Dwyer Instruments Proximity 195 Series, Proximity 295 Series Specifications-installation And Operating Instructions

Page 1

Bulletin V -195/295

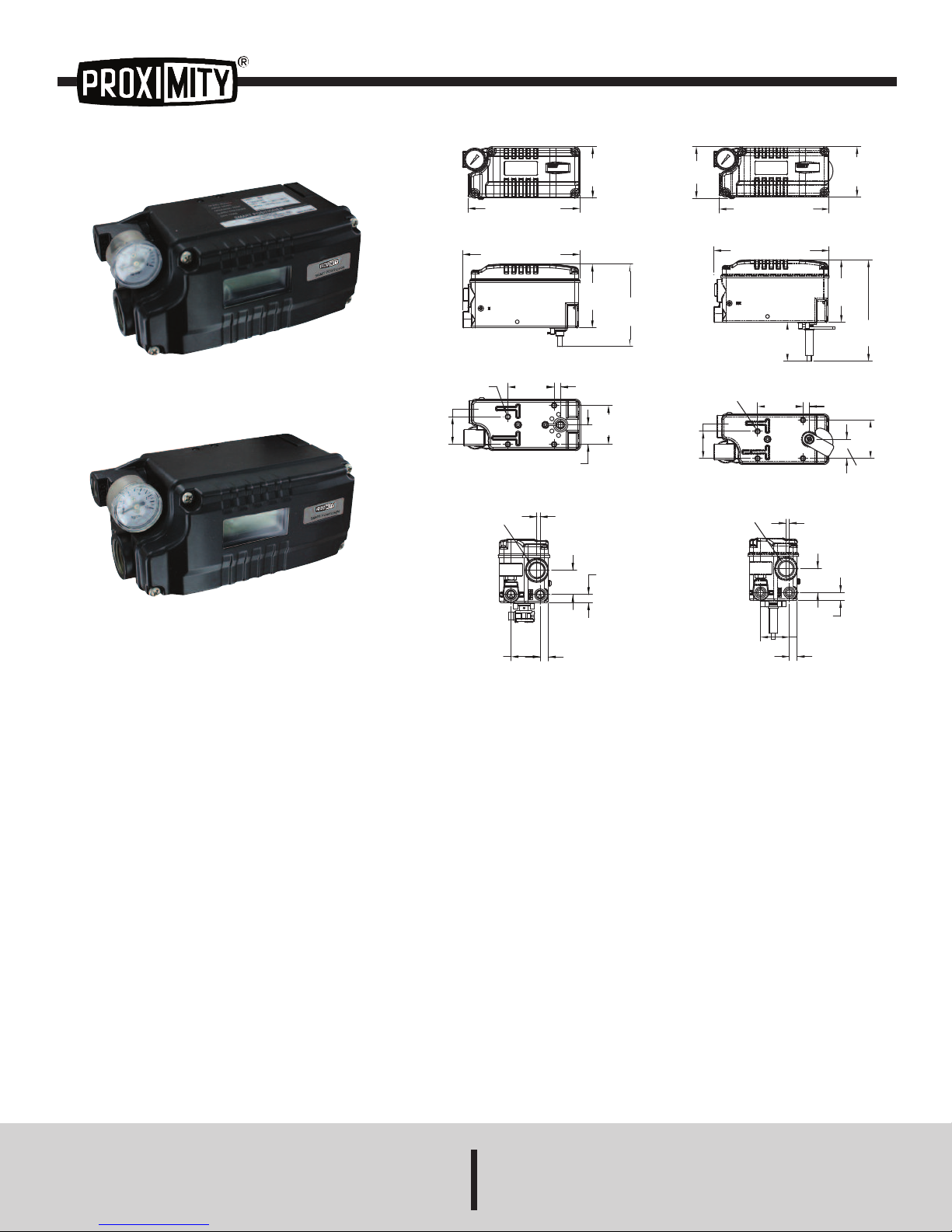

1 57/64˝

[

48.00]

1

11/32˝

[34.00]

5/16˝ [8.00]

2 1/4˝

[

57.00]

15/16˝

[24.00]

3 3/32˝

[

78.50]

4˝

[

101.60]

5 45/64˝ [144.80]

2 1/2˝

[

63.60]

5 7/16˝ [138.30]

1 27/64˝

[36.00]

25/64˝

[10.00]

1 3/16˝

[30.00]

25/64˝

[10.00]

5/32˝

[4.00]

CONDUIT ENTRY

1/2 NPT

4

X M6 TAP

L

CD SCREEN

SMART POSITIONER

CONDUIT ENTRY

1/2 NPT

1 57/64˝

[48.00]

1 11/32˝

[34.00]

5/16˝ [8.00]

2

1/4˝

[

57.00]

15/16˝

[24.00]

3

3/32˝

[

78.50]

5 1/64˝

[

127.32]

5 45/64˝ [144.80]

2 1/2˝

[

63.60]

5 7/16˝ [138.30]

1 27/64˝

[36.00]

25/64˝

[10.00]

1 3/16˝

[30.00]

25/64˝

[10.00]

5/32˝

[4.00]

2 37/64˝

[65.40]

4X M6 TAP

LCD SCREEN

1 59/64˝

[48.82]

SMART POSITIONER

Series 195 & 295 Smart Positioners

Specifications - Installation and Operating Instructions

195

Series 195

Series 295

295

The Series 195 and 295 Smart Positioners are a compact way to control the

valve stroke accurately using an input signal of 4 to 20 mA from the controller. In

addition, a highly efficient microprocessing operator built into the product.

Performs various functions such as auto calibration, PID control, alarm and Hart

protocol.

Features

• LCD allows user to directly check the positioner condition in the field.

• Endures severe vibration.

• Operates normally regardless of changes in supply pressure during operation.

• Simple-to-use auto calibration.

• Low air consumption reduces operating cost.

• Compact size allows for installation on small actuators.

• Can be used in low voltage (8.5 V), leaving no limitation in controller.

• Variable orifice is applied in case of a small actuator, the hunting is controlled

• HART

• Analog feedback signal (4 to 20 mA).

• The adjustment of valve characteristics (linear, quick open, equal percentage)

• Specific flow control is available with setting 16 points at users’ command.

• Tight shut-close and shut-open can be set in the programming menu.

• PID parameters can easily be adjusted in the field without additional

• Split ranges such as 4 to 12 mA, with 12 to 20 mA available.

• The positioner can manually actuate the valve or damper.

to the optimum condition during operation.

