Page 1

LOW PRESSURE PORT

[7.14]

[36.51]

®

E

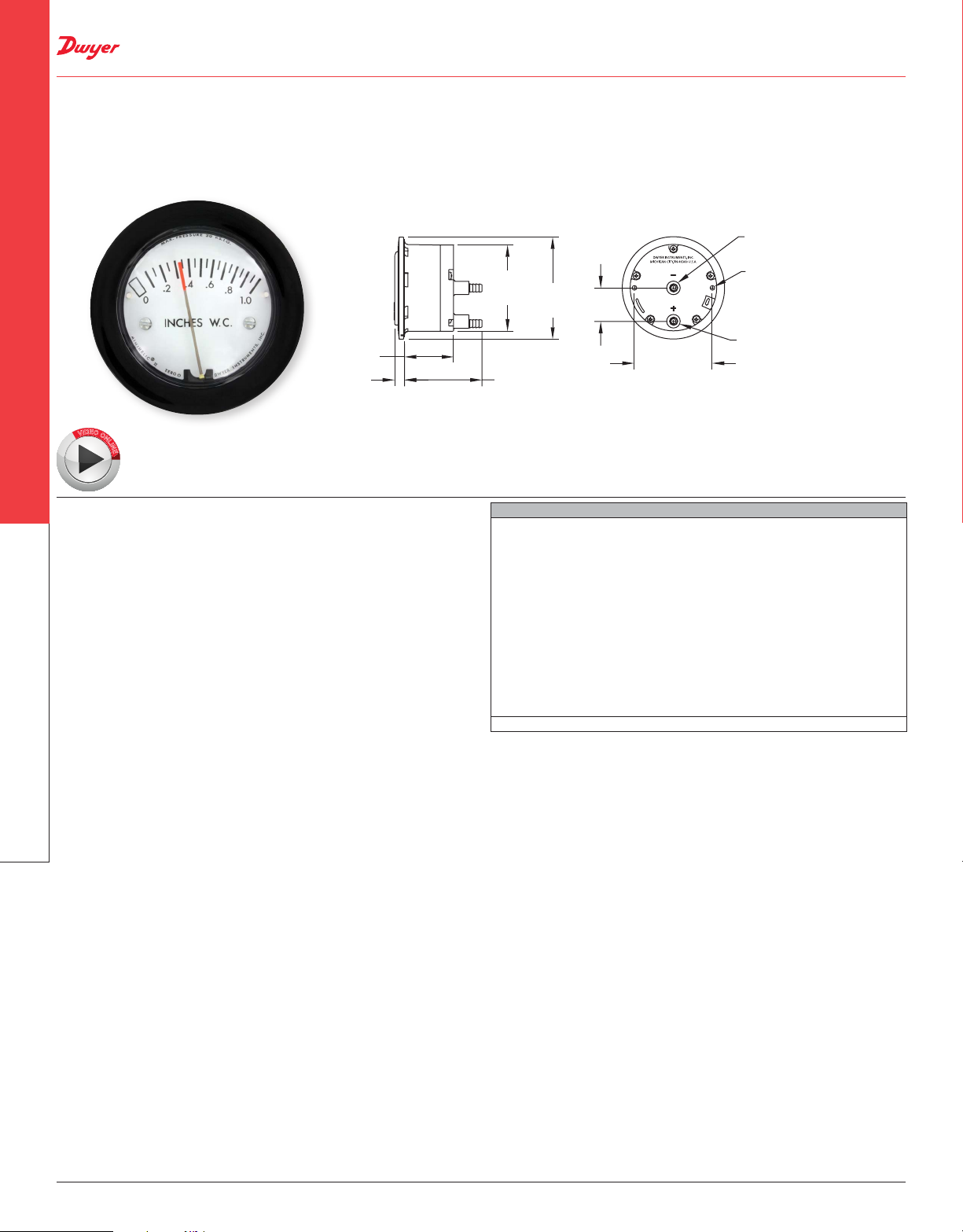

SERIES 2-5000

MINIHELIC® II DIFFERENTIAL PRESSURE GAGE

Combining High Accuracy, Compactness, Dependability, and Low Cost

PRESSURE

Ø2-19/32

1-7/16

9/32

E

O

D

I

V

O

N

L

I

N

[65.88]

2-3/8

[60.33]

Ø3-1/16

[77.79]

1

[25.40]

2-21/64 [59.18]

SURFACE

MOUNT HOLES

Ø7/16 [11.11] HOLE IN

PANEL FOR SURFACE MOUNT

(2) Ø5/32 HOLES

IN PANEL FOR SURFACE

MOUNT

HIGH PRESSURE PORT

Ø7/16 [11.11] HOLE IN

PANEL FOR SURFACE MOUNT

Combining clean design, small size and low cost with enough accuracy for all but the

most demanding applications our Series 2-5000 Minihelic

®

II Differential Pressure

Gage offers the latest in design features for a dial type differential pressure gage. It is

our most compact gage but is easy to read and can safely operate at total pressures

up to 30 psig.

