Page 1

Series 1900 Pressure Switch

POWER INPUT

TERMINALS

+ –

GROUNDING

SCREW

®

Specications - Installation and Operating Instructions

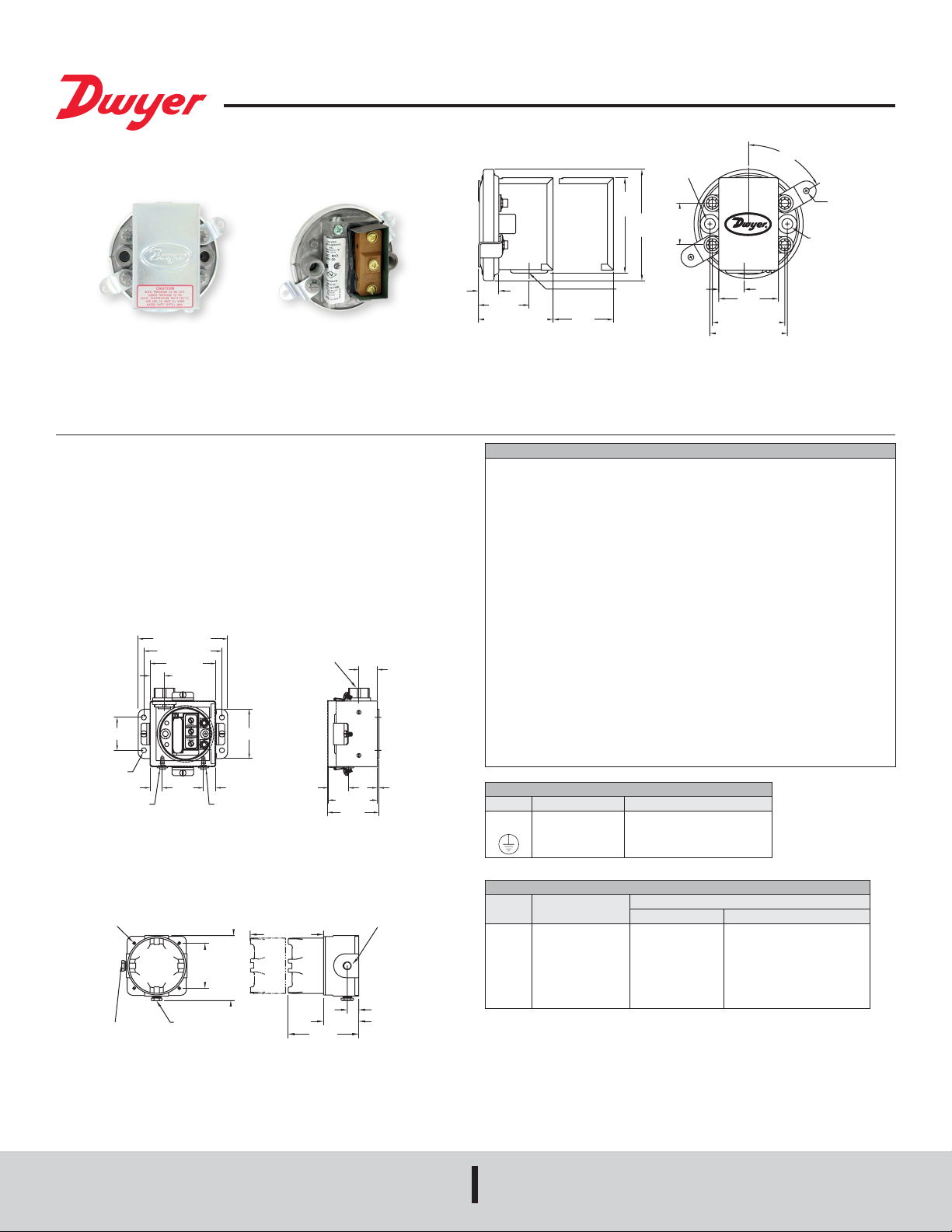

1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

3

41/64

[16.27]

1-19/32

[40.48]

2-11/32 [59.53]

1-3/4 [44.45]

CLEARANCE

FOR

COVER REMOVAL

[76.20]

ø 7/8 [22.23]

CONDUIT

CONNECTION

ø 3-1/2

[88.90]

1-5/16

[33.32]

TYP

51/64

[20.24]

1-7/8

[47.63]

2-9/32 [57.94]

2-7/16 [61.90]

Bulletin E-56

60° TYP

(2) ø 3/16 [4.76]

MOUNTING

HOLES ON

A 4-3/16

[106.36] B.C.

