ULTRASONIC FLOWMETER

TYPE: PUX2 (Flow transmitter)

PSX2 (Detectors)

Instruction Manual

Dwyer Instruments, Inc. B

ulletin F-9-PUX2

IN 1F i

PREFACE

Manufacturer : Dwyer Instruments, Inc.

Type : Described in nameplate on main frame

Date of manufacture : Described in nameplate on main frame

Product nationality : Japan

Note) Windows, Windows NT, Windows Vista, Excel, are registered trade marks of Microsoft Corporation.

Modbus is a registered trademark of Schneider Automation.

Issued in August, 2008

This manual explains cautions in use, wiring, operation, installation, troubleshooting and maintenance, and op-

tions of the portable type ultrasonic fl owmeter Please read through the manual thoroughly before using the

instrument.

Keep this manual available for reference by appropriate operation and maintenance personnel.

Notice

• This manual and contents may not be copied or reused in whole or in

part without prior permission.

• Contents of the manual are subject to change without prior notice.

© Dwyer Instruments, Inc. 2008

Bulletin F-9-PUX2

ii

CONTENTS

1. OVERVIEW ............................................................................................................................. 1

2. CHECK OF DELIVERED ITEMS .......................................................................................... 2

2.1 On purchase of fl ow transmitter (type: PUX2)..................................................................................2

2.2 On purchase of detector (type: PSX2) ...............................................................................................3

2.3 Reserved for future use .....................................................................................................................4

3. CHECK MODEL AND SPECIFICATION ............................................................................. 5

4. NAME AND EXPLANATION OF EACH PART .................................................................. 8

4.1 Name and explanation of main unit and detector ..............................................................................8

4.2 Explanation of keys .........................................................................................................................10

4.3 Handling of SD memory card ..........................................................................................................11

4.3.1 Precautions for handling of SD memory card .........................................................................11

4.3.2 Formatting forms ......................................................................................................................11

4.3.3 Insertion and removal ..............................................................................................................12

4.3.4 Data recording to SD memory card .........................................................................................13

5. POWER ON AND POWER OFF .......................................................................................... 16

5.1 Operating power supply...................................................................................................................16

5.2 Turning on the power and language preference ..............................................................................17

5.3 Power OFF .......................................................................................................................................18

6. WIRING ................................................................................................................................. 19

6.1 Diagram ...........................................................................................................................................19

6.2 Connection of dedicated cables .......................................................................................................19

6.3 Connection of analog input/output cable(4 to 20 mA DC) .............................................................20

6.4 Connection of USB cable ................................................................................................................20

7. INPUT OF PIPING SPECIFICATIONS ............................................................................... 21

7.1 Display of pipe setup screen ............................................................................................................21

7.2 Entry of site name (not required measurement) ..............................................................................24

7.3 Outer diameter of piping (unit: mm)(range: 13 to 6000 mm) .........................................................27

7.4 Piping material .................................................................................................................................28

7.5 Wall thickness (unit: mm) (range: 0.1 to 100.00mm) ....................................................................29

7.6 Lining material ................................................................................................................................30

7.7 Lining thickness (unit: mm) (range: 0.01 to 100.00 mm) ...............................................................31

7.8 Kind of fl uid ....................................................................................................................................32

7.9 Viscosity ..........................................................................................................................................33

7.10 Selection of sensor mounting method .............................................................................................34

7.11 Kind of sensor ..................................................................................................................................35

7.12 Transmission voltage (used when an indicator is 1 or less during measurement) ..........................36

7.13 Completion of PROCESS SETTING ..............................................................................................37

8. MOUNTING OF DETECTOR .............................................................................................. 38

8.1 Selection of mounting location ........................................................................................................38

8.2 Selection of detector ........................................................................................................................41

Bulletin F-9-PUX2

iii

8.3 Use of surface-treated accessories ...................................................................................................43

8.4 How to mount small size (standard) sensor and small outer diameter sensor to pipe .....................44

8.4.1 How to mount a sensor (V method) .........................................................................................44

8.4.2 How to mount a small size (standard) sensor (Z method) ........................................................45

8.5 How to mount large and medium size sensor ..................................................................................47

8.5.1 How to determine mounting position .......................................................................................47

8.5.2 How to connect medium size sensor ....... ...............................................................................48

8.5.3 How to connect large size sensor ................................... ........................................................50

8.5.4 Mounting of medium type sensor on pipe ................................................................................51

8.5.5 How to mount large size sensor to pipe ...................................................................................53

8.6 How to mount high temperature sensor to pipe ...............................................................................54

8.6.1 How to mount a sensor (V method) .........................................................................................54

8.6.2 How to mount a sensor (Z method) ..........................................................................................55

8.7 How to fold gage paper (used for determining mounting position) ................................................57

9. START MEASURING .......................................................................................................... 58

10. SETTING OPERATION (APPLICATION) .......................................................................... 63

10.1 How to use SITE SETUP function (SITE SETUP page) ................................................................64

10.1.1 SITE MEMORY: when registering data which are set and calibrated on the page ................64

10.1.2 ZERO ADJUSTMENT: when performing zero adjustment ...................................................66

10.1.3 UNIT OF OUTPUT: when changing unit of each output ........................................................67

10.1.4 OUTPUT CONTROL: when controlling measured value (output control function) ..............69

10.1.5 TOTALIZER: when performing the total process of measured data (totalize) .......................73

10.2 Setting of data logger function ........................................................................................................76

10.2.1 “Logger Operation” mode ........................................................................................................77

10.2.2 Logger data fi le format .............................................................................................................79

10.2.3 LOGGING: when logging (recording) measured data ............................................................80

10.2.4 “LOGGER DATA”: when checking or printing logged data ..................................................83

10.3 Setting of system (SYSTEM SETUP screen)..................................................................................88

10.3.1 BASIC SETUP: when setting the system................................................................................88

10.3.2 “ANALOG INPUT/OUTPUT”: when performing analog input/output and calibration ........95

10.3.3 “CALORIE MODE”: when measuring consumed heat quantity ..........................................103

10.4 Setting of range (setting screen for input/output range) ................................................................106

10.4.1 Setting the input range: When setting the range for the input current or input voltage.

Setting range: 0.000 to ±9999999999 ....................................................................................106

10.4.2 Setting the output range ..........................................................................................................108

10.5 Use of printer function (PRINTER screen) ...................................................................................112

10.5.1 Selection of printing mode .....................................................................................................112

10.5.2 Example of printing ................................................................................................................113

10.5.3 PRINT OF TEXT ...................................................................................................................114

10.5.4 PRINTING OF GRAPH .........................................................................................................115

10.5.5 PRINT OF LIST .....................................................................................................................116

10.5.6 STATUS DISPLAY ...............................................................................................................116

10.6 Maintenance function (MAINTENANCE screen) ........................................................................117

10.6.1 Checking receiving status for transit time ..............................................................................117

10.6.2 Check for analog input/output ................................................................................................122

Bulletin F-9-PUX2

iv

10.6.3 SD memory card .....................................................................................................................124

10.6.4 LCD check .............................................................................................................................127

10.6.5 Software .................................................................................................................................128

10.7 Flow velocity distribution display function (optional) ..................................................................130

10.7.1 Installing Detector ..................................................................................................................130

10.7.2 Operation ................................................................................................................................135

10.8 Contents of errors in status display................................................................................................140

10.8.1 How to check status display ...................................................................................................140

10.8.2 Action on error .......................................................................................................................141

11. MAINTENANCE AND CHECKUP ................................................................................... 144

12. ERROR AND REMEDY ..................................................................................................... 146

12.1 Error in LCD Display ....................................................................................................................146

12.2 Error of key ....................................................................................................................................146

12.3 Error in measured value .................................................................................................................147

12.4 Error in analog output ....................................................................................................................150

13. EXTERNAL COMMUNICATION SPECIFICATION ...................................................... 151

14. HOW TO USE PRINTER .................................................................................................... 152

14.1 How to connect printer ..................................................................................................................152

14.2 How to load printer roll sheet ........................................................................................................154

15. REPLACEMENT OF BUILT-IN BATTERY ..................................................................... 155

16. APPENDIX .......................................................................................................................... 156

16.1 Piping data ....................................................................................................................................156

16.2 Command tree................................................................................................................................164

16.3 Specifi cations .................................................................................................................................166

16.4 Q & A ............................................................................................................................................171

16.5 File contents of SD memory card ..................................................................................................176

16.5.1 Types of measured data to be logged .....................................................................................176

16.5.2 Measured data fi le ..................................................................................................................177

16.5.3 Flow velocity profi le data fi le .................................................................................................179

16.5.4 Regarding RAS.......................................................................................................................179

Bulletin F-9-PUX2

v

Be sure to observe the following precautions. They offer important information on safety.

Ɣ The degree of injuries or damages resulting from improper handling of this device is indicated

by different symbols.

CAUTION

Improper handling of this device may cause dangerous

situations that result in personal injury or property damage.

Ɣ The following symbols describe items to be observed.

The symbol indicates “prohibition”.

The symbol provokes “cautions”.

The symbol indicates “mandatory”

action to be taken.

Do not modify this device.

Be careful. It may result in fire.

Be sure to pull out the plug.

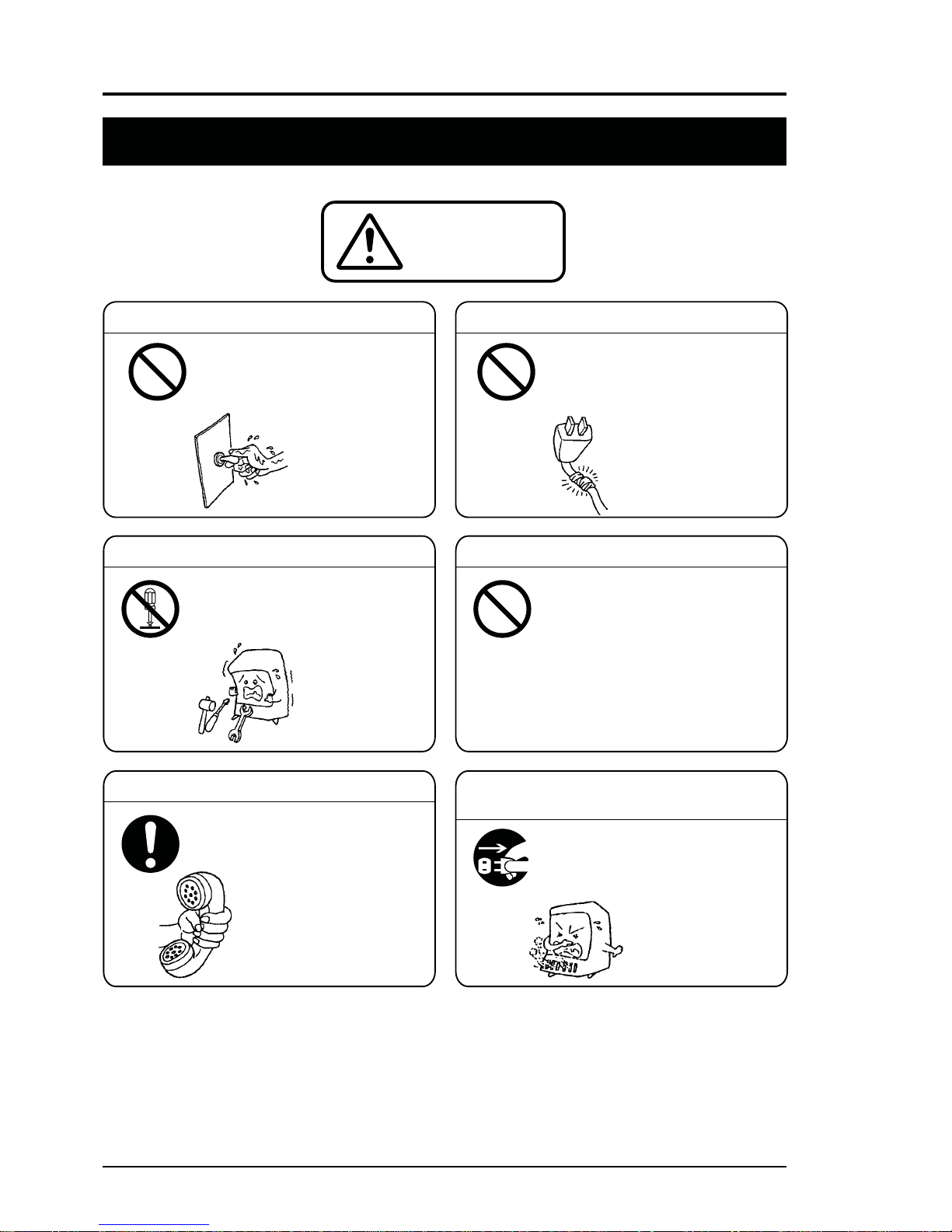

WARNING SYMBOLS AND THEIR MEANINGS

Bulletin F-9-PUX2

vi

Be sure to read the “Safety Precautions” carefully beforehand for the correct and safe use of this device.

