Page 1

®

SERIES DH

DIGIHELIC® DIFFERENTIAL PRESSURE CONTROLLER

3-in-1 Instrument: Gage, Switch and Transmitter, Square Root Extractor for Air Flow

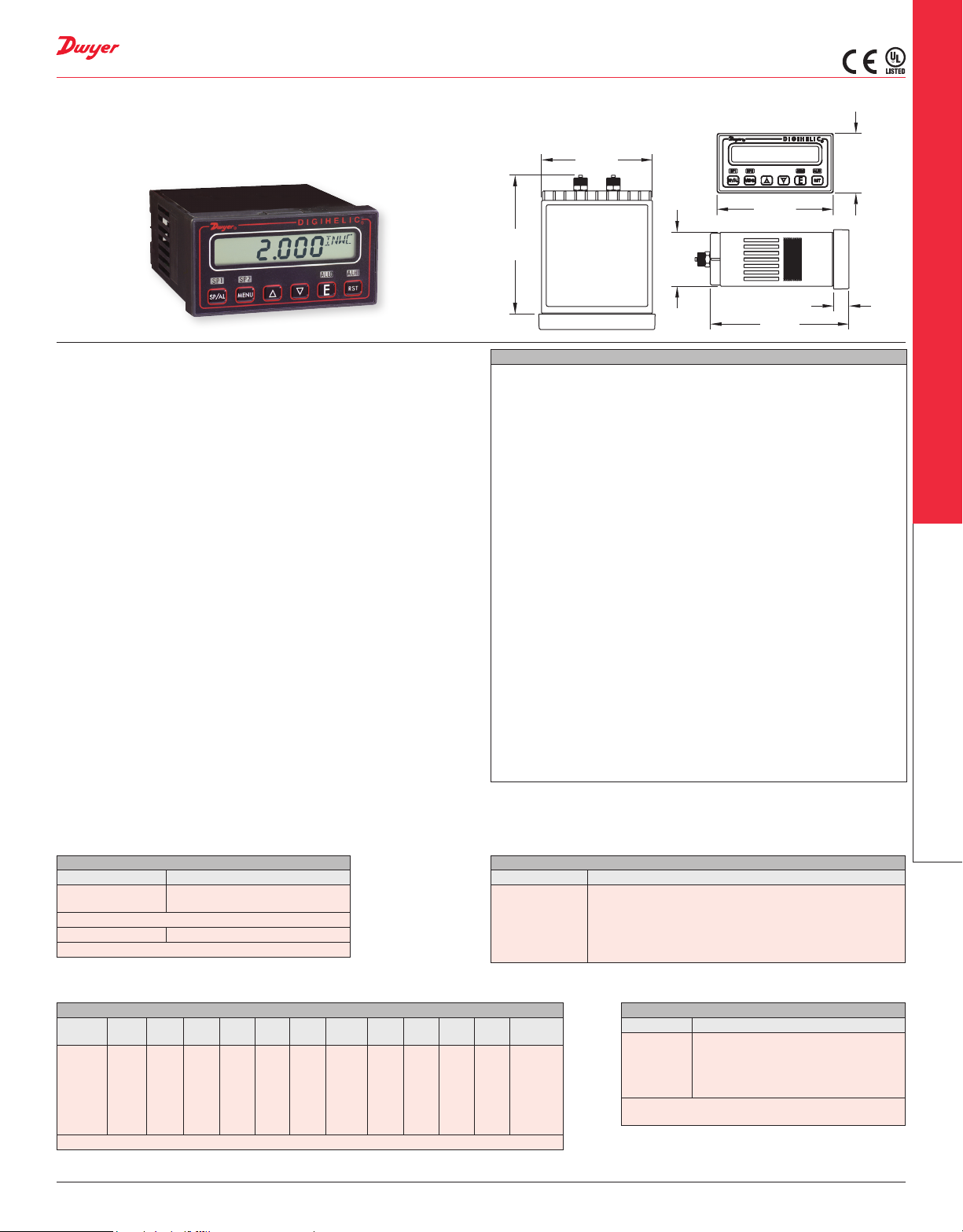

3-19/32

4-1/2

[114.30]

The Series DH Digihelic® Differential Pressure Controller is a 3-in-1 instrument

possessing a digital display gage, control relay switches, and a transmitter with current

output. The Digihelic

applications, achieving a 0.5% full-scale accuracy on ranges from 0.25 to 100 in w.c.

The Digihelic

operation in several commonly used engineering units. Two SPDT control relays with

adjustable dead bands are provided along with a scalable 4 to 20 mA process output.

The Series DH provides extreme exibility in power usage by allowing 120/220 VAC

and also 24 VDC power which is often used in control panels.

Programming is easy using the menu key to access 5 simplied menus which provide

access to: security level; selection of pressure, velocity or ow operation; selection of

engineering units; K-factor for use with ow sensors; rectangular or circular duct for

inputting area in ow applications; set point control or set point and alarm operation;

alarm operation as a high, low or high/low alarm; automatic or manual alarm reset;

alarm delay; view peak and valley process readings; digital damping for smoothing

erratic process applications; scaling the 4 to 20 mA process output to t your

application’s range; Modbus

FEATURES/BENEFITS

• 3-in-1 instrument allows the reduction of several instruments with one product,

saving inventory, installation time and money

• Velocity of ow modes, a square root output coincides with the actual ow curve for

greater precision

• Power usage of 120/220 VAC or 24 VDC provides exibility to incorporate device in

control panel

• Secure menu program provides access to device operation only for the right skill

level

• Modbus

control

APPLICATIONS

• SCFM duct ow

• Industrial ovens air ow

• Filter status

• Clean room pressurization

• Fume hood air ow

• Surgical and medical room pressurization

• Damper and fan control

®

communications supports Process and HVAC system integration and

®

controller is the ideal instrument for pressure, velocity and ow

®

controller allows the selection of pressure, velocity or volumetric ow

®

communications; and eld calibration.

