Page 1

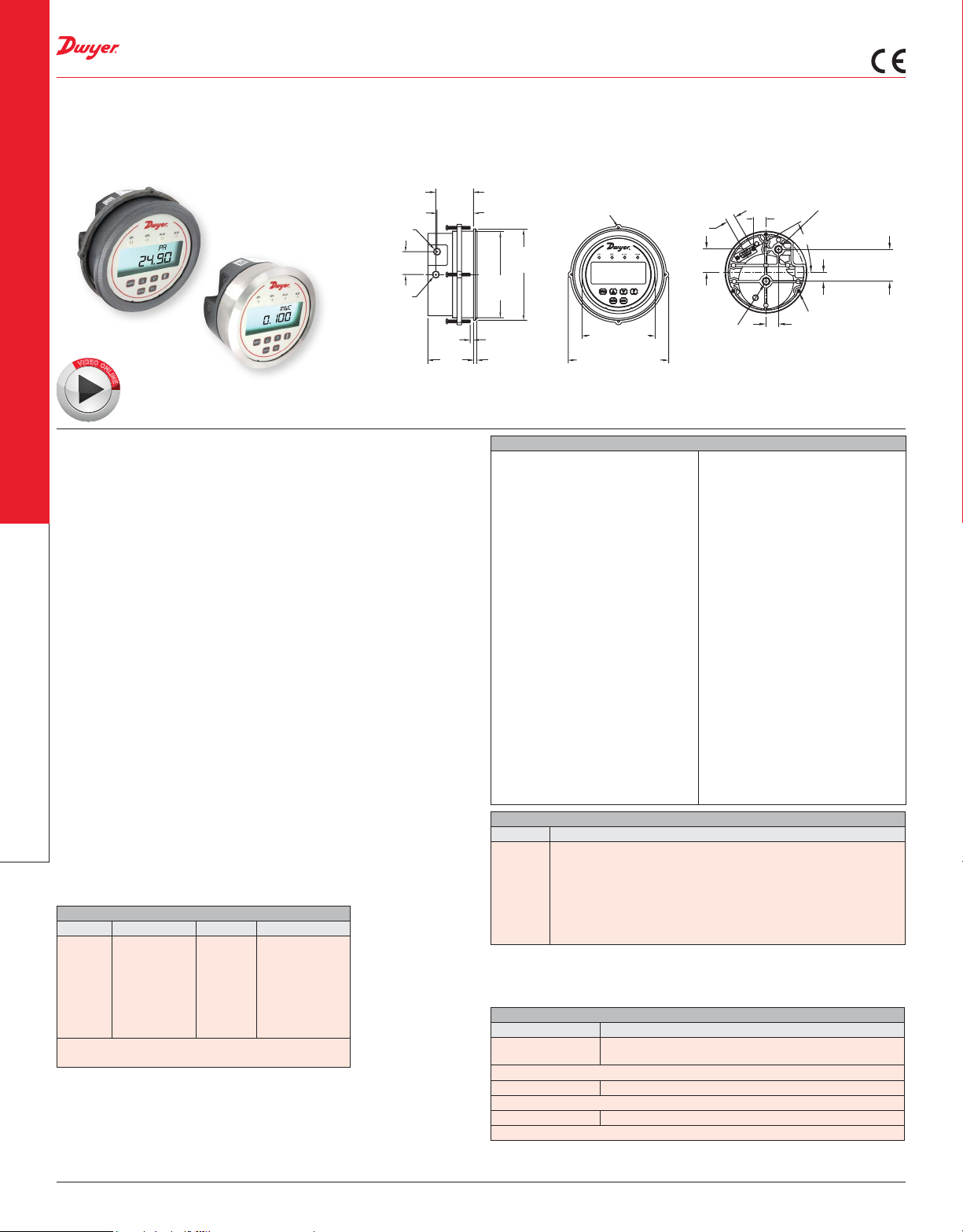

[4] 6-32 HOLES EQUALLY

2-1/16

[44.45]

SERIES DH3

E

DIGIHELIC® 3 DIFFERENTIAL PRESSURE CONTROLLERS

Digihelic® Controller in Photohelic® Gage, Square Root Output for Flow

PRESSURE

1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

1-1/4

[31.75]

1/8 FEMALE NPT

LOW PRESSURE

CONNECTION

E

O

D

I

V

O

N

L

I

N

Note: Shown with optional -SS bezel.

Backward compatible

+

with Magnehelic® gage.

The Series DH3 Digihelic® 3 Differential Pressure Controllers are 3-in-1 instruments

possessing a digital display gage, control relay switches, and a transmitter with current

output all packed in the popular Photohelic

features allows the reduction of several instruments with one product, saving inventory,

installation time and money. The Digihelic

pressure, velocity and ow applications, achieving a 1.5% or better full-scale accuracy

®

gage style housing. Combining these 3

®

controller is the ideal instrument for

on ranges down to the extremely low 0.25 in w.c. to 2.5 in w.c. full-scale. Ranges of 5 in

w.c. and greater maintain 0.5% FS accuracy. Bi-directional ranges are also available.

The Series DH3 Digihelic

volumetric ow operation in several commonly used engineering units. 2 SPDT control

®

controller allows the selection of pressure, velocity or

relays with adjustable deadbands are provided along with a scalable 4-20 mA process

output.

Programming is easy using the menu key to access 5 simplied menus which provide

access to: security level; selection of pressure, velocity or ow operation; selection of

engineering units; K-factor for use with ow sensors; rectangular or circular duct for

inputting area in ow applications; set point control or set point and alarm operation;

alarm operation as a high, low or high/low alarm; automatic or manual alarm reset;

alarm delay; view peak and valley process reading; digital damping for smoothing

erratic process applications; scaling the 4-20 mA process output to t your applications

range and eld calibration.