Do not touch the switch with a wet hand. Do not break or pull the power cord.

Do not put heavy items

on the power cord.

Do not modify or pull the

power cord.

Otherwise it may break

and result in electric

shock and fire.

Do not disassemble.

Do n o t disassemble this

device.

Otherwise it may resu lt in an

accident.

Do not use electric parts soaked in water

Replace electric parts or wires

soaked in water due to floods

or some other reasons with

new ones.

Otherwise it may resu lt in

electric shock or fire.

Do not repair.

Do not use the flammable

gases or volatile agents

such as paint thinner near

the device.

Otherwise it may resu lt

in explosion or fire.

Pull out the plug immediately in

case of an emergency

In case of abnormal odor, smoke

or fire is perceived, pull the power

plug immediately.

Ask an authorized

serviceperson or your

dealer for repair.

Otherwise it may

result in electric

shock or fire.

Do not touch the switch

with a wet hand.

Otherwise it may resu lt in

electric shock.

WARNING

Prohibition

Prohibition

Prohibition

Disassemble

is prohi bited.

Pull out

the plug

SAFETY PRECAUTIONS

Bulletin F-9-PUX2

vii

CAUTION

Keep warning labels clean.

Ask an authorized waste disposal

specialist for disposal.

Do not splash water.

Prohibition

Prohibition

Be careful when carrying the device.

Inspect the power plug periodically.

Clean or replace the warning

labels so that they can always be

read correctly.

Otherwise it may result in an

accident.

Do not dispose the device

without proper authorization.

Otherwise it may cause

environmental pollution or result

in an accident.

Do not wash or splash water on

the electrical parts inside the

device.

Otherwise it may result in electric

shock.

When carrying the device,

exercise care to avoid physical

shock or vibration.

Otherwise it may cause failure.

For connecting the cable,

turn the power off.

For connecting cable to terminal

of the middle size detector

(Type: PSX2-E), or the large size

detector (Type: PSX2-D), turn

the power off.

Inspect the power plug once

every 6 months. Wipe the dust

off the plug and insert it securely.

Otherwise it may result in electric

shock or fire.

Match power capacity

with the device ratings.

Fire hazard

Be sure to connect the device to

the power source of proper

voltage and current rating.

Otherwise it may result in fire.

Use an exclusive power adapter

and built-in battery.

Prohibition

Do not use a power adapter or

built-in Lithium ion battery that is

not exclusive to the main unit.

Otherwise it may break and

cause failure.

• Ambient temperature:

Charge time; 0 to +40°C

In use; –20 to +60°C

Storage time; –20 to +50°C

Use the device in

favorable environment.

Do not use the device in an

environment subjected to dust

or corrosive gases.

Otherwise it may cause failure.

Flow transmitter

• Ambient temperature:

–10 to +55°C (Without printer)

–10 to +45°C (Witt printer)

• Ambient humidity: 90% RH or less

Detector:

• Ambient temperature: –20 to +60°C

• Ambient humidity:

Large/middle size detector; 100% RH or less

Others; 90% RH or less

Bulletin F-9-PUX2

viii

CAUTION

Cause of machine malfunction. Cause of machine malfunction.

Prohibition Prohibition

Use in a place which is remote

from electrical devices (motor,

transformer, etc.) which generate

electromagnetic induction noise,

electrostatic noise, etc.

Fire or damage may result.

Do not use in a place which is

near cell phones, wireless

devices, etc., which may cause

the machine blunder.

Except the main unit (printer, power

adapters, etc.), it is not protected

for dust or waterproof.

Avoid using the product in a place

where it will be exposed to water or

humidity.

Bulletin F-9-PUX2

1

1. OVERVIEW

This PUX2 is a portable type ultrasonic fl owmeter that allows easy measurement of fl ow rates

in pipes by installing a set of sensors on the outside of the piping.

A combination of the latest electronics and digital signal processing technologies enables the instrument

to provide a compact and convenient solution to accurately measure system fl ow rates without breaking or

opening the serial transmission and removable memory card functionality allows easy data acquisition and

analysis.

Bulletin F-9-PUX2

2

2. CHECK OF DELIVERED ITEMS

2.1 On purchase of fl ow transmitter (type: PUX2)

Conversion unit Carrying case

Strap

AC power supply

adapter

Power connector

conversion cord

Power cord

Analog input/

output cord (1.5m)

USB cable (1m)

BNC adapter

CD-ROM

Instruction manual

(

Loader Instruction

manual

(

Roll paper

(

)

(

)

SD memory card

(256MB)

Dedicated signal

cable (5m×2 pcs)

Without printer (PUX2)

With printer (PUX2-PR)

Bulletin F-9-PUX2

3

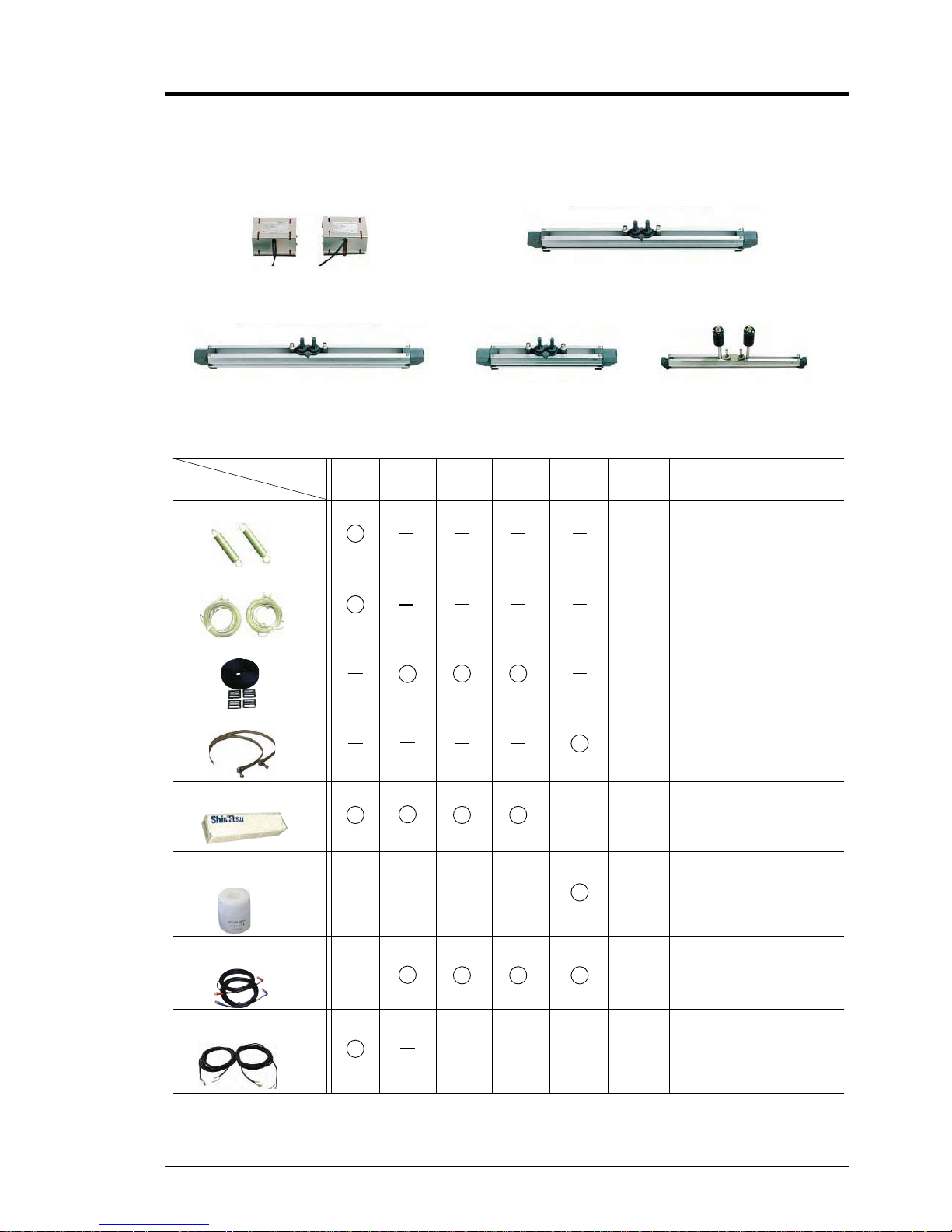

2.2 On purchase of detector (type: PSX2)

The following parts are included.

(1) Main unit

(Type: PSX2-D) (Type: PSX2-A)

(Type: PSX2-E) (Type: PSX2-B) (Type: PSX2-HT)

(2) Accessories

• Fastening springs

• I 2mm wire rope

• Plastic cloth belt

• Stainless steel belt

• Silicone grease

•

Grease for

high temperature

• Cable for exclusive use

(BNC at both ends)

• Cable for exclusive use

(BNC at one end)

PSX2-

D

Kind of

detector

PSX2-

A

PSX2-

E

PSX2-

B

PSX2-

HT

Quantity Remarks

2 pcs

2 pcs

1 pc

4 pcs

(long)

2 pcs

(short)

1 pc

1 pc

2 pcs

2 pcs

Mfg: Shinetsu

Chemical Industry

Type:G40M (100g)

Mfg: Shinetsu

Chemical Industry

Type: KS62M (100g)

.

.

.

Bulletin F-9-PUX2

4

2.3 Reserved for future use

Bulletin F-9-PUX2

5

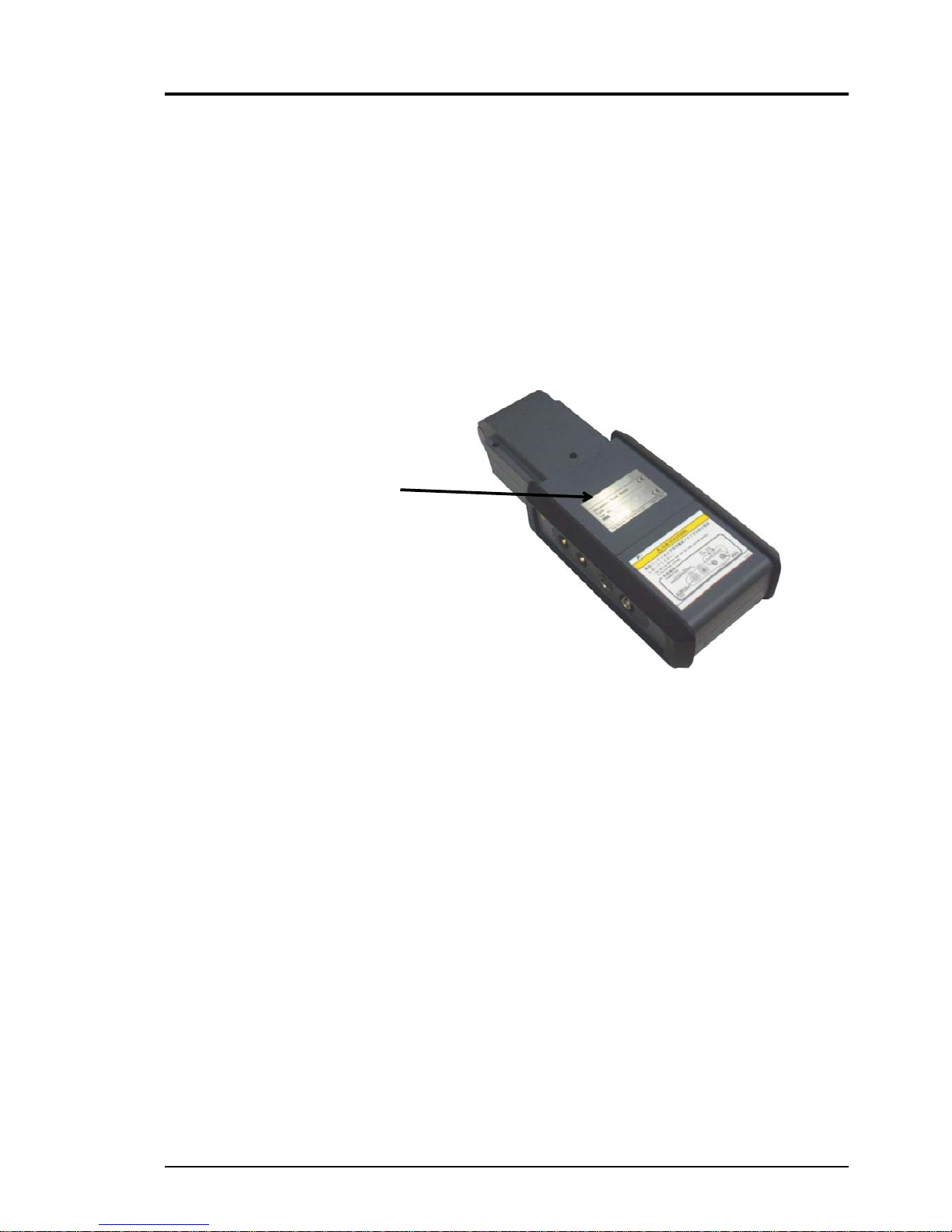

3. CHECK MODEL AND SPECIFICATION

The specifi cation plates attached to the frame of fl ow transmitter and the detector list the type and specifi -

cations of the product.

