Page 1

39/64

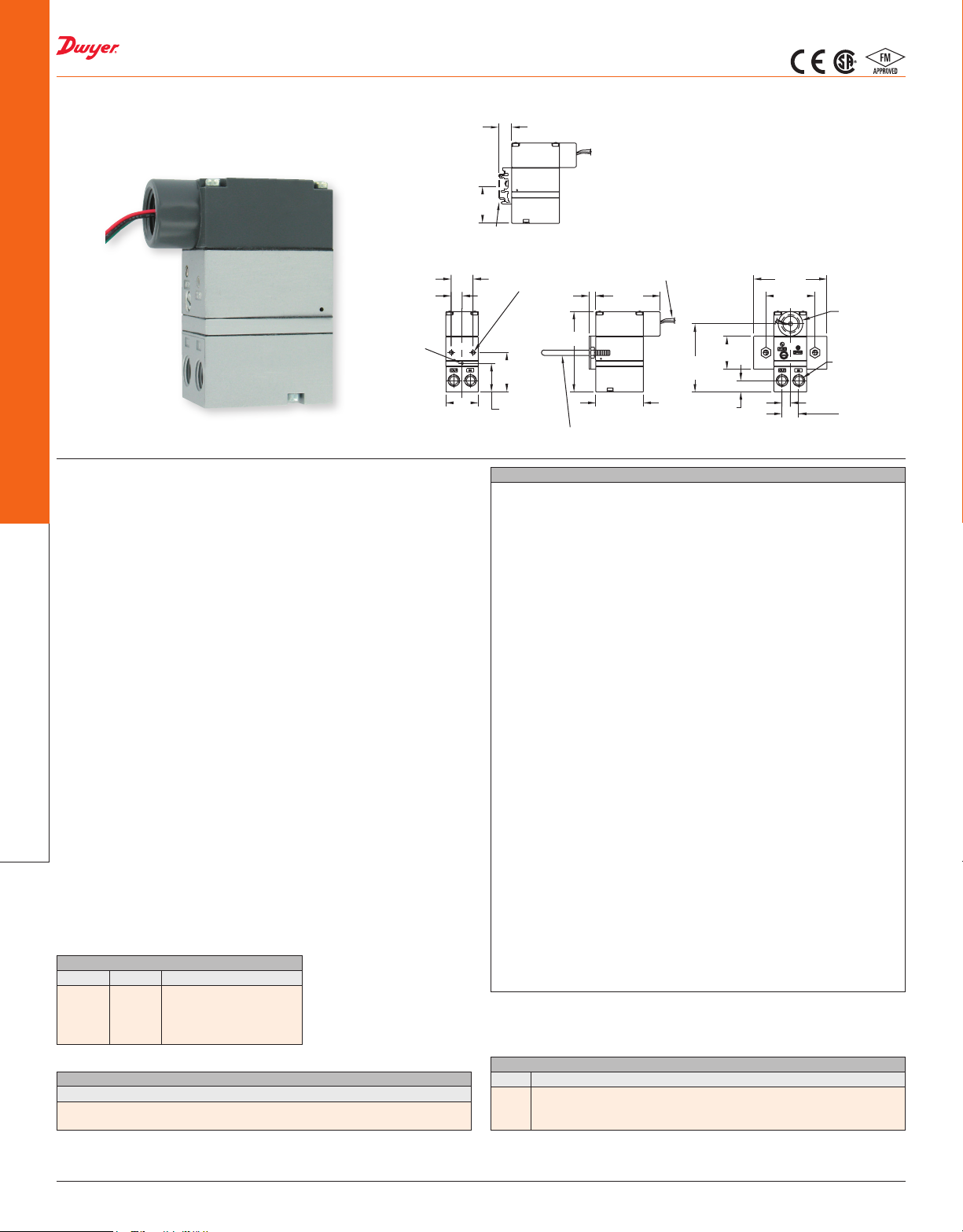

[ø3.17]

OPTION FOR 1-1/2 PIPE

S

SERIES 2700 & 2800 | PROXIMITY® BY DWYER

CURRENT TO PRESSURE TRANSDUCER

VALVES

NEMA 4X Enclosure, Compact Size, Reliable

1/2

[12.7]

ø1/8

[15.5]

1-11/16

[42.7]

DIN RAIL MOUNTING

OPTION

1

[25.4]

1-1/2

[38.1]

MOUNTING HOLES

#10-32 UNF-2B x 3/8 DP

2 PLCS

5/16

[7.92]

3-11/16 [93.7]

1-51/64

[45.7]

1-19/64

[33.0]

PIPE CLAMP MOUNTING

2-15/16

[74.7]

2-3/16

[55.4]

22 GA. WIRE LEADS

APPROX. 18˝ LONG

POS, NEG, GRD

1-1/2 [38.1]

3-1/8

[79.2]

33/64

[13.1]

3-23/64

[85.3]

2-1/4

[57/2]

IN & OUT PORT

1/4-18 NPT

4 PLCS

25/64

[9.72]

ø1-1/8

[ø28.7]

1/2 NPT

49/64

[19.4]

The Series 2700 Current to Pressure Transducer combines economical startup cost,

low air consumption, and reliable performance to make the 2700 a great investment.

