Page 1

SERIES TUF | ULTRASONIC ENERGY METER

®

FEATURES/BENEFITS

• Lower maintenance costs with local parameter display and no moving parts

• BACnet MS/TP or Modbus® RTU data communication protocol output allows for easy transfer of data

• Flow and temperature monitor in one unit eliminates the need for multiple units

• Produced to meet EN1434 MID approval for accuracy and quality

DESCRIPTIONAPPLICATIONS

• Heat metering

• Utilities billing

• Tenant billing

• Monitoring of water heating or cooling: radiators, fan coils

The Series TUF Ultrasonic Energy Meter is a highly accurate and

stable energy meter. It utilizes ultrasonic technology to measure heating

and cooling energy consumption. The Series TUF incorporates a

owmeter, temperature meter, and a calculator into a single, compact

unit. The size and lack of moving parts means the Series TUF requires

minimal maintenance. The 8-digit LED display enables easy reading of

the meter’s recorded values; including temperature, ow-rate, energy

consumption, etc. These features make it ideal for installation on chillers,

boilers, and individual apartment piping. With the optional couplings it

is capable of being used with either NPT or BSPT pipe sizes. It is the

perfect meter for tenant billing applications.

Modbus® is a registered trademark of Schneider Automation, Inc.

Page 2

Service Clean, compatible liquids.

4-1/4

T

2.8´ WATER-IN

FLOW SENSOR

DNXX

H

4-1/4

[108.00]

L

[2 COMMUNICATION,

2 POWER]

4´ RETURN PIPE

TEMP SENSOR

2X D

THREAD

4´ FLOW PIPE

TEMP SENSOR

2.8´ WATER-OUT

FLOW SENSOR

2.8´ WATER-IN

FLOW SENSOR

4´ 4-CORE

WIRE

BALL

BALL

Y

D

TEMPERATURE SENSOR

Wetted Materials Brass and 316L SS.

Range See chart.

Display 8-digit LED.

Accuracy BTU: EN1434/CJ128 Class 2; Flow: ±(2+(0.02 Qp/Q))%; Temperature: ±0.1°C.

Power Requirements 24 VAC/VDC (model dependent) or 3.6 V ER26500 lithium metal battery, user supplied and installed, battery acts as

back-up if power is lost.

Power Consumption 1 W.

Temperature Limits Ambient: 41 to 131°F (5 to 55°C); Process: 36 to 203°F (2 to 95°C).

Humidity Limit <93%.

Pressure Limits 232 psi (16 bar) for DN15 to DN40; 362 psi (25 bar) for >DN50.

Pressure Drop <1.5 psi (10 kPa).

Process Connection See chart.

Serial Communications Modbus® RTU or BACnet MSTP (selectable)**.

Enclosure Rating IP65.

Enclosure Material Plastic.

Repeatability Flowmeter: 1%.

Electric Connections 3 ft (0.91 m) 4x0.2 mm2 cable with terminal block.

Flow Direction Unidirectional.

Mounting Orientation Horizontal or vertical.

Weight See chart.

Agency Approvals CE.

