Page 1

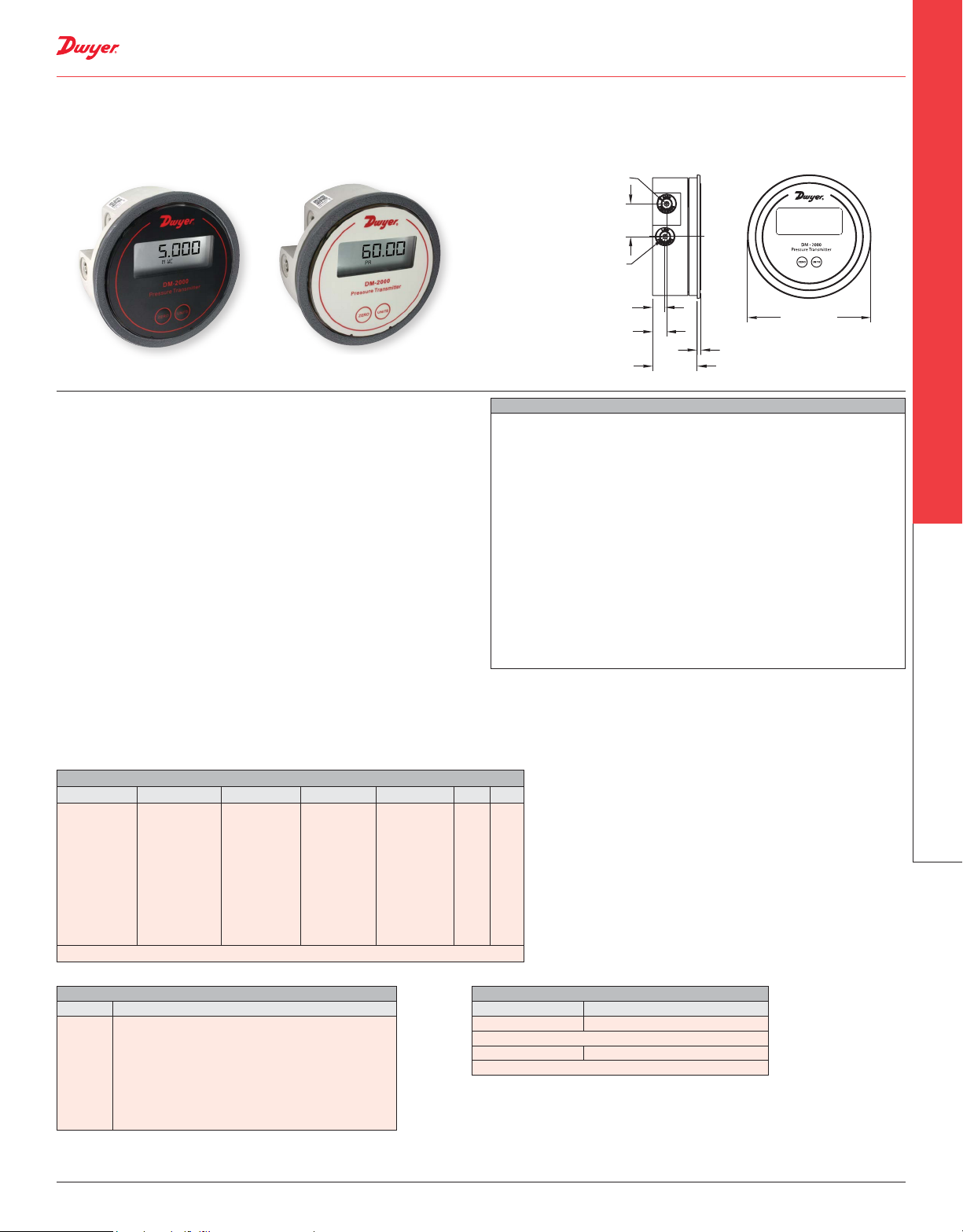

HIGH PRESSURE PORT

[42.86]

LOW PRESSURE POR

SERIES DM-2000

DIFFERENTIAL PRESSURE TRANSMITTERS

Same Size as Standard Magnehelic® Differential Pressure Gage

DM-2000-LCD DM-2100-LCD

[31.75]

7/16

[11.11]

17/32

[13.50]

1-1/4

T

1-11/16

5/32

[3.97]

ø4-3/4

[120.65]

PRESSURE

The Dwyer Series DM-2000 Differential Pressure Transmitters sense the pressure

of air and compatible gases and sends a standard 4-20 mA output signal. The DM-

2000 housing is specically designed to mount in the same diameter cutout as a

standard Magnehelic

to specic ranges.

