Page 1

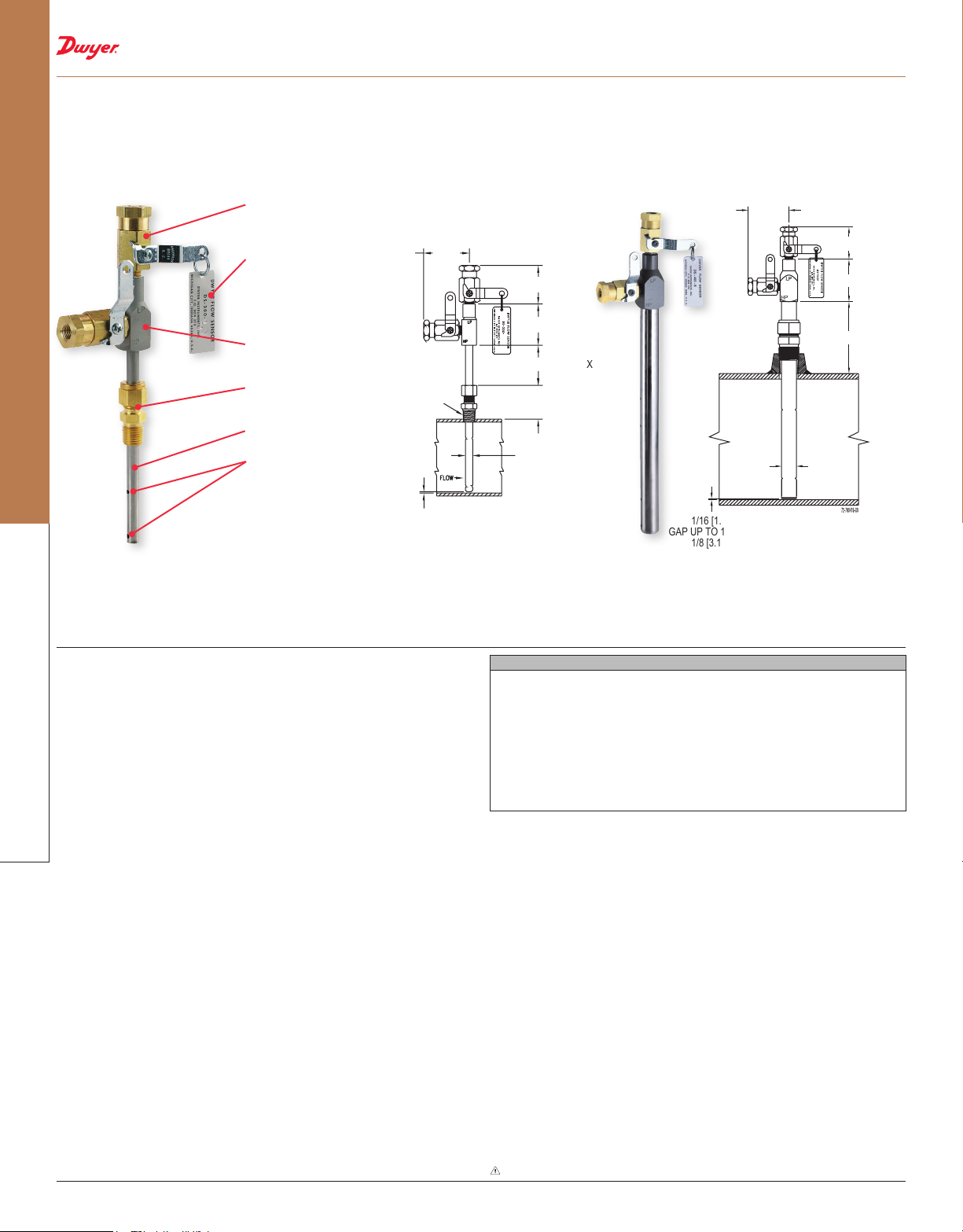

CLEARANCE

1-15/16

GAP 14˝ PIPE AND UP

2-1/16

SERIES DS

IN-LINE FLOW SENSORS

FLOW

Use with the Dwyer® Differential Pressure Gages or Transmitters

Valves — Standard, brass

with TFE seat and Buna-N

O-ring.

1/4 NPT

1/16 [1.59]

[49.21]

1-5/8 [41.28]

1-3/4 [44.45]

1-11/16 [42.86] APPROX

1-7/16 [36.53]

5/16 [7.94]

GAP UP TO 12˝ PIPE

Large 3/4 inch diameter for extra strength in lengths to 24 inches

Nameplate — Stainless

steel permanently attached

with split ring. Includes

complete size and model

information.