®

communication available for configurating parameters or monitoring the

valve position.

available.

communicator.

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

SPECIFICATIONS

Input Signal: 4 to 20 mA DC.

®

Input Impedance: 460 Ω max @ 20 mA DC.

Enclosure: Aluminum.

Air Supply: 35 to 116 psi (2.4 to 8 bar).

Air Connection: 1/4˝ NPT.

Gage Connection: 1/8˝ NPT.

Conduit Connection: 1/2˝ NPT.

Linearity: ±0.5% FS.

Hysteresis: ±0.5% FS.

Sensitivity: ±0.2% FS.

Repeatability: ±0.3% FS.

Air Consumption: .0004 scfm (.01 LPM) at 20 psig (1.4 bar) supply.

Flow Capacity: .32 scfm (9 LPM) at 20 psi (1.4 bar) supply.

Stroke:

195: 0.19 to 1.38˝ (5 to 35 mm);

295: 0 to 90°.

Enclosure Rating: NEMA 4X (IP66).

Temperature: Operating: -22 to 185°F (-30 to 85°C).

Weight: 1.8 lb (.82 kg).

Lever:

195: 39 to 1.57˝ (10 to 40 mm);

295: NAMUR.

HART® is a registered trademark of Hart Communication Foundation.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

tructure

0

1

00

5

0

0

100

50

0

100

50

S

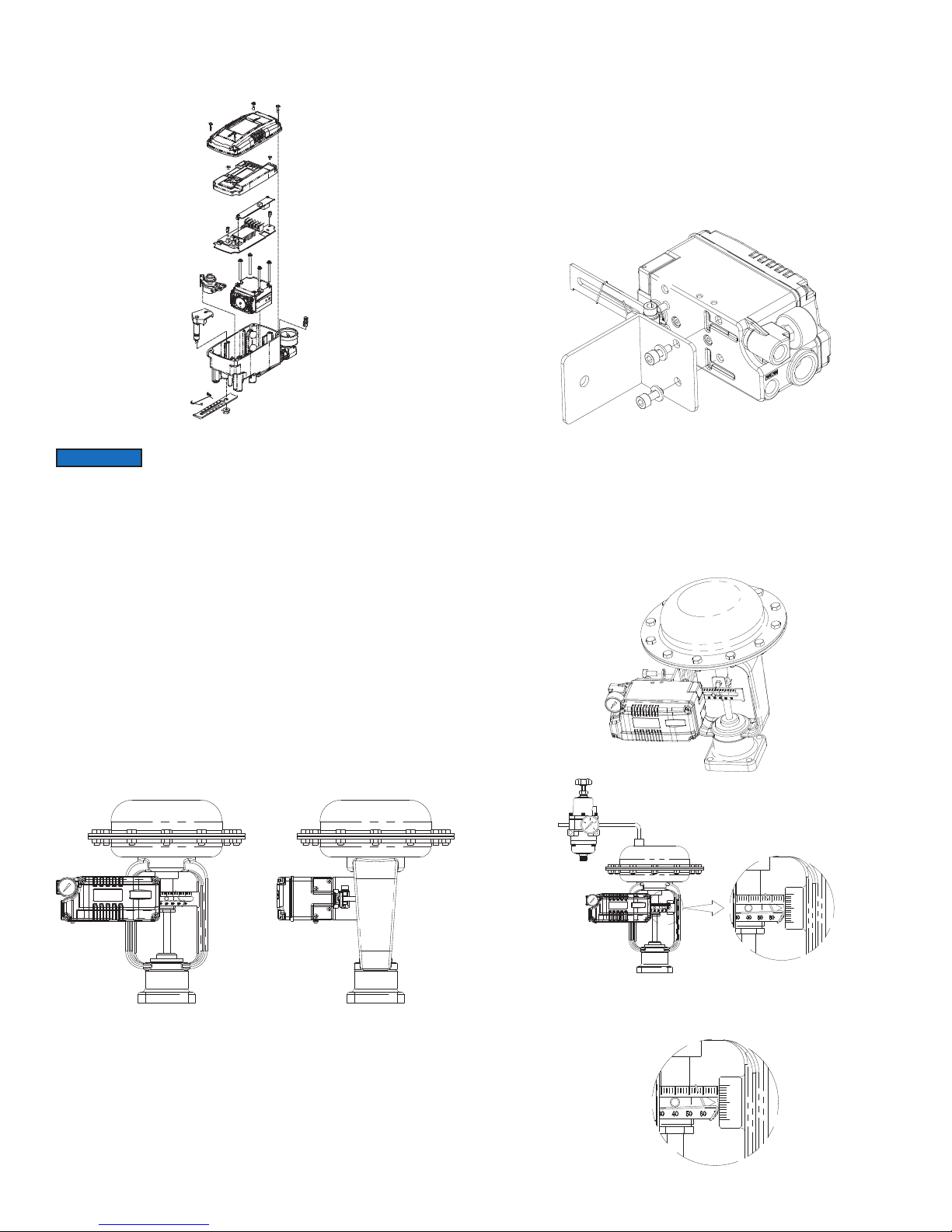

he structure of the 195 is shown below. The Series 295 structure is the same as

T

he linear model without the feedback lever.

t

age 2

nstalling Series 195 with Bracket

I

t is necessary to make a proper bracket to attach on the actuator yoke.

I

he most important considerations in the design of the bracket are as follows:

T

Series 195 feedback lever should be at 50% of valve stroke.

•

P

• Feedback level connection bar of actuator clamp should be connected in the

position so that the valve stroke and the numbers carved on feedback lever are

fitted.

f the bracket meets the above conditions, Series 195 can be installed very easily.

I

. Assemble Series 195 and bracket with bolts. Use standard bolts in bolt holes on

2

the backside of the unit.

Installation

OTICE

N

When the positioner is replaced or installed with the actuator,

make sure of the following:

• All inputs and supply pressure to the valve, actuator and other instruments must

be shut down.

The control valve must be separated from the system with a bypass valve or other

•

quipment so that the entire system does not shut down.

e

• No pressure remains in the actuator.

Tools For Installation

• Hexagonal wrenches

• (+) Screw driver

• (-) Screw driver

• Spanners for hexagon head bolts

Series 195 Installation

Series 195 is used for linear motion valves, such as Dwyer Instruments globe

valves, using a spring return type diaphragm actuator or piston actuator. The Series

195 consists of the following components. Be sure that all the components are

included.

