Page 1

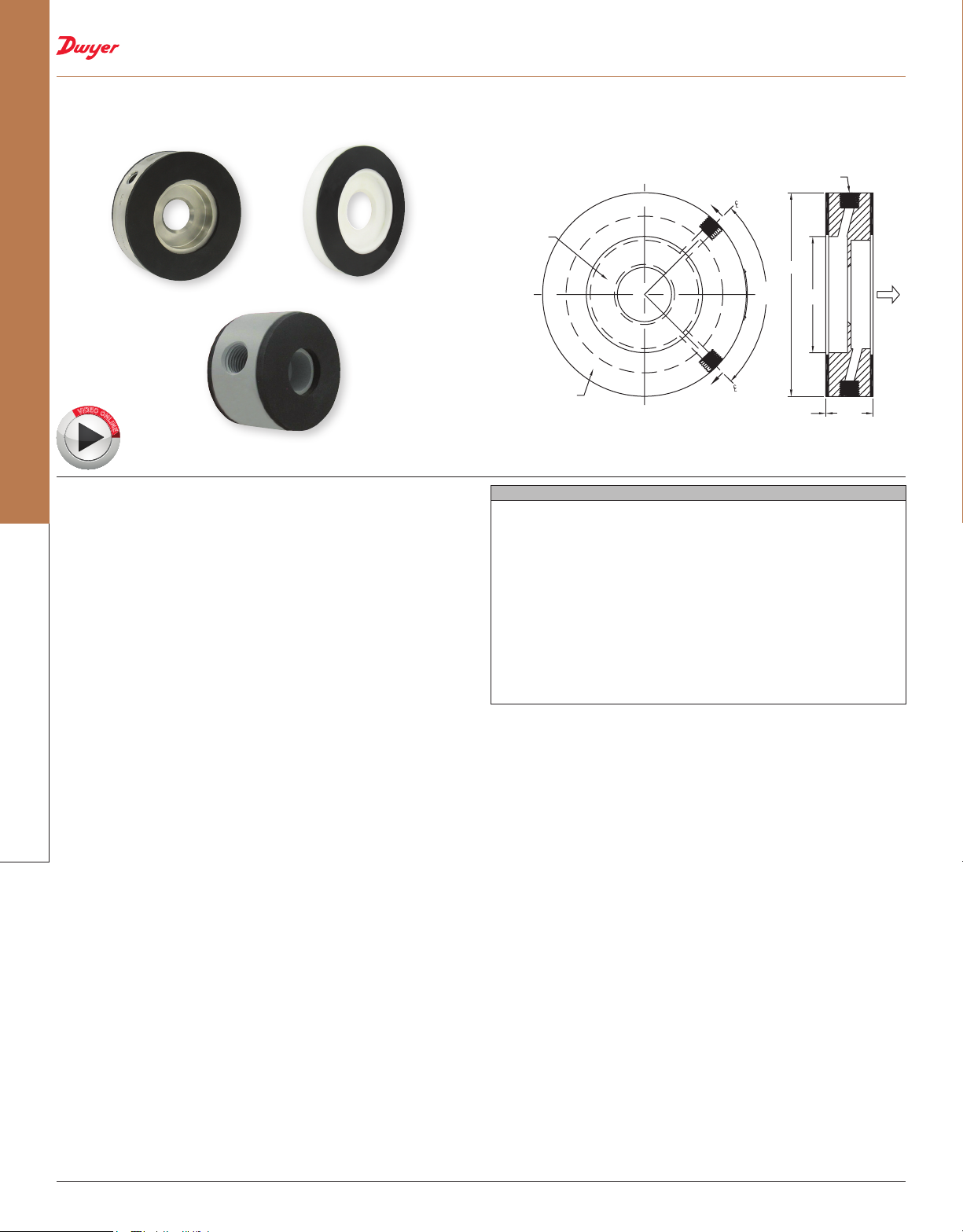

ADHERED TO FACES

ORIFICE PLA

THICK

1/4˝ NPT PRESSURE FITTING

®

E

SERIES OP, PE & TE

ORIFICE PLATE FLOWMETERS

FLOW

PVC or PTFE, Liquid and Gas Use Options

OP

E

O

D

I

V

O

N

L

I

N

PE

TE

TE

1/8 [3.18]

TYPICAL

BODY

[CARRIER RING]

HI

A

PRESSURE

OD

4-1/2

[114.3]

LOW

A

PRESSURE

INCLUDES RING GASKET

ID

FLOW

1-1/4

[31.75]

Flowmeters,

The Series OP Orice Plate Flowmeters are a complete ow metering package.

