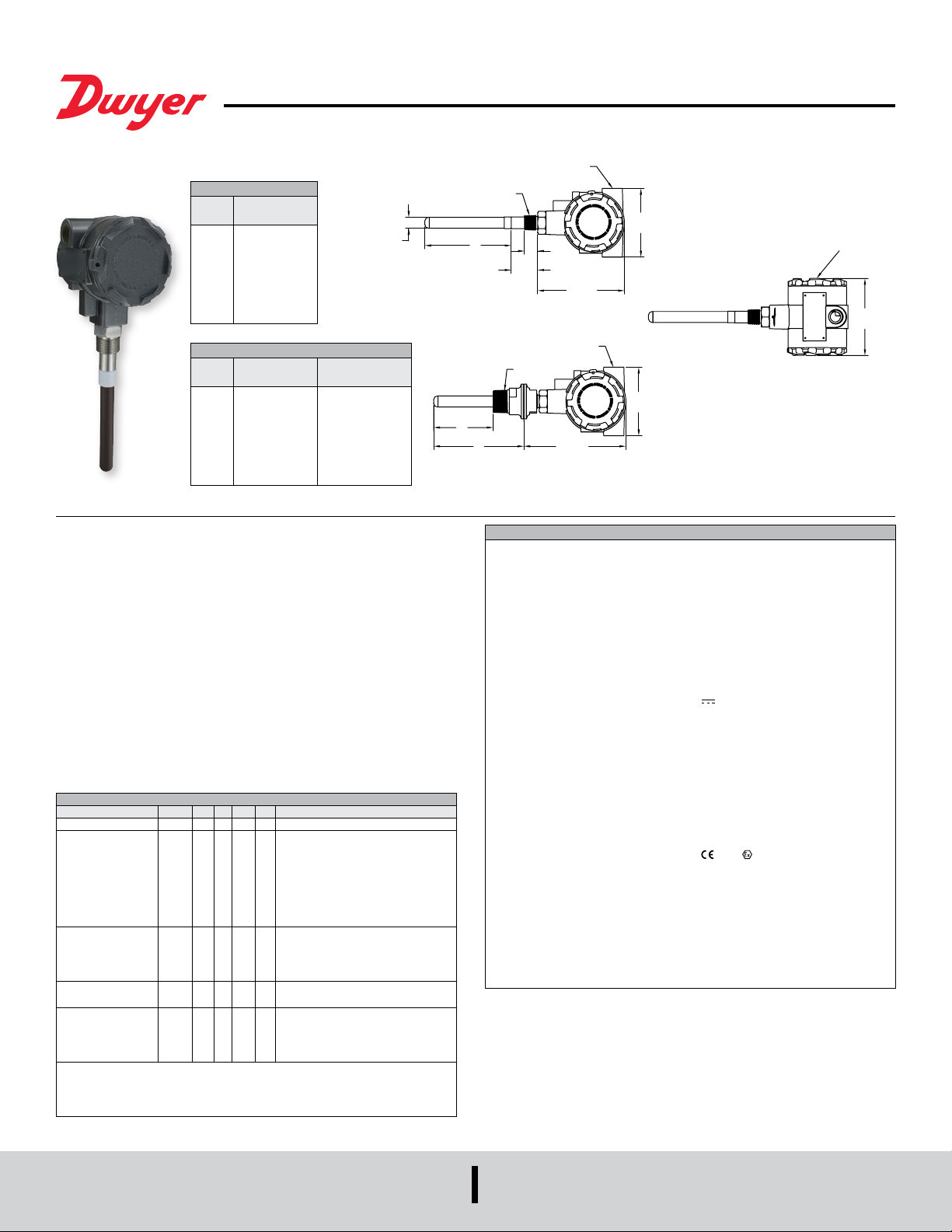

Series PMT2 Particulate Transmitter

2X 1/2˝ NPT OR M20 ELECTRICAL ENTRY

[15.88]

L

1.13]

[147.64]

®

Specications - Installation and Operating Instructions

Bulletin PC-PMT2-M

The SERIES PMT2 Particulate Transmitter is designed to measure particulate emission

levels from dust collector discharge. Using DC coupled electrostatic induction sensing

technology, the transmitter monitors a pA current that is generated as particulate

passes near the probe; a 4 to 20 mA signal will vary based on the particulate level. The

PMT2 offers 6 sensitivity ranges allowing the user to choose the range that will best t

the application. The range and test selector switch can also be set to output a 4 mA or

20 mA signal to assist with set up or trouble shooting. Averaging time setting can be

used to dampen the signal if desired.

FEATURES/BENEFITS

• Simple 2-wire installation for PLC and control panels

• Non-stick PTFE coated probe to prevent false readings from moist and conductive

dusts, condensate, and dust buildup

• Remote zero calibration helps to decrease maintenance time

MODEL CHART

Example PMT2 -05 -A -U2 PMT2-05-A-U2

Series PMT2 Particulate transmitter

Probe

Length

Process

Connection

Enclosure Rating A2

Options STM2Stainless steel tag

*Options that do not have ATEX or IECEx.

Attention: Units without the A2 sufx are not Directive 2014/34/EC (ATEX)

compliant. These Units are not intended for use in potentially hazardous

atmospheres in the EU. These unites may be CE marked for other Directives

of the EU.