• Series 195 main body

• Feedback lever and lever spring

• Flange nut (attached on the bottom of main shaft of Series 195 body)

• Four hexagon head bolts M8x1.25P

. After assembling Series 195 and bracket with bolts, attach it using the bolt holes

3

f the actuator yoke. Do not tighten completely. There must be some space.

o

4. Install the bar connected with Series 195’s feedback lever on the actuator clamp.

The slot length between Series 195’s feedback lever is .26˝ (6.5mm), so the

diameter of the connection bar should be less than .25˝ (6.3 mm).

5. Connect the air filter regulator with the actuator temporarily. Set supply pressure

of air filter so that the actuator clamp is positioned at 50% of valve stroke.

Series 195 Installation Example

• Four M8 plate washers

6. Insert the connection bar attached on the actuator clamp into the slot of Series

195’s feedback lever. In order to reduce hysteresis, it should appear as shown:

Page 3

he connection bar inserted correctly between feedback lever and lever

0

1

00

50

90

°

50 %

50

SMART POSITIONER

10 20 30 40 50 60 70

10 20 30 40 50 60 70

N

o

T

o

u

c

h

!

20

T

pring

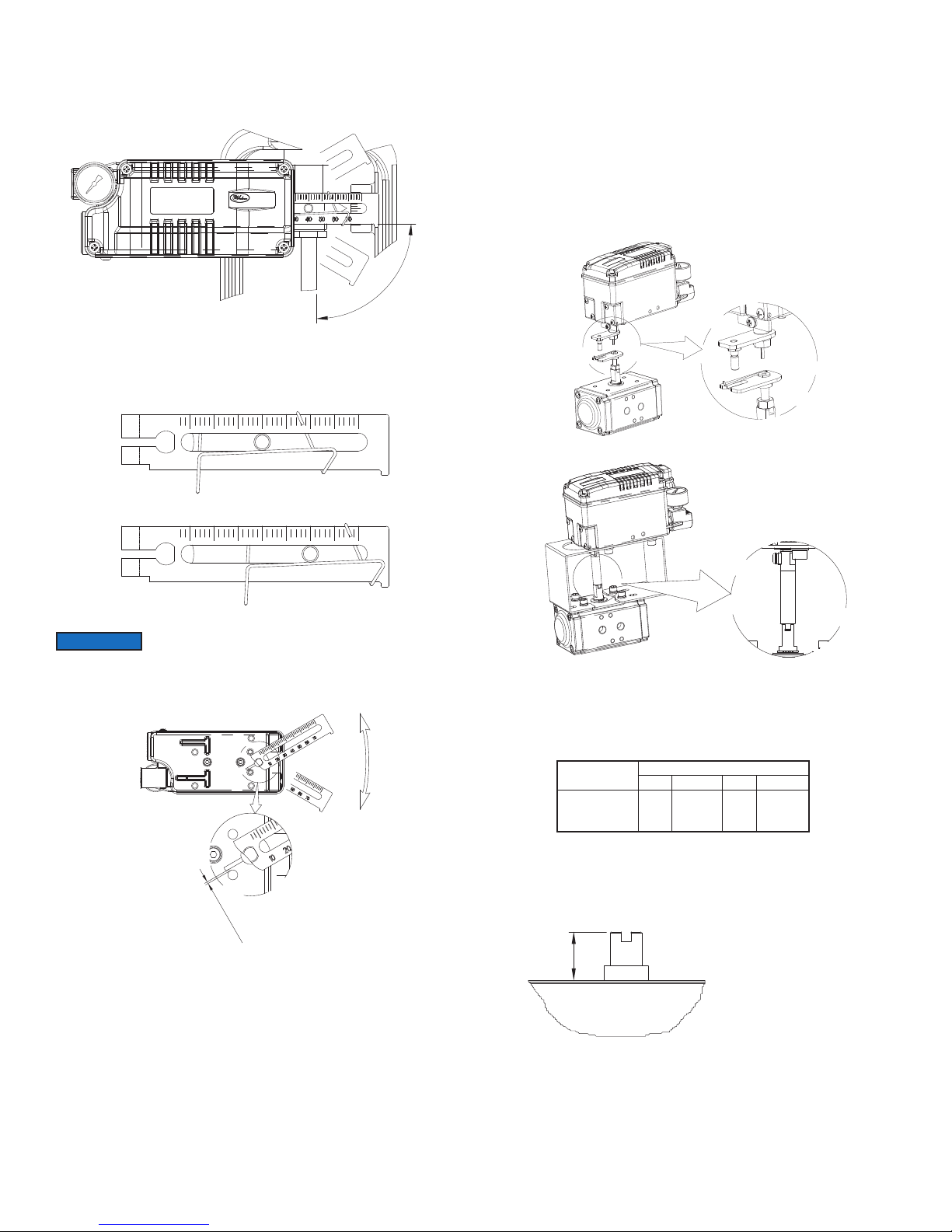

s

. Check that the Series 195’s feedback lever is level at 50% of valve stroke. If not,

7

ove the bracket or feedback link until it is level. Product linearity becomes work if

m

Series 195 is installed without being level at 50% of valve stroke.

8. Check the valve stroke. The numbers indicating the stroke are carved in the

eries 195’s feedback lever. Set the connection bar attached on the actuator clamp

S

o the number on the feedback lever applicable to the valve stroke, as shown in the

t

ollowing picture. To set the connection bar and the number, move the bracket

f

attached on Series 195 or connection bar from side to side.

age 3

. Once the Series 195 is installed according to the above procedures, tighten the

9

olts and nuts of the bracket and feedback lever connection bar completely.

b

eries 295 Installation

S

Series 295 is designed for rotary motion valves, such as Dwyer Instruments ball

and butterfly valves, using rack and pinion, scotch yoke or complex type actuators

whose stem is rotated 90°. Series 295 positioners consist of the following

omponents:

c

Series 295 main body

•

Fork lever and lever spring to attach on actuator

•

1 bracket

•

• Four hex bolts M8x1.25P

• Four M8 plate washers

eries 295 Installation Example of Fork Lever

S

P

Installation Position of Connection Bar for Valve Stroke

NOTICE

and 100%, the feedback lever should not reach to the lever stopper on the backside

of the Series 195 unit. If the feedback lever reaches the lever stopper, move

attachment of Series 195 away from the yoke center.

