Bulletin E-81-PS

Series PSC/PSI Proximity Sensors

Specifications – Installation and Operating Instructions

INTRODUCTION - Proximity Sensors

The Proximity Controls range of proximity sensors includes inductive and Capacitive proximity switches and a Test unit. These are

listed and stocked in our catalog for fast service. Should you need

a non-listed varient please contact the sales office.

Inductive (PSI) switches will detect all metals. Capacitive (PSC)

switches will detect nearly all solids, powders and liquids. The A800 Test Unit will give a functionality test to all versions stocked in

the catalog and will test most three wire DC proximity switches

from other manufacturers.

SENSING DISTANCE

Sensing ranges refer to a 1 mm thick square target of earthed mild

steel with sides of 3 x the nominal sensing distance. If the target

is a different material, or of another size, there will be a variation

in the sensing distance.

MATERIAL

Mild Steel

Cast Iron

Aluminum Foil

Stainless Steel

Brass

Aluminum

Copper

Water

PVC

Glass

Ceramics

Wood

Beer

Coca Cola

Lubricating Oil

MATERIAL FACTORS

INDUCTIVE

1.0

1.1

0.9

0.7

0.4

0.35

0.3

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

CAPACITIVE

1.0

1.0

1.0

1.0

1.0

1.0

1.0

0.9

0.9

0.5

0.4

from 0.2

0.9

0.9

0.1

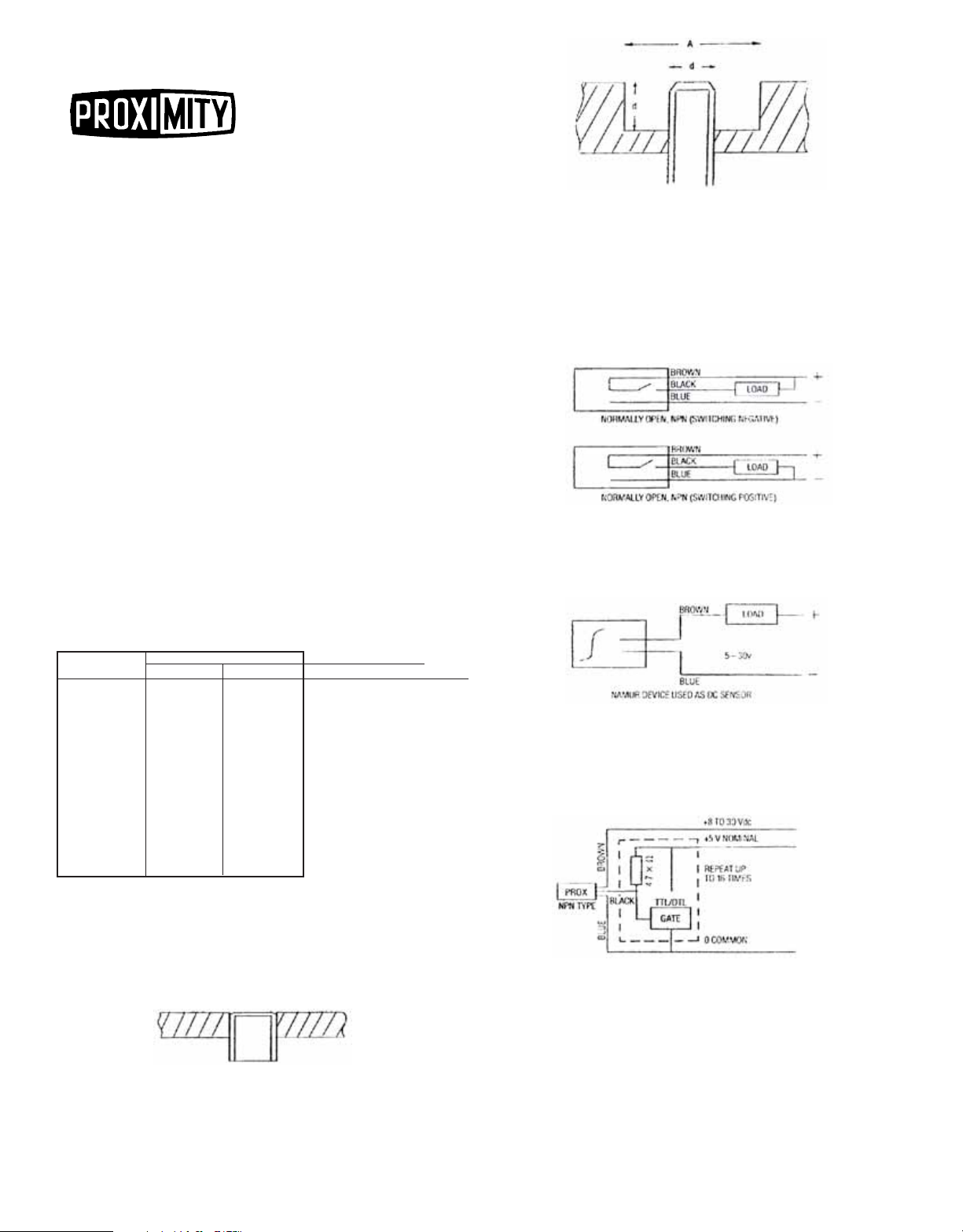

INSTALLATION (MECHANICAL)

Flush Mounting

Units designed for flush mounting, including all inductives listed in

the catalog, may be fitted in surrounding metal as shown.

NOTE: Capacitive switches can, if required, be tuned down to be

fitted flush in metal. See section on sensitivity adjustment.

INSTALLATION (ELECTRICAL)

Single Units

DC units have transistor output, and normally have three wires,

but NAMUR standard DC sensors have only two wires.

3 Wire DC Switch

2 Wire DC Sensor

Note that units with two wires must be connected to their power

supply with a load in series, or they will be damaged. Consult catalog for load rating.

Logic Interface

Proximity sensors may be interfaced with most types of industrial

logic. Most DC units are open collector type and therefore require

an external pull up resistor when used with TTl as shown.

Flush Fitting

Non-Flush Mounting

Units designed for non-flush mounting, including Capacitive

