Page 1

BULLETIN F-55

["A"]

["B"]

["C"]

Series HF IN-LINE Flow Monitors

Specifications - Installation and Operating Instructions

Series HF Flow Monitors combine the simplicity of a

sharp edged orifice disk with a variable area flow

monitor to provide a low cost way to measure flow at

high pressures. These monitors are tubular, with all

internal wetted parts sealed within the body casing.

Running through the body is a tapered shaft which is

centered in the bore by pilot disks at each end.

Surrounding the shaft are a sharp-edged floating

orifice disk, a transfer magnet and return spring. The

disk and transfer magnet are held in the “no flow”

position by a biased return spring. As flow moves

through the monitor, it creates a differential pressure at

the orifice disk forcing the disk and transfer magnet

against the return spring. As flow increases, the

differential pressure at the disk increases, forcing the

disk and transfer magnet to move along the tapered

center shaft. As flow decreases, the biased return

spring forces the disk and transfer magnet down the

center shaft, returning to the “no flow” position. In metal

casing monitors, disk and magnet movement are not

visible so a magnet follower is located outside the body

casing, magnetically coupled to the internal transfer

magnet. As flow increases, motion of the internal

magnet moves the magnet follower outside the body

casing, under the scale.

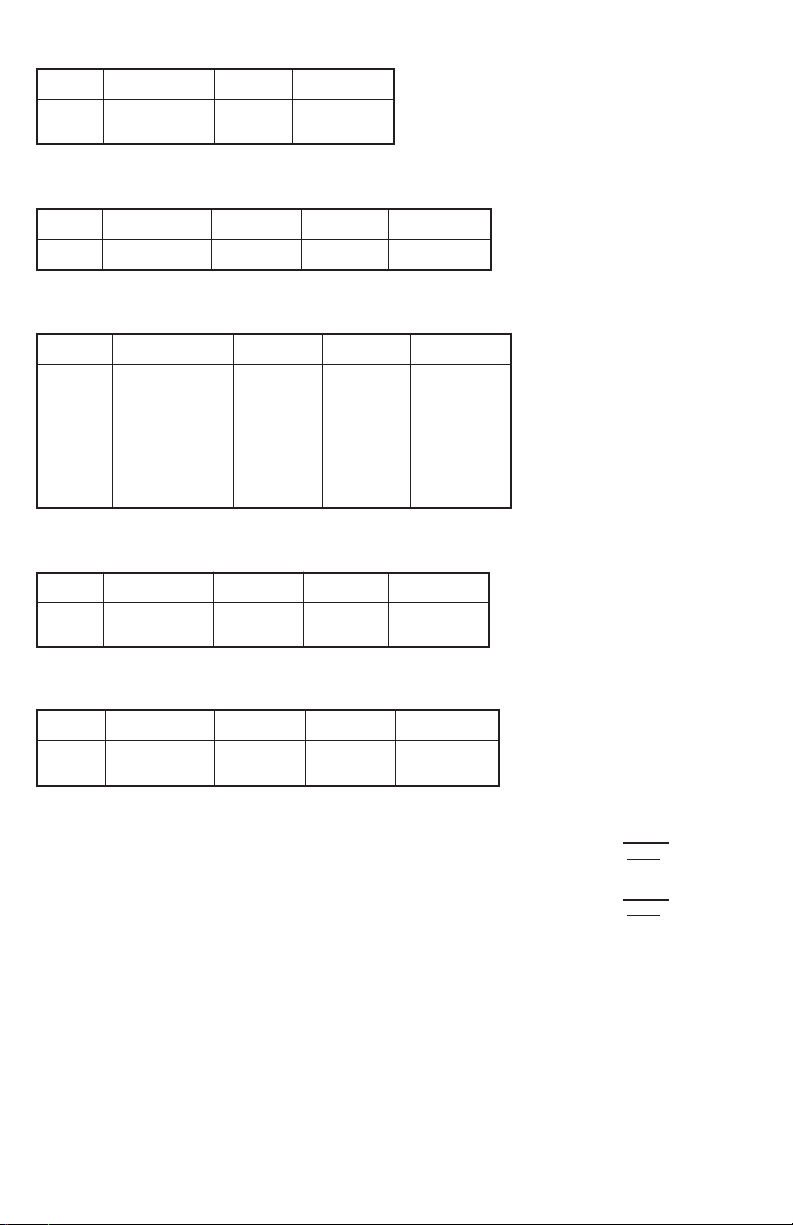

Valve Size

1/8 NPT

1/4 to 1/2 NPT

3/4 to 1 NPT

1-1/4 to 1-1/2 NPT

2 NPT

SPECIFICATIONS

Service: Compatible gases or liquids.

Wetted Materials: Body: Aluminum, brass or 304 SS;

Seals: Buna-N or Fluoroelastomer; Magnet: PTFE

coated Alnico; Other internal parts: 304 SS.

Maximum Viscosity: 500 SSU.

Temperature Limits: HFA, HFL, HFB and HFS

Models: 240°F (116° C); HFH Models: 400°F (204°C).

Pressure Limits: HFA Models: 600 psig (41 bar);

HFL, HFB and HFH Models: 3500 psig (240 bar);

HFS Models: 6000 psig (413 bar).

Accuracy: ±2% FS over entire range.

Repeatability: ±1% of full scale.

Shipping Weight: 1/8 to 1/2˝ female NPT Models; 2

lb (0.9 kg); 3/4 to 1˝ female NPT Models: 3.5 lb (1.59