They incorporate a stainless steel orice plate with a unique holder or carrier ring

containing metering taps and integral gaskets. The Series OP is available in line sizes

from 1/2˝ to 24˝ and can be used with compatible liquids and gases.

FEATURES/BENEFITS

• Mounted with standard anges with no need of specialty anges

• Reduced installation costs with simple installation by slipping the unit between

standard anges

• Easy access with corner type metering taps

• Long operation life with corrosion free material

• Stainless steel wetted parts assures long term reliability and accuracy

• Proven through a wide range of applications for energy efciency

APPLICATIONS

• Fluid ow rates in building water lines

• Boiler feedwater

• Cooling water

• Combustion or compressed air

Orice Plate

• Steam ow

The SERIES PE & TE Orice Plate Flowmeters are two series of plastic orice plate

ow metering packages incorporating a unique holder or carrier ring containing

metering taps and integral gaskets. They can be used in place of other primary

differential products for efciency and cost effectiveness.

The Series PE orice plate owmeter is of PVC construction and is available in line

sizes from 1/2 to 24˝. This series can be used for air and most gases and meets or

exceeds ASME, AGA & ISO standards.

The Series TE orice plate owmeter is of PTFE construction and is available in line

sizes from 1/2 to 24˝. This Series can be used with gases, liquids, corrosive and high

temperature uids.

FEATURES/BENEFITS

• Mounted with standard anges with no need of specialty anges

• Reduced installation costs with simple installation by slipping the unit between

standard anges

• Easy access with corner type metering taps

• Long operation life with corrosion free material

• Proven through a wide range of applications for energy efciency

• PTFE construction yields excellent chemical and weather resistance

• TE models are ame retardant without factory gaskets

• Low friction leading to minimum wear and long operation life

APPLICATIONS

• Fluid ow rates in building water lines

• Boiler feedwater

• Cooling water

• Combustion or compressed air

• Steam ow

SPECIFICATIONS

Service: OP & TE: Compatible liquids and gases; PE: Clean air and compatible

gases.

Wetted Material: OP: 304 SS, Buna-N gaskets; PE: Gray PVC, Buna-N gaskets;

TE: PTFE, Buna-N gaskets.

Accuracy: 0.6% FS. (Beta = .2-.6) ±0.7% for Beta greater than .6.

Temperature Limits: OP: -50 to 200°F (-45 to 93°C); PE: 140°F (60°C) max; TE:

-40 to 200°F (-40 to 93.3°C).

Pressure Limits: OP: Limited only by pipe and ange rating restrictions.

Head Loss: 1-Beta ratio2 eg: 1-0.72 = 1-0.49 = 51% of the d.p.

Line Sizes: 1/2˝ to 24˝.

Process Connection: 1/4˝ female NPT.

Installation: Standard ange. OP: Any rating (orice anges not required); PE &

TE: 125#/150# rating.

Pipe Requirements: General requirements 10 diameter upstream and 5 diameter

downstream of orice plate.

Weight: Varies with line size. See chart.