The unit converts a variable current signal to a proportional pneumatic output. It has

input and output ports on both the front and back which allows for versatile plumbing.

The NEMA 4X enclosure enables the unit to be installed indoors or outdoors, however,

the unit is not vibration resistant. It is FM and CSA approved for intrinsically safe

operation. The 2700 is designed for remote or panel mounting. An integral volume

booster provides high ow capacity, increasing control speed in critical applications.

Other features include external zero and span adjustments which are convenient for

eld calibration.

The Series 2800 Current to Pressure Transducer utilizes a closed loop pressure

feedback system that closely controls output and compensates for vibration, mounting

angle, temperature, and supply pressure variations. These characteristics make this

unit ideal for eld mounting on a valve. The control mechanism is a piezoceramic

actuator encapsulated in a protective skin, which provides a constant defense against

humidity and contaminants. These features make this unit ideal for use in demanding

applications. The 2800 also comes in a NEMA 4X enclosure and is eld reversible.

Transducers

It is FM and CSA approved intrinsically safe, as well. For ease of installation, this

Current to Pressure

model has input and output ports on both the front and back and can be easily panel

mounted.

SERIES 2700 FEATURES/BENEFITS

• NEMA 4X enclosure

• FM and CSA approved for intrinsically safe

• Designed for remote or panel mounting

• Integral volume booster

SERIES 2800 FEATURES/BENEFITS

• NEMA 4X enclosure

• FM and CSA approved for intrinsically safe

• Vibration and position insensitive

• Input and output ports on front and back

MODEL CHART

Model Input Output

2713-WP

2716-WP

2813-WP

2816-WP

4-20 mA

4-20 mA

4-20 mA

4-20 mA

3 to 15 psig (0.2 to 1.0 bar)

6 to 30 psig (0.4 to 2.1 bar)

3 to 15 psig (0.2 to 1.0 bar)

6 to 30 psig (0.4 to 2.1 bar)

APPLICATIONS

• Controlling valve actuators,

pneumatic valve positioners,

air cylinders, clutches, brakes,

dampers, louvers and pumps

SPECIFICATIONS

Service: Oil free, clean dry air ltered to 40 microns.

Input Signal: 4-20 mA.

Air Supply: Min: 5 psig (0.3 bar) above max output; Max: 100 psig (6.9 bar).

Output: 3 to 15 psig (0.2 to 1.0 bar), 6 to 30 psig (0.4 to 2.1 bar).

Accuracy: Series 2800: ±0.1% of span.

Linearity: Series 2700: < ±0.5% of span.

Hysteresis: Series 2700: < 0.5% of span; Series 2800: ±0.1% of span.

Repeatability: Series 2700: < 0.5% of span; Series 2800: ±0.1% of span.

Deadband: Series 2800: 0.02% of span.

Supply Pressure Sensitivity: Series 2700: < 0.1% of span per 1.0 psig (0.1 bar).

Power Requirement: Loop powered.

Temperature Limits: Series 2700: -20 to 150°F (-29 to 66°C); Series 2800:

Operating: -40 to 160°F (-40 to 71°C); Storage: -40 to 200°F (-40 to 93°C).

Pressure Connections: 1/4˝ female NPT.

Electrical Connection: 1/2˝ female NPT.

Air Consumption: Series 2700: 0.03 scfm (0.01 l/s) at midrange typical; Series

2800: 0.025 scfm (0.01 l/s) at midrange typical.

Output Capacity: 4.5 scfm (2.1 l/s) at 25 psig (1.7 bar) supply; 12.0 scfm (5.7 l/s)

at 100 psig (6.9 bar) supply.

Enclosure: Chromate-treated aluminum with epoxy paint.

Enclosure Rating: NEMA 4X (IP66) and intrinsically safe.

Weight: Series 2700: 1.3 lb (0.59 kg); Series 2800: 0.8 lb (0.37 kg).

Agency Approvals: CE, CSA, FM.

SERIES 2700

FM Intrinsically Safe Ratings: Class I, II, III, Division 1, Groups C, D, E, F and G;

Class I, Division 2, Groups A, B, C and D; Class II and III, Division 2, Groups F and G.

CSA Intrinsically Safe Ratings: Class I, Division 2, Groups C and D; Class II,

Groups E, F and G; Class III.

SERIES 2800

FM Intrinsically Safe Ratings: Class I, II, and III, Division 1, Groups C, D, E, F,

and G; Class I, Zone 0, Group IIB; Class I, II, and III, Division 2, Groups A, B, C, D,

F, and G.

CSA Intrinsically Safe Ratings: Class I, Division 2, Groups A, B, C and D; Class

II, Division 2, Groups F and G; Class III.

OPTIONS

Description

Valve mount, for factory mounting and calibration to Hi-Flow

current-to-pressure transducer model number as sufx (Series 2800 only)

™

control valves, add

DWYER INSTRUMENTS, INC. 440

ACCESSORIES

Model Description

A-180

Valve mounting bracket, for Hi-Flow

A-181

DIN rail mounting kit, suitable for EN-50035, EN-50042, and EN-50022 rails

A-182

Pipe mounting kit, for 1-1/2 and 2˝ pipes

™

control valves (Series 2800 only)

Filters and Regulators: See page 446

Loading...

Loading...