Page 1

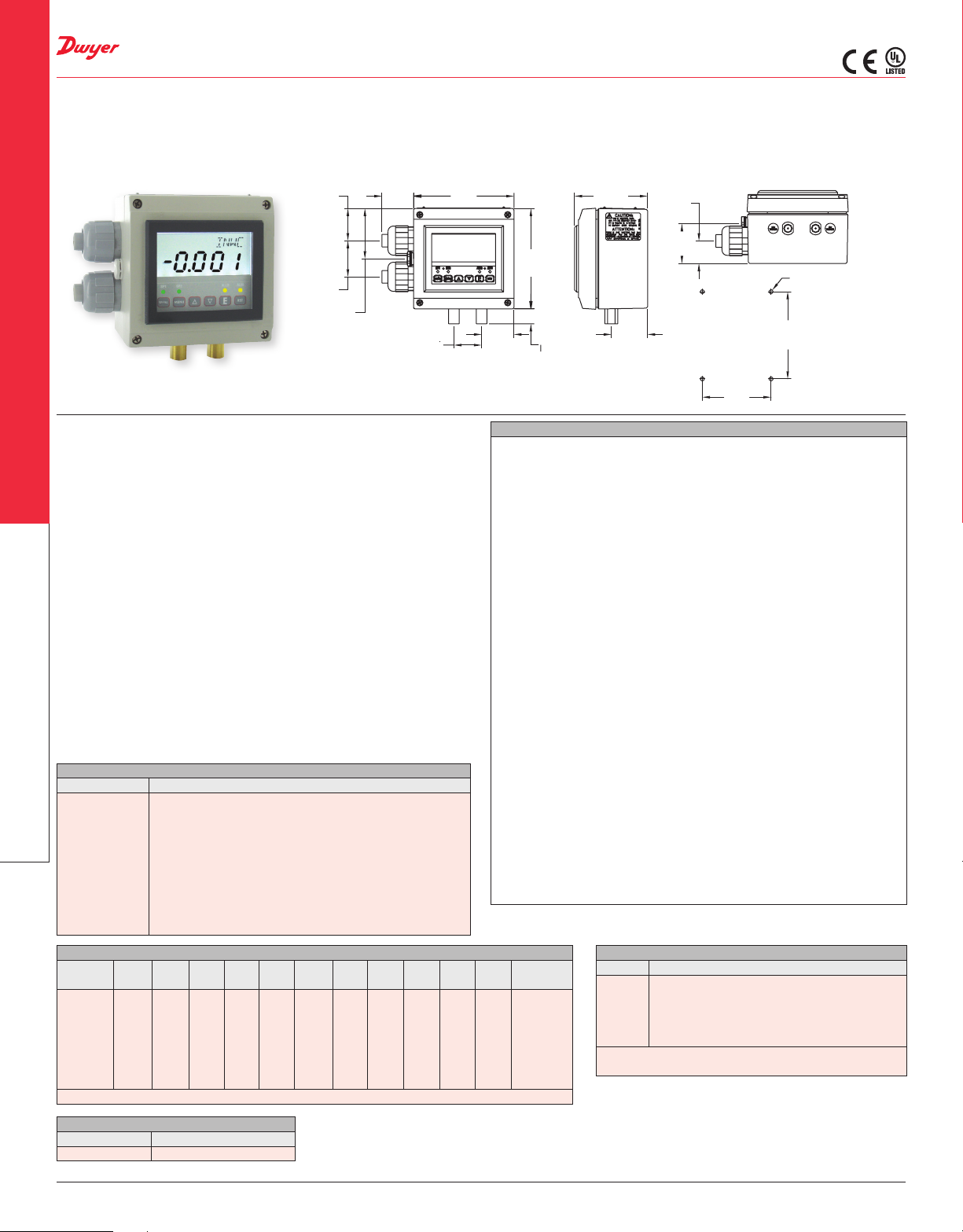

1-45/64

1-31/64

[83]

®

SERIES DHII

DIGIHELIC® II DIFFERENTIAL PRESSURE CONTROLLER

NEMA 4 (IP66) Housing With Large, Bright LCD, Square Root Output for Flow

PRESSURE

Differential Pressure

1-1/2

[38.35]

[43.18]

2-23/64

[59.94]

The Series DHII Digihelic® II Differential Pressure Controller takes all the features

of the standard Digihelic

4 (IP66) housing.

The Digihelic

process output and Modbus

display that can easily be seen from long distances. The electrical wiring has also been

enhanced in the DHII with its detachable terminal blocks. The removable terminals

allow the install to easily wire the terminal block outside the housing and then attach

to the circuit board, reducing wiring difculties and installation time on the process.

The Digihelic

this product to be the perfect choice when mounting pressure controls outdoors in

such applications as rooftop air handlers. This housing also makes it the ideal solution

for surface mounting in clean rooms or facilities where water or a cleaning solution is

utilized in maintaining plant cleanliness.