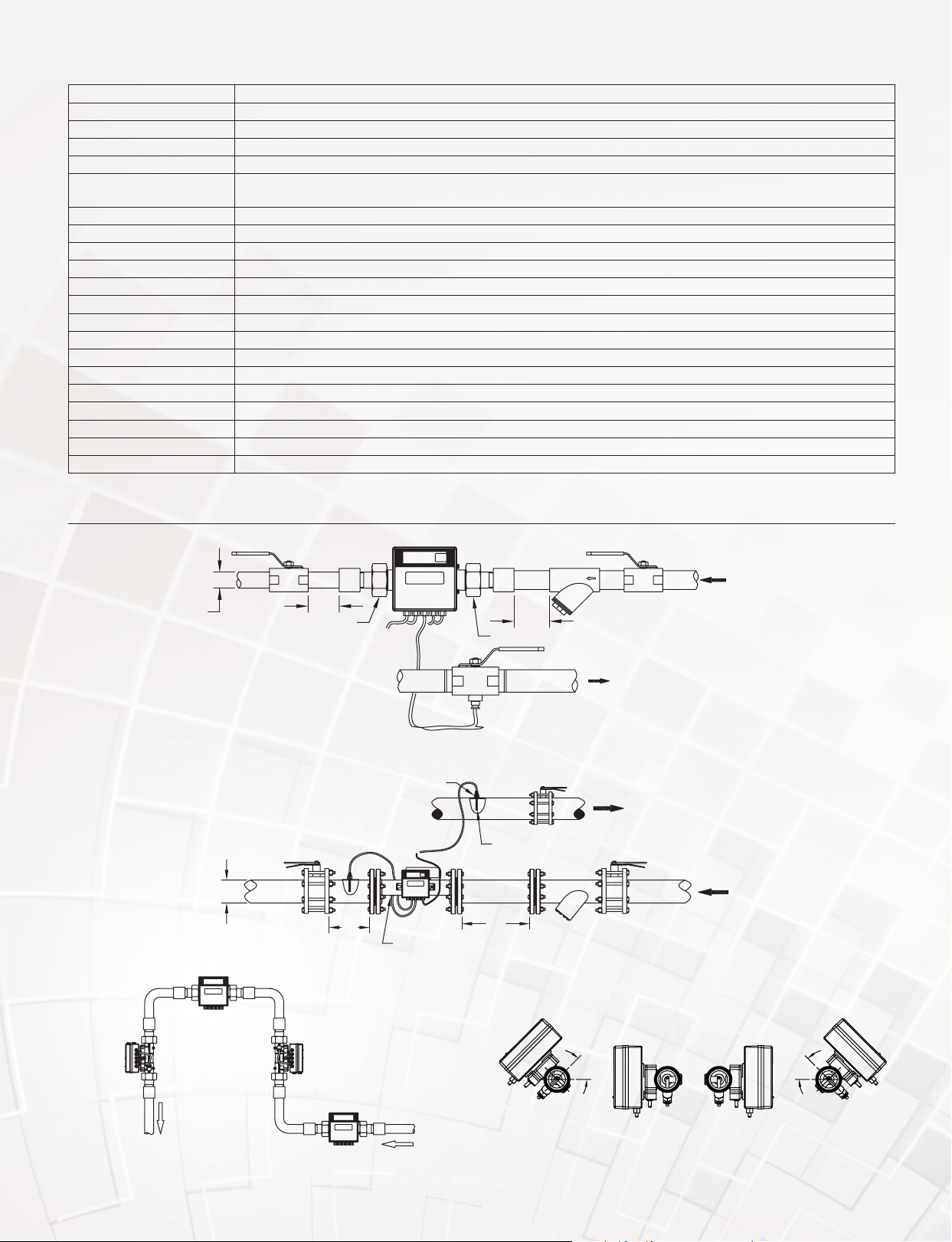

INSTALLATION

VALV E

STRAIGHT

JOINT

5D

UNION NUT

STRAIGHT

JOINT

FILTER

PIPEPIPEPIPE PIPE PIPE

10D

UNION NUT

WATER RETURN

BALL

VALV E

VALV E

WATER SUPPL

Installation diagram for TUF-150/400

D

BUTTERFLY

VALV E

PIPE PIPE

5D

SENSOR

SLEEVE

SUPPLY WATER

BUTTERFLY

VALV E

RETURN WATER

TEMPERATURE

SENSOR

10D

FILTER

WATER RETURN

BUTTERFLY

VALV E

WATER SUPPLY

Installation diagram for TUF-500/2000

45° MIN.

Installation positions Mounting rotation

45° MIN.

Page 3

DIMENSIONS AND WIRING DIAGRAMSPECIFICATIONS

4-1/4

T

2.8´ WATER-IN

FLOW SENSOR

DNXX

H

4-1/4

[108.00]

L

[2 COMMUNICATION,

2 POWER]

4´ RETURN PIPE

TEMP SENSOR

2X D

THREAD

4´ FLOW PIPE

TEMP SENSOR

2.8´ WATER-OUT

FLOW SENSOR

2.8´ WATER-IN

FLOW SENSOR

4´ 4-CORE

WIRE

Model

TUF-500-XX

TUF-650-XX

TUF-800-XX

TUF-1000-XX

TUF-1250-XX

TUF-1500-XX

TUF-2000-XX

[108.00]

Dimensions in [mm] Flow Rate GPM [LPM]

Model

TUF-150-XX

TUF-200-XX

TUF-250-XX

TUF-320-XX

TUF-400-XX

4´ FLOW PIPE

TEMP SENSOR

4´ 4-CORE WIRE

[2 COMMUNICATION,

4-21/64 [110.00]