kg); 1-1/2˝ female NPT Models: 11 lb (5 kg); 2˝ female

NPT Models: 13.5 lb (6.12 kg).

“A”

Reference

1.25

1.875

2.375

3.500

3.500

“B”

Wrench Flats

0.875

1.250

1.750

2.250

2.250

“C”

Reference

4.813

6.562

7.125

10.125

12.625

DWYER INSTRUMENTS, INC.

Page 2

Aluminum body for air or other non-corrosive gases:

Wetted Parts: Aluminum, PTFE coated Alnico, 304 SS and Buna-N

Connection

Model

HFA-0-01

HFA-1-12

HFA-1-22

Aluminum body for oil based fluids:

Wetted Parts: Aluminum, PTFE coated Alnico, 304 SS and Buna-N

Model

HFL-2-05

HFL-4-25

Brass body for water based fluids (non-steam):

Wetted Parts: Brass, PTFE coated Alnico, 304 SS and Buna-N

Model

HFB-0-01

HFB-0-02

HFB-2-05

HFB-3-15

HFB-3-20

HFB-4-35

HFB-5-50

HFB-5-100

HFB-6-75

HFB-6-150

304 Stainless Steel body for high-pressure fluids:

Wetted Parts: 304 SS, Fluoroelastomer and PTFE

Model

HFS-0-01

HFS-2-02

HFS-2-10

Size

1/8˝ female NPT

1/4˝ female NPT

1/4˝ female NPT

Connection

Size

1/2˝ female NPT

1˝ female NPT

Connection

Size

1/8˝ female NPT

1/8˝ female NPT

1/2˝ female NPT

3/4˝ female NPT

3/4˝ female NPT

1˝ female NPT

1-1/2˝ female NPT

1-1/2˝ female NPT

2˝ female NPT

2˝ female NPT

Connection

Size

1/8˝ female NPT

1/2˝ female NPT

1/2˝ female NPT

Range, Air

SCFM

2-12

2-12

4-23

Range, GPM

Oil

0.5-5

2-25

Range, GPM

Water

0.05-1

0.2-2

0.5-5

2-15

2-20

4-40

5-50

10-100

8-75

20-150

Range, GPM

Water

0.05-1

0.2-2

0.5-10

Max. Pressure

Drop, PSID

3.32

3.32

3.61

Range, LPM

Oil

1-19

7.5-95

Range, LPM

Water

.19-3.8

.75-7.5

1-19

7.5-55

7.5-75

19-130

19-189

38-379

31-284

76-568

Range, LPM

Water

0.19-3.8

0.75-7.5

1.9-38

Max. Pressure

Drop, PSID

6.08

8.41

Max. Pressure

Drop, PSID

1.98

5.58

7.18

10.2

6.2

15.2

9.25

25.59

14.95

39.86

Max. Pressure

Drop, PSID

1.98

5.58

8.68

Brass Body High Temperature 400˚F for water based fluids:

Wetted Parts: Brass, PTFE coated Alnico, 304 SS and Fluoroelastomer

Model

HFH-2-05

HFH-2-10

HFH-4-35

READING THE MONITOR

Note the red reference line running 360° around the

white magnet follower. This line moves in direct

proportion to the movement of the internal orifice disk.

