Page 1

®

SERIES RPME | ROOM PRESSURE MONITOR

FEATURES/BENEFITS

• 2 SPDT relays allow for local alarming and alarming to control system

• Automatic or manual alarm reset

• Visual LED alarms provide immediate local alert allowing corrective action to be taken quicker to eliminate the problem from

becoming widespread

• Stores peak and valley process readings

• Same installation diameter as Magnehelic® gage which simplies eld upgrade to RPME room pressure monitor

• Password protected setup menu ensures no errors by untrained personnel

• Clean manufacturing areas

• Clean rooms

• Research labs

• Vivariums

DESCRIPTIONAPPLICATIONS

The Series RPME Room Pressure Monitor is designed for low differential

pressure applications that require stringent pressure monitoring and

alarming. The Series RPME can be congured to monitor positive or

negative pressure in protected environments and clean manufacturing

areas. The RPME room pressure monitor is a complete system with a xed

segment LCD which enables access to pressure, security, calibration, and

alarm setup. The RPME room pressure monitor has a brushed stainless

steel bezel that allows for easy cleaning.

The RPME has built-in status indication LEDs that will appear green when

within the user-dened pressure set range and will appear orange when

outside of the pressure set range. 2 SPDT independent control relays with

adjustable deadbands are also provided along with a 4-20 mA process

output.

Page 2

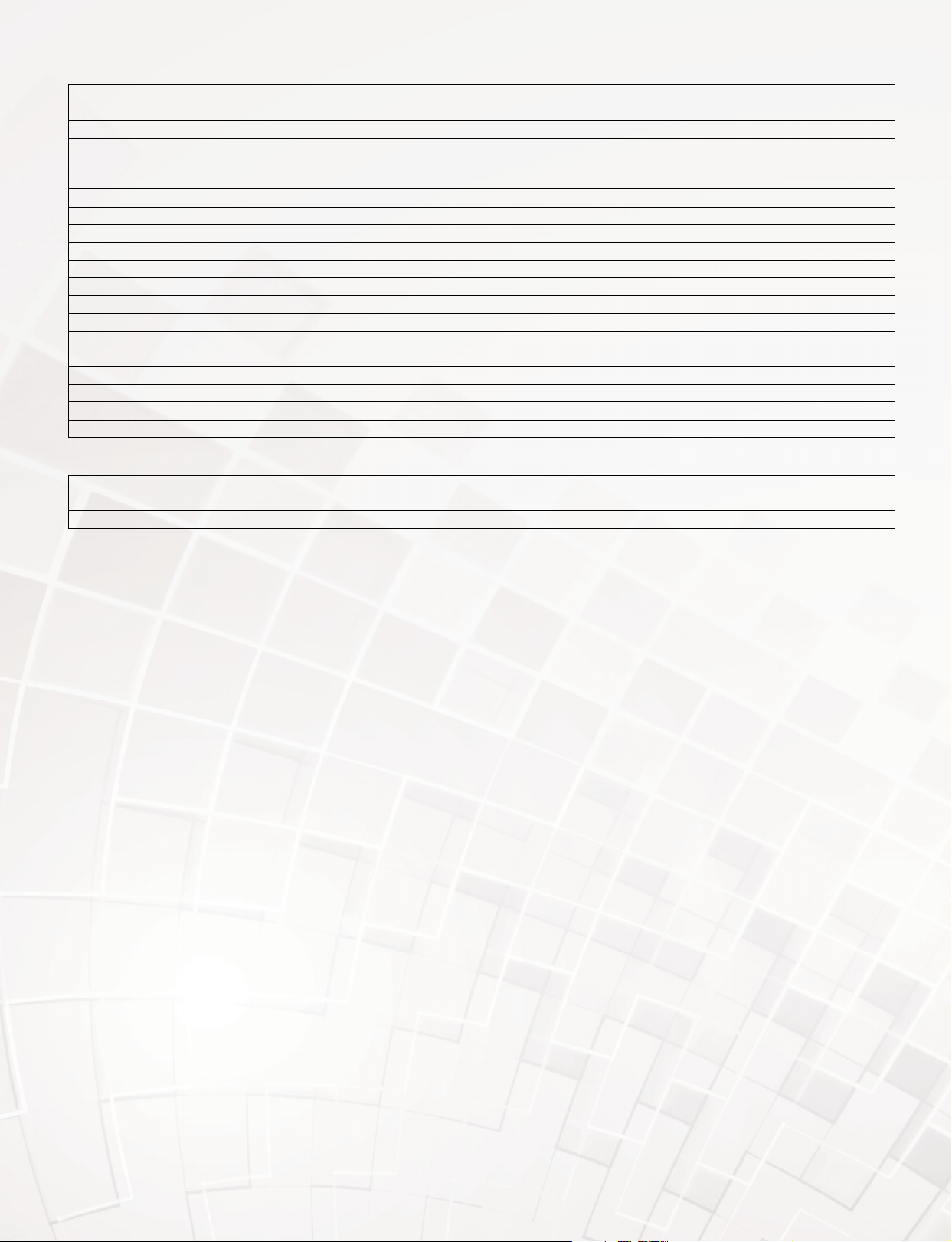

Service Air and non-combustible, compatible gases.