1/8 FEMALE

NPT LOW

PRESSURE

CONNECTION

Series 1910 pressure switch. All

pressure and electrical connections

and set point adjustments are on one

side for easy installation.

Advanced design and precision construction permit these switches to perform many

of the tasks of larger, costlier units. Designed for air conditioning service, they also

serve many uidics, refrigeration, oven and dryer applications. For use with air and

non-combustible gases. Series 1900 Pressure Switches are available with set points

of 0.07 to 20 inches water column. Set point adjustment can be made easily - before or

after installation. Range screw is inside conduit enclosure to help prevent tampering.

For easy mounting and access, pressure and electrical connections and set point

adjustment are located on one side. This permits installation in corners or spaces too

small for other switches.

SPECIAL MODELS & ACCESSORIES

Special close coupled street elbow for right angle pressure connections. Can be

installed on switch anytime. Zinc plated aluminum.

5-7/16 [138.1]

4-3/4 [120.7]

4 [101.6]

7/8 [22.22]

Ø5/16

[Ø7.938]

3/4 [19.05]

HIGH PRESSURE

CONNECTION 1/8 N.P.T.

Weatherproof Housing

16 ga. steel enclosure with gasketed cover (NEMA 4) for wet or oily conditions.

Withstands 200 hour salt spray test. Wt. 5 Ibs. (2.3 kg). Switch must be factory installed.

Change 1910 base number to 1911 and add -WP sufx. Example: 1911-1-WP.

4X Ø.281

[7.14]

1/8 FEMALE

NPT HIGH PRESSURE

CONNECTION

LOW PRESSURE

CONNECTION 1/8 N.P.T.

2X 6-1/8

[155.58]

2X 4-1/4

[107.95]

1/8 FEMALE NPT

LOW PRESSURE

CONNECTION

Series 1910 switch with conduit

enclosure off. Shows electric switch

and set point adjustment screw.

1/2 NPT WEATHERPROOF

ELECTRICAL CONNECTION

3 [76.20]2 [50.80]

3/4 [19.05]

1-1/4

[31.75]

6-1/2 [165.10]

CLEARANCE FOR

COVER REMOVAL

6-5/8

[168.28]

3 [76.20]

3-1/8

[79.38]

1/2 NPT

PROCESS CONNECTION

1-1/8 [28.58]

3/32

[2.381]

3X 1-1/16

[26.99]

3 [76.20]

The Dwyer-engineered force-motion amplier increases the leverage of

diaphragm movement and results in a switch with excellent sensitivity and

repeatability.

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Environment: Standard model intended for indoor use.

Wetted Materials: Consult factory.

Temperature Limits: -30 to 180°F (-34 to 82.2°C) (32°F for non dry air).

Pressure Limits: 45 in w.c. (11.2 kPa) continuous, 10 psig (68.95 kPa) surge.

Humidity Limit: 80% RH (non-condensing).

Altitude Limit: 6560 ft (2000 m) max.

Switch Type: Single-pole double-throw (SPDT).

Repeatability: ±3%.

Electrical Rating: 15 A @ 120-480 VAC (~), 60 Hz. Resistive 1/8 HP @125

VAC(~), 1/4 HP @ 250 VAC(~), 60 Hz. Derate to 10 A for operation at high cycle

rates.

Electrical Connections: 3 screw type, common, normally open and normally

closed.

Installation Category: III (transient over-voltage).

Process Connections: 1/8˝ female NPT.

Mounting Orientation: Diaphragm in vertical position. Consult factory for other

position orientations.

Set Point Adjustment: Screw type inside conduit enclosure.

Pollution Degree: 2.

Weight: 1lb. 4.5 oz. (581 g).

Agency Approvals: CE, UL, CSA, FM.