When fluid is flowing, the flow rate is read by aligning

the red reference line with the closest scale graduation.

SPECIFIC GRAVITY OR DENSITY EFFECT

Standard water monitors are calibrated with water and

oil monitors are calibrated with .873 S.G. oil. Flow

indication will read high for heavier fluids and low for

lighter fluids. A correction factor for other specific

gravities can be established using the following

formulas.

Connection

Size

1/2˝ female NPT

1/2˝ female NPT

1˝ female NPT

Range, GPM

Water

0.5-5

1-10

5-35

Range, LPM

Water

1-19

3.8-38

19-130

Max. Pressure

Drop, PSID

7.18

8.68

13.46

For Water Monitors use:

Actual = Observed Reading x 1.0

For Oil Monitors use:

Actual = Observed Reading x 0.873

VISCOSITY EFFECT

The Series HF Flow Monitor incorporates a unique

floating sharp-edged orifice disk which provides greater

operating stability and accuracy over wide ranging

viscosities up to 500 SSU.

√

√

S.G.

S.G.

Page 3

BASIC APPLICATION INFORMATION

The flow monitor can be installed directly in the fluid

line without flow straightening or special piping. They

are suitable for measuring the flow rate of most liquids

which do not contain particles larger than 74 microns.

1. The magnetic follower is sealed inside the Lexan

tube to allow use in areas where the unit might be

sprayed or washed with soap water.

2. Mount the monitor in a location allowing easy

access for reading and maintenance.

3. The monitor should not be located near hot pipes or

equipment which could damage the window tube

and/or scale.

4. Mount the monitor at least 1 ft (.3 m) from large

electric motors which can weaken or demagnetize

the internal magnet.

5. Aluminum should not be used for water.

WARNINGS AND PRECAUTIONS

1. These monitors are designed to operate in systems

that flow only in one direction, matching the

direction indicated by the arrow on the flow scale.

Operation in the reverse direction can damage the

monitor or other system components.

2. The window tube is made of polycarbonate which

can be safely cleaned with soap and water. many

other cleaning agents can damage this material,

causing discoloration or crazing. To check

compatibility, call General Electric’s polycarbonate

Compatibility Reference Line at 1(800)845-0600,

USA.

3. To maintain accuracy and repeatability, many

internal parts are precision machined and thus

require filtration or at least 74 micron or 200 mesh

screen.

4. All monitors are tested and calibrated using a light

hydraulic oil. Units are well drained, but some oil

residue may remain. Please check compatibility

with your fluid. Cleaning may be required before

use. See “Cleaning and Inspection.”

5. When installing aluminum or brass monitors onto

steel pipe, take caution not to over tighten

connections. Threads could strip if over tightened.

6. Aluminum and brass monitors should not be used in

systems where piping is not supported. Heavy

weight can cause the monitor to bend and

malfunction.

7. Do not exceed the maximum operating pressure or

temperature limit.

8. Pressure and flow surges can disengage the outer

magnet follower from the transfer magnet. If this

occurs, a shock suppressor should be used to avoid

repetitive malfunctions.

9. Caution should be used when using Teflon® thread

tape on joints. Leave at least 1/8˝ (3 mm) of

exposed pipe on the end.

10. These monitors use an internal transfer magnet in

their design. Because of this be aware of the

following:

a. Keep computer disks or tapes away from these

units.

b. If metal particles are flowing through this device,

a magnetic filter may be required.