switches, must be separated from teh surrounding metal as

shown.

Note that 3 wire DC-Compact V3 bodied switches are designed for

use directly with TTL and have a built-in pull up resistor.

Multiple Units: Parallel

DC sensors may be connected directly in parallel as in shown. The

number (N) of switches is usually only limited by the availability of

sufficient supply current. Note that the compact V bodied switches

Non Flush

Fitting

A= Not Less

Than 3d

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

have an internal pull-up resistor with a resistance of 12 kilohms.

The maximum number of compact switches in parallel is:

N=Rating Load Current (mA) x 12 Kilohm / V supply.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Multiple Units: Series

The maximum number of DC sensors connected in series is limited by the supply voltage (V supply), the voltage drop across a

closed switch (V switch) and either the minimum working voltage

of the switch or minimum working voltage of the load, whichever is

greater (V min).

The diagram above shows a typical series configuration of PNP

sensors. For NPN types, swap the blue for brown wire and reconnect.

GENERAL INFORMATION

LED Indicators

Most Proximity sensors are fitted with indicator lights (LED’s) at

the cable end. The LED indicates the state of the switch output.

Maximum Voltage

The maximum voltage of DC proximity sensors is 30 V. It is sometimes forgotten that a rectified 24 VAC supply has a peak value of

1.4 X the AC RMS value (34V).

NOTE: These switches should be installed by competent personnel only. Please check wiring and supply voltages before switching on. If there are any technical questions regarding installation

or application of Proximity sensors please contact the technical

sales department.

A-800 DC Proximity Switch Test Unit

The A-800 is fitted with two PP3 batteries ready for use. This unit

will test most 3 wire DC proximity switches PSI (metal sensing),

PSC (most materials), the magnet sensing Detector (DT), photoelectrics or ultrasonics.

Standard color coding for 3 wire Proximity switches is

Brown=Positive (+), Black=Load, Blue=Negative (–). Note: Some

universal DC switches can vary. Follow the maufacturer’s wiring

instructions.