2-1/16

NPT

SURFACE MOUNTING

Measurement Technology Piezoresistive.

Wetted Materials Consult factory.

Housing Material Die cast aluminum case and SS bezel.

Accuracy ±0.5% RSS (includes non-linearity: ±0.49%, hysteresis: ±0.05% and non-repeatability: ±0.05%), or ±1% RSS

(includes non-linearity: ±0.99%, hysteresis: ±0.05% and non-repeatability: ±0.05%).

Pressure Limits Ranges 0.5 and 1.0 in w.c: 9 psi; Ranges 2.5 and 5 in w.c. : 1.5 psi.

Temperature Limits 32 to 140°F (0 to 60°C).

Compensated Temperature Limits 32 to 140°F (0 to 60°C).

Thermal Effects 0.02%/°F (0.036%/°C) from 77 °F (25 °C).

Power Requirements 12-28 VDC, 12-28 VAC 50 to 400 Hz.

Power Consumption 3 VA max.

Output Signal 4-20 mA DC into 900 Ω max.

Zero and Span Adjustments Accessible via menus.

Response Time 8 ms.

Display Backlit 4 digit LCD 0.4˝ height LED indicators for set point and alarm status.

Electrical Connections 15 pin male high density D-sub connection. 18˝ (46 cm) cable with 10 conductors included.

Process Connections 1/8˝ female NPT. Side or back connections.

Mounting Orientation Mount unit in vertical plane. Size: 4-3/4˝ (120.7 mm) OD x 2-21/32 (67.5 mm).

Weight 1.75 lb (794 g).

SWITCH SPECIFICATIONS

Switch Type 2 SPDT relays.

Electrical Rating 1 A @ 30 VAC/VDC.

Set Point Adjustment Adjustable via keypad on face.