Check that they represent the type ordered.

1

Bulletin F-9-PUX2

Check Part number

on identification

plate.

6

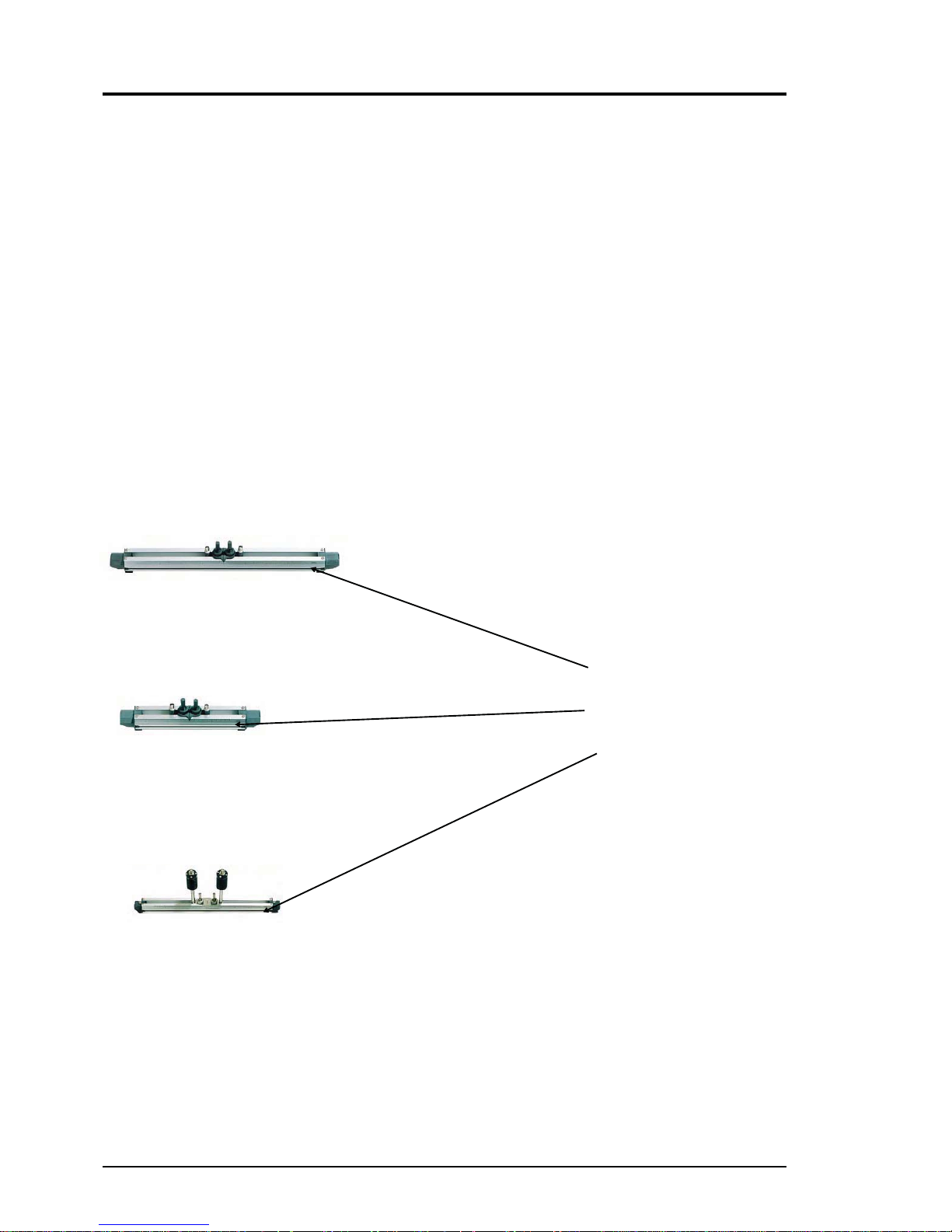

Bulletin F-9-PUX2

Check part identification & specification (cont'd)

Note)

Use a guide rail for applications in which ultrasonic signal penetration is

difficult, for example piping is very old, cast iron pipe, piping with mortar

liners, or high turbidity liquid or flow profile.

A

pplicable diameter Range:

V Method: 50mm to 250mm (1.97 in. to 9.84 in.) (PSX2-HT)

V Method: 50mm to 300mm (1.97 in. to 11.81 in.) (PSX2-A)

Z Method: 150mm to 400mm (5.91 in. to 15.75 in.)(PSX2-HT, PSX2-A)

Location of

identification

plates

PSX2-A/E

PSX2-B

PSX2-HT

7

Bulletin F-9-PUX2

Check part identification & specification (cont'd)

Location of

identification

plates

PSX2-D

PSX2-C

8

4. NAME AND EXPLANATION OF EACH PART

• Keyboard : Used for turning on/off power supply of the main unit, controlling the

printer, inputting fl uid specifi cations and setting the transmitter functions.

• Display window : Displays measured value. Also used for display during programming and

data input.

Because this is a large-size graphic LCD, indications are easy to read.

Even at a dark place, indications can be read by using the backlight.

• Printer (option) : Capable of printing all information of the transmitter including print of

display screen capture and printout of measured value.

*Transmitter includes a logger function (for storing measured values in

memory). After storing a few day's data in memory by the logger function,

it may be printed.

Note) Chinese language selection will print Japanese.

• Detector : Attached to a pipe and receives/transmits ultrasonic waves.

• Cable for exclusive use:

Used for transmitting and receiving signals between transmitter and detec-

tors for fl ow measurement.

• Rubber : Protects the main unit from drop impact etc.

4.1 Name and explanation of main unit and detector

Bulletin F-9-PUX2

9

12V DC

(power connector)

AI/AO (4 to 20mA DC analog I/O connector)

UP STREAM

(detector connector on upstream side)

DOWN STREAM

(detector connector on downstream side)

Rightside

SD memory card

Note) SD logo is a registered trademark.

Note

Cap

USB

LCD contrast

adjusting knob

Bottom

• Connectors : 12V DC

Connector of main unit power supply. Inputs 12V DC.

Insert the plug of the power adapter specifi ed for this instrument.

: UP STREAM (upstream side), DOWN STREAM (downstream side)

Receptacles to connect detector cables.

Connect matching the upstream and downstream sides.

: ANALOG IN/OUT

Connect analog input/output signals (4 to 20mA DC).

Analog input signal: 2 points

CH1: 4 to 20mA DC or 1 to 5V DC

CH2: 4 to 20mA DC

Analog output signal: 1 point

4 to 20mA DC

: USB

USB port. Connect to an external system such as personal computer.

: SD memory card

SD card slot. The measurement data and the screen data can be saved.

: Contrast adjusting knob

Adjust the LCD contrast.

Note) Be careful not to lose the protective cap attached to power connector and analog input/

output connector.

Bulletin F-9-PUX2

10

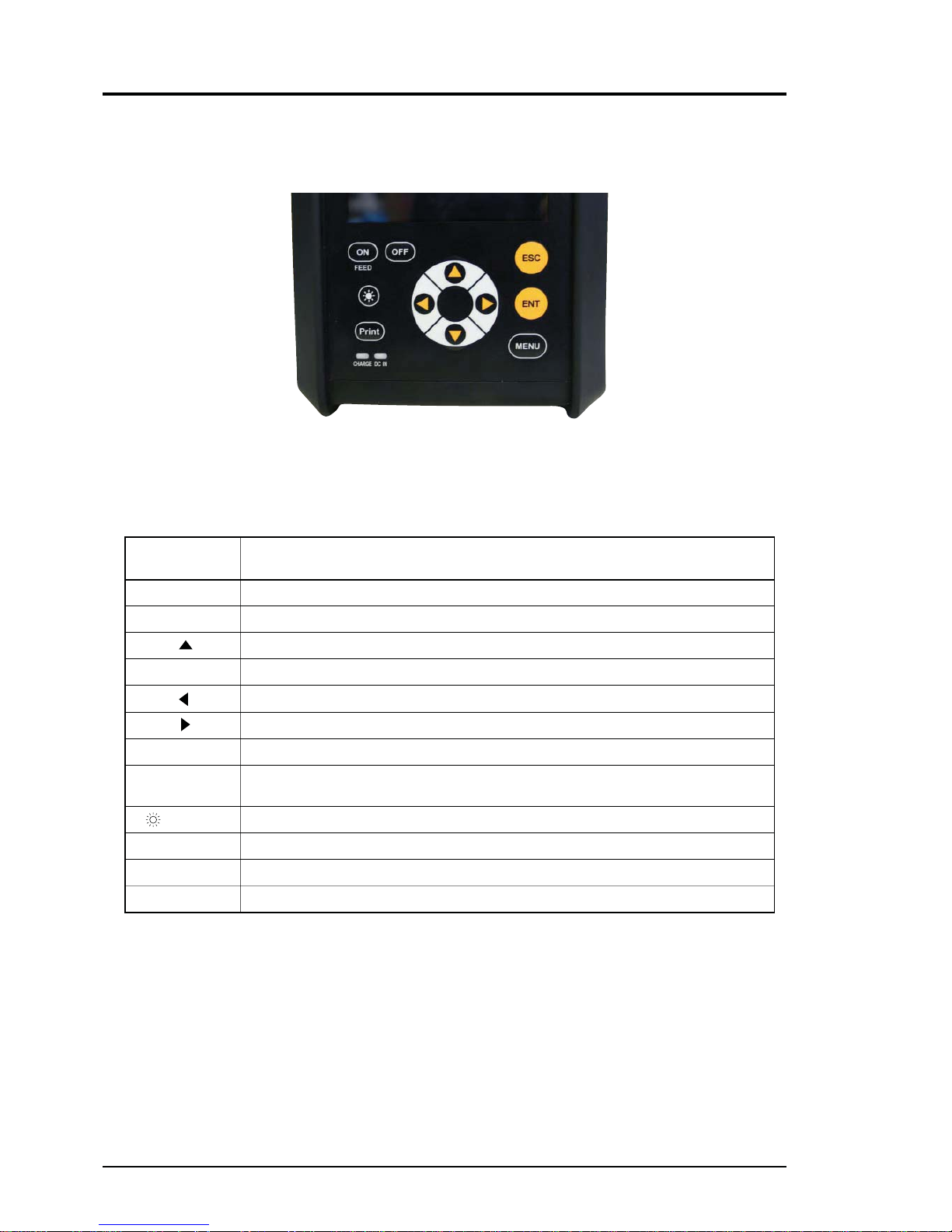

4.2 Explanation of keys

Fig. 3-1 shows the layout of keys and Table 3-1 explains each key.

Fig. 4-1 Layout of keys

Table 4-1 Explanation of keys

Description

The keyed-in data, selected item, etc. will be set by pressing this key.

Cancels any setting.

Moves the cursor upward, increments set value, etc.

(repeats if held down)

Moves the cursor downward, decrements set value, etc. (repeats if held down

)

Moves the cursor leftward, change scale, etc.

(repeats if held down)

Moves the cursor rightward, change scale, etc.

(repeats if held down)

Turns on/off power supply.

Print of the display screen or save the data to SD memory card.

(outputs a hard copy).

Turns on/off the backlight of display screen.