DWYER INSTRUMENTS, INC. 264

Page 2

®

SERIES OP, PE & TE

ORIFICE PLATE FLOWMETERS

PVC or PTFE, Liquid and Gas use Options

FLOW

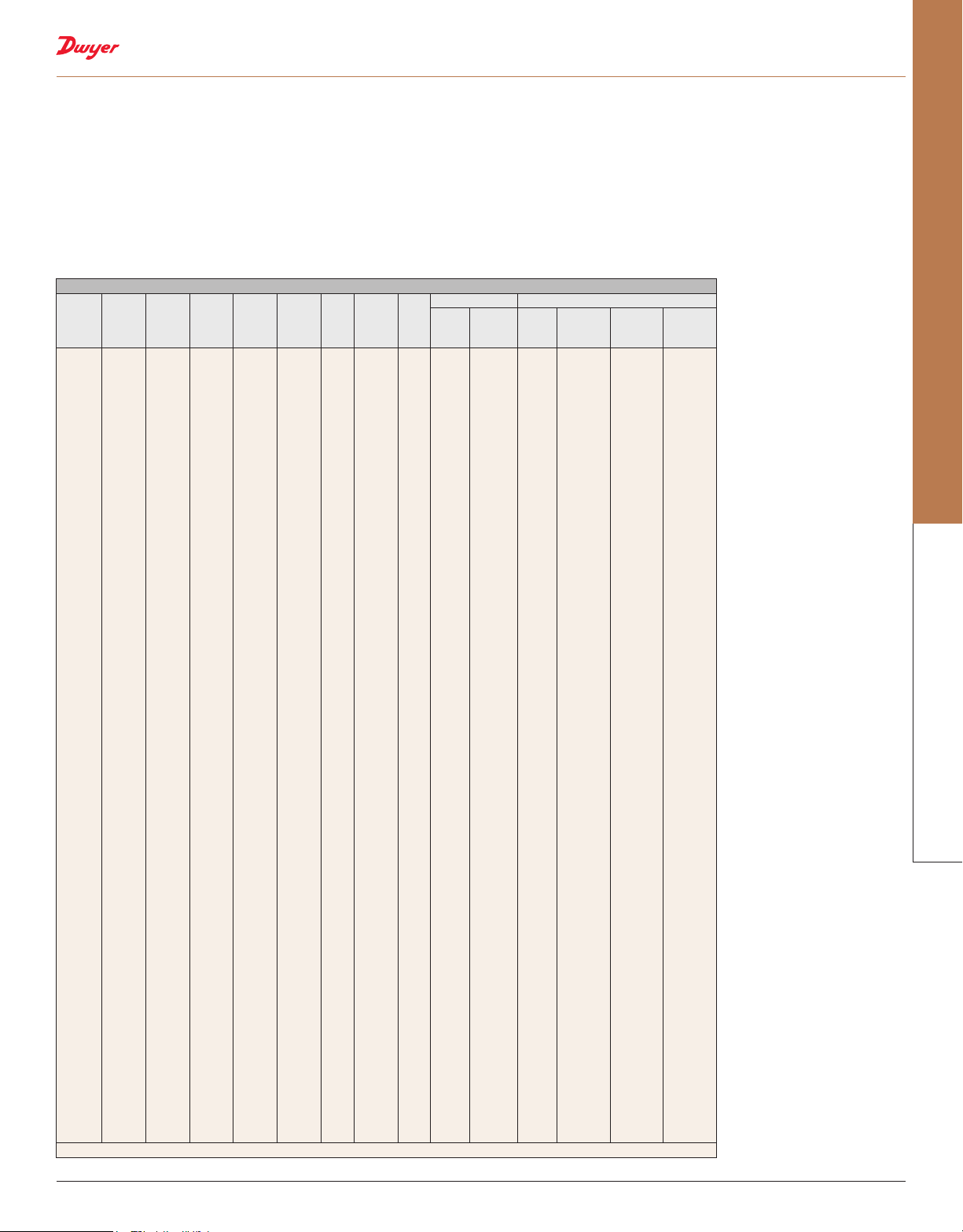

SERIES OP ORIFICE PLATE FLOWMETER –

CAPACITY STRUCTURE

• Material 304/304 L, gaskets Buna-N

• Based on 70°F, 14.7 psia (base conditions)

• Beta value based on std sch pipe I.D.