FEATURES/BENEFITS

• NEMA 4 housing enables a range of uses both outdoors or indoors where water is

present

• Large backlight LCD display provides local reading from a distance

• Detachable terminal blocks reduce wiring difculties saving installation time

APPLICATIONS

• Air handlers

• Clean rooms

Gages/Switches, Transmitters

ACCESSORIES

Model Description

MN-1

A-301

A-302

A-438

A-489

A-302F-A

Digihelic Links

MODEL CHART - AVAILABLE PRESSURE ENGINEERING UNITS

Model

DHII-002

DHII-004

DHII-006

DHII-007

DHII-008

DHII-009*

DHII-010*

*Velocity and volumetric ow not available on bi-directional range units and models DHII-009 & DHII-010.

OPTIONS

Use order code: Description

-NIST NIST calibration certicate

®

II Pressure Controller combines the 2 SPDT control relays, 4 to 20 mA

®

II Differential Pressure Control in the NEMA 4 (IP66) enclosure enables

in

w.c.

.2500

1.000

5.000

10.00

25.00

50.00

100.0

®

Pressure Controller and packages them in a robust NEMA

®

communications with a large, brightly backlit 4 digit LCD

Mini-Node™ USB/RS-485 converter

Static pressure tip for 1/4˝ metal tubing connection

Static pressure tip for 3/16˝ and 1/8˝ I.D. plastic or rubber

tubing

Surface mounting brackets

4˝ straight static pressure tip with ange

303 SS static pressure tip with mounting ange; for 3/16˝ ID

rubber or plastic tubing; 4˝ insertion depth; includes mounting

screws

™

Communications software

ft

mm

w.c.

-

.4167

.8333

2.083

4.167

8.333

cm

w.c.

w.c. psi in Hg

6.350

0.635

25.40

2.540

127.0

12.70

254.0

25.40

635.0

63.50

1270

127.0

2540

254.0

-

.1806

.3613

.9032

1.806

3.613

mm

Hg mbar Pa kPa hPa oz/in

-

0.467

-

1.868

.3678

9.342

.7356

18.68

1.839

46.71

3.678

93.42

7.356

186.8

[37.62]

0.623

2.491

12.45

24.91

62.27

124.5

249.1

1-5/16

62.28

249.1

1245

2491

6227

-

-

[33]

4-23/32

[120]

-

0.249

1.245

2.491

6.227

12.45

24.91

4-23/32

[120]

1-17/32

[38.61]

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Housing Material: Aluminum, glass.

Accuracy: ±0.5% at 77°F (25°C) including hysteresis and repeatability (after 1 hour

warm-up).

Stability: < ±1% per year.

Pressure Limits: Ranges ≤ 2.5 in w.c. = 2 psi; 5˝: 5 psi; 10˝: 5 psi; 25˝: 5 psi; 50˝:

5 psi, 100˝: 9 psi.

Temperature Limits: 32 to 140°F (0 to 60°C).

Compensated Temperature Limits: 32 to 140°F (0 to 60°C).

Thermal Effects: 0.020%/°F (0.036/°C) from 77°F (25°C).

Power Requirements: High voltage power = 100 to 240 VAC, 50 to 400 Hz or 132

to 240 VDC; Low voltage power = 24 VDC ±20%.

Power Consumption: Low voltage power = 24 VDC - 130 mA max; High voltage

power = 100 to 240 VAC, 132 to 240 VDC - 7 VA max.

Output Signal: 4 to 20 mA DC into 900 Ω max.

Zero & Span Adjustments: Accessible via menus.

Response Time: 250 ms (dampening set to 1).

Display: 4 digit backlit LCD 0.6˝ height. LED indicators for set point and alarm

status.

Electrical Connections: Euro type removable terminal blocks with watertight

conduit ttings for 1/2˝ watertight conduit.

Process Connections: 1/8˝ female NPT.

Enclosure Rating: Designed to meet NEMA 4 (IP66).

Mounting Orientation: Mount unit in horizontal plane.

Weight: 2 lb 10 oz (1.19 kg).

Serial Communications: Modbus

Agency Approvals: CE, UL.

SWITCH SPECIFICATIONS

Switch Type: 2 SPDT relays.

Electrical Rating: 8 amps at 240 VAC resistive.

Set Point Adjustment: Adjustable via keypad on face.

0.623

0.144

2.491

0.578

12.45

2.890

24.91

5.780

62.27

14.45

124.5

28.90

249.1

57.80

DWYER INSTRUMENTS, INC. | 34

45/64

[17.78]

2

3-7/16

[87.12]

1-45/64

[43.18]

MODEL CHART - BI-DIRECTIONAL* RANGES

Model Range

DHII-012

DHII-014

DHII-015

DHII-016

DHII-017

*Velocity and volumetric ow not available on

bi-directional range units and models DHII-009 & DHII-010.

Process Tubing Options: See page 455 (Gage Tubing Accessories)

1-1/16

[26.97]

1-7/8

[47.5]

4X Ø3/16 [4.76]

CLEARANCE HOLES FOR

MOUNTING

MOUNTING HOLE

PATTERN

3-17/64

®

RTU, RS485, 9600 baud.

0.25 to 0 to 0.25 in w.c.

1.0 to 0 to 1.0 in w.c.

2.5 to 0 to 2.5 in w.c.

5 to 0 to 5 in w.c.

10 to 0 to 10 in w.c.

®

is a registered trademark of Schneider Automation, Inc.

Modbus

4-1/8

[105]

Loading...

Loading...