Head — Machined

stainless steel.

Packing gland — Brass

compression tting.

Sensor tube — 304 SS.

Sensing ports — Multiple

upstream and downstream

ports sized and positioned

to provide effective

accurate pressure

averaging, even at lower

velocities.

Series DS-300 Series DS-400

1/16 [1.60]

1/8 [3.175]

[52.40]

1-5/8 [41.28] TYP.

2-1/8 [53.98]

3-5/8 [92.08] APPROX.

3/4 [19.05]

DIA.

The Series DS In-Line Flow Sensors are two Series of averaging Pitot tubes for

compatible gases and liquids that provide accurate and convenient ow rate sensing,

for schedule 40 pipe, when purchased with suitable differential pressure gage with

appropriate range. The Series DS-300 Averaging Flow Sensors are designed to be

In-Line

inserted in the pipeline through a compression tting and available for pipe sizes from

Flow Sensors,

1 to 10˝ (2.5 to 25.4 cm). Accessories include adapters with 1/4˝ SAE 45° ared ends

compatible with hoses supplied with the Model A-471 Portable Capsuhelic

The Series DS-400 Averaging Flow Sensors are designed for insertion lengths up

to 24˝ (61 cm) and include a pair of 1/8˝ NPT x 1/4˝ SAE 45° ared adapters which

are compatible with hoses used in the Model A-471 Portable Capsuhelic

The supplied solid brass mounting adapter has a 3/4˝ dia. compression tting to lock

in required insertion length and a 3/4˝ male NPT thread for mounting in a threaded

branch connection (not included).

FEATURES/BENEFITS

• Multiple sensing point measurement and built-in averaging capability eliminates

the need for “traversing” the owing stream with single point velocity pressure

measurement saving time

• Extremely reliable, proven technology, Pitot tubes, have been used in ow

measurement for years

• All models include convenient and quick-acting quarter-turn ball valves to isolate the

sensor for zeroing with 1/8˝ female NPT valve assembly process connections.

• Furnished with instrument shut-off valves on both pressure connections with 1/8˝

female NPT connections rated at 200 psig (13.7 bar) and 200°F (93.3°C)

• Where valves are not required, they can be omitted at reduced cost

• The Series DS-400 Averaging Flow Sensors are quality constructed from extra

strong 3/4˝ dia. stainless steel to resist increased forces encountered at higher ow

rates with both air and water

• Economical ow indication when used with appropriate differential pressure gage

• Rugged construction yields, non-clogging, stable design

®

®

Gage Kit.

Gage Kit.

SPECIFICATIONS

Service: Compatible gases or liquids.

Wetted Materials: Sensor tube: 304 SS; Compression tting: brass.

Temperature Limit: 200°F (93.3°C).

Pressure Limit: 200 psig (13.78 bar) at 200°F (93.3°C).

Pipe Sizes: DS-300: 1 to 10˝ (2.5 to 25.4 cm); DS-400: 6 to 24˝ (15.2 to 61 cm).

Process Connections: DS-300: 1/4˝ male NPT compression tting included; DS-

400: 3/4˝ male NPT compression tting included.

Piping Connections: DS-300: 1/8˝ female NPT; optional 1/8˝ female NPT x 1/4˝

SAE 45 ared adapter sold separately; DS-400: 1/8˝ female NPT with 1/8˝ female

NPT x 1/4˝ SAE 45 ared adapters include.

Weights: Consult factory.