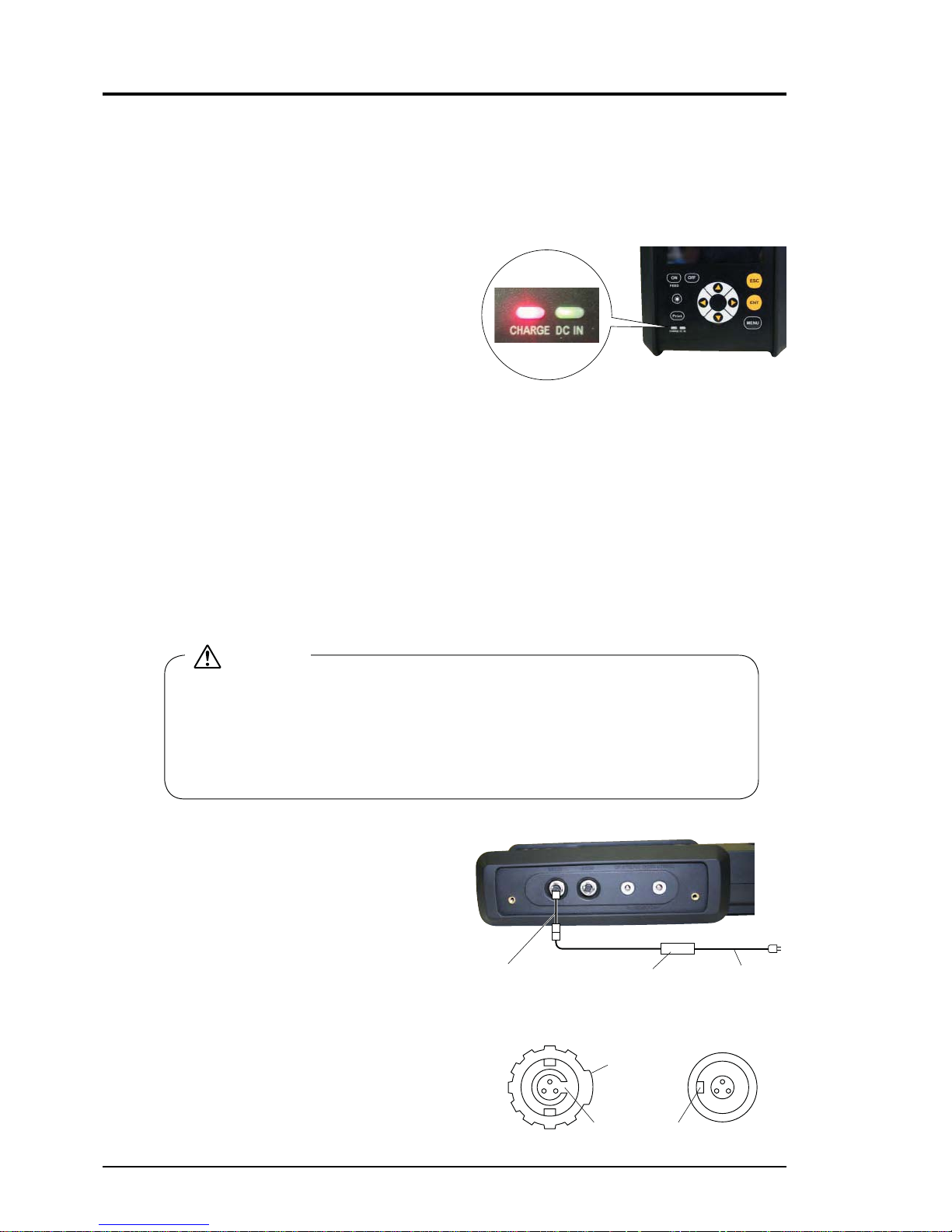

Turns ON in charge. Turns OFF in fully charged condition.

Turns ON with power cable connected.

Displays MENU screen.

Key indication

or lamp

ENT

ESC

ź

ON/OFF

PRINT

(LIGHT)

FAST CHARGE

DC IN

MENU

Bulletin F-9-PUX2

11

4.3 Handling of SD memory card

Use an SD memory card for recording measured data, fl ow velocity profi le data and screen data.

The equipment is capable of accommodating an SD memory card of capacity up to 8GB. An

SD memory card of capacity 256MB is provided as an option.

Compatible media

• SD memory card

Speed class: Class2, 4, 6

• SDHC memory card

Speed class: Class4, 6

4.3.1 Precautions for handling of SD memory card

(1) Use an SD memory card or SDHC memory card that has been formatted based on a standard.

(2) Make sure to format the SD memory card or SDHC memory card based on its standard.

(3) Firmly insert the SD memory card (or SDHC memory card; hereinafter the same) in the appro-

priate direction, and assure that it has been properly mounted.

(4) Do not remove the card during data read/write operation. Data may be broken or erased.

It is recommended that data stored on the card is periodically backed up.

Important data is lost if the SD memory card is broken. Make sure to back up the data on the

SD memory card.

4.3.2 Formatting forms

For formatting an SD memory card, use dedicated formatting software the memory card manufacturer provides. Data read/write is not permitted if the card is not property formatted.

Formatting forms

• FAT12: 64MB

• FAT16: 128MB, 256MB, 512MB, 1GB, 2GB

• FAT32: 4GB, 8GB

Bulletin F-9-PUX2

12

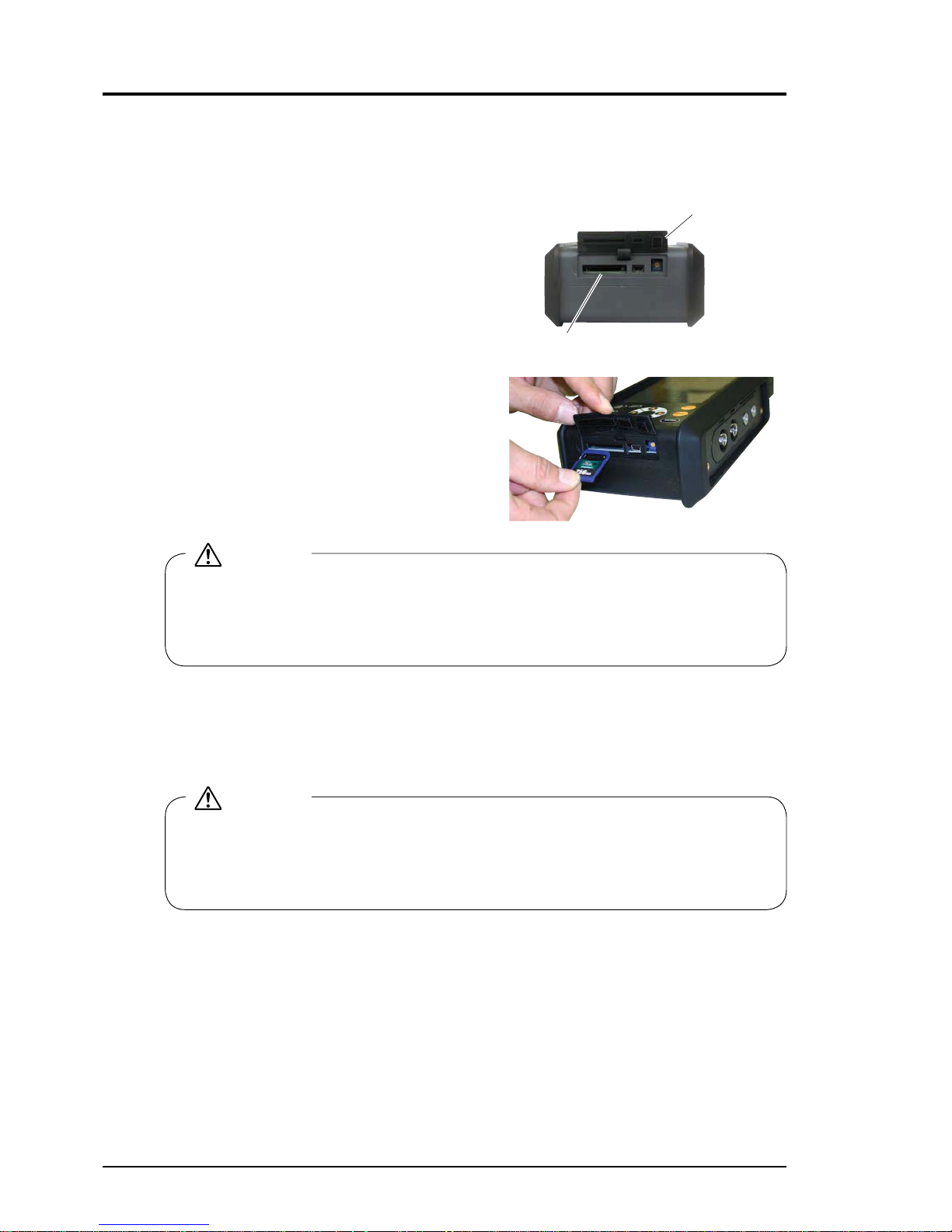

4.3.3 Insertion and removal

Methods for insertion and removal of an SD memory card are described below.

(1) Insertion

Step 1) Open the cap from the main unit bottom

face.

SD memory card slot

Cap

Step 2) Insert a memory card into the memory

card slot in the main unit bottom face in

the direction shown on the right.

Card push-in system is adopted for card

mounting. Positively push in the memory

card to the lock-up position.

When inserting, align the memory card body to match the slot.

Do not insert the card at an angle. Card should slide into slot freely without force. If the

memory card is pushed with force in the state where the card is inserted as tilted, the connector in the main unit will be broken. Be careful.

CAUTION

(2) Removal

Card push-in system is adopted for card mounting. Push the card in straight. The card is unlocked and can be removed.

The data stored on a memory card can be directly read with a PC.

• Do not remove the memory card during data write operation.

• Do not remove the memory card before the main unit identifi es the inserted memory card

after its insertion.

• Be careful with static electricity at the time of removal of the memory card.

CAUTION

Bulletin F-9-PUX2

13

4.3.4 Data recording to SD memory card

(1) Types of recorded data

Recorded data is of three different types indicated below.

(1) Measured data: One logger fi le is composed of a confi guration fi le and a data fi le.

Confi guration fi le: Records logger start-up time and relevant logger data

fi les.

Data fi le: Records logging data in a specifi c period produced by logger and

quick logger.

The data fi le is stored as divided by 65,500 lines for permitting

high-speed access and due to restrictions in the maximum number

of lines of CSV display of spreadsheet software.

(2) Flow velocity profi le: Records fl ow velocity plofi le data for an hour.

(3) Screen copy: Records screen display copy data.

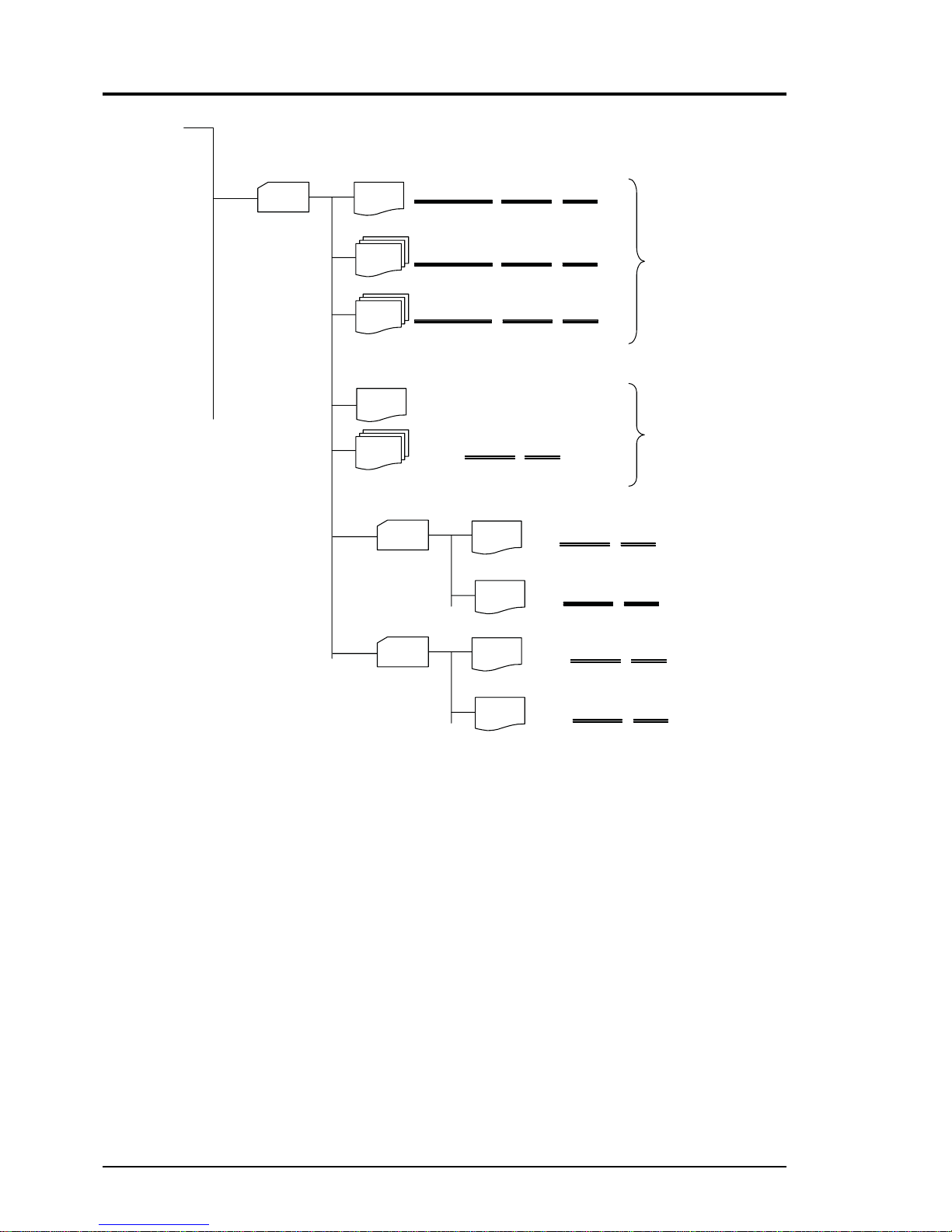

(2) File confi guration

Recorded data is stored as fi les on an SD memory card.

The fi le confi guration is such that a folder of site name is located just beneath the root folder and

the following data manipulated by the subject site name is stored beneath said folder.

A folder of site name is created at the time of registration of a site name described in “10.1.1

SITE MEMORY”.

The recorded data is stored in the folder of the site name selected by site selection described in

“10.1.1 SITE MEMORY”.