FEATURES/BENEFITS

• Removable lens and rear-housing provides easy, cost-effective servicing

• Accuracy and value provides an excellent solution for OEM and user applications

• Durable housing materials make it well-suited for rough environments and total high

pressure

APPLICATIONS

• Room positive pressure sensing

• Cabinet air-purging

• Medical respiratory equipment

• Air samplers

• Electronic air cooling systems

DifferentialPressureGages

• Laminarowhoods

• Localindicationonlterstatus

• Face velocity on fume hood

• Duct pressures

SPECIFICATIONS

Service: Air and compatible gases.

Wetted Materials: Consult factory.

Housing:

Glassllednylon;polycarbonatelens.

Accuracy: ±5% of FS at 70°F (21.1°C).

Pressure Limits: 30 psig (2.067 bar) continuous to either pressure connection.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

2-1/16˝(52.39mm)diameterdialface.

Size:

Mounting Orientation: Diaphragm in vertical position. Consult factory for other

position orientations.

Process Connections:

Barbed,for3/16˝IDtubing(standard);1/8˝maleNPT

(optional).

Weight: 6 oz (170.1 g).

Agency Approvals: Meets the technical requirements of EU Directive 2011/65/EU

(RoHS II).

Caution: For use only with air or compatible non-corrosive gases.