BASIC INSTALLATION

Series HF Flow Monitors are installed in-line and are

direct reading. They can be mounted in a vertical or

horizontal position as long as flow is in the direction of

the arrow on the side. No straight pipe is required

before or after the monitor. If necessary, 90° elbows

can be installed on both ends without significant flow

variation. When installing, apply a small amount of pipe

thread sealant tape or pipe thread sealant to assure a

good seal. Locate filter, if used, in front of monitor and

in a location allowing easy access for routine

maintenance. Refer to Warnings and Precautions for

additional information.

FLUID FLOW IN REVERSE DIRECTION

These monitors will not allow flow in the reverse

direction, opposite to the arrow on the scale. In the

reverse direction unit will act like a leaky check valve.

If the application requires occasional reverse flow,

install a check valve in parallel with the monitor which

will force flow around the unit when reversed. This type

of check valve can be obtained from your local fluid

component distributor.

WARNING: Do not remove monitor from system

without proper and adequate safety measures if

fluid or gas is toxic, corrosive or flammable. Shut

down system and relieve pressure before removing

flow monitor from system.

DISASSEMBLY

Important: It is not necessary to remove the window

tube or window seals to clean the monitor. Note how

the unit is disassembled to aid in reassembly.

Warning - Shut down system and relieve pressure

before removing monitor from flow line.

1. Use a clean, dry cloth to remove all foreign matter

from exterior of monitor, especially around threaded

connections.

2. Remove monitor from flow line.

3. With the arrow on the scale pointing upward, secure

the unit in a vice using the flats on the inlet

connection. DO NOT apply wrench or vice to Lexan

tube.

4. Use a wrench on the flats provided on the outlet

connection and turn counter-clockwise to loosen.

Either port may come loose. Do not remove end

connection at this time.

5. Remove monitor from vice. Hold unit so the end

connection that has been loosened is on top.

Remove loose connection.

6. Tilt open end of monitor over a clean cloth to

expose inner cartridge. Remove inner cartridge

assembly from body casing. NOTE: Because the

transfer magnet is coupled magnetically to the

magnet follower, you will notice a light resistance

when removing the cartridge. If cartridge does not

slide out, insert a wooden dowl in opposite end of

monitor and push or rap lightly on dowel until

cartridge breaks free. IMPORTANT: If inner

cartridge does slide out freely, it may be a sign of

contamination. Locate and remove the source of

contamination before returning monitor to service or

the problem will reoccur. It may be necessary to

install finer filtration or a magnetic filter in the

system. The transfer magnet is a powerful Alnico

magnet. Keep it away from metal chips and filings.

They can be difficult to remove when reassembling

and will cause premature failure.

7. Examine inner cartridge assembly for

contamination. If the inner cartridge assembly has

no contamination and is working properly,

reassemble unit and return to service. If

contamination is found, proceed to Cleaning and

Inspection.

Page 4

CLEANING AND INSPECTION

1. Soak inner cartridge assembly in a suitable

cleaning solvent or soap and water. Caution:

When using a compressed air hose, wear proper

eye protection.

2. Remove parts from solvent. Use compressed air

and/or scrub lightly with a soft brush to remove any

remaining contaminants. Remove any magnetized

particles from transfer magnet.

3. Remove any contaminants from inside body

casing.

4. If inner cartridge assembly or body casing cannot

be cleaned, is scored, pitted or damaged beyond

repair, replace monitor.

5. Clean polycarbonate window with soap and water

or a compatible cleaning solvent.

6. Clean and inspect O-ring assemblies for nicks and

cuts. Replace as necessary.

7. After monitor is cleaned, reassemble in reverse

order of disassembly.

8. Clean and inspect monitor every six months.

Properly filtered monitor will provide years of

trouble free service. If unit is not properly protected

by a filter, damage and malfunction can occur.

Damage caused by excessive contamination is not

covered by warranty.

9. If the cartridge clip is removed or lost, a new clip

should be used. Cartridge retainer clips are Waldes

No. 5105-12H for 1/4˝ and 1/2˝ models, No. 510518H for 3/4˝, 1˝, 1-1/2˝, and 2˝ models.