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Housing Material: ABS plastic, UL approved 94 V-0.

Accuracy: ±0.5% at 77°F (25°C) including hysteresis and repeatability.

Stability: < ±1% per year.

Pressure Limits: Ranges ≤ 2.5 in w.c. = 2 psi; 5˝: 5 psi; 10˝: 5 psi; 25˝: 5 psi; 50˝: 5

psi, 100˝: 9 psi.

Temperature Limits: 32 to 140°F (0 to 60°C).

Compensated Temperature Limits: 32 to 140°F (0 to 60°C).

Thermal Effects: 0.020%/°F (0.036/°C) from 77°F (25°C).

Power Requirements: High voltage power = 100 to 240 VAC, 50 to 400 Hz or 132

to 240 VDC. Low voltage power = 24 VDC ±20%.

Power Consumption: Low voltage power = 24 VDC - 130 mA max; High voltage

power = 100 to 240 VAC, 132 to 240 VDC - 7VA max.

Output Signal: 4 to 20 mA DC into 900 Ω max.

Zero & Span Adjustments: Accessible via menus.

Response Time: 250 ms.

Display: 4 digit LCD 0.4˝ height. LED indicators for set point and alarm status.

Electrical Connections: Screw terminals.

Process Connections: Compression tting for use with 1/8˝ ID X 1/4˝ OD tubing

(3.175 mm ID x 6.35 mm OD). Optional barbed tting for 3/16˝ ID tubing.

Enclosure Rating: Face designed to meet NEMA 4X (IP66).

Mounting Orientation: Mount unit in horizontal plane.

Size: 1/8 DIN.

Panel Cutout: 1.772 x 3.620 in (45 x 92 mm).

Weight: 14.4 oz (408 g).

Serial Communications: Modbus

Agency Approvals: CE, UL.

SWITCH SPECIFICATIONS

Switch Type: 2 SPDT relays.

Electrical Rating: 8 amps at 240 VAC resistive.

Set Point Adjustment: Adjustable via keypad on face.

[91.28]

3-25/32

[96.04]

1-3/4

[44.45]

[114.30]

®

RTU, RS485, 9600 baud.

4-1/2

1-15/16

[49.21]

1/2

[12.70]

PRESSURE

Gages/Switches, Transmitters

Differential Pressure

OPTIONS

To order add sufx: Description

-B

-NIST

Example: DH-004-NIST

-FC Factory calibration certicate

Example: DH-004-FC

MODEL CHART - AVAILABLE PRESSURE ENGINEERING UNITS

Model

DH-002

DH-004

DH-006

DH-007

DH-008

DH-009*

DH-010*

*Velocity and volumetric ow not available on bi-directional range units and models DH-009 & DH-010.

in

w.c.

.2500

1.000

5.000

10.00

25.00

50.00

100.0

Barbed tting for 3/16˝ ID tubing

NIST traceable calibration certicate

ft

mm

w.c.

-

-

.4167

.8333

2.083

4.167

8.333

cm

w.c.

w.c. psi in Hg

6.350

0.635

25.40

2.540

127.0

12.70

254.0

25.40

635.0

63.50

1270

127.0

2540

254.0

-

-

.1806

.3613

.9032

1.806

3.613

-

-

.3678

.7356

1.839

3.678

7.356

mm

Hg mbar Pa kPa hPa oz/in

0.467

0.623

62.28

1.868

9.342

18.68

46.71

93.42

186.8

2.491

12.45

24.91

62.27

124.5

249.1

249.1

1245

2491

6227

-

-

-

0.249

1.245

2.491

6.227

12.45

24.91

ACCESSORIES

Model Description

MN-1

A-266

A-203

Digihelic Links

2

0.623

0.144

2.491

0.578

12.45

2.890

24.91

5.780

62.27

14.45

124.5

28.90

249.1

57.80

Mini-Node™ USB/RS-485 converter; the Mini-Node™ converters

are an easy solution for utilizing the Digihelic

485 serial communication and connecting to virtually any PC.

®

surface mounting bracket

Digihelic

1/8˝ ID x 1/4˝ OD PVC tubing

™

Communications Software

MODEL CHART - BI-DIRECTIONAL* RANGES

Model Range

DH-012

DH-014

DH-015

DH-016

DH-017

*Velocity and volumetric ow not available on

bi-directional range units and models DH-009 & DH-010.

Modbus

Process Tubing Options: See page 455 (Gage Tubing Accessories)

0.25 to 0 to 0.25 in w.c.

1.0 to 0 to 1.0 in w.c.

2.5 to 0 to 2.5 in w.c.

5 to 0 to 5 in w.c.

10 to 0 to 10 in w.c.

®

is a registered trademark of Schneider Automation, Inc.

®

controller’s RS-

DWYER INSTRUMENTS, INC. |

35

Loading...

Loading...