Testing Instructions

Connect the switch to the A-800. Place a suitable target in front of

the switch. If it is functioning correctly, the test unit will give audio

and visual indication showing that the switch operates and indicating functionality of the switch according to the chart below.

SENSITIVITY ADJUSTMENT

Inductive Switches

Inductive PSI sensors are not adjustable.

Capacitive Switches

Install the capacitive PSC sensor in its final position. Remove the

black cover screw to gain access to the adjustment potentiometer.

Turn the adjusting potentiometer clockwise to increase sensitivity

or counterclockwise to reduce sensitivity. For example, the range

and sensitivity of capacitive sensors can be adjusted to tune out

the sidewall of a plactic container or glass window of a signt glass

such that the level of liquid, granules or powders on the other side

of the plastic or glass can be detected.

For this application tune out the sight glass or wall with the container empty, detune the sensor so it cannot see the window or

wall. Then test the settings by introducing the target material

inside the container. Caution should be taken with materials that

leave a residue inside the container as this may be sensed.

NOTE: To maintain the IP65 rating on capacitive sensors, it is

imperative that the black cover screw be replaced after adjustment.

SWITCH TYPE

PNP N.O.

PNP N.C.

NPN N.O.

NPN N.C.

BUZZER & LED ON WHEN

Target in range

Target not in range

Target in range

Target not in range

LED

PNP

PNP

NPN

NPN

A-800 DC TEST UNIT

If the Proximity switch does not give such feedback when correctly connected to the tester, it has probably failed. NOTE: The A-800

will not test 2 wire AC or DC switches.

LED Functions

Green I/O LED Switch connected and unit on

Red (Battery) LED Battery low indicator

PNP or NPN LED Indicated switch type

Further Information:

Proximity is a Division of Dwyer Instruments, Inc. For further information, a copy of our latest catalog, other products or details concerning our nearest distributor please call our sales office.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Proximity Division of

Dwyer Instruments, Inc.

102 Highway 212

P.O. Box 373,

Michigan City, IN 46360-0373

U.S.A

Tel: 219/879-8000

Fax: 219/872-9057

INSTALLATION AND WIRING INSTRUCTIONS

• INDUCTIVES

• CAPACITIVES

• TEST UNIT

INTRODUCTION

The Proximity range includes inductive and Capacitive proximity

switches and a Test unit. These are listed and stocked in out catalog for fast service. Should you need a non listed variant please

contact the sales office.

Inductive switches will detect all metals. Capacitive switches will

detect nearly all solids, powders and liquids, and the A-800 test

unit will give a functionality test to all versions stocked in the catalog and will test most three wire DC proximity switches from other

manufacturers.

This range covers many industrial applications.

SENSING DISTANCE

Inductive and Capacitive

Sensing ranges refer to a 1 mm thick square target of earthed mild

steel with sides of 3X the nominal sensing distance. If the target is

of other material, or a different size, there will be variation in the

sensing distance.

MATERIAL

Mild Steel

Cast Iron

Aluminum Foil

Stainless Steel

Brass

Aluminum

Copper

Water

PVC

Glass

Ceramics

Wood

Beer

Coca Cola

Lubricating Oil

MATERIAL FACTORS

INDUCTIVE

1.0

1.1

0.9

0.7

0.4

0.35

0.3

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

CAPACITIVE

1.0

1.0

1.0

1.0

1.0

1.0

1.0

0.9

0.9

0.5

0.4

from 0.2

0.9

0.9

0.1

NOTE: Capacitive switches can, if required, be tuned down to be

fitted flush in metal. See section on sensitivity adjustment.

INSTALLATION (ELECTRICAL)

Single Units

DC units have transistor output, and normally have three wires,

but NAMUR standard DC sensors have only two wires.

3 Wire DC Switch

2 Wire DC Sensor

Note that units with two wires must be connected to their power

supply with a load in series, or they will be damaged. Consult catalog for load rating.

Logic Interface

Proximity sensors may be interfaced with most types of industrial

logic. Most DC units are open collector type and therefore require

an external pull up resistor when used with TTl as shown.