Page 3

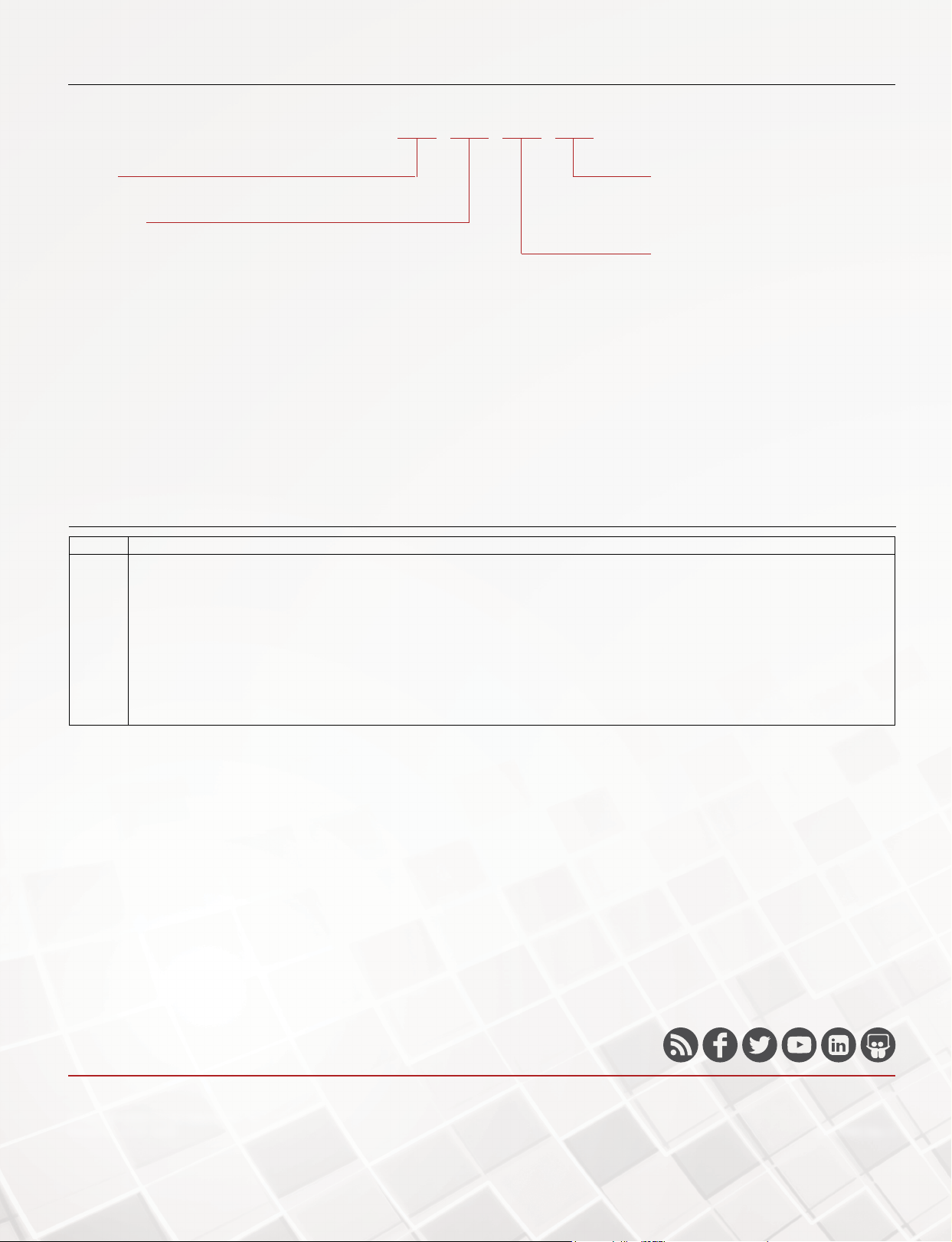

DIMENSIONSSPECIFICATIONS

2-1/16

NPT

SURFACE MOUNTING

1/2 [12.70]

1-9/32

[32.54]

1/8 FEMALE

LOW PRESSURE

CONNECTION

11/16

[17.46]

11/16

[17.46]

1/8 FEMALE

NPT HIGH PRESSURE

CONNECTION

30Ø

[3]Ø3/16 [4.77] HOLES EQUALLY

SPACED ON A 4-1/8 [104.78] B.C.

1/2

[12.70]

1-3/4

[44.45]

1/8 FEMALE

NPT HIGH PRESSURE

CONNECTION

1.250

[31.75]

1/8 FEMALE

NPT LOW PRESSURE

CONNECTION

[52.39]

[50.80]

2-1/2

[63.50]

2

4-47/64

[120.14]

4-31/64

[113.79]

Ø4 [101.60]

1/8 [3.18]

FACE

Page 4

®

HOW TO ORDER

Use the bold characters from the chart below to construct a product code.

RPME -B -003 -COO

SERIES

RPME: Room pressure monitor

ACCURACY

-B: ±0.5% RSS accuracy

-C: ±1% RSS accuracy

ACCESSORIES

Model Description

A-220

A-285

A-299

A-300

A-417A

A-418A

A-465

Clear exible vinyl tubing is easily inspected, and is therefore best for test applications where a possibility of uid entering the tubing exists.

3/16˝ ID x 5/16˝ OD, lengths to 500´; 45 psi maximum pressure @ 73°F.

Remote alarm annunciator with visible/audible alarm and acknowledge switch

Mounting bracket ush mount Magnehelic

6.3˝ x 7.7˝ x 4.0˝, 1.30 lb

Flat aluminum bracket for ush mounting

Static pressure pickup. For use in clean rooms, 60 micron lter picks up static pressure. SSwall plate ts 2˝ x 4˝ electrical box. Sealed with

foam gasket, screws included. Barbed brass tting holds 1/8˝ to 3/16˝ ID tubing.

Static pressure pickup. Room mount with Delta Style plastic enclosure ts 2˝ x 4˝ electrical box. Fine mesh screen hides static pressure

pickup port. Clean connection to 1/8˝ to 3/16˝ I.D. tubing and pressure sensor. Sealed with foam gasket, screws included.

Flush mount space pressure sensor, white plastic

OPTIONS

-COO: Certicate of US origin

-NIST: NIST traceable calibration certicate

-FC: Factory test report

RANGE

-003: 0 to 0.5 in w.c.

-004: 0 to 1 in w.c.

-005: 0 to 2.5 in w.c.

-006: 0 to 5 in w.c

-014: -0.5 to 0 to 0.5 in w.c.

-015: -1 to 0 to 1 in w.c.

-016: -2.5 to 0 to 2.5 in w.c.

-017: -5 to 0 to 5 in w.c.

®

gage in bracket. Bracket is then surface mounted. Steel with gray hammertone epoxy nish.

O

DWYER INSTRUMENTS, INC.

©Copyright 2020 Dwyer Instruments, Inc.

Printed in U.S.A. 12/20 DS-RPME Rev. 2

Important Notice: Dwyer Instruments, Inc. reserves the right to make changes to or discontinue any product or service identied in this publication without notice. Dwyer advises its customers to obtain the

latest version of the relevant information to verify, before placing any orders, that the information being relied upon is current.

Loading...

Loading...