(1) Measured data … Just beneath the folder of site name

Case of logger

• Confi guration data fi le name of created logger: logging name_date_hour.ini

• Data fi le name of created logger: logging name_date_hour.csv

Case of logger

• Confi guration data fi le name of created logger: QUICK_date_hour.ini

• Data fi le name of created logger: QUICK_date_hour.csv

A data fi le can be edited with spreadsheet software.

See “16.5.2 Measured data fi le” located toward the end of the volume for the recording

format.

(2) Flow velocity distribution … Beneath VEL folder just beneath folder of site name

• Created flow velocity distribution data file name: Vel_date_hour.csv

A data fi le can be displayed using fl ow velocity distribution demonstrate function of PC

loader software.

See “16.5.3 Flow velocity distribution fi le” located toward the end of the volume for the

recording format.

(3) Screen copy …Beneath DISP folder just beneath folder of site name

• Created screen copy file name: DISP_date_hour.csv

Recording format: bitmap

Bulletin F-9-PUX2

14

Root

(Folder)

Site name

VALVE_Open_20060703_163100.csv

Date

Time

QUICK_20060704_163100.ini

Logger

(File)

(File)

(File)

QUICK_20060703_163100.csv

Date

Time

Quicklogger

VEL

Flow velocity

distribution

Vel_20060704_163100.csv

Data

Time

Vel_20060705_163100.csv

Date

Time

DISP

Hard copy

DISP_20060704_163100.bmp

Date

Time

DISP_20060705_163100.bmp

Date

Time

VALVE_Open_20060705_183100.csv

Date

Time

VALVE_Open_20060703_163100.ini

Date

Time

Log name

Log name

Log name

(File)

(File)

(File)

(File)

(File)

(File)

Fig. 4-2 File confi guration

Bulletin F-9-PUX2

15

(3) Recording capacity

The recording capacity depends on the capacity of the SD memory card.

One logger fi le is composed of a confi guration fi le and a data fi le.

The data fi le is stored as divided by 65,500 lines for permitting high-speed access and due to

restrictions in the maximum number of lines of CSV display of spreadsheet software.

The maximum number of data fi les in a logger is 20 fi les in case of a continuous logger, and

is 550 fi les in case of an appointed time logger. If the capacity becomes short during logging

operation, logging operation terminates with the following screen displayed.

Replace the SD memory card immediately, if this screen is displayed.

Press the

ESC

key, or remove the memory card, the message will be cleared.

Note) After reaching the maximum data fi le, the logging will stop.

Recording capacity in case an SD memory card of 256 MB is used with continuous logger

Where the preservation period is 30 seconds and where logger data of all of 14 types is

stored, it is possible to store measured data for about a year.

In the case stated above, the measured data is divided into 16 fi les, and the capacity of a fi le is

about 15 MB.

See “10.2.1 Setting of data logger function” for the continuous logger and appointed time logger.

See “16.5.1 Types of measured data to be logged” for logger data types.

Bulletin F-9-PUX2

16

5. POWER ON AND POWER OFF

5.1 Operating power supply

There are two methods available for energizing this instrument; by the built-in battery or with

the power adapter.

(1) Energizing with built-in battery

(1) To charge the battery

Turn OFF the instrument power and

connect the AC power adapter. The

“CHARGE” LED is lighted in red, and

“DC IN” LED is lighted in green.

When the instrument is fully charged,

"CHARGE” LED goes out.

* About 3 hours will be required for charging..

* In the fully charged condition, the instrument can measure for about 12 hours.

(On condition that the display backlight is turned off and the printer is unused, do not use

current output. The ambient temperature is near normal temperature (20°C).)

Note) The charging limit of the built-in battery is 0 to +40°C. If the charging is operated beyond

that range, it will cause hi-temp leak, performance deterioration, and short battery life.

(2) To energize by built-in battery

When turning on the power supply without connecting the power adapter, the instrument

will be energized by the built-in battery.

Before use, the battery should be fully charged.

(2) Energizing by power adapter

• AC power adapter

(1) Connect the power connector conversion

mode to the output plug for AC power

adaptor. (The products have already

been connected.)

(2) Connect the plug of the power connector

conversion mode to the 12V DC connector of the main unit. Inserts joining the

connected projection to the cutout, turns

the sleeve lock.

(3) Insert the input plug of this adapter into

the power receptacle.

This adapter has an input voltage range

of 90 to 264V AC (at 50/60Hz).

(4) Insert the input plug of AC adapter into

the outlet.

• Use the exclusive power adapter only. Don’t use other adapters, or it may result in

an accident.

• Except the main unit (printer, power adapters, etc.), it is not protected for dust or

waterproof.

Avoid using the product in a place where it will be exposed to water or humidity.

CAUTION

Power connector

conversion cord

AC power supply

adapter

Power cord

Cord side connector Flow transmitter side

connector

Sleeve

ProjectionCutout

Bulletin F-9-PUX2

17

5.2 Turning on the power and language preference

(1) Press the ON switch of the main unit to turn ON the power.

(2) Turn ON the power, and the following

screen appears.

(3) If no selection is chosen on the

the screen for about 5 sec. the

“MEASURE” screen appears.

Note1) Select any of 6 languages (Japanese, English, German, French, Spanish, and Chinese).

Note2) To return to the “Language Selection” screen from the “MEASUREMENT” screen in

display, turn OFF the power once and then turn it ON again. In the initial screen that is

displayed, press the

ENT

key.

ENT

ENT

Language to be set is

displayed.

To select the language

Note:

From the next step, the

language you selected can

be used.

When the language is displayed (for about

5 sec.), press the ENT key, and

the “Language Selection”screen appears.

In the screen that is displayed, select

your desired language and press the ENT

key. It returns to the “MEASUREMENT”

screen.

Bulletin F-9-PUX2

18

5.3 Power OFF

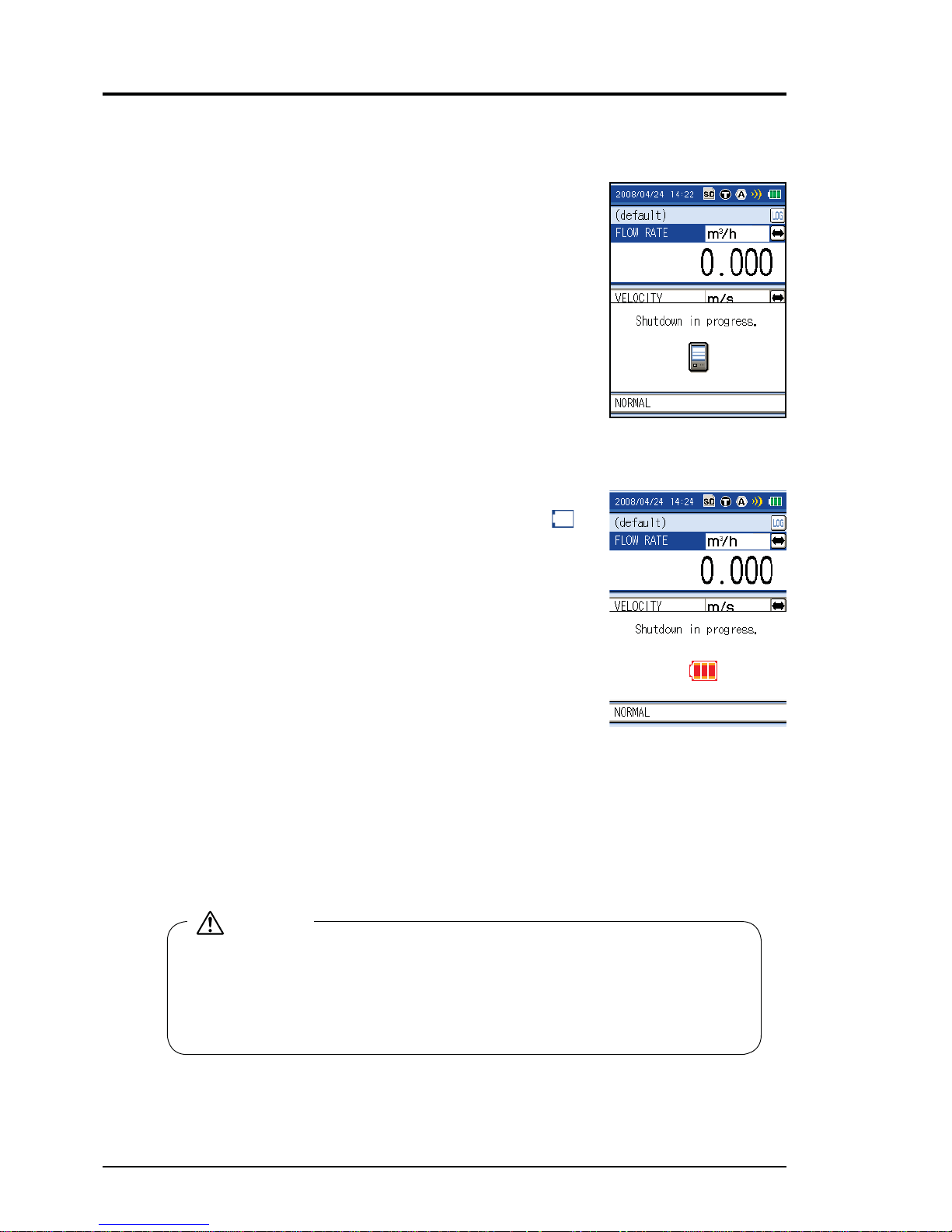

(1) Power OFF by [OFF] switch

Keep pressing the [OFF] switch on the main unit for 3 seconds or

longer, to turn OFF the power.

In case where measured data is being logged to an SD memory

card, execute logging interrupt processing before turning OFF the

power.

(2) Power OFF caused by drop in capacity of built-in battery

In case of operation with built-in battery, the power is turned OFF

about 40 minutes (see Note) after remaining capacity short (

) is

indicated.

In case where measured data is being logged to an SD memory

card, execute logging interrupt processing before turning OFF the

power.

Note) This length of time varies by ambient temperature and bat-

tery conditions. The time depends on use conditions.

(3) Precautions for parameter setup change

When parameter setup is changed, parameters are stored in the internal non-volatile memory

upon return to the measurement screen.

The stored parameters are held even when the power is turned OFF.

Caution: If the power is turned OFF without returning to the measurement screen after parameter setup changes, the parameters are not stored, and setup is required again.

Do not operate the main unit using an AC power adaptor in the state where the builtin battery is removed from the main unit.

• If the power cable is disconnected from the power outlet or if power failure arises

while measured data is being logged to the SD memory card, the data written to

the SD memory card may be lost.

CAUTION

Bulletin F-9-PUX2

19

6. WIRING

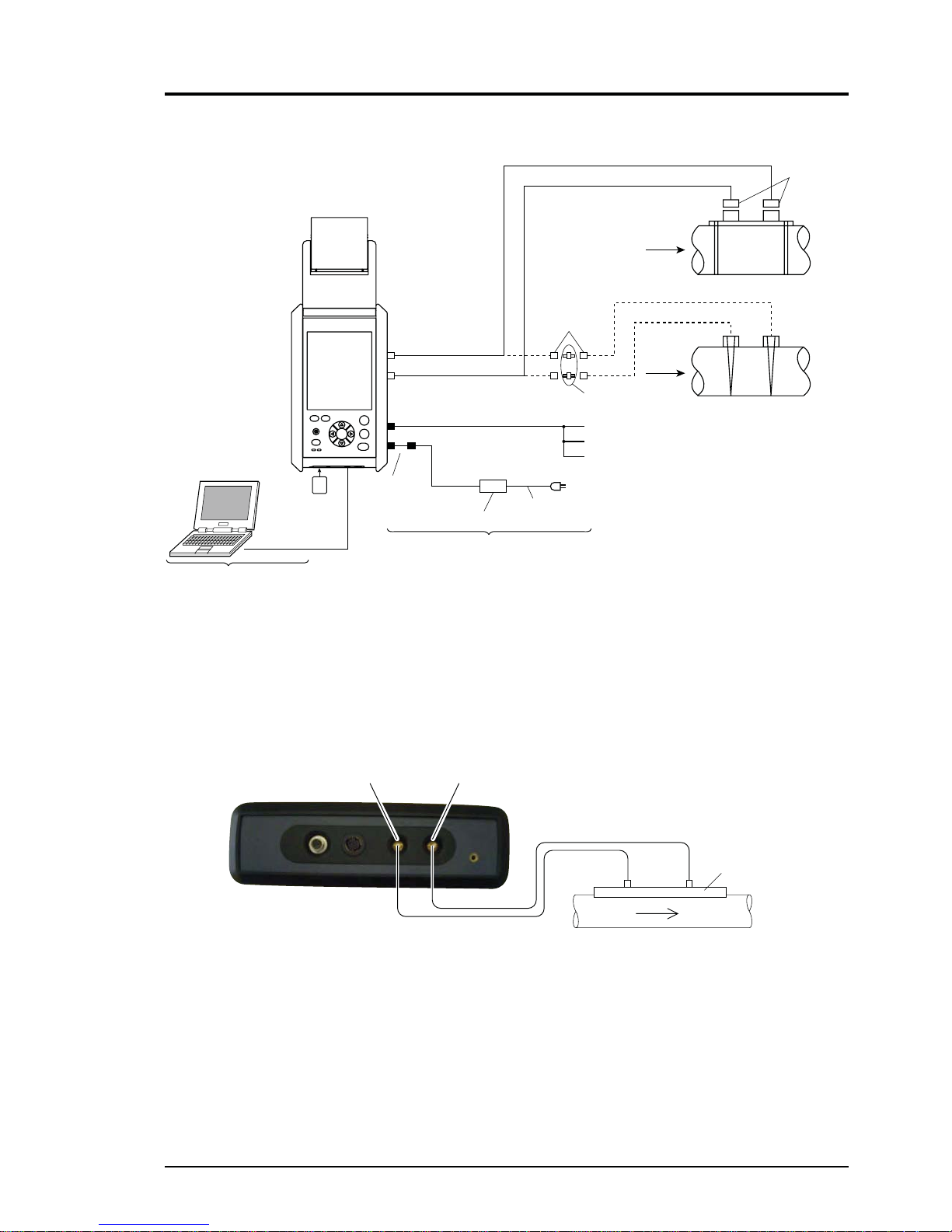

6.1 Diagram

SD

CHARGE DC IN

FEED

P

ESC

ON

OFF

Print

ENT

MENU

Printer

(option)