5-1/8 [130.00]

6-19/64 [160.00]

7-3/32 [180.00]

7-7/8 [200.00]

2 POWER]

H

4´ FLOW PIPE

TEMP SENSOR

4´ RETURN PIPE

TEMP SENSOR

4´ 4-CORE

[2 COMMUNICATION,

2 POWER]

2X D

THREAD

G3/4B

3-31/32 [101.00]

G1B

3-31/32 [101.00]

G11/4B

4-11/64 [106.00]

G11/2B

4-29/64 [113.00]

G2B

4-49/64 [121.00]

2.8´ WATER-IN FLOW SENSOR

2.8´ WATER-OUT FLOW SENSOR

WIRE

Max

Flow

(Qs)

13 [50]

22 [83]

31 [117]

53 [200]

88 [333]

´N´ NO. OF HOLES

[SEE TABLE]

DNXX

L

Nominal

Flow

Range (Qp)

6.6 [25]

11 [42]

15 [58]

26 [100]

44 [167]

2.8´ WATER-OU

FLOW SENSOR

Min

Flow

(Qi)

0.1 [0.5]

0.2 [0.8]

0.3 [1.2]

0.5 [2]

0.9 [3.3]

Weight

lb [kg]L D H

3.1 [1.4]

3.1 [1.4]

4.1 [1.8]

5.2 [2.3]

6.6 [3.0]

H

ØD1 B.C.

L

ØD2

ØD

4´ RETURN PIPE TEMP SENSOR

Dimensions in [mm] Flow Rate GPM [LPM]

Max Flow

7-7/8 [200]

7-7/8 [200]

8-55/64 [225]

9-27/32 [250]

9-27/32 [250]

11-13/16 [300]

13-25/32 [350]

6-1/2 [165.00]

7-9/32 [185.00]

7-7/8 [200.00]

8-21/32 [220.00]

9-27/32 [250.00]

11-7/32 [285.00]

13-25/64 [340.00]

9-27/32 [250]

10-7/16 [265]

11-1/32 [280]

12-13/64 [310]

12-63/64 [330]

14-11/64 [360]

15-15/16 [405]

4-59/64 [125.00]

5-45/64 [145.00]

6-19/64 [160.00]

7-3/32 [180.00]

8-17/64 [210.00]

9-29/64 [240.00]

11-39/64 [295.00]

45/64 [18.00]

45/64 [18.00]

45/64 [18.00]

45/64 [18.00]

45/64 [18.00]

55/64 [22.00]

55/64 [22.00]

(Qs)

4

132 [500]

4

220 [833]

8

352 [1333]

8

528 [2000]

8

881 [3333]

8

1321 [5000]

12

2202 [8333]

Nominal

Flow

Range (Qp)

66 [250]

110 [417]

176 [667]

264 [1000]

440 [1667]

660 [2500]

1101 [4167]

Min

Flow

(Qi)

0.7 [2.5]

1.1 [4.2]

1.8 [6.7]

2.6 [10]

4.4 [17]

6.6 [25]

11 [42]

Weight

lb [kg]L ØD H ØD1 ØD2 N

30.8 [14]

30.2 [13.7]

37.5 [17]

41.8 [19]

57.3 [26]

70.5 [32]

141 [64]

Page 4

®

HOW TO ORDER

• Choose 1 ultrasonic energy meter model

• Choose pipe tting model given the appropriate tting size (for DN15 to DN40 only)*

Example: TUF-150-MD, Fitting Size: A, select pipe tting Model WM-ACC-C01 or WM-ACC-C11.