FEATURES/BENEFITS

• 3-in-1 instrument allows the reduction of several instruments with one product,

saving inventory, installation time and money

Differential Pressure

• Full-scale accuracy of 1.5% or better even on extremely low ranges, and 0.5% for

ranges above 5 in w.c. provide for greater measurement precision

Gages/Switches, Transmitters

• Secure menu program provides access to device operation only for the right skill

level

• Optional stainless steel bezel is the same installation diameter as Magnehelic® gage

and simplies eld upgrade to DH3 pressure controller

APPLICATIONS

• SCFM duct ow

• Filter status

• Duct or building static pressure

• Damper and fan control

MODEL CHART

Model Ranges Model Ranges

DH3-002

DH3-003

DH3-004

DH3-005

DH3-006

DH3-007

DH3-009

*Velocity and volumetric ow not available on bi-directional

0 to 0.25 in w.c.

0 to 0.5 in w.c.

0 to 1 in w.c.

0 to 2.5 in w.c.

0 to 5 in w.c.

0 to 10 in w.c.

0 to 25 in w.c.

*DH3-010

*DH3-011

*DH3-013

*DH3-014

*DH3-015

*DH3-016

*DH3-017

*DH3-018

0 to 50 in w.c.

0 to 100 in w.c.

0 to ±0.25 in w.c.

0 to ±0.5 in w.c.

0 to ±1 in w.c.

0 to ±2.5 in w.c.

0 to ±5 in w.c.

0 to ±10 in w.c.

range units and models DH3-010 and DH3-011.

[52.39]

[50.80]

2-1/2

[63.50]

2

SPACED ON A 5-1/8 [130.18]

B.C. PANEL MOUNTING

[12.70]

Ø5

[127.00]

ø4-47/64

[120.25]

5/8 [15.88]

PANEL MAX

3/16

[4.76]

Ø4 [101.60]

FACE

5-1/2 [139.70] O.D.

MOUNTING RING

SPECIFICATIONS

Service: Air and non-combustible,

compatible gases.

Wetted Materials: Consult factory.

Housing Material: Die cast aluminum

case and bezel.

Accuracy: ±1.5% for 0.25 in and ±0.25

in w.c. ranges. Ranges 0.5 in to 5 in

w.c. and corresponding bi-directional

(except ±2.5 in w.c.) ±1%; All other

ranges: ±0.5% @ 77°F (25°C) including

hysteresis and repeatability (after 1 hour

warm-up).

Stability: < ±1% per year.

Pressure Limits: Ranges (uni- and

corresponding bidirectional), ≤ 1 in w.c.:

9 psi; 2.5 and 5 in w.c.: 1.5 psi; 10 in

w.c.: 3 psi; 25 in w.c.: 8 psi; 50 in w.c.: 15

psi; 100 in w.c.: 20 psi.

Temperature Limits: 32 to 140°F (0 to

60°C).

Compensated Temperature Limits: 32

to 140°F (0 to 60°C).

Thermal Effects: 0.020%/°F (0.036/°C)

from 77°F (25°C). For 0.25 in and ±0.25

in w.c. ranges: ±0.03%/°F (±0.054%/°C).

Power Requirements: 12-28 VDC, 1228 VAC 50 to 400 Hz.

Power Consumption: 3 VA max.

ACCESSORIES

Model Description

A-298

A-301

A-302

A-302F-A

A-370

A-489

Flat aluminum bracket for ush mounting

Static pressure tip for 1/4˝ metal tubing connection

Static pressure tip for 3/16˝ and 1/8˝ I.D. plastic or rubber tubing

303 SS static pressure tip with mounting ange; for 3/16˝ I.D. rubber or

plastic tubing; 4˝ insertion depth; includes mounting screws

Mounting bracket ush mount bracket; bracket is then surface

mounted; steel with gray hammertone epoxy nish

4˝ straight static pressure tip with ange

OPTIONS

To order add sufx: Description

-SS 304 brushed stainless steel bezel.

with standard Magnehelic

Example: DH3-004-SS

-NIST NIST traceable calibration certicate

Example: DH3-004-NIST

-FC Factory calibration certicate

Example: DH3-004-FC

11/16

1/2

[17.46]

1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

30°

1-9/32

[32.54]

1/8 FEMALE

NPT LOW

PRESSURE

CONNECTION

11/16

[17.46]

1/2

[12.70]

[3] Ø3/16 [4.77] HOLES

EQUALLY SPACED ON A

4-1/8 [104.78] B.C.

SURFACE MOUNTING

Output Signal: 4-20 mA DC into 900

Ω max.

Zero & Span Adjustments: Accessible

via menus.

Response Time: 250 ms (damping set

to 1).

Display: Backlit 4 digit LCD 0.4˝ height

LED indicators for set point and alarm

status.

Electrical Connections: 15 pin male

high density D-sub connection. 18˝ (46

cm) cable with 10 conductors included.

Process Connections: 1/8˝ female

NPT. Side or back connections.

Mounting Orientation: Mount unit in

vertical plane.

Size: 5˝ (127 mm) OD x 3-1/8˝ (79.38

mm); -SS bezel: 4-3/4˝ (120.7 mm) OD x

2-21/32 (67.5 mm).

Weight: 1.75 lb (794 g).

Agency Approvals: CE.

SWITCH SPECIFICATIONS

Switch Type:

Electrical Rating: 1 A @ 30 VAC/VDC.

2 SPDT relays.

Set Point Adjustment: Adjustable via

keypad on face.

+

®

Backward compatible

gage installation diameter

1-3/4

DWYER INSTRUMENTS, INC. | 36

Process Tubing Options: See page 455 (Gage Tubing Accessories)

Loading...

Loading...