After installation, operate the valve from 0 to 100% stroke using

an air filter regulator on the actuator. When the stroke is both 0

Series 295 Installation Example of Namur Shaft

Installing Series 295 with Bracket

Series 295 is supplied with a standard bracket. The bracket consists of two parts

and is used with a NAMUR shaft. The bracket is assembled in the factory based on

.79˝ (20 mm) of actuator stem height. If the actuator stem height is higher, such as

1.18˝ (30 mm) or 1.97˝, use the table below to check hole positions.

Actuator Stem

Height (H)

20 mm

30 mm

50 mm

Ex) If H is 30 mm, A-L should be locked in H:30 hole, B-L in H:20, 30, A-R in H:30,

and H:20, 30 with bolts.

1. Typically actuator stem heights (H) are .79, 1.18, and 1.97 inches (20, 30, and

50 mm). After checking H, assemble brackets following previous guidelines. The

bracket is set at .79˝ (20 mm) in the factory.

2. Attach the bracket to the actuator using hex bolts. The diameter of the bracket

bolt holes is .24˝ (6 mm). Using spring washers or thread lock compound so the

bolts will not be loosened by vibration or impact. The direction of the bracket varies

by operating conditions, but normal direction is depicted in the following picture.

That is, when the piping of actuator and Series 295 is as shown in direction A, the

bracket hole and indicator attached on the bottom of the Series 295 main shaft

should be mounted in the same direction.

Markings of Bolt Holes

B-L

A-L

H: 20, 30

H: 20

H: 20, 30

H: 30

H: 50

H: 50

B-R

A-R

H: 20, 30

H: 20

H: 20, 30

H: 30

H: 50

H: 50

Actuator Stem (H)

Actuator

Page 4

. Set the rotation position of the actuator stem as the initial zero point, which is 0%

450

SMART POSITIONER

450

3

troke. For a spring return type actuator, the actuator stem is always rotated to the

s

ero point without supply pressure, making it easy to check the zero point. If the

z

ctuator is double-acting, check whether the rotation direction of the actuator is

a

clockwise or counter-clockwise, or the rotation direction of the actuator using

supply pressure.

. Set the actuator stem as the initial zero point and install a fork lever as showing

4

n the following picture. Confirm the position of initial zero point when the actuator

i

tem is turned clockwise and counter-clockwise. Installation angle of the fork lever

s

hould be about 45 degrees based on the linear shaft. But the angle is not related

s

to the NAMUR shaft.

ounter-Clockwise

C

age 4

. Free from solid particles. Result of being passed through 5 micron or finer filter.

2

. Does not contain oil or lubricating oil.

3

. Comply with ANSI/ISA-57.3 1975(R1982) or ISA S7.3-1975(R1981).

4

. Not used beyond the range of 20 to 100 psi (140 to 700 kPa).

5

P

6. Set supply pressure of air filter regulator to 10% higher than operating pressure

of actuator.

onditions of Pipe

C

. Remove foreign objects from inside of pipe.

1

. Do not use squeezed or broken pipe.

2

. To maintain flow rate of Series 295, use a pipe with inner diameter of greater than

3

.24˝ (6 mm) (outer diameter .39˝ (10 mm)).

Piping Connection With Actuator

eries 195 and Series 295 can operate either single or double acting actuators.

S

Clockwise

Installation Position of Fork Lever

5. Once the fork lever position is set, lock the check nuts on the bottom of the fork

lever by turning clockwise. Set the upper height of the fork lever to .24 to .43˝ (6 to

11 mm) lower than the upper height of the bracket.

6. Attach the Series 295 unit to the bracket. Fix the clamping pin on the main shaft

center of the Series 295 into the hole of the fork lever. Insert the connection bar

attached on the main shaft lever into the fork lever slot to be locked by the fork lever

spring. This is to fit the main shaft of the Series 295 to the center of the actuator

stem. If they are not fitted correctly, too much force on the main shaft will greatly

reduce product durability.

7. Attach the Series 295 base and the bracket with hex bolts and plate washers. It

is best to lock the bracket and Series 295 together by inserting four bolts after

checking the position.

iping Connection Example of Series 195 with Single Acting Actuator

P

Piping Connection Example of Series 295 with Single Acting Actuator

Single Acting Actuator

To operate a single acting actuator, connect OUT1 port to actuator supply

pressure port. Close off the OUT2 port with the supplied 1/4˝ NPT plug.

Power Connection

CAUTION

1. Before connecting terminal, power must be shut off.

2. Use ring type terminal against oscillation, impact, etc.

3. Series 195 and 295 positioners use 4 to 20 mA DC for power. Minimum supply

current is 3.2 mA (standard type) and 3.8 mA (HART

®

type). Maximum supply

current must not exceed 24 mA. In order to protect the Smart Positioner, the ground

terminals should be grounded.

4. Use twisted cable with conductor sectional area at least 0.0019 in

2

(1.25 mm2),

and suitable for 600V as on conductor table of NEC Article 310. Outer diameter of

cable should be .25 to .39˝ (6.35 to 10 mm). Use shielded wire against

electromagnetic waves and noise.

5. Do not install the cable near equipment such as a high-capacity transformer or

motor.

PIPING CONNECTION

NOTICE

1. To prevent ingress of moisture, oil and dust, give careful

consideration to the choice of supply pressure compressor and

piping.

2. It is recommended to attach a filter or air filter regulator in front of the supply port

of the Series 295 unit..

Conditions of Supply Pressure

1. Dry air with a dew point that is at least 50°F (10°C) lower than that of the ambient

temperature.

Terminal Plate of Series 195 & 295

Page 5

erminal Connection of Feedback Signal

Stopper

T

. Open cover by loosening the four M4 bolts on the positioner cover.

1

. Loosen locking bolts of terminal plate.

2

. Insert a cable through the cable connector in the

3

positioner.

4. Use a ring type cable terminal so that it does not come out.

5. Insert terminal bolts in terminal holes of cable and lock them with (+) terminal and

(-) terminals on the terminal plate. Tighten terminal bolts with 1.1 lbs-ft (15 kfgcm)

f torque.

o

. Be sure not to change the polarity of the terminals.