DWYER INSTRUMENTS, INC. | 26

Page 2

®

SERIES 2-5000

MINIHELIC® II DIFFERENTIAL PRESSURE GAGE

Combining High Accuracy, Compactness, Dependability, and Low Cost

PRESSURE

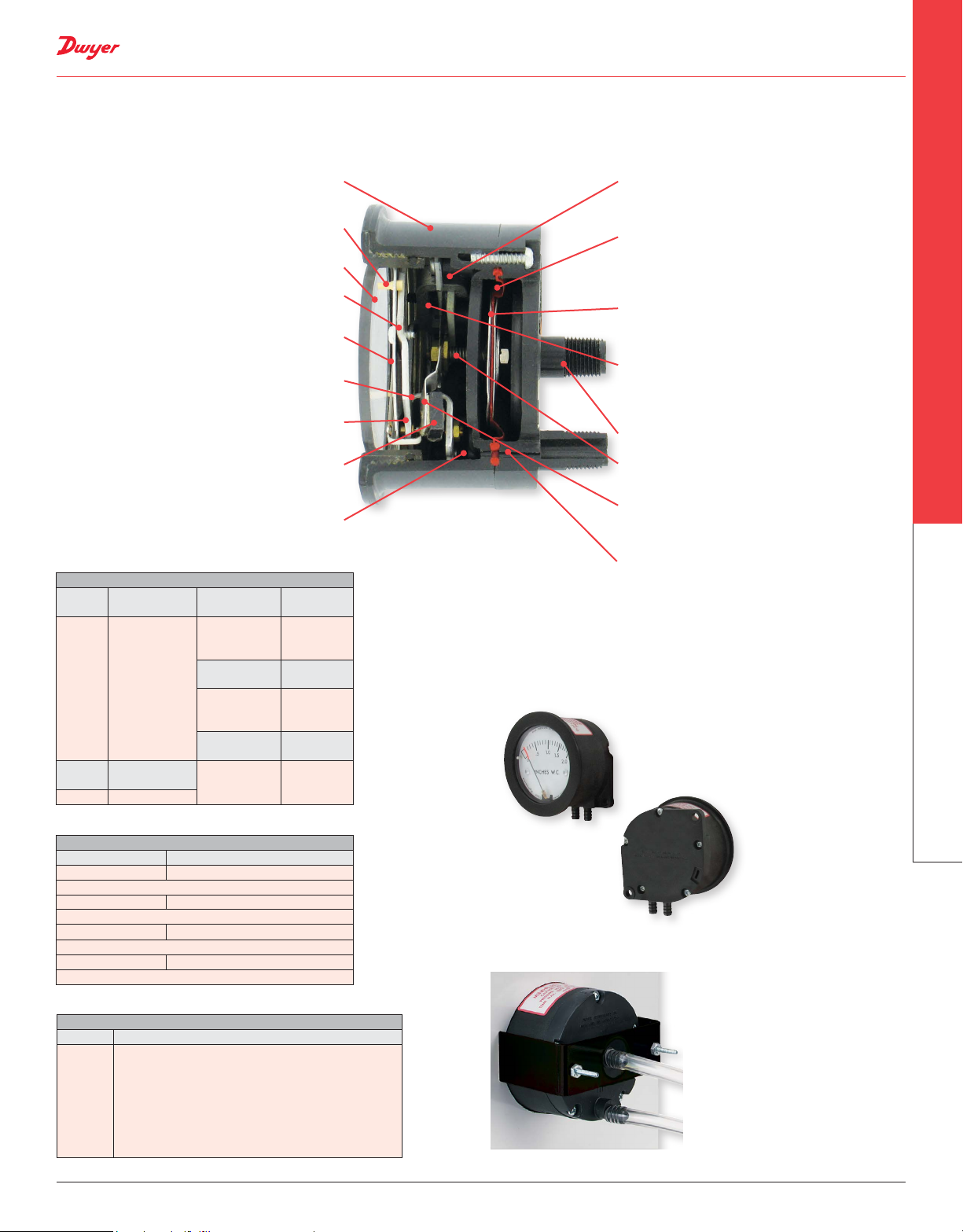

Housing is molded from strong mineral and glass lled

nylon.

Pointer stops of molded rubber prevent pointer

over-travel without damage.

Full view lens is removable and molded of acrylic.

Aluminum scale litho -printed black on white, enhances

readability.

Red tipped aluminum pointer, rigidly mounted to helix

is easy to see.

Wishbone assembly provides mounting for helix, helix

bearings, and pointer shaft.

Jewel bearings provide virtually friction-free helix

motion.

Helix is free to rotate in jewel bearings. It aligns with

magnetic eld of magnet to transmit pressure indications

to poi nte r.

Zero adjustment screw, loc ated behind the removable

lens, eliminates tampering.

MODEL CHART

Model

2-5000-0

2-5001

2-5002

2-5003

2-5005

2-5010

2-5020

2-5040

2-5060

2-5100

Model

2-5205 0-5

Range,

Inches of Water Model

0-0.5

0-1.0

0-2.0

0-3.0

0-5.0

0-10

0-20

0-40

0-60

0-100

Range,

PSI

2-5000-25MM

2-5000-50MM

2-5000-100MM

Model

2-5000-125PA

2-5000-250PA

2-5000-500PA

Model

2-5000-1KPA

2-5000-3KPA

Range,

MM of Water

0-25

0-50

0-100

Range,

Pascals

0-125

0-250

0-500

Range,

kPa

0-1

0-3

SURFACE MOUNTING

Range spring calibration clamp xes live length of

spring for proper gage calibration and is factory set and

sealed.

Silicone rubber diaphragm allows accurate response

to a broad range of temperatures and at extremely low

pressure. Incorporates blow out area for overpressure

protection.

Diaphragm support plates of lightweight aluminum on

each side of the diaphragm minimize position or at titude

sensitivity and help dene pressure area.

Flat leaf range spring reacts to pressure on the

diaphragm. Live length is adjustable for calibration. Small

amplitude of motion minimizes inaccuracies and assures

long life.

Low pressure tap connects to rear chamber.

Coil spring link provides a resilient connection between

the diaphragm and the range spring.

Ceramic magnet mounted on a molded bracket at the

end of the range spring rotates the helix without direct

mechanical linkage.

High pressure tap connects with the front chamber

through passageway in the plastic case and a sealing

ring molded into the edge of the diaphragm.

Differential Pressure Gages

Optional surface mounting with back

mounting plate allows for quick installation

to any surface. Process connections are

barbed and point downwards. Add -BB for

bottom barbed surface mount option.

OPTIONS

To order add sufx: Description

-NPT 1/8˝ male NPT connections

Example: 2-5001-NPT

-BB Bottom barbed surface mount

Example: 2-5001-BB

-NIST NIST traceable calibration certicate

Example: 2-5001-NIST

-FC Factory calibration certicate

Example: 2-5001-FC

ACCESSORIES

Model Description

A-302F-A

A-434

A-489

A-497

A-609

A-480

303 SS static pressure tip with mounting ange; for 3/16˝

ID rubber or plastic tubing; 4˝ insertion depth; includes

mounting screws

Portable kit

4˝ straight static pressure tip with ange

Surface mounting bracket

Air lter kit

Plastic static pressure tip

PANEL MOUNTING

Mounting hardware is supplied with the

®

Minihelic

a single hole, 2-5/8˝ (67 mm) in diameter.

Panel thickness up to 1/2˝ (13 mm) can be

accommodated with the hardware supplied.

If necessary, surface mounting of the gage

can be accomplished by means of two 4-40

screws into the tapped mounting bracket

stud holes in the rear of the gage. Surface

mounting requires clearance holes in the

panel for the two pressure taps.

Process Tubing Options: See page 455 (Gage Tubing Accessories)

II gage for panel mounting through

DWYER INSTRUMENTS, INC. |

27

Loading...

Loading...