output: Select LIQUID or AIR. Factory default is LIQUID.

UNITS

Sets the transmitter display and output unit of measure. Select INCHES, FEET, CM, or

METER. Factory default is INCHES.

SHOW

Sets the transmitter display for distance measure or percentage measure. Select

DISTANCE or PERCENT. Factory default is DISTANCE.

HELP

Displays a guide to the menu items in this menu. Press ENTER to display.

EXIT

Exits DISPLAY menu and goes back to the top menu. Press ENTER to go back to the

top menu or press INDEX to loop back through the DISPLAY menu options.

LIQUID Output will be the height of the liquid in the tank.

AIR Output will be the height of the air above the liquid in the tank.

EXIT Exit without making changes.

INCHES Display and output will be in inches.

FEET Display and output will be in feet.

CM Display and output will be in centimeters.

METER Display and output will be in meters.

EXIT Exit without making changes.

DISTANCE Display will be in units of distance.

PERCENT Display will be in percentage of range.

EXIT Exit without making changes.

Page 6

TANK MENU

If the tank dimensions are known these menu item can be used to set the 4 and 20 mA

points manually. See Figure 6 below. Press INDEX to advance to the next menu item.

Press ENTER to retain the value.

HEIGHT

Sets the 4 mA value. Program as the distance from the transducer face to the 4 mA

value desired (normally the bottom or lowest value of the tank). Factory default is the

maximum range of the model. Use the UP and DOWN buttons to change the value

in the length units the unit has been programmed for. The programmed value can

be anywhere in the range below FILL HEIGHT. If reverse mA is used then this will

become the 20 mA value.

FILL HEIGHT

Sets the 20 mA value. Program as the distance from the HEIGHT (normally the

bottom of the tank) to the 20 mA value desired. Factory default is the maximum range

of the model minus the blind zone distance of 8˝ (20 cm). Use the UP and DOWN

buttons to change the value in the length units the unit has been programmed for. The

programmed value can be anywhere in the range above HEIGHT. The maximum value

for FILL HEIGHT is the maximum range of the unit minus the blind zone distance of

8˝ (20 cm). The blind zone distance is automatically subtracted from the FILL HEIGHT

value programmed. If reverse mA is used then this will become the 4 mA value.

NOTICE

within the BLIND ZONE and that the FILL H is not higher than the HEIGHT. If these

parameters are not maintained, unit may remain in WARM UP mode until the proper

levels have been input. If unit is in WARM UP ensure no targets are within the BLIND

ZONE area and cycle power to return to set up to update the set up parameters.

When setting up HEIGHT and FILL HEIGHT ensure that the

minimum BLIND ZONE requirements are adhered to with no target

OUTPUT MENU

Press INDEX to advance to the next menu item. Press ENTER to retain the value.

SAFE MODE

Sets the output of the transducer for fail-safe mode. The transmitter will output the safe

mode programmed setting if the transmitter loses the echo signal. Select 22 mA, 21

mA, 20 mA, 4 mA or HOLD. Factory default value is 22 mA. Unit will resume normal

operation when echo signal is again received.

22 mA Output of 22 mA.

21 mA Output of 21 mA.

20 mA Output of 20 mA.

4 mA Output of 4 mA.

HOLD Output of last known signal is held.

EXIT Exit without making changes.

REVERSE MA

Sets the transmitter output to be forward or reverse acting. Select NORM or REV.

Factory default is NORM with 4 mA set at the maximum range of the unit and 20 mA

set at the end of the blind zone. See Figure 7 below.

Note: HEIGHT and FILL H must be set before reversing the output.

NORM 4 mA is set to be the bottom of the tank (tank empty) and 20 mA is set to be

the height the liquid can go in the tank (tank full).

REVERSE 20 mA is set to be the bottom of the tank (tank empty) and 4 mA is set to

be the height the liquid can go in the tank (tank full).

EXIT Exit without making changes.

BLIND ZONE 8 [203.2]

20 mA [FULL]

4 mA

[EMPTY]

Figure 6: Height and ll height

HELP

Displays a guide to the menu items in this menu. Press ENTER to display.

EXIT

Exits TANK menu and goes back to the top menu. Press ENTER to go back to the top

menu or press INDEX to loop back through the TANK menu options.

BLIND ZONE 8 [203.2]

4 mA [FULL]

20 mA

[EMPTY]

Figure 7: Reverse output operation

HELP

Displays a guide to the menu items in this menu. Press ENTER to display.

EXIT

Exits OUTPUT menu and goes back to the top menu. Press ENTER to go back to the

top menu or press INDEX to loop back through the OUTPUT menu options.

Page 7

TARGET CAL MENU

Target Calibration sets the tank empty and tank full distances for the transmitter output

based on the actual level in the tank. This is good to use if the tank dimensions are

unknown or if it is desired to ll and empty the tank for precise measurement points.

Press INDEX to advance to the next menu time. Press ENTER to retain the value.

See Figure 8 below.

FULL

Fill the tank to the full liquid level desired. Press ENTER and this level will be saved.

EMPTY

Drain the tank to the empty level desired. Press ENTER and this level will be saved.

HELP

Displays a guide to the menu items in this menu. Press ENTER to display.

EXIT

Exits TARG CAL menu and goes back to the top menu. Press ENTER to go back to

the top menu or press INDEX to loop back through the TARG CAL menu options.

BLIND ZONE 8 [203.2]

[MIN R]

VALUES MENU

SETUP

Displays the current programmed setup for the unit. This is scrolling data that will

return to the VALUES menu after displaying all the parameters. Values shown are:

MEASUR, then the setting; UNITS, then the setting; SHOW, then the setting; HEIGHT,

then the setting; FILL H, then the setting; SAFE, then the setting; REV MA, then the

setting.

DIAGNOSTICS

Displays diagnostic items that may be relevant to the transmitter and its performance

in the application. This is scrolling data that will return to the VALUES menu after

displaying all the parameters. Values shown are RANGE, then the setting; TEMP, then

the setting; ECHO, then the setting; POWER, then the setting; VER, then the setting.

RESET

Resets the programming to factory default settings.

YES Resets the programming to factory default settings.

NO Exits without making changes.

EXIT

Exits VALUES menu and goes back to the top menu. Press ENTER to go back to the

top menu or press INDEX to loop back through the VALUES menu options.

HELP MENU

Contains contact information for Dwyer Instruments, Inc.

HEIGHT

[MAX R]

Figure 8: Target calibration

FILL H

Page 8

MAINTENANCE & REPAIR

Other than the controls mentioned in this manual there are no user maintenance

adjustments or routine servicing required for this product. The unit is not eld

repairable and should be returned to the factory if service is required. Disassembly or

modications made by the user will void the warranty and could impair the continued

safety of the product. If repair is required obtain a Returned Goods Authorization

(RGA) number and send the unit, freight prepaid, to the address below. Please include

a detailed description of the problem and conditions under which the problem was

encountered.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

This symbol indicates waste electrical products should not be disposed

of with household waste. Please recycle where facilities exist. Check with

your Local Authority or retailer for recycling advice.

MERCOID

Printed in U.S.A. 2/20 FR# 443689-00 Rev. 2©Copyright 2020 Dwyer Instruments, Inc.

A DIVISION OF

DWYER INSTRUMENTS, INC.

Loading...

Loading...