Detector

Detector

Exclusive use signal cable

To connect signal cables for PSX2-A/B/E/HT

To connect signal cables for PSX2-C/D

BNC

connector

BNC connector

BNC adaptor

Signal cable

AO analog output 4 to 20mA DC

AICH1 analog input 4 to 20mA DC or 1 to 5 V DC

AICH2 analog input 4 to 20mA DC

Analog input/output cable

AC90 to 264V

Power cord

AC power adaptor

Power connector

Conversion cord

To connect PC

PC

Flow

transmitter

USB cable

SD memory

card

for use AC adaptor

Sensor input

(the downstream side)

Sensor input

(the upstream side)

6.2 Connection of dedicated cables

This cable is used for connecting the detector to the main unit.

(1) Connect dedicated cables to the upstream and downstream sides of the detector.

(2) Connect one cable connected to the upstream side of the detector to the “UP STREAM”

connector of the main unit, and connect the other cable connected to the down stream side

of the detector to the “DOWN STREAM” connector.

DOWN STREAMUP STREAM

Upstream Downstream

Flow direction

Detector

Bulletin F-9-PUX2

20

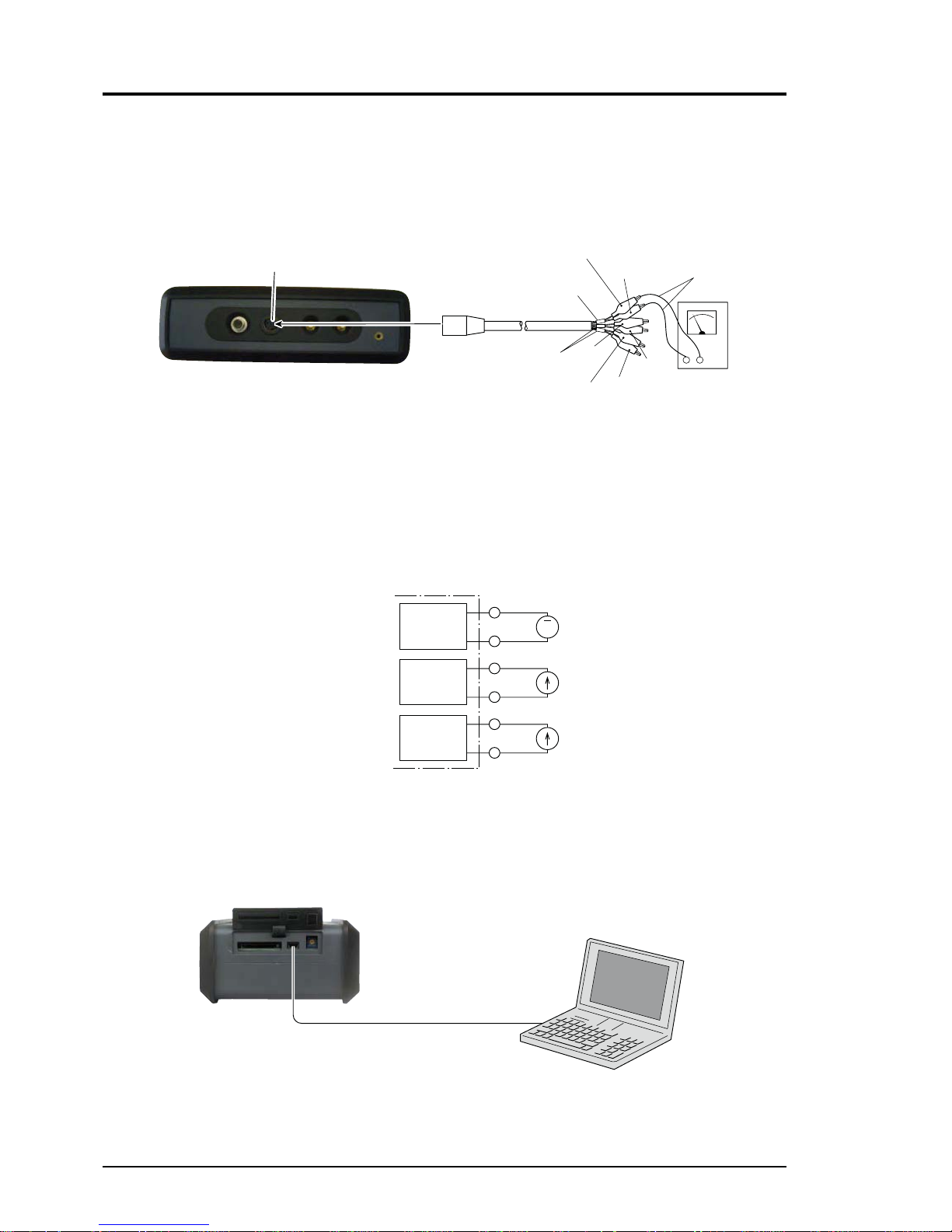

6.3 Connection of analog input/output cable

(4 to 20 mA DC)

This cable is used for connection of receiving instruments (indicators, recorders, etc.) and fl ow

transmitter to the main unit. Analog I/O cable is connected as shown below. The cable end is

treated with a clip.

Red (+)

Red

(+)

Black (í)

Black

(í)

4 to 20mA

−

+

AO

(output)

AI/AO

Note) Plug the

connector

into AI/AO.

AI

(input)

Indicator,

recorder,

controller, etc.

Red

(+)

Black

(í)

AIch2

AO

AIch1

(1) Connect clips of the analog I/O cable to the (+) and (í) sides of the receiving instruments,

respectively.

(2) Connect the analog I/O cable to the “AI/AO” connector at the side panel of the main unit.

Note) Allowable load resistance of analog output should be adjusted to 600: or less.

Input resistance of analog input is 200:

Red

Converter

Black

Red

Black

Red

Black

AO

AI CH1

AI CH2

í

+

A

6.4 Connection of USB cable

When PC software is used, open the cap of down face of the main unit and USB port of PC;

transmit connecting “USB” port with USB cable.

For PC software, refer to Chapter 12.

Mini USB cable

Maximum 3m

Bulletin F-9-PUX2

21

7. INPUT OF PIPING SPECIFICATIONS

Before installing the detector, set the specifi cations of a pipe in the main unit to allow measurements.

Caution) Measurements cannot be accomplished without these settings.

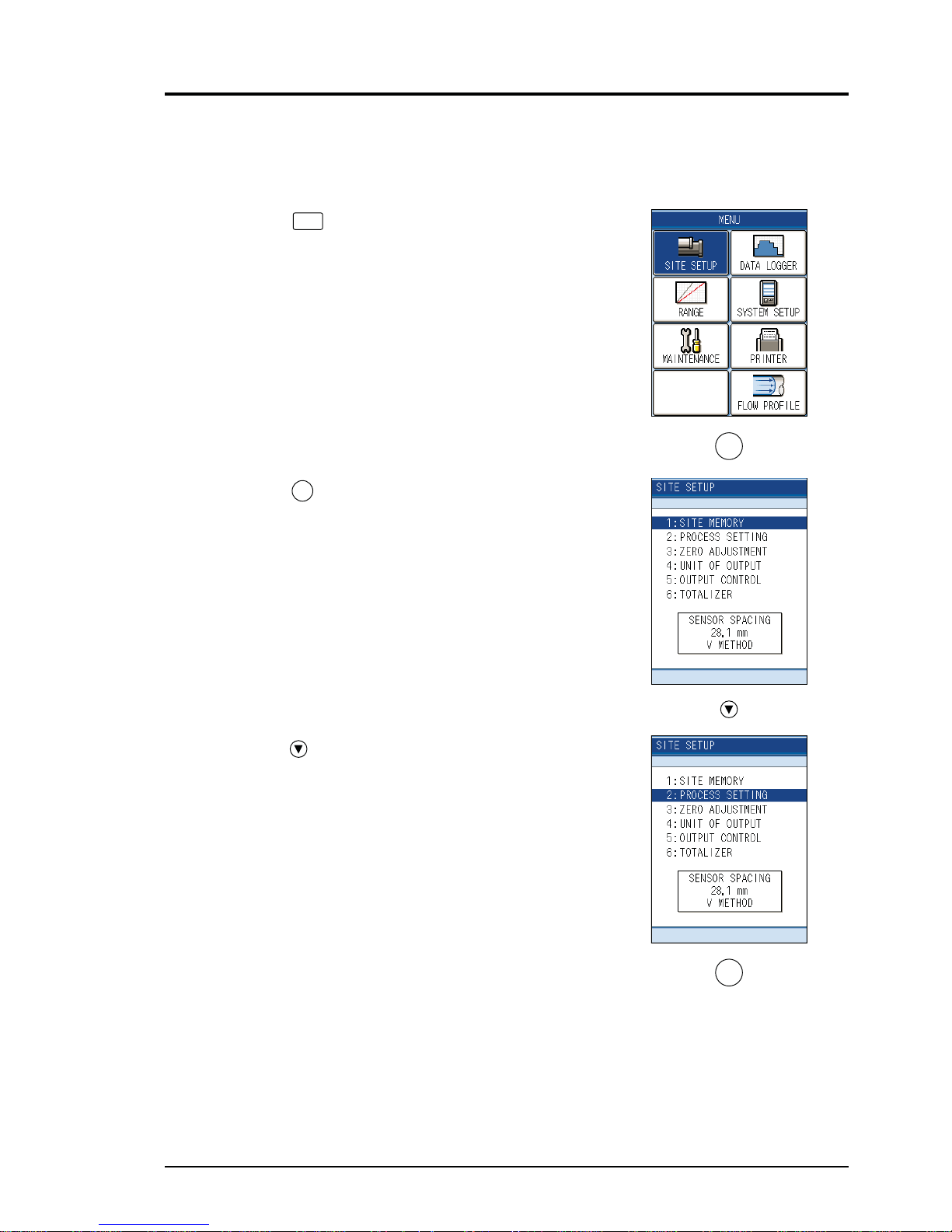

7.1 Display of pipe setup screen

(1) Press the

MENU

key on the “MEASURE” screen to

display the “MENU” screen.

(2) Check that the “SITE SETUP” is reversed from

white to blue.

ENT

(3) Press the

ENT

key, and the “SITE SETUP” screen

is displayed.

(4) Press the key, and move the cursor to “2: PRO-

CESS SETTING”.

ENT

Bulletin F-9-PUX2

22

(5) Pressing the

ENT

key returns to the “PROCESS

SETTING” screen.

(6) Outline of PIPE PARAMETER (Parameter ĺ Page No. for reference)

Sets external dimensions of pipe ĺ P27

Sets pipe material ĺ P28

Sets lining thickness ĺ P29

Set kind of fluid ĺ P32

Sets sensor mounting method ĺ P34

Sets lining material ĺ P30

Sets pipe thickness ĺ P31

Sets type of sensor ĺ P35

Sets transmission voltage ĺ P36

Bulletin F-9-PUX2

23

(7) Display of mounting dimensions

After you fi nish the site setting on establish site screen, “Decision” is reversed from white to

blue by pressing

ENT

key.

Displays the message “After mounting the sensor, perform Zero point adjustment”, then goes back to

“SITE SETUP” screen.

At the last line the “SENSOR SPACING” value is displayed.

ENT

Mounting

dimension

Install the sensor according to chapter 8. MOUNTING OF DETECTOR and the mounting

dimension is as displayed on the last line.

• For small pipe diameter, the sensor mounting length can be 0.0mm.

• When the sensor mounting length is 0.0mm, error of the measurement is approximately ±2 to 5%.