APPLICATIONS

• Remediation

• Natural, are, ue, stack gas

• Boiler feedwater

• Cooling water

• Superheated, saturated, or geothermal steam

• Combustion or compressed air

• Oil ow monitoring

DWYER INSTRUMENTS, INC. 262

USA: California Proposition 65

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Page 2

®

SERIES DS

IN-LINE FLOW SENSORS

Use with the Dwyer® Differential Pressure Gages or Transmitters

FLOW

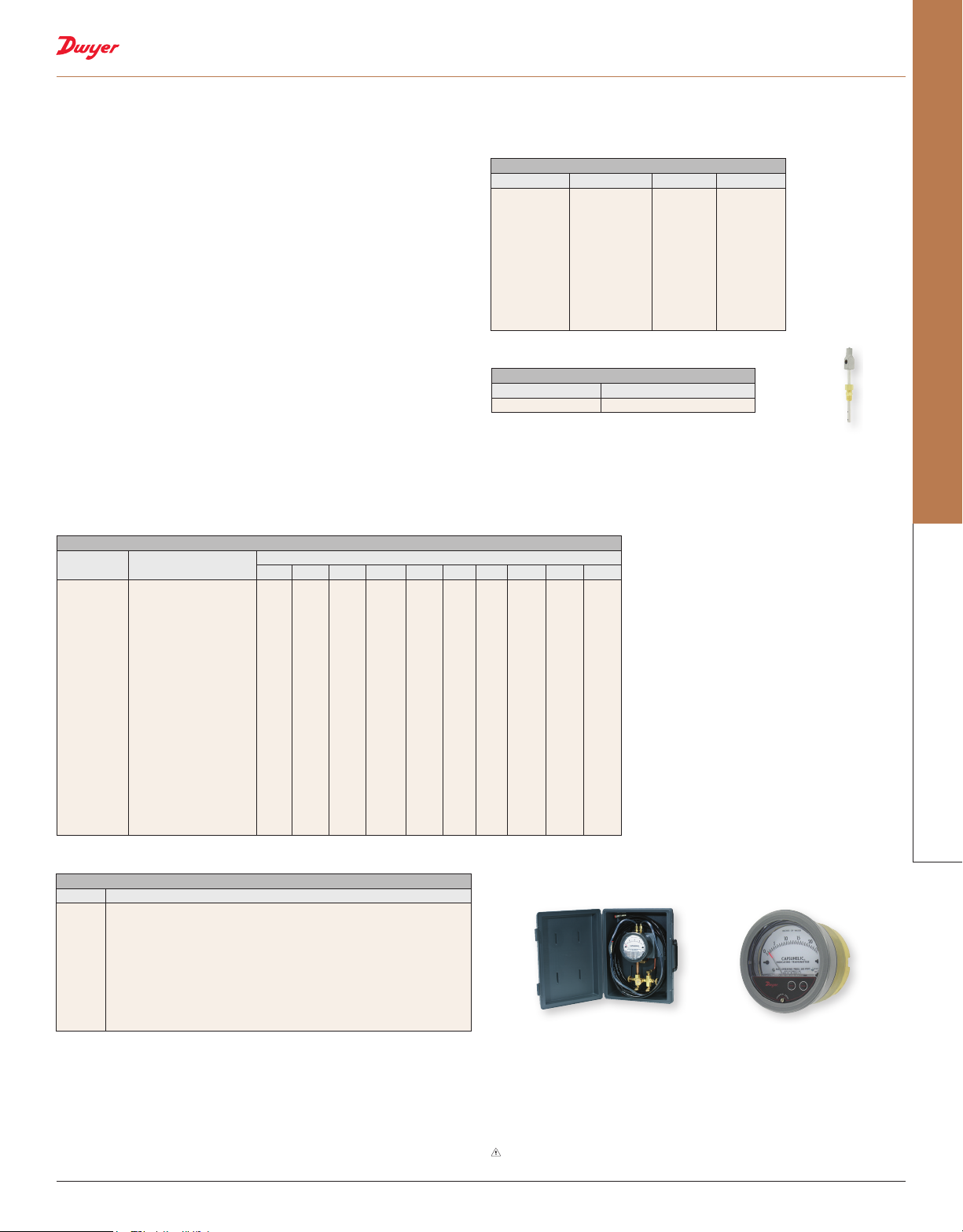

HOW TO ORDER

Merely determine the pipe size into which the ow sensor will be mounted and

designate the size as a sufx to Model DS-300. For example, a ow sensor to be

mounted in a 2˝ pipe would be a Model No. DS-300-2˝.

For non-critical water and air ow monitoring applications, the chart below can be

utilized for ordering a stock Capsuhelic

300 ow sensor. Simply locate the maximum ow rate for the media being measured

under the appropriate pipe size and read the Capsuhelic

water column to the left. The DS-300 sensor is supplied with installation and operating

instructions, Bulletin F-50. It also includes complete ow conversion information for the

three media conditions shown in the chart below. This information enables the user

to create a complete differential pressure to ow rate conversion table for the sensor

and differential pressure gage employed. Both the Dwyer

sensor feature excellent repeatability so, once the desired ow rate is determined,

deviation from that ow in quantitative measure can be easily determined. You may

wish to order the adjustable signal ag option for the Capsuhelic

easily identied reference point for the proper ow.

Capsuhelic

ow units are available on special order for more critical applications. Customer

supplied data for the full-scale ow (quantity and units) is required along with

the differential pressure reading at that full ow gure. Prior to ordering a special

Capsuhelic

Bulletin F-50 to obtain complete data on converting ow rates of various media to the

sensor differential pressure output. With this bulletin and after making a few simple

calculations, the exact range gage required can easily be determined.

RANGE CHART

Gage Range

(in w.c.)