Ultrasonic

Energy

Meter Model

TUF-150-MD

TUF-200-MD

TUF-250-MD

TUF-320-MD

TUF-400-MD

TUF-500-MD*

TUF-650-MD

TUF-800-MD

TUF-1000-MD

TUF-1250-MD

TUF-150-BN

TUF-200-BN

TUF-250-BN

TUF-320-BN

TUF-400-BN

TUF-500-BN*

TUF-650-BN

TUF-800-BN

TUF-1000-BN

TUF-1250-BN

Body

Size†

DN15

DN20

DN25

DN32

DN40

DN50

DN65

DN80

DN100

DN125

DN15

DN20

DN25

DN32

DN40

DN50

DN65

DN80

DN100

DN125

Pipe Size

1/2

15

3/4

20

1

25

1-1/4

32

1-1/2

40

2

50

2-1/2

65

3

80

4

100

5

125

1/2

15

3/4

20

1

25

1-1/4

32

1-1/2

40

2

50

2-1/2

65

3

80

4

100

5

125

Fitting

Size Communication

A

B

C

D

E

-

-

-

-

A

B

C

D

E

-

-

-

-

-

Modbus

Modbus

Modbus

Modbus

Modbus

Modbus

Modbus

Modbus

Modbus

Modbus

BACnet

BACnet

BACnet

BACnet

BACnet

BACnet

BACnet

BACnet

BACnet

BACnet

®

®

®

®

®

®

®

®

®

®

Meter

Connection

G-3/4

G1

G1-1/4

G1-1/2

G2

Flange

Flange

Flange

Flange

Flange

G-3/4

G2

G1-1/4

G1-1/2

G2

Flange

Flange

Flange

Flange

Flange

GPM (LPM)

Min Flow

(Qi)

0.1 (0.5)

0.2 (0.8)

0.3 (1.2)

0.5 (2)

0.9 (3)

1.3 (5)

2.2 (8.3)

3.5 (13.3)

5.3 (20)

8.8 (33)

0.1 (0.5)

0.2 (0.8)

0.3 (1.2)

0.5 (2)

0.9 (3)

1.3 (5)

2.2 (8.3)

3.5 (13.3)

5.3 (20)

8.8 (33)

Nominal

Flow

Range (Qp)

6.6 (25)

11 (42)

15 (58)

26 (100)

44 (167)

66 (250)

110 (417)

176 (667)

264 (1000)

440 (1667)

6.6 (25)

11 (42)

15 (58)

26 (100)

44 (167)

66 (250)

110 (417)

176 (667)

264 (1000)

440 (1667)

Max

Flow (Qs)

13 (50)

22 (83)

31 (117)

53 (200)

88 (333)

132 (500)

220 (833)

352 (1333)

528 (2000)

881 (3333)

13 (50)

22 (83)

31 (117)

53 (200)

88 (333)

132 (500)

220 (833)

352 (1333)

528 (2000)

881 (3333)

Weight

lb (kg)in mm

3.1 (1.4)

3.1 (1.4)

4.1 (1.8)

5.2 (2.3)

6.6 (3)

33 (15)

10.1 (4.6)

13.5 (6.1)

16.5 (7.5)

21.1 (9.6)

3.1 (1.4)

3.1 (1.4)

4.1 (1.8)

5.2 (2.3)

6.6 (3)

33 (15)

10.1 (4.6)

13.5 (6.1)

16.5 (7.5)

21.1 (9.6)

Model Power Requirements

TUF-XXX-XX

TUF-XXX-XX-DC

24 VAC/VDC

24 VDC

*A pipe tting is required to use the DN15 to DN40 energy meters. The DN50 has a ange connection and does not require a pipe tting.

†For additional sizes up to 8˝ (203.2 mm) contact factory.

ACCESSORIES

Fitting Size Pipe Fitting Model* Process Connection Size Weight lb (kg)

A

A

B

B

C

C

D

D

E

E

*Each model includes 1 tting.

WM-ACC-C01

WM-ACC-C11

WM-ACC-C02

WM-ACC-C12

WM-ACC-C03

WM-ACC-C13

WM-ACC-C04

WM-ACC-C14

WM-ACC-C05

WM-ACC-C15

1/2˝ NPT

1/2˝ BSPT

3/4˝ NPT

3/4˝ BSPT

1˝ NPT

1˝ BSPT

1-1/4˝ NPT

1-1/4˝ BSPT

1-1/2˝ NPT

1-1/2˝ BSPT

0.6 (0.3)

0.6 (0.3)

1.2 (0.5)

1.2 (0.5)

1.8 (0.8)

1.8 (0.8)

2.3 (1.1)

2.3 (1.1)

4.4 (2)

4.4 (2)

Modbus® is a registered trademark of Schneider Automation, Inc.

DWYER INSTRUMENTS, INC.

©Copyright 2019 Dwyer Instruments, Inc.

Printed in U.S.A. 5/19 DS-TUF Rev. 4

Important Notice: Dwyer Instruments, Inc. reserves the right to make changes to or discontinue any product or service identied in this publication without notice. Dwyer advises its customers to obtain the

latest version of the relevant information to verify, before placing any orders, that the information being relied upon is current.

Loading...

Loading...