EXPLANATION OF SYMBOLS

Symbol Publication Description

IEC 60417 - 5032

~

IEC 60417 - 5019

SERIES 1910 SWITCHES - MODELS OPERATING RANGES, DEADBANDS

Operating Range,

Model

in w.c.

1910-00

0.07 to 0.15

1910-0

0.15 to 0.5

1910-1

0.40 to 1.6

1910-5

1.40 to 5.5

1910-10

3.0 to 11.75

1910-20

4.0 to 20.0

Alternating current

Protective conductor terminal

Approximate Dead Band

At Min. Set Point At Max. Set Point

0.04

0.10

0.15

0.30

0.40

0.40

0.04

0.10

0.16

0.30

0.40

0.50

Explosion-Proof Housing

NEMA 7, 9 NEMA 3. (7 lbs). Switch must be factory installed. Change model to 1911

and add -EXPL sufx. Example: 1911-1-EXPL. Aluminum base and cover rated Class

I, Groups C & D, Div. 1. Class II, Groups E, F, & G, Div. 1.

DWYER INSTRUMENTS, INC.

Page 2

INSTALLATION

1. Select a location that is free from excessive vibration, corrosive atmosphere and

where the ambient temperature is within the limits for these switches.

2. Mount standard switches with the diaphragm in a vertical plane and with switch

lettering and nameplate in an upright position. Some switches are position

sensitive and may not reset properly unless they are mounted with the diaphragm

vertical. (Special units can be furnished for other than vertical mounting

arrangements if required.)

3. Connect switch to source of pressure, vacuum or differential pressure. Metal tubing

with 1/4˝ O.D. is recommended, but any tubing which will not restrict the air ow

can be used. Connect to the two 1/8˝ female NPT pressure ports as noted below:

• Differential pressures - connect pipes or tubes from source of greater pressure

to high pressure port marked HI-PR and from source of lower pressure to low

pressure port marked LO-PR.

• Pressure only (above atmospheric) - connect tube from source of pressure to

high pressure port. The low pressure port is left open to atmosphere.

• Vacuum only (below atmospheric pressure) - connect tube from source of

vacuum to low pressure port. The high pressure port is left open to atmosphere.