CAUTION

Bulletin F-9-PUX2

24

7.2 Entry of site name (not required measurement)

Enter the name of the site (where measurement is

performed). This name is registered with process

setting ((4) of page 21).

(1) Move the cursor to “1: SITE MEMORY” on the

SITE SETUP screen.

Note) Before setting the “2. Establish setting”,

the Site registration is required.

(2) Press the

ENT

key to display the SITE MEMORY

screen.

(3) Press the

ENT

key after checking that cursor is

placed in the MODE.

ENT

(4) When the mode selection screen appears, move

the cursor to “REGISTRATION” and press the

ENT

key.

ENT

ENT

Bulletin F-9-PUX2

25

(5) Move the cursor to the unregistered fi eld and press

the

ENT

key.

ENT

(6) When the entering screen appears, enter the name

of the site.

Up to 10 characters can be entered.

(See the following for the method of entering.)

ENT

[Reference] Description of character entry screen

Select a character and press the

ENT

key. Characters will be displayed one by one in the entry fi eld.

Select “BS” and press the

ENT

key to delete characters one by one.

In case of stoping entry in the middle, select “CAN” and press the

ENT

key to return to the original

SITE MEMORY screen.

Character entry field

Key for registering characters

in the entry field

Cancel key for character entry.

Character display

Key for deleting a character

in the entry field

Bulletin F-9-PUX2

26

(7) Move the cursor to “END” and press the

ENT

key

to complete the character entry.

When moving the cursor in the character entry fi eld

Press the

ESC

key so that the cursor “ | ” will change to

“ Ű”.

The cursor can be moved by the and the key.

For entering characters to the place the cursor is

moved, press the

ESC

key

The cursor moves to the character entry fi eld.

Note 1) Entry can be made with alphanumeric characters.

Note 2) To stop character entry in the middle, select “CAN” and press the

ENT

key.

The original SITE MEMORY screen reappears.

Bulletin F-9-PUX2

27

7.3 Outer diameter of piping

(Range: 13 to 6000 mm / 0.51 to 236 inch)

The “OUTER DIAMETER” is reversed from

white to blue, on the “PROCESS SETTING”

screen

Press the

ENT

key, the screen of “OUTER DIAMETER” for selecting the input method of outer

diameter measurement and “PERIMETER” screen

will appear.

Press the

ENT

key after the selection to enter the

outer dimension.

Use the

or key to cause the digit to move in

the right and left direction

Use the

or key to enter the numeric value.

After entry, press the

ENT

key.

Note) Enter outer dimensions, not nominal

diameter (example: 20A o 20).

ENT

ENT

ENT

Example) When the outer diameter of piping is 318.5 mm:

ENT

ENT

Outer

diameter

Perimeter

Outer diameter of piping

Perimeter of piping

Bulletin F-9-PUX2

28

7.4 Piping material

Press the key so the “PIPE MATERIAL” is

reversed from white to blue.

Press the

ENT

key, and the “PIPE MATERIAL”

screen will appear.

Select the material by the

or key.

After entry, press the

ENT

key.

When “OTHERS” is selected:

Enter the sound velocity (range: 1000 to 3700m/

s). See page 163, Table (28).

ENT

ENT

ENT

Example) When the piping material is cast iron:

Bulletin F-9-PUX2

29

7.5 Wall thickness (range: 0.1 to 100.00mm / 0.004 to 3.9 in.)

Press the key, so the “WALL THICKNESS” is

reversed from white to blue.

Press the

ENT

key, Wall thickness can be entered

(See pages 156 to 162, Piping Data ).

Use the

or key to move the digit to the left

and right.

Using the

or key, enter the value. After

entry, press the

ENT

key.

B : Lining

thickness

B

A : Wall

thickness

A

Lining and wall thickness of piping

If the wall thickness is not known, measure

it by a wall thickness gauge, and enter the

value.

ENT

ENT

ENT

Example) When the wall thickness is 1.25 mm:

Bulletin F-9-PUX2

30

7.6 Lining material

Press the key, so the “LINING MATERIAL” is reversed from white to blue.

Press the

ENT

key, the “LINING MATERIAL”

screen will appear.

Select the material, using the

or key. After

selection, press the

ENT

key.

When “OTHERS” is selected:

Enter the sound velocity (range 1000 to 3700m/s).

See page 163, Table (28).

ENT

ENT

ENT

Example) When the lining material is mortar:

Bulletin F-9-PUX2

31

7.7 Lining thickness (unit: mm) (range: 0.01 to 100.00 mm)

When the lining material is set to items other than

“None” in 7.6 Lining material.

Press the

key, so the “LINING THICKNESS” is

reversed from white to blue.

Press the

ENT

key, lining thickness value entry

can be performed.

The cursor can shift the numeric digit by the

or

key. The numeric can be entered by the or

key.

After entry, press the

ENT

key.

ENT

ENT

ENT

Example) When the lining thickness is 1.25 mm:

Bulletin F-9-PUX2

32

7.8 Kind of fl uid

Jump to 3/4 page with or key.

Select kind of fl uid.

For fl uid having no entry, enter sound velocity.

(Range: 500 to 2500 m/s or 1640 to 8202 ft/s)

Press the

or key, so the “KIND OF FLUID” is

reversed from white to blue.

Press the

ENT

key to display the “KIND OF FLU-

ID” screen.

Select the kind of fl uid by the

or key.

After selection, press the

ENT

key.

When “OTHERS” is selected:

Enter sound velocity. See page 163, Table (27)

and (29).

ENT

ENT

Bulletin F-9-PUX2

33

7.9 Viscosity

There is no need to change “1.0038E-6m2/s” when measuring water.

Return the screen by pressing the

key.

Remarks

Dynamic viscosity coeffi cient is set to water (20°C).

When measuring accurately or measuring fl uid other

than water, enter as needed.

(See page 163, Table (29).)

(Range: 0.001 × 10

í6

to 999.999 × 10í6m2/s)

Press the

key, so the “VISCOSITY” is reversed

from white to blue.

Press the

ENT

key, you can enter the dynamic viscosity coeffi cient.

Move the digit by pressing the

or key and

enter numeric values by using the

or key.

After entry, press the

ENT

key.

ENT

ENT

Bulletin F-9-PUX2

34

7.10 Selection of sensor mounting method

Mounting methods available for the sensor are

V method and Z method as illustrated.

To select the mounting method;

Press the

key, so the “SENSOR MOUNT” is

reversed from white to blue.

Press the

ENT

key. The “SENSOR MOUNT”

screen will appear.

Select either V or Z method by the

or

key.

Remarks

Select the V method generally. Use the Z method in

the following cases:

• Ample space is not provided.

• High turbidity

• Weak receiving waveform

• Thick scale is deposited on the pipe internal surface.

V method

Z method

(Except.

Small sensor PSX2-B)

ENT

ENT

Bulletin F-9-PUX2

35

7.11 Kind of sensor

Press the key, so “SENSOR TYPE” is reversed

from white to blue.

Press the

ENT

key to display the sensor type.

Select any sensor from the type code of sensor to

be used.

Select the sensor by the

or key.

ENT

ENT

Bulletin F-9-PUX2

36

7.12 Transmission voltage (used when an indicator is 1 or

less during measurement)

Press the key, so the “TRANS. VOLTAGE” is

reversed from white to blue.

Press the

ENT

key, the screen is ready to allow the

selection of the transmission voltage level.

Use the

or key to select the level.

Select “40Vpp” or “80Vpp” generally.

If the indicator cannot be set to MAX with

the level at “160Vpp”, ultrasonic wave

may be attenuated due to contamination or

scales deposited on the piping external and

internal surfaces. Change measurement

location.

Example) When transmission voltage is

set to “160Vpp”:

ENT

The indicator will be updated on the mea-

surement screen only.

If less than 2 indicators (intensity of receiving

waveform) are displayed on the measurement

screen, raise the transmission voltage.

ENT

ENT

Indicator

Bulletin F-9-PUX2

37

7.13 Completion of PROCESS SETTING

After the settings are completed, press the key so

“DECISION” is reversed from white to blue.

Pressing the

ENT

key to complete settings, and then

returns to the “SITE SETUP” screen.

After mounting the sensor, perform zero point

calibration.

ENT

MENU MENU

Note) When the inner mounting diameter is 13mm, the sensor mounting method is 0.0mm or less de-

pending on the pipe materials.

Necessary pipe thickness for fl uid water [unit: mm (inch)]

CARBON STEEL 2.1 FRP 3.21

STAINLESS STEEL 1.87 DUCTILE IRON 2.15

PVC 3.69 PEEK 3.69

COPPER 3.82 PVDF 3.69

CAST IRON 2.98 ACRYLIC 2.70

ALUMINUM 1.99 PP 3.69

When the sensor mounting length is 0.0mm or less, error of the measurement is approximately ±2

to 5%.

Bulletin F-9-PUX2

(.085)

(.074)

(.145)

(.150)

(.117)

(.078)

(.126)

(.085)

(.145)

(.145)

(.106)

(.145)

38

8. MOUNTING OF DETECTOR

8.1 Selection of mounting location

Detector mounting location, i.e., the conditions of the pipe subjected to fl ow rate measurement

exert a great infl uence on measurement accuracy. So select a location meeting the conditions

listed below.

(1) There is a straight pipe portion of 10D or more on the upstream side and that of 5D or more on

the downstream side.

(2) No factors to disturb the fl ow (such as pump and valve) within about 30D on the upstream side.

L 10D

Detector

L 50D

L 30D

Flow control valve exists on upstream side.

Flow control valve exists on downstream side.

L 10D

L 10D

L 10D

L 5D

L 30D

1.5D

L 50D

More than

0.5D

More than

10D

More than

10D

D

L 5D

L 5D

Check valve

P

Stop valve

More than 10D

90° bend

Te e

Diffuser

Reducer

Valves

Pump

Classification For upstream side For downstream side

Extracted from Japan Electric and Machinery Industry Society (JEMIS-032)

Bulletin F-9-PUX2

39

(3) Pipe is always fi lled with fl uid. Neither air bubbles nor foreign materials are contained in the

fl uid.

(4) There is an ample maintenance space around the pipe to which the detector is to be mounted

(see fi gure below).

Note 1) Secure an adequate space for allowing a person to stand and work on both sides of a

pipe.

Note 2) D indicates the inside diameter of a pipe.

D + 1200 or more

600

or more

D

600

or more

200

or more

200

or more

Not e

2000 or more

D : Pipe diameter

Space required for mounting detector

(5) The piping must completely be fi lled with fl uid when it fl ows.

Pump

Air-collecting

Good

Good

Pipe may

not be filled

with liquid.

Pipe may not be filled with liquid.

(6) For a horizontal pipe, mount the detector within ±45° of the horizontal plane.

For a vertical pipe, the detector can be mounted at any position on the outer circumference.

Horizontal plane

Pipe

Deposits of

sludge

Air bubbles

45°

45°

Bulletin F-9-PUX2

(47)

(

23.6

)

(

23.6

)

unit: mm (in.)

40

(7) Avoid mounting the detector near a deformation, fl ange or welded part on the pipe.

Welded part Flange or welded Welded part

Bulletin F-9-PUX2

41

8.2 Selection of detector

(1) Selection of mounting methods

There are 2 methods for mounting the detector; V method and Z method. For the mounting

space, see the following sketch.

Length of frame of each sensor

Frame

Length of frame of each sensor

L L

L: Mounting dimension

<Small diameter sensor, small sensor or high-temperature sensor>

mounting dimension for

sensor displayed on the

SITE SETUP screen

D

D

<Large/Medium sensor>

Detector

L

V method

Detector

L

Z method

V method Z method

Mounting method

Employ the Z method in the following cases.

• Mounting space need be saved (mounting space of the Z method is about one half of the V

method's).

• Turbid fl uid such as sewage is to be measured.

• Pipe has mortar lining.

• A thick fi lm of scale may have been formed on the inner surface of pipe because it is old.

• In sufi cient received signal-strength with mounting detectors in V method while using maxi-

mum transmission voltage.

Bulletin F-9-PUX2

42

(2) Image fi gure of mounting dimension

PSX2-C

V method

V method

V method

Z method Z method Z method

Mounting dimensions

Mounting

dimensions

Mounting

dimensions

Mounting

dimensions

Mounting dimensions

Mounting dimensions

Mounting

method

Mounting

dimensions

Type

Mounting

method

Mounting

dimensions

Type

Mounting

method

Mounting

dimensions

PSX2-C PSX2-D PSX2-A/E/HT

PSX2-D

(3) Detector selection standards

The Z method for large size sensor is recommended for outer diameter 300mm or more.

PSX2-D should be used as much as possible for pipes such as old pipes, cast iron pipes, and mortar lining pipes, through which it is diffi cult for ultrasonic signals to pass.