Note that 3 wire DC-Compact V3 bodied switches are designed for

use directly with TTL and have a built-in pull up resistor.

INSTALLATION

Flush Mounting

Units designed for flush mounting which include all inductives listed in the catalog may be fitted in surrounding metal (or other material) as shown.

Multiple Units: Parallel

DC sensors may be connected directly in parallel as in shown. The

number (N) of switches is usually only limited by the availability of

sufficient supply current. Note that the compact V bodied switches

have an internal pull-up resistor with a resistance of 12 kilohms.

The maximum number of compact switches in parallel is:

N=Rating Load Current (mA) x 12 Kilohm / V supply.

Non-Flush Mounting

Units designed for non-flush mounting which includes the

Capacitive switches must be separated from surrounding metal as

shown overleaf.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

IMPORTANT

These switches should be installed by competent personnel only.

Please check wiring and supply voltages before switching on.

TECHNICAL INFORMATION

If there are any technical inquiries regarding the installation or

application of Proximity sensors please contact the Technical

Sales Department.

Multiple Units: Series

DC the maximum number of DC sensors in series is limited by the

supply voltage (V supply) the voltage drop across a closed switch

(V switch), and either the minimum working voltage of the switch

or the minimum working voltage of the load, whichever is greater

(V min).

The diagram shows a typical series configuration of PNP sensors.

For NPN types swop the blue for the brown wire and reconnect.

SENSITIVITY ADJUSTMENT

Inductive sensors are not adjustable.

Capacitive Switches

Install the capacitive sensor in its final position. Remove the black

cover screw to gain access to the adjustment potentiometer. Turn

the adjusting potentiometer clockwise to increase sensitivity or

anticlockwise to reduce sensitivity.

For example, the range and sensitivity of capacitive sensors can

be adjusted to tune out the sidewall of a plastic container or the

glass window of a sight glass such that the level of liquid, granules

of powders on the other side of the container wall or sight glass

can be detected.

For this applications tune out the sight glass or wall with the container empty, detune the sensor until it cannot see the window or

wall, and test your settings by introducing the target material inside

the container. Caution should be taken with materials that leave a

residue inside the container.

A-800 DC PROXIMITY SWITCH TEST UNIT

The A-800 is fitted with 2 PP3 batteries ready for use. This unit will

test most 3 wire DC proximity switches, inductives (metal sensing)

or capacitives photoelectrics or ultrasonics (which sense most

materials).

Standard color coding for 3 wire proximity switches is

Brown=Positive (+), Black=Load, Blue=Negative (–). [Note: some

universal DC switches can vary, try to follow makers wiring instructions}

TESTING INSTRUCTIONS

Connect the switch to the A-800 Place a suitable target in front of

the switch. If the switch is functioning correctly, the unit will give

audio and visual indication showing the switch operates and indicating the functionality of the switch according to the chart below.

SWITCH TYPE

PNP N.O.

PNP N.C.

NPN N.O.

NPN N.C.

BUZZER & LED ON WHEN

Target in range

Target not in range

Target in range

Target not in range

LED

PNP

PNP

NPN

NPN

If the proximity switch does not give such feedback when correctly connected to the tester it has probably failed.

[Note: The A-800 will not test 2 wire AC or DC switches]

LED Functions

Green I/O LED Switch connected and unit on

Red (Battery) LED Battery low indicator

PNP or NPN LED Indicated switch type

Further Information:

Proximity is a Division of Dwyer Instruments, Inc. For further information, a copy of our latest catalog, other products or details concerning our nearest distributor please call our sales office.

Replace cover over adjusting potentiometer

To maintain the IP65 rating on capacitive sensors it is imperative

the black cover screw is replaced after adjustment.

GENERAL INFORMATION

Most Proximity sensors are fitted with indicator lights (LED’s) at

the cable end. The LED indicates the state of the switch output.

The maximum voltage of d.c. Proximity sensors is 30V. It is sometimes forgotten that a rectified 24V a.c. supply has peak value of

1.4 x the a.c. RMS value (34V).

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 2/10 FR# 71-443092-51

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...