Pressure connections are inherent to the glass lled plastic molded housing making

installation quick and easy. Digital push-button zero and span simplify calibration over

typical turn-potentiometers. An optional 3.5 digit LCD shows process and engineering

units. A single push-button allows eld selection of 4 to 6 engineering units depending

on range.

FEATURES/BENEFITS

• Zero and span controls provide easy calibration checks and shorter installation time

to get device running and monitoring

• Quick response to pressure changes means no delay in signaling and alerting to

critical situations

• Easy to read LCD display provides immediate local alerts allowing corrective action

to be taken quicker to eliminate the problem from becoming widespread

• Same size as Magnehelic® simplies eld upgrade to digital pressure gage by

reducing install steps

• Tamper proof button conguration to prevent accidental changes to the settings

APPLICATIONS

• Differential pressure across lters

• Fan control

• Static pressures in ducts or buildings

MODEL CHART

Model Range (in w.c.) Pa mm w.c. mBar kPa psi

DM-2001-LCD

DM-2002-LCD

DM-2003-LCD

DM-2004-LCD

DM-2005-LCD

DM-2006-LCD

DM-2007-LCD

DM-2012-LCD

DM-2013-LCD

DM-2019-LCD

Note: For white overlay change -20 to -21. Example: DM-2102-LCD

®

gage. A wide range of models are available factory calibrated

0 to .100

0 to .250

0 to .500

0 to 1.000

0 to 2.00

0 to 3.00

0 to 5.00

0 to ±.250

0 to ±.500

0 to ±.200

24.9

62.2

124.3

249

497

746

1243

0 to ±62.2

0 to ±124.3

0 to ±49.8

2.54

6.35

12.70

25.4

50.8

76.2

127-0

0 to ±6.35

0 to ±12.70

0 to ±5.08

.249

.622

1.243

2.49

4.97

7.46

12.43

0 to ±.622

0 to ±1.243

0 to ±.498

-

.124

.249

.497

.746

1.243

-

-

-

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Accuracy: ±1% FS, ±30 Pa model ±4% FS at 70°F.

Stability: ±1% FS/yr.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

Pressure Limits: 10 psig (0.69 bar).

Thermal Effect: ±0.055% FS/°F (0.099% FS/°C), ±30 Pa model ±0.13% FS/°F

(0.234% FS/°C).

Power Requirements: 10-35 VDC (2 wire).

Output Signal: 4-20 mA.

Zero and Span Adjustments: Digital push-button zero and span.

Loop Resistance: DC: 0 to 1250 Ω maximum.

Current Consumption: DC: 38 mA max.

Electrical Connections: Screw-type terminal block.

Display: 3.5 digit LCD, 0.7˝ H.

Process Connections: 1/8˝ ID tubing.

Mounting Orientation: Vertical.

Weight: 4.8 oz (136 g).

-

-

-

-

-

.108

.180

-

-

-

Differential Pressure Transmitters

ACCESSORIES

Model Description

A-299

A-300

A-302F-A

A-320-A

A-489

SCD-PS

Surface mounting bracket

Flat ush mounting bracket

303 SS static pressure tip with mounting ange; for 3/16˝

ID rubber or plastic tubing; 4˝ insertion depth; includes

mounting screws

Instrument enclosure

4˝ straight static pressure tip with ange

100-240 VAC/VDC to 24 VDC power supply

OPTIONS

To order add sufx: Description

-NIST NIST traceable calibration certicate

Example: DM-2002-LCD-NIST

-FC Factory calibration certicate

Example: DM-2002-LCD-FC

Process Tubing Options: See page 455 (Gage Tubing Accessories)

DWYER INSTRUMENTS, INC. |

63

Loading...

Loading...