6

Inner Terminal Connection to Ground

1. The ground is necessary for the safety of the positioner and system.

2. The ground terminals are inside the terminal in the center of the terminal plate,

and outside terminal beside outer cable entry. Use any ground terminal that is

vailable. Resistance must be less than 100 Ω.

a

age 5

ariable Orifice

V

unting can occur if the actuator volume is too small. In this case, adjust the

H

ariable orifice using a (-) flathead screwdriver. Hunting is prevented by reducing

v

he flow rate of supply pressure transmitted to the actuator.

t

Auto Calibration and Basic Operations

AUTION

C

Buttons Operations

Series 195 and 295 positioners perform various functions using four buttons. The

position of the buttons is shown below:

<Enter> : is used to go to the main menu, save adjusted parameter values, or

hoose sub menus.

c

Esc> : is used to return to previous menu.

<

UP> : is used to move to another menu or change parameter values.

<

<DOWN> : is used to move to another menu or change parameter values.

ince this makes the valve or actuator move, before auto

S

alibration, the valve must be separated from the entire system.

c

P

3. For use with inside ground, open cover by loosening the four screws of positioner

cover.

4. In order to maintain the ground connection, use a ring type ground cable terminal

to prevent it from coming out.

S/E Button (SUP/EXT Buttons)

There are “SUP” and “EXT” buttons next to the LCD display of the Series 195 and

295 positioners. If the “SUP” button is pressed, air pressure will be supplied to the

actuator. If the “EXT” button is pressed, the air pressure will be exhausted from the

actuator. This function is used when diagnosing actuator operation.

RUN mode

After connecting the power to the positioner, the following is displayed on the LDC

in 6 seconds.

RUN on the bottom line means that the Smart Positioner adjusts valve stroke based

on an outside signal (4 to 20 mA), and PV refers to the number on the LCD. In RUN

mode, valve stroke is changed according to input signal.

Run PV

1

Run SV %

2

Run SV mA

3

Run MV

4

Run Vel

5

Run Err

6

There are six options in RUN mode. In order to change display, push <ESC> and

<UP> at the same time. When the buttons are pushed, display order is changed. If

the <ESC> and <DOWN> buttons are pushed simultaneously, the order is opposite

and if <ESC> is pushed only, display returns to RUN mode.

First Auto Calibration

First auto calibration is usually used when the positioner has not been set, such as

the initial setting with valve at the valve company, or replacement with other product

in the field. In this case, all parameters are set by using the AUTO2 calibration.

CAUTION

AUTO1 calibration. This is because the valve company sets optimum parameters,

so it is better that those registered parameters are not changed by AUTO1

calibration.

1. Connect power. Any values between 4 to 20 mA (DC) can be used for power.

After connecting power, ‘READY 3, 2, 1’ message appears on the LDC, which

means preparing to operate PCB circuit and parts. The following message is

displayed in 6 seconds. Push <ENTER> for 6 seconds at RUN mode and AUTO

CAL message should appear.

2. Push <ENTER> and then AUTO1 mode is started.

3. Push <DOWN> and AUTO2 mode is displayed.

4. Push <ENTER> at AUTO2 mode. Auto 2 calibration is started and the next

modes are displayed in order on the LCD. Normally it will take 3 to 5 minutes for

auto calibration in AUTO2 mode, but it can be different based on actuator’s volume.

Process Value

Set Value

Set Value

Manipulate Value

Velocity

Error

When the positioner is installed on the valve in the field after

setting, we recommend using AUTO2 calibration rather than

Valve Stroke (%)

Input Signal (0 to 100%)

Input Signal (4 to 20 mA)

Motor/Piezo Valve Manipulate Value (Digit)

Current Value Stem’s Velocity (Digit)

Difference Between SV and PV (%)

Page 6

. When Auto calibration is done, ‘COMPLETE’ message appears on the LCD. After

5

seconds the procedure is returned to RUN mode and valve stroke controlled by

4

he input signal will be displayed as a percentage.

t

. Zero, Span, PID parameters and RA/DA are automatically set when Auto 2

6

calibration is completed.

Entire Modes and Functions

<ENTER>

6 seconds

<

uto Calibration (AUTO CAL)

A

ENTER>

<ENTER> <DOWN>

OMPLETED

C

The calibration of the Positioner is simply performed by Auto calibration. There are

3 types of Auto calibration: AUTO1, AUTO2 and AUTO3.

AUTO1 calibration is useful for users in the field. AUTO2 calibration is for valve

ompanies or the initial parameter setting for the positioner.

c

t takes about 2-3 minutes for Auto calibration and it can be different based on the

I

actuator's volume. AUTO2 and AUTO3 calibration set the RA/DA automatically.

Zero Point

AUTO1

UTO2

A

UTO3

A

uto Calibration Types

A

o

o

x

End Point

o

o

x

KP, KI, KD

RA/DA

x

x

o

o

o

o

Auto 1 Calibration (AUTO1)

In this mode, all parameters necessary for valve operation are set except KP, KI,

KD and RA/DA. AUTO1 is used to re-execute calibration in the field after being

installed.

1. Push <ENTER> for 6 seconds in RUN mode and AUTO CAL message should

appear.

2. Push <ENTER> and then AUTO1 mode is displayed.

3. Push <ENTER> again at AUTO1 mode and Auto 1 calibration is started.

4. When Auto 1 calibration is done, ‘COMPLETE’ message appears on the LCD.

After 4 seconds the procedure returns to RUN mode and the valve stroke by current

input signal is displayed as a percentage.

<ENTER>

6 seconds

COMPLETED

<ENTER> <ENTER>

age 6

. Push <UP> or <DOWN> and valve stem moves up or down. Regardless of

4

A/DA, if <UP> is pushed, valve stem moves up (in case of linear valve). If

R

DOWN> is pushed, valve stem moves down. In order to make the valve stem

<

ove fast, push <ENTER> with <UP>, or <DOWN>. Push <ESC> and MANUAL

m

P

mode is displayed.

UP> only

<

UP>+<ENTER>

<

DOWN> only

<

<DOWN>+<ENTER>

Increase stem value slowly

Increase stem value quickly

ecrease stem value slowly

D

ecrease stem value quickly

D

Parameter Mode (PARAM)

Parameter Types

There are four types in Parameter mode: Dead Zone, KP, KI, and KD.

hese values are reflected as soon as they are changed, therefore the appropriate

T

alues are found by checking the valve’s motion in real time.

v

Dead Zone (dEAdZONE)

This is the range of error % that the positioner is not adjusted. Hunting or oscillation

due to friction between the stem and packing is prevented by this parameter.

P

K

his is a proportion constant value that is correction by error %. If this value is too

T

ig, there can be hunting, even though it finds position by the input signal. If the

b

value is too small, accuracy gets worse.