• 1.25˝ overall thickness

• Orice plate thickness is 0.125˝

MODEL CHART

OP

OP

Weight

Model

(lb)PEModel

OP-A-1

1.00

OP-A-2

1.00

OP-A-3

1.00

OP-B-1

1.00

OP-B-2

1.00

OP-B-3

1.00

OP-C-1

2.00

OP-C-2

2.00

OP-C-3

2.00

OP-D-1

2.00

OP-D-2

2.00

OP-D-3

2.00

OP-E-1

2.00

OP-E-2

2.00

OP-E-3

2.00

OP-F-1

3.00

OP-F-2

3.00

OP-F-3

3.00

OP-G-1

4.00

OP-G-2

4.00

OP-G-3

4.00

OP-H-1

5.00

OP-H-2

5.00

OP-H-3

5.00

OP-J-1

7.00

OP-J-2

7.00

OP-J-3

7.00

OP-K-1

8.00

OP-K-2

8.00

OP-K-3

8.00

OP-L-1

10.00

OP-L-2

10.00

OP-L-3

10.00

OP-M-1

14.00

OP-M-2

14.00

OP-M-3

14.00

OP-N-1

20.00

OP-N-2

20.00

OP-N-3

20.00

OP-O-1

30.00

OP-O-2

30.00

OP-O-3

30.00

OP-P-1

40.00

OP-P-2

40.00

OP-P-3

40.00

OP-Q-1

48.00

OP-Q-2

48.00

OP-Q-3

48.00

Note: Differential pressure values should be less than 50% of the inlet absolute pressure.

PE-A-1

PE-A-2

PE-A-3

PE-B-1

PE-B-2

PE-B-3

PE-C-1

PE-C-2

PE-C-3

PE-D-1

PE-D-2

PE-D-3

PE-E-1

PE-E-2

PE-E-3

PE-F-1

PE-F-2

PE-F-3

PE-G-1

PE-G-2

PE-G-3

PE-H-1

PE-H-2

PE-H-3

PE-J-1

PE-J-2

PE-J-3

PE-K-1

PE-K-2

PE-K-3

PE-L-1

PE-L-2

PE-L-3

PE-M-1

PE-M-2

PE-M-3

PE-N-1

PE-N-2

PE-N-3

PE-O-1

PE-O-2

PE-O-3

PE-P-1

PE-P-2

PE-P-3

PE-Q-1

PE-Q-2

PE-Q-3

PE

Weight

(lb)TEModel

1.00

TE-A-1

1.00

TE-A-2

1.00

TE-A-3

1.00

TE-B-1

1.00

TE-B-2

1.00

TE-B-3

1.00

TE-C-1

1.00

TE-C-2

1.00

TE-C-3

1.00

TE-D-1

1.00

TE-D-2

1.00

TE-D-3

2.00

TE-E-1

2.00

TE-E-2

2.00

TE-E-3

2.00

TE-F-1

2.00

TE-F-2

2.00

TE-F-3

2.00

TE-G-1

2.00

TE-G-2

2.00

TE-G-3

2.00

TE-H-1

2.00

TE-H-2

2.00

TE-H-3

3.00

TE-J-1

3.00

TE-J-2

3.00

TE-J-3

3.00

TE-K-1

3.00

TE-K-2

3.00

TE-K-3

4.00

TE-L-1

4.00

TE-L-2

4.00

TE-L-3

5.00

TE-M-1

5.00

TE-M-2

5.00

TE-M-3

6.00

TE-N-1

6.00

TE-N-2

6.00

TE-N-3

7.00

TE-O-1

7.00

TE-O-2

7.00

TE-O-3

9.00

TE-P-1

9.00

TE-P-2

9.00

TE-P-3

10.00

TE-Q-1

10.00

TE-Q-2

10.00

TE-Q-3

TE

Weight

(lb)

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

3.00

3.00

3.00

4.00

4.00

4.00

4.00

4.00

4.00

6.00

6.00

6.00

8.00

8.00

8.00

10.00

10.00

10.00

15.00

15.00

15.00

18.00

18.00

18.00

SERIES PE ORIFICE PLATE FLOWMETER –

AIR CAPACITY STRUCTURE

• Material PVC, gaskets Buna-N

• Based on 70°F, 14.7 psia (base conditions)

• Beta value based on std sch pipe I.D.