Type Diameter Temperature

PSX2-B

13 100mm (V method)

í40 +100°C

í40 +100°C

í40

+200°C

í40 +80°C

Detector

PSX2-A

50 300mm (V method)

PSX2-HT

50 250mm (V method)

PSX2-D

200 3000mm (V method)

200

6000mm

(Z method)

í40 +80°

F PSX2-C

200 600mm (V method)

200

1200mm (Z method)

150 400mm (Z method)

150 400mm (Z method)

Bulletin F-9-PUX2

Type

PSX2-A/B/E/HT

43

8.3 Use of surface-treated accessories

Eliminate pitting, corrosion, unevenness, etc. with paint thinner and sandpaper from the pipe

portion where the detector is to be mounted.

Note) In case jute is wound on a pipe, it should be peeled off before the above treatment.

When cast iron pipe is used, grind the sensor mounting surface by using a sander for

smoothness.

Jute is wound

Detector Width

Pipe

Width

Small outer

diameter PSX2-B

320 mm (12.6") or more

Small size

(standard) sensor

PSX2-A

540 mm (21.3") or more

Large size sensor

PSX2-D

Medium size sensor

PSX2-C

Mounting dimension

(L) + 200 mm (7.9") or more

Mounting dimension

(L) + 200 mm (7.9") or more

High temperature

PSX2-HT

530 mm (20.9") or more

Bulletin F-9-PUX2

44

8.4 How to mount small size (standard) sensor and small

outer diameter sensor to pipe

8.4.1 How to mount a sensor (V method)

(1) Loosen the lock nut and slide the sensor so as to

meet the mounting dimension and then tighten

the nut.

Element holder

Lock nut

Saddle

Scale

Cursor

Mounting

dimension (L)

Frame

BNC connector

(2) Apply a coat of silicone grease to the transmit-

ting surface of the sensor. Spread the compound

over the entire area.

Keep the sensor retracted by turning the element

holder counterclockwise.

After cleaning the surface of the pipe, the sensor

should be mounted

Transmitter unit

Element holder

(3) Fix the both ends (saddles) of the sensor to the

pipe by cloth belts.

Mounting will be facilitated by winding the

cloth belts on the pipe in advance.

Cloth belts are usable at 80°C or lower. If beyond 80°C, stainless steel belts should be used.

(High-temperature stainless steel type of

belt)

Cloth belt

(4) Make sure the sensor is mounted in parallel with

the pipe axis and the mounting dimension is

right. Then, turn the element holder clockwise

until the sensor comes in close contact with the

pipe.

Stop turning the element holder when it stiffens

because the transmitting surface comes in contact with the pipe surface. Be careful not to turn

the holder excessively.

Element holder

Cable

CAUTION

Apply a small quantity (like toothpaste) of

silicon grease to the transmitter unit.

Bulletin F-9-PUX2

45

8.4.2 How to mount a small size (standard) sensor (Z method)

(1) Remove saddle set screws at 4 loca-

tions, and remove a saddle and a sensor unit out of the frame.

Also, remove a saddle on the guide rail

for small size sensor (option).

Element holder

Lock nut

Saddle

Scale

Curser

Frame

BNC connect or

Guide rail for small size sensor

(2) Mount the removed sensor unit on the

guide rail for small size sensor.

Fasten the sensor unit with mounting

dimension (L).

Mounting

dimension (L)

(3) Spread silicone grease over the whole

transmitting surface of the sensor.

Turn the element holder counterclockwise to return the sensor.

After cleaning the surface of the pipe,

the sensor should be mounted.

Element holder

Silicone grease

Transmitting surface

(4) Mount each sensor individually on the

marking line.

Front view Back view

Upper side of

the marking line

Bottom side of

the marking line

Bulletin F-9-PUX2

46

(5) Make sure that the sensor is mounted in paral-

lel with the piping and that the mounting position is correct. Then, turn the element holder

clockwise until the sensor is fi rmly fi tted to the

piping.

Stop turning the element holder where the

transmitting surface contacts the surface of

pipe, and thus the element holder will not

rotate.

Do not turn it excessively.

Element holder

Cable

Bulletin F-9-PUX2

47

8.5 How to mount large and medium size sensor

8.5.1 How to determine mounting position

Determine the mounting position by carrying out the following work.

For this work, gauge paper is necessary (For the gauge paper, refer to page 57).

(1) Match the edge of gauge paper with the line at

about 100mm (3.9") from one end of the pipe portion

treated for detector mounting, and wind the

gauge paper so that the line marked on the paper

is parallel with the pipe axis (fi x with tape not to

allow deviation). At this time, the edge of gauge

paper should be aligned.

Align this edge.

100mm

Line drawn

on gauge paper

(2) Extending the line marked on the gauge paper,

mark straight line A on the pipe.

Draw line A.

(3) Mark a line along on edge of the gauge paper.

The intersection of this line and straight line A is

replaced with A

0

.

Draw a line

along the edge.

A0

(4) In mounting by the V method, peel the gauge

paper and measure the mounting dimension

from A

0

to determine A2 position. At this position, mark a line orthogonal to the straight line

A.

A

0

and A2 become the mounting positions.

Example) L = 200mm (7.9")

A0A2

200mm

(5) In mounting by the Z method, measure the

circumference from A

0

with a measuring tape.

At 1/2 of the circumference, determine points B

0

and B

1

, and mark a line (straight line B) con-

necting those points.

A0A1

B1 B0

Straight line B

A0, A1B0, B1

(6) Mark the points B0 and peel off the gauge paper.

Measure the mounting dimension from B

0

to

determine B

2

position. At this position, make a

line orthogonal to the straight line B.

A

0

and B2 become the mounting positions.

Example) L = 100mm (3.9")

B2

B2

B0

B0

100mm

A0

Bulletin F-9-PUX2

48

8.5.2 How to connect medium size sensor for PSX2-C type only

(1) Remove the sensor cover.

(2) Mount the sensors so that the upstream and

downstream sensors can be distinguished from

each other.

Remove the cable clamp.

Note) In case of removing the cable clamp, be

sure not to lose the nut.

Driver

Cable

clamp

Cable

clamp

Nut

(3) Insert the coaxial cable through the cable lead-in

port.

loosen the terminal screws (G, +).

Connect core line white to (+), shield wire to

(G).

Note) At this time, remove the resistor.

Coaxial cable

CAUTION

Be careful not to cut your hands or etc. by

the cover.

CAUTION

For connecting coaxial cable to terminal,

turn the power off.

Bulletin F-9-PUX2

49

(4) Secure the coaxial cable with the cable clamp.

Cable clamp

(5) Put the cover on the detector.

Bulletin F-9-PUX2

50

8.5.3 How to connect large size sensor for PSX2-D type only

(1) Slide the detector cover slightly. Remove the

cover with a driver.

Cover

Transmission direction mark

(2) Determine the mounting position of sensor on

the pipe.

Align the transmission direction marks.

Transmission direction mark

(3) Put a mark on the inlet of coaxial cable.

When the pipe is horizontally installed with the

detector, allow the coaxial cable to be suspended

to prevent entry of water from the cable inlet.

When the pipe is installed vertically, it does not

matter how the coaxial cable should be installed.

Note) Upstream and downstream sensors

should be able to be identifi ed.

(4) Connect the coaxial cable to terminal (G, +) and

fi x it with the cable clamp.

Connect core line white to (+), shield wire to

(G).

Cable retainer

Rubber bushing

(5) Install the cover.

CAUTION

• Be careful not to cut your hands or etc. by the cover.

• For connecting coaxial cable to terminal, turn the power off.

Bulletin F-9-PUX2

51

8.5.4 Mounting of medium type sensor on pipe

Mounting the detector using the following procedure.

(1) Provide wire rope for the upstream and the

downstream detectors.

Make sure that the length of the wire rope is

longer than the circumference of the pipe.

(2) Lay the wire rope around the pipe at the position

of the upstream detector.

Then hook the mounting spring into the wire

rope.

(3) Spread silicone fi ller over the whole transmitting

side of the sensor.

Care should be taken to prevent entry of air

bubbles.

(4) After cleaning the surface of the pipe, the sensor

should be mounted.

(5) Spread the wire rope near the marked lines in

the left-right direction, bring the sensor in close

contact and fi t the wire rope.

Make sure that the matching mark on the sensor

is aligned with the marking line.

Transmitting mark

Matching mark

Marking

line

Sensor

Marking line

Mounting spring

Pipe

CAUTION

Be careful not to cut your hands or etc. by the wire rope.

Bulletin F-9-PUX2

52

(6) Make sure that the center mark on the sensor is

aligned with the marking line. Then, connect the

coaxial cable to the transmitter.

Note) Do not pull the coaxial cable.

If it is pulled, the sensor is shifted which

results in incorrect measurements.

(7) After mounting the upstream sensor, mount the

downstream sensor in the same way.

The fi gure is for mounting by the Z method.

Upstream

side

Cable side

Cable sideTransmitting marker side

Transmitting marker side

Downstream

side

Marking line

Matching mark

Bulletin F-9-PUX2

53

8.5.5 How to mount large size sensor to pipe

(1) Height adjustment of guide plate

• Place the sensor on the pipe surface in parallel

with the pipe axis.

• Loosen the guide plate fi xing screw and slide

the guide plate until its edge and transmitting

surface touch the surface of pipe.

• Then tighten the fi xing screw.

Pipe

Guide plate

Fixing screw

Transmission

surface

Transmission

direction mark

180

600

Sensor

Marked lines

Fastening

spring

Loosen this wire clip

and pull the wire rope.

Pipe

Transmitting

surface

(2) How to determine the length of wire rope

• Place the sensor on the marked lines and fi t the

wire rope and fastening spring.

• Loosen the wire clip and pull the wire rope

until the overall length of fastening spring

approximates 180mm (7.1"). Then tighten the

wire clip.

(The fastening spring has a free length of

110mm or 4.3")

• While fi xing the wire rope, remove the sensor.

(3) Mounting of sensor

• Wipe off contaminates from the transmitting

surface of sensor and the sensor mounting

surface of pipe.

• Apply the silicone grease on the transmitting

surface of sensor wile spreading it evenly.

• Film thickness of the silicone grease should be

about 3mm.

• Spread the wire rope near the marked lines

in the left-right direction, bring the sensor in

close contact and fi t the wire rope.

• Align the matching mark of sensor with the

marked line. In addition, make the transmitting direction marks of sensors face each

other.

• Make sure the matching mark of sensor is

aligned with the marked line and connect the

coaxial cable to the converter.

Note) Do not pull the coaxial cable. Other-

wise, the sensor will be activated to

disturb measurement.

Transmission mark

Matching mark

Marked line

Sensor

Marked line

Fastening spring

Pipe

Transmission

mark

Mounting

dimension (L)

Matching

mark

Marked lline

CAUTION

Be careful not to cut your hands or etc. by the

wire rope.

Bulletin F-9-PUX2

54

8.6 How to mount high temperature sensor to pipe

8.6.1 How to mount a sensor (V method)

(1) Loosen the lock nut and slide the sensor so

as to meet the mounting dimension and then

tighten the nut.

BNC connect

Element holder

Lock nut

Saddle

Cursor

Frame

Scale

Mounting

dimension

(L)

(2) Apply a coat of grease for high temperature to

the transmitting surface of the sensor. Spread

the compound over the entire area.

Keep the sensor retracted by turning the element holder counterclockwise.

After cleaning the surface of the pipe, the sensor should be mounted.

High temperature

grease

Spatula

Transmission

unit

(3) Fix the both ends (saddles) of the sensor to

the pipe by stainless belts.

Stainless belt

Stainless belt

(4) Make sure the sensor is mounted in parallel

with the pipe axis and the mounting dimension is right. Then, turn the element holder

clockwise until the sensor comes in close

contact with the pipe.

Stop turning the element holder when it stiffens because the transmitting surface comes in

contact with the pipe surface. Be careful not

to turn the holder excessively.

Element

holder

Cable

CAUTION

Be careful not to cut your hands or etc. by the

stainless belt.

Bulletin F-9-PUX2

55

8.6.2 How to mount a sensor (Z method)

(1) Remove saddle set screws at 4 loca-

tions, and remove a saddle and a sensor unit out of the frame.

Also, remove a saddle on the guide rail

for high temperature sensor (option).

BNC connector

Element

holder

Lock nut

Saddle

Cursor

Frame

Scale

Guide rail for high temperature sensor

Sensor unit

(2) Mount the removed sensor unit on the

guide rail for high temperature sensor.

Fasten the sensor unit with mounting

dimension (L).

Mounting

dimension (L)

(3) Spread high-temperature grease over

the whole transmitting surface of the

sensor.

Turn the element holder counterclockwise to return the sensor.

After cleaning the surface of the pipe,

the sensor should be mounted.

Element holder

Transmitting surface

High temperature

grease

Spatula

(4) Mount each sensor individually on the

marking line.

Front view Back view

Upper side of

the marking line

Bottom side of

the marking line

Bulletin F-9-PUX2

56

(5) Make sure that the sensor is mounted

in parallel with the piping and that the

mounting position is correct. Then,

turn the element holder clockwise until

the sensor is fi rmly fi tted to the piping.

Stop turning the element holder where