KI

This is an integral constant value adding or subtracting the correction that is

orrected error % on the previous correction signal. If this value is too big, there can

c

e oscillation. If it is too small, the time to find the exact position increases.

b

KD

This is a differential constant value adding the previous correction signal with the

changing correction signal by the error % change rate.

Adjustment of Parameter

Dead Zone (dEAdZONE)

1. Push <ENTER> at RUN mode for 6 seconds and AUTO CAL message appears.

2. Push <DOWN> twice and PARAM mode is displayed.

3. Push <ENTER> and dEAdZONE mode is displayed.

4. Push <ENTER> again and *EAdZONE message appears.

5. Adjust dEAdZONE value by pushing <UP> or <DOWN>. Adjusted value is

applied immediately without additional operation. Users can easily check its

adjustment by changing the current input signal to the positioner. Optimum control

value is found by adjusting values during valve operation.

6. Push <ENTER> to save the value. +EAdZONE message appears on LCD.

Auto 2 Calibration (AUTO2)

All parameters necessary to operate the valve are set. This calibration is used

when the positioner is first installed with valve. Refer back to First Auto Calibration.

Auto 3 Calibration (AUTO3)

All parameters necessary to operate the valve are set except zero and end point.

This function is used to re-execute auto calibration without changing the zero and

end point after adjusting them manually.

1. Push <DOWN> at AUTO2 and AUTO3 is displayed.

2. Push <ENTER> and AUTO3 calibration is started. The remaining procedures of

this calibration are the same as other calibrations.

Manual Mode

Manual mode is used to raise or lower the valve stem manually. In this mode, valve

stroke is adjusted only by operating buttons, not by the current input signal. This

mode does not affect controlling data registered in the positioner. It only is used to

move the valve stem up and down.

1. Push <ENTER> at RUN mode until AUTO CAL message is displayed.

2. Push <DOWN> and MANUAL mode is displayed.

3. Push <ENTER> again. Two lines appear on the LCD. The upper line indicates

valve stroke by percentage and the lower line indicates absolute value of inner

resistance of the positioner. “MA” means that Manual mode is in operation.

<ENTER>

6 seconds

<UP>/<DOWN> <ESC>

<DOWN> <ENTER>

COMPLETED

<ENTER>

6 seconds

<ENTER> <UP>/<DOWN>

COMPLETED

<ENTER>

6 seconds

then <ENTER>

7. Push <ESC> three times to return to RUN mode.

<ENTER>

<ESC>

3 times

Page 7

P

Feed back signal

(

12 ~ 30V)

4

~ 20 mA

I

NPUT

K

-3. Adjustment method and procedure same as dEAdzone.

1

. Push <DOWN> at dEAdZONE mode and KP mode is displayed.

4

. Push <ENTER> and *KP message appears on LCD.

5

6. Adjust KP values with <UP> or <DOWN>. Adjusted value is applied immediately

without additional operation. Users can easily check its adjustment by changing the

current input signal to the positioner. Optimum control value is found by adjusting

alues during valve operation.

v

. Push <ENTER> to save the value. +KP message appears on LCD.

7

. Push <ESC>.

8

<ENTER> <DOWN>

<UP>/<DOWN>

then <ENTER>

3 times

<ESC>

3 times

<ENTER>

COMPLETED

9. Push <ESC> twice to return to RUN mode.

T

P

-3. Adjustment method and procedure same as dEAdZONE.

1

4. Push <DOWN> 7 times at dEAdZONE mode and PT mode is displayed.

5. Push <ENTER> at PT mode and *PT message appears on LCD.

6. Adjust PT value with <UP> or <DOWN>. Adjusted value is applied immediately

without additional operation. Users can easily check its adjustment by changing the

urrent input signal to the positioner. Optimum control value is found by adjusting

c

he values during valve operation. Push <ENTER> to save the value and +PT

t

essage appears on LCD.

m

age 7

P

<ENTER>

6 seconds

ENTER> <ESC>

<

ESC>

<

djustment of zero point (1 to 4) and end point (5 to 9) of transmitter.

A

<DOWN>

3 times

UP>/<DOWN>

<

hen <ENTER>

t

ENTER><DOWN> <UP>/<DOWN>

<

OMPLETED

C

<ENTER>

hen <ENTER>

t

If valve zero point and end point are changed, transmitter is also changed

automatically. Usually there is no need for the transmitter zero point and end point

o be adjusted by users, but if transmitter output signal is unstable, transmitter zero

t

oint and end point should be adjusted. The ammeter showing feedback signal is

p

ecessary and the connection should be down as shown.

n

7. Push <ESC>.

<ENTER> <DOWN>

<UP>/<DOWN>

then <ENTER>

7 times

<ESC>

3 times

<ENTER>

COMPLETED

8. Push <ESC> twice to return to RUN mode.

HAND CAL

When auto calibration is started, Series 195 and 295 positioners set zero points

and end points based on full stroke.

Hand Calibration Types

PV_ZERO: Edit mode to change the zero point of valve.

PV_END: Edit mode to change the end point of a valve.

TR_ZERO: Edit mode to change the zero point of transmitter.

TR_END: Edit mode to change the end point of transmitter.

Adjustment of valve zero point (1 to 5) and end point (6 to 10).

1. Push <ENTER> at RUN mode for 6 seconds and the AUTO CAL mode is

displayed. Push <DOWN> three times, and the HAND CAL mode is displayed.

2. Push <ENTER> at HAND CAL mode and PV_ZERO mode is started.

3. Push <ENTER> at PV_ZERO mode and *PZ mode is started. At this mode it is

available to change valve zero point, and the valve stem moves automatically to the

current zero point. On LCD, the valve stroke is displayed as 0%. +PZ message that

indicates edit mode of zero point and inner value showing current zero point

position is also displayed.

4. Adjust valve stem by pushing <UP> or <DOWN>. When valve stem has arrived

at the desirable zero point, save it with <ENTER>. +PZ message appears on LCD.

5. Push <ESC> to return to PV-ZERO mode. (Push <ESC> twice to return to RUN

mode.)

6. In order to change valve end point, push <DOWN> at PV_ZERO mode and

PV_END mode begins.

7. Push <ENTER> at PV_END mode and *PE mode is displayed. At this mode it is

available to change valve end point, and the valve stem moves automatically to

current end point. On LCD, the valve stroke is displayed 100%. *PE message

indicating edit mode of end point and inner value of end point is also displayed.

8. Adjust valve stem with using <UP> or <DOWN>. When valve stem arrives at

desirable end point, save it with <ENTER>. +PE message appears on LCD.