CAUTION

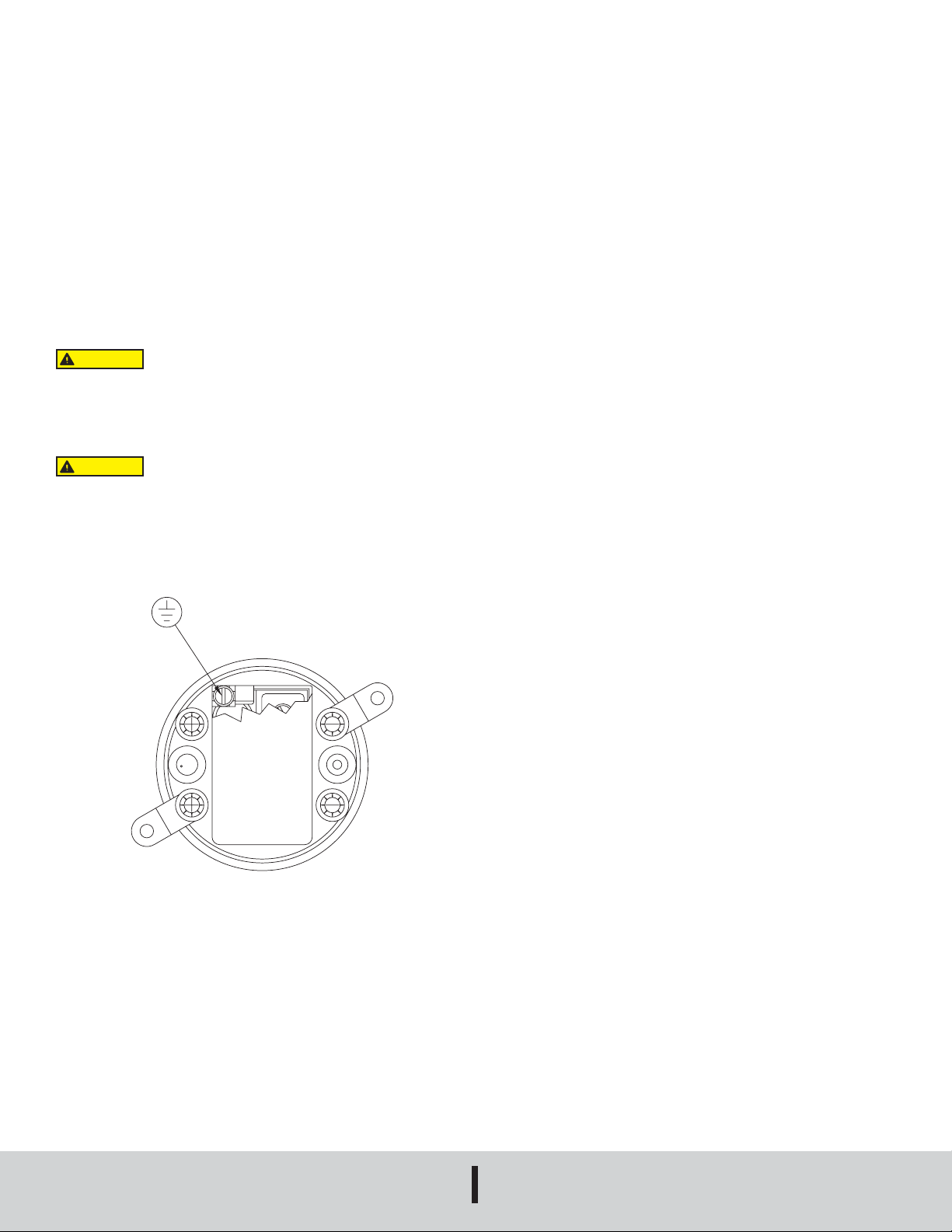

4. Electrical connections to the standard single pole, double throw snap switch are

provided by means of screw terminals marked “common”, “norm open”, and “norm

closed”. The normally open contacts close and the normally closed contacts open

when pressure increases beyond the set point.

Power must be off while wiring connections are being made.

OPERATION

Pressure acting on the power diaphragm rotates the amplifying lever, which in turn

extends the range spring and rotates the snap switch input lever. When the set point

is reached, the snap switcch is actuated and the electrical contacts make or break.

ADJUSTMENT

To change the set point, proceed as follows:

A. Remove the snap-on cover from the conduit enclosure by loosening its retaining

screw and pulling rmly at its bottom end. Turn the slotted adjustment screw at

the top of range spring housing clockwise to raise the set point pressure and

counter-clockwise to lower the set point.

B. The recommended procedure for calibrating or checking calibration is to use a

“T” assembly with three rubber tubing leads, all as short as possible and the

entire assembly offering minimum ow restriction. Run one lead to the pressure

switch, another to the manometer of known accuracy and appropriate range, and

apply pressure through the third tube. Make nal approach to the set point very

slowly. Note that manometer and pressure switch will have different response

times due to different internal volumes, lengths of tubing, uid drainage etc. Be

certain the switch is checked in the position it will assume in use, i.e. with

diaphragm in a vertical plane and switch lettering and nameplate in an upright

position.

C. For highly critical applications it is a good idea to check the set point adjustment

and reset it as necessary once or twice in the rst few months of operation. This

will compensate for any change in initial tension which may occur in the spring

and diaphragm. For most applications this change will not be signicant and no

resetting will be required.

CAUTION

5. Switch loads should not exceed the maximum specied current rating of 15 amps

resistive. Switch capabilities decrease with high load inductance or rapid cycle

rates. Whenever an application involves either of these factors, the user may nd

it desirable to limit the switched current to 10 amps or less in the interest of

prolonging switch life.

Do not exceed the specied voltage rating. Permanent damage

not covered by warranty may result.

MAINTENANCE

Moving parts of these switches are sealed in and are permanently tamper proof. The

single adjustment is that of the set point. Care should be taken to keep the switch

reasonably dry and free from dust or dirt. No lubrication or unusual precautions are

required for normal use.

DWYER INSTRUMENTS, INC.

Loading...

Loading...