• 1.25˝ overall thickness

• Orice plate thickness is 0.125˝

Water Capacity Air Capacity - Flow in SCFM

Line

Size Bore Beta

1/2˝

0.200˝

1/2˝

0.310˝

1/2˝

0.430˝

3/4˝

0.250˝

3/4˝

0.400˝

3/4˝

0.580˝

1˝

0.300˝

1˝

0.520˝

1˝

0.720˝

1.25˝

0.400˝

1.25˝

0.700˝

1.25˝

1.00˝

1.5˝

0.500˝

1.5˝

0.800˝

1.5˝

1.100˝

2˝

0.600˝

2˝

1.000˝

2˝

1.450˝

2.5˝

0.750˝

2.5˝

1.250˝

2.5˝

1.750˝

3˝

0.920˝

3˝

1.500˝

3˝

2.150˝

4˝

1.200˝

4˝

2.000˝

4˝

2.800˝

5˝

1.500˝

5˝

2.500˝

3.500˝

5˝

1.800˝

6˝

3.000˝

6˝

4.200˝

6˝

2.400˝

8˝

4.000˝

8˝

5.600˝

8˝

3.000˝

10˝

5.000˝

10˝

7.000˝

10˝

3.600˝

12˝

6.000˝

12˝

8.400˝

12˝

4.000˝

14˝

6.600˝

14˝

9.300˝

14˝

4.500˝

16˝

7.600˝

16˝

10.700˝

16˝

0.32

0.50

0.69

0.30

0.49

0.70

0.29

0.49

0.69

0.29

0.51

0.72

0.31

0.50

0.68

0.29

0.48

0.70

0.30

0.50

0.70

0.30

0.49

0.70

0.30

0.50

0.70

0.30

0.50

0.69

0.30

0.49

0.69

0.30

0.50

0.70

0.30

0.50

0.70

0.30

0.50

0.70

0.30

0.50

0.70

0.30

0.50

0.70

in d.p.

w.c.

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

20

100

320

Flow in

GPM

0.62

3.44

13.00

0.97

5.69

23.82

1.38

9.63

36.15

2.46

17.48

71.77

3.85

22.73

83.95

5.52

35.34

147.74

8.63

55.54

216.30

12.97

79.94

324.16

22.03

141.51

547.1

34.39

220.80

853.09

49.46

317.74

1226.98

87.95

565.77

2195.86

137.35

883.04

3421.26

197.73

1271.62

4930.86

244.14

1537.49

6052.57

308.76

2038.95

8007.74

1

in d.p.

w.c.

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

20

100

200

at 14.7

psia

(0 psig)

2.35

12.21

32.77

3.65

20.21

59.92

5.24

34.2

91.28

9.31

62.09

180

14.57

80.82

212.18

20.92

125.74

372.09

32.71

197.54

543.99

49.17

282.9

816.7

83.58

503.76

1380.03

130.48

786.23

2152.83

187.86

1331.63

3097.20

333.87

2014.95

5532.00

521.58

3145.50

8626.42

750.9

4530

12430.00

927.14

6477.67

15251.50

1172.63

7264.58

20179.85

SERIES TE ORIFICE PLATE FLOWMETER –

CAPACITY STRUCTURE

• Material PTFE, gaskets Buna-N

• Based on 70°F, 14.7 psia (base conditions)

• Beta value based on std sch pipe I.D.

• 1.25˝ overall thickness

• Orice plate thickness is 0.250˝

at 20

psig

3.63

19.58

56.15

5.66

32.44

102.91

8.11

54.92

156.51

14.41

99.75

309.97

22.55

129.68

363.93

32.38

202.03

639.87

50.64

317.58

936.56

76.13

454.77

1404.95

129.44

810.06

2373.02

202.11

1264.42

3701.57

291

1820.05

5325.20

517.25

3241.45

9525.43

808

5060.38

14846.80

1163.44

7288.16

21397.00

1436.59

8812.87

28262.66

1817.05

11688.26

34749.32

at 100

psig

6.61

36.37

107.47

10.3

60.26

197.2

14.8

102.09

300

26.3

185.5

595.2

41.16

241.5

697.39

59.13

375.8

1227.63

92.48

590.91

1798.86

139.06

846.21

2696.28

236.48

1507.64

4553.68

369.29

2353.51

7103.22

531.75

3387.93

10219.28

945.28

6034.85

18290.00

1476.77

9421.74

28506.17

2126.47

13570.33

41089.02

2625.81

16409.42

50427.78

3321.32

21764.08

66737.64

Flowmeters,

Orice Plate

DWYER INSTRUMENTS, INC.

265

Loading...

Loading...