9. Push <ESC> to return to PV-END mode.

10. Push <ESC> twice and RUN mode is displayed.

1. Push <DOWN> at PV-END mode and then TR_ZERO mode is displayed.

2. Push <ENTER>. *R_ZERO mode is started and at this mode users can adjust

the zero point of the transmitter. Valve stem is moved to zero point automatically.

3. Push <UP> or <DOWN>. The number on the LCD is changed and the measured

current value is changed accordingly on an ammeter equipped outside. Adjust it to

be 4 mA and push <ENTER> to save it. +R_ZERO message is displayed.

4. Push <ESC>. TR_ZERO mode is displayed.

5. Push <DOWN> at TR_ZERO mode. Then TR_END mode is displayed. (Push

<ESC> twice to return to RUN mode.)

6. Push <ENTER>. *TR_END mode is started and at this mode users can adjust

the end point of the transmitter. The valve stem is moved to the end point

automatically.

7. Adjust measured current value to be 20 mA on ammeter with <UP> or <DOWN>

buttons. Push <ENTER> to save it. +R_END message appears.

<DOWN> <ENTER> <UP>/<DOWN>

<ESC> <DOWN> <ENTER>

<UP>/<DOWN>

then <ENTER>

<ESC>

then <ENTER>

COMPLETED

8. Push <ESC>. TR-END mode is displayed.

Page 8

alve Mode

1

00%

Strok

0

4

20

mA

Quick Open

Linear

EQ%

V

his mode adjusts the various characteristics.

T

ction Type (ACT)

A

It can be set to Direct Action (DA) or Reverse Action (RA).

Characteristics (CHAR)

et Characteristics. There are three types of valve characteristics: Linear (LIN),

S

Q% (EQ), and Quick Open (QO). The following is the example of the three

E

haracteristic curves.

c

age 8

djustment of User Characteristics (USER SET)

A

. Push <ENTER> at VALVE mode and ACT RA or ACT DA is displayed.

1

. Push <DOWN> twice, then USER SET mode is started.

2

. Push <ENTER>. *PO SET mode is displayed. In this mode, users can adjust the

3

P

first point of characteristic in 16 points. The number on the LCD is the valve stroke

percentage set to P0.

4. Adjust the valve stroke percentage using <UP> or <DOWN>.

. Save it with <ENTER>. While P0 value is being saved, *P1 SET mode is

5

isplayed.

d

. *P1 SET mode is used to adjust the second point characteristic in 16 points.

6

djustment method is the same as P0* SET mode.

A

7. Save the valve stroke percentage from P2 to P15 SET mode, save it with

<ENTER>.

8. After adjustment of valve stroke percentage at *P15 SET mode, save it with

ENTER>.

<

. +SER SET is displayed. Sixteen points of valve stroke percentage are all set.

9

ush <ESC> three times to return to RUN mode.

P

User Characteristics (USER SET)

When a specific characteristic is needed but not included in the above

haracteristics, the user can make a specific characteristic curve by choosing 16

c

oints voluntarily according to the field conditions the user’s need.

p

Tight Shut Open (TSHUT OP)

This allows the user to fully open valve at any value around the 20 mA current input

signal.

Tight Shut Close (TSHUT CL)

This allows the user to completely close valve at value around 4 mA input signal

from outside.

Split Range Control (SPLIT)

This allows the user to control entire stroke with input signals of 4 to 20 mA, 4 to

12 mA or 12 to 20 mA.

Adjustment of Acting Type (ACT)

1. Push <ENTER> at RUN mode for six seconds and then AUTO CAL mode is

displayed. Push <DOWN> four times to go into VALVE mode.

2. Push <ENTER> and ACT RA (in case of RA) is displayed.

3. Push <ENTER> again, then *ACT RA is displayed.

4. Adjust to *ACT DA by pushing <UP> or <DOWN> and save it with <ENTER>.

+ACT DA message appears.

5. Push <ESC> three times to return to RUN mode.

<ENTER>

6 seconds

<ENTER> <UP>/<DOWN>

<DOWN>

3 times

then <ENTER>

<ENTER>

<ESC>

3 times

<ENTER>

seconds

6

UP>/<DOWN>

<

hen <ENTER>

t

ENTER> <ENTER>

<

<DOWN>

times

3

ENTER> <UP>/<DOWN>

<

seconds

6

<ENTER>

hen <ENTER>

t

Adjustment of Tight Shut Open (t SHUT OP)

1. Push <Enter > at VALVE mode and ACT RA or ACT DA is displayed. Push

<DOWN> three times at this mode. t SHUT OP is displayed.

2. Push <ENTER>. *SHUT OP mode is displayed, and in this mode users can set

stroke at the time of Tight Open. Initial setting is done at 100%, which means

cancellation of this function. Adjust the value (ex: 95.0%) by pushing <UP> or

<DOWN> and save it with <ENTER>. +SHUT OP is displayed.

3. Push <ESC> three times to return to RUN mode.

<ENTER>

6 seconds

<UP>/<DOWN>

then <ENTER>

<DOWN>

3 times

<ESC>

3 times

<ENTER>

<ESC> 3 times

then <ENTER>

Adjustment of Tight Shut Close (T SHUT CL)

1. Push <ENTER> at VALVE mode and ACT RA or ACT DA is displayed. Push

<DOWN> four times at this mode. TSHUT CL is displayed.

2. Push <ENTER>. *SHUT CL mode is displayed and in this mode users can set

stroke at the time of Tight Close. Initial setting is done as 0.3%. 0% means

cancellation of this function. Adjust the value (ex: .5%) by pushing <UP> or

<DOWN> and save it by pushing <ENTER>. +SHUT CL is displayed.

3. Push <ESC> three times to return to RUN mode.

COMPLETED

Adjustment of Characteristics (CHAR)

1. Push <ENTER> at VALVE mode and then push <DOWN>. CHAR LIN (in case

of linear characteristics) mode is displayed.

2. Push <ENTER>. *HAR LIN mode is displayed and characteristics can be

adjusted at the mode.

3. Adjust Characteristics (ex: EQ) by pushing <UP> or <DOWN> and save it with

<ENTER>. + HAR EQ is displayed.