RECOMMENDED FILTRATION

The manufacturer recommends system filtration of at

least a 74 micron filter or a 200 mesh screen. If

inadequate filtration has caused monitor failure, it will

normally fail in the open position. Some systems may

require a magnetic filter. Important: Monitor damage

caused by excessive contamination is not covered by

warranty.

STABILIZED CONTAMINATION

The goal of filtration is to create effective protection

from system contamination. Proper filtration stabilizes

contamination to allow fluid components to function

properly. A fluid system is considered stabilized when

“contamination in” equals “contamination out.” Proper

filtration must reduce initial contamination to a

stabilized level within an acceptable time period. The

entire system should be stabilized in time to prevent

premature wear or damage to monitor components.

CONTAMINATION SOURCES

Fresh Fluid - When new or fresh fluid is stored inside

holding tanks, the fluid may be contaminated with scale

or metal flakes from inside the tank. To prevent this

type of contamination, filter fresh fluid before adding to

the system.

New Machinery - When building new machines, a

certain amount of built-in contamination is

unavoidable. Typical built-in contamination might

include dust, dirt, chips, fibers, sand, flushing solutions,

moisture, weld splatters and pipe sealants. Flushing

the system before operation can reduce contamination

but cannot eliminate it entirely. Unless the system is

flushed at a high velocity some contamination will not

be dislodged until the system is in operation. System

contamination can cause fluid component malfunction.

Environmental Contamination - When performing

routine maintenance, the systems fluid is commonly

exposed to environmental contamination. Exercise

caution during routine maintenance to prevent this type

of contamination. Change breather filter and system air

filter regularly.

Self-Generated Contamination - Self-generated

contamination is a product of wear, cavitation, fluid

breakdown and corrosion. Systems that are carefully

flushed, maintained and have fresh fluids added,

mainly have self-generated contamination. In this

case, proper filtration can help prevent fluid component

malfunction.

COMPRESSIBILITY OF AIR AND GASES

Air and gases are extremely compressible. Gas

density increases as pressure increases. In most

cases, correction factors should be used to obtain

accurate readings. See correction factors below.

CALIBRATION

All standard Dwyer Instruments,Inc. air flow monitors

are calibrated for air with a specific gravity of 1.0 at 100

psig and 70°F (6.89 bar and 21.1°C). Monitors are

calibrated in SCFM, Standard Cubic Feet per Minute. A

standard cubic foot or air is defined as a cubic foot of

air at 70°F at atmospheric pressure, 14.7 PSI at sea

level. Since most industrial pneumatic systems

typically operate at 90-100 PSI, standard Dwyer

Instruments, Inc. Monitors are calibrated for inlet

conditions of 100 PSI at 70°F. When operating the

monitor at other pressures or temperatures, a

correction factor should be used to maintain the

original design accuracy of the monitor. When inlet

pressure of the monitor is at or near 100 PSI, the air

flow can be read directly from the monitor scale. When

pressure is other than 100 PSI, use the following

correction factor tables.

CORRECTION FACTORS FOR AIR AND GASES

SCFM (indicated) x (CF) = SCFM (actual)

1) x (f2) x (f3)

CF = (f

Note: It is not necessary to use all correction factors.

TABLE 1

(f1) PRESSURE CORRECTION FACTORS

14.7 + psig

f1=

––––––––––

√

114.7 psia

TABLE 2

(f2) TEMPERATURE CORRECTION FACTORS

√

√

530

––––––––

460 + °F

1

–––––––

Sp. Gr

.

f2=

TABLE 3

(f3) SPECIFIC GRAVITY CORRECTION FACTOR

f3=

INTERNAL GAGE PRESSURE

System pressure will vary from location to location in a

typical dynamic air or gas system. Because of this, it is

important that an accurate pressure gage be used to

determine flow conditions as close as possible to the

inlet port of the flow monitor.

©Copyright 2015 Dwyer Instruments, Inc Printed in U.S.A. 7/15 FR# 440843-00 Rev. 4

DWYER INSTRUMENTS, INC.

Loading...

Loading...