2

2

2

5

5

5

10

10

10

25

25

25

50

50

50

100

100

100

®

gages with special ranges and/or direct reading scales in appropriate

®

differential pressure gage for ow read-out, we recommend you request

Media

@ 70°F

Water (GPM)

Air @ 14.7 PSIA (SCFM)

Air @ 100 PSIG (SCFM)

Water (GPM)

Air @ 14.7 PSIA (SCFM)

Air @ 100 PSIG (SCFM)

Water (GPM)

Air @ 14.7 PSIA (SCFM)

Air @ 100 PSIG (SCFM)

Water (GPM)

Air @ 14.7 PSIA (SCFM)

Air @ 100 PSIG (SCFM)

Water (GPM)

Air @ 14.7 PSIA (SCFM)

Air @ 100 PSIG (SCFM)

Water (GPM)

Air @ 14.7 PSIA (SCFM)

Air @ 100 PSIG (SCFM)

®

differential pressure gage for use with the DS-

®

gage range in inches of

®

Capsuhelic® gage and ow

®

gage to provide an

Full Range Flows by Pipe Size (Approximate)

1˝ 1-1/4˝ 1-1/2˝ 2˝ 2-1/2˝ 3˝ 4˝ 6˝ 8˝ 10˝

4.8

8.3

11.5

20.5

30

19.0

50.0

7.7

30.0

83.0

11.0

41.0

120.0

18.0

63.0

185.0

25.0

90.0

260.0

36.5

135.0

370.0

33.0

90.5

14.0

51.0

142.0

19.0

72.0

205.0

32.0

112.0

325.0

44.0

161.0

460.0

62.0

230.0

660.0

42.0

120.0

18.0

66.0

190.0

25.5

93.0

275.0

40.5

155.0

430.0

57.5

205.0

620.0

82.0

300.0

870.0

65.0

210.0

34.0

118.0

340.0

45.5

163.0

470.0

72.0

255.0

760.0

100.0

360.0

1050.0

142.0

505.0

1500.0

113

325

47

178

610

67

250

740

108

390

1200

152

560

1700

220

800

2300

49

183

510

78

289

820

110

410

1100

173

640

1800

247

900

2600

350

1290

3600

MODEL CHART

Model Description Model Description

DS-300-1˝

DS-300-1-1/4˝

DS-300-1-1/2˝

DS-300-2˝

DS-300-2-1/2˝

DS-300-3˝

DS-300-4˝

DS-300-6˝

DS-300-8˝

DS-300-10˝

OPTIONS

To order add sufx: Description

-LV DS-300 or DS-400 less valves

86

205

330

760

920

2050

138

320

510

1200

1600

3300

195

450

725

1690

2000

4600

310

720

1130

2630

3300

7200

435

1000

1600

3700

4600

10000

620

1500

2290

5000

6500

15000

1˝ pipe size

1-1/4˝ pipe size

1-1/2˝ pipe size

2˝ pipe size

2-1/2˝ pipe size

3˝ pipe size

4˝ pipe size

6˝ pipe size

8˝ pipe size

10˝ pipe size

350

560

1340

2130

3600

6000

560

890

2150

3400

5700

10000

800

1260

3040

4860

8100

15000

1250

2000

4860

7700

13000

22000

1800

6400

18500

DS-400-6˝

DS-400-8˝

DS-400-10˝

DS-400-12˝

DS-400-14˝

DS-400-16˝

DS-400-18˝

DS-400-20˝

DS-400-24˝

6˝ pipe size

8˝ pipe size

10˝ pipe size

12˝ pipe size

14˝ pipe size

16˝ pipe size

18˝ pipe size

20˝ pipe size

24˝ pipe size

-LV option

Flow Sensors,

In-Line

ACCESSORIES

Model Description

A-160

A-161

A-471

631B

Threaded branch connection, 3/8˝ NPT, forged steel, 3000 psi

Brass bushing, 1/4˝ x 3/8˝

Portable kit. For portable operation, the A-471 Capsuhelic

gage kit is available complete with tough polypropylene carrying case,

mounting bracket, 3-way manifold valve, two 10´ high pressure hoses,

and all necessary ttings.u

Capsuhelic

transmitter for use with DS-300/400 ow sensors. Use Series 631B

Capsuhelic

®

portable

®

wet/wet differential pressure transmitter. Low pressure

®

wet/wet differential pressure transmitter.

Capsuhelic® gage shown

installed In A-471 portable kit

USA: California Proposition 65

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Series 631B

uSee page 31 (Series 4000)

DWYER INSTRUMENTS, INC.

263

Loading...

Loading...