4. Push <ESC> three times to return to RUN mode.

<ENTER> <DOWN> <ENTER>

<UP>/<DOWN>

then <ENTER>

<ESC>

3 times

COMPLETED

<ENTER>

6 seconds

<UP>/<DOWN>

then <ENTER>

<DOWN>

4 times

<ESC>

3 times

<ENTER>

<ESC> 3 times

then <ENTER>

Page 9

djustment of Split Range (SPLIT)

A

. Push <ENTER> at VALVE mode and ACT RA or ACT DA is displayed.

1

. Push <DOWN> five times and SPLIT mode is displayed. The numbers on the

2

CD are the range of current signal input to the positioner. 4 to 20 mA current signal

L

is set as the standard.

3. Push <ENTER>. *SPLIT mode is displayed and input signal range can be

adjusted. Adjust input signal range with <UP> or <DOWN> and save it with

ENTER>.

<

. +SPLIT mode is displayed while saving adjusted range. Push <ESC> three times

4

o return to RUN mode.

t

<ENTER>

6 seconds

<UP>/<DOWN>

then <ENTER>

<DOWN>

5 times

<ESC>

3 times

<ENTER>

<ESC> 3 times

then <ENTER>

VIEW Mode

his mode provides users with various information about the Series 195 and 295

T

ositioners. In this mode, users can change the valve stroke types displayed on the

p

CD to % or numbers. Refer to the next table for information and description

L

displayed on VIEW mode.

1. Push <DOWN> at AUTO CAL mode and VIEW mode is displayed.

2. Push <ENTER> at VIEW mode, then information mode is started.

. Check information by using <UP> or <DOWN> and push <ESC>.

3

. Push <ESC> again to return to RUN mode.

4

<DOWN>

4 times

<ESC>

<ENTER> <UP>/<DOWN>

COMPLETED

confirm the changes,

then <ESC>

Description

YT-2500L

VERSION

HART V

POL AddR

bIAS VI

Positioner model

Main software version

HART Protocol version

Channel address that is used in HART Protocol

BIAS value for motor/piezo valve control. Can be adjusted only by

manufacturer.

0Y 0d

Total used time duration. If a unit was used less than 1 minute, the

time does not accumulate.

FULL_OP

FULL_CL

VM NOR

Erro

VALUE I

ABS

Time elapsed for valve to fully open.

Time elapsed for valve to fully close.

Display type of valve stroke on LCD (either in percentage or value).

Display error code or warning message <Figure XX>.

Current I-Value. Can be adjusted only by manufacturer.

Display absolute resistance value.

Information Checked on VIEW Mode

age 9

rror and Warning Code

E

f there are any problems during Series 195 and 295 positioner operation, you can

I

heck the error and warning code at VIEW mode as follows:

c

P

Error Code

This code is displayed when the Series 195 and 295 positioner control becomes

impossible. Code C, D applies.

rror Code

E

T ERR L

M

T ERR H

M

ode Description and Cause

C

Positioner is improperly installed.

Positioner lever is not parallel to

the ground at 50% point. Lever is

t lower position than actual 50%

a

oint.

p

ositioner is improperly installed.

P

ositioner lever is not parallel to

P

the ground at 50% point. Lever is

at lower position than actual 50%

Action

Re-install/mount the positioner.

ake sure the feedback lever

M

oes not touch the stopper at both

d

and 100%.

0

Re-install/mount the positioner.

Make sure the feedback lever

does not touch the stopper at both

and 100%.

0

point.

heck if supply pressure is stable

CHK AIR

NG ERR

R

alve does not operate when

V

ositioner receives “Full Open”

p

ignal during auto calibration.

s

Operating angle is too small due

to improper mounting of

C

and appropriate.

Adjust bracket so the positioner

can be mounted closer to actuator.

positioner.

erform BAS calibration.

C

Error 10% or above persists more

han 1 minute.

t

o valve movement.

N

Friction of valve is too large.

P

heck setting pressure of actuator

C

and set the pressure as

recommended.

Setting pressure of actuator

hanges.

c

-Value reaches at maximum or

D

I

inimum limit point.

m

Friction of valve changes.

Setting pressure of actuator

erform AUTO calibration.

P

heck setting pressure of actuator

C

nd set the pressure as

a

recommended.

changes.

Warning Code

This code is displayed when the positioner control is available but there is a

possibility of malfunction or low accuracy. Code B, F, G, H applies.

Warning Code

B

Code Description and Cause

PV end-PV zero range is below

500. The angle of feedback

lever is too small.

Action

Re-install/mount the positioner.

Make sure the feedback lever

does not touch the stopper at

both 0 and 100%.

After re-installation, perform

AUTO1 calibration.

F

Time elapsed for either full-open

or full-close is less than 1

second.

Use variable orifice.

Replace actuator with larger

capacity.

The size of the actuator is

too small.

G

Pv zero is below 100.

The angle of feedback lever

is too large.

H

Pv end is over 4000.

The angle of feedback lever

is too large.

Re-install/mount the positioner.

After re-installation, perform

AUTO1 calibration.

Re-install/mount the positioner.

After re-installation, perform

AUTO1 calibration.

Page 10

AINTENANCE/REPAIR

U

sed timeUser Set

ENT

: Enter button

Manual Mode

Auto 2

Auto cal

RUN Mode

E

NT

(5 sec)

E

SC

E

SC

Auto 1

ENT

BIAS

Auto 3

E

SC

E

SC

V_O

ESC

E

SC

Hart ver.CharacterK P

End point

ViewValveHand calParameter

ESCESC ESC ESCESC

E

SC

Start point

Dead Zone

E

SC ESC

ENT ENT

E

SC

Sof ver.

RA / DA

ENT ENT

BIAS

Tight shut onTR end point

K D

Tight shut oTR start point

K I

E

SC

E

SC

E

SC

E

SC

E

SC

E

SC

Polling Add

E

SC

E

SC

ESC ESCESC

E

SC

I

value

S

plit control

ESC

E

SC

: Up button

ESC

: Down button

: Esc button

Error code

F

ull close time

E

SC

Full open time

E

SC

ESC

View method

E

SC

ESC

ESC

E

SC

E

SC

K

I_

K P_

ESC

K

D_

M

pon final installation of the Series V-195/295, no routine maintenance is required.

U

he Series V-195/295 is not field serviceable and should be returned if repair is

T

eeded. Field repair should not be attempted and may void warranty.

n

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

ustomer service to receive a Return Goods Authorization number before shipping

c

he product back for repair. Be sure to include a brief description of the problem

t

lus any additional application notes.

p

age 10

P

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 7/14 FR# RV-443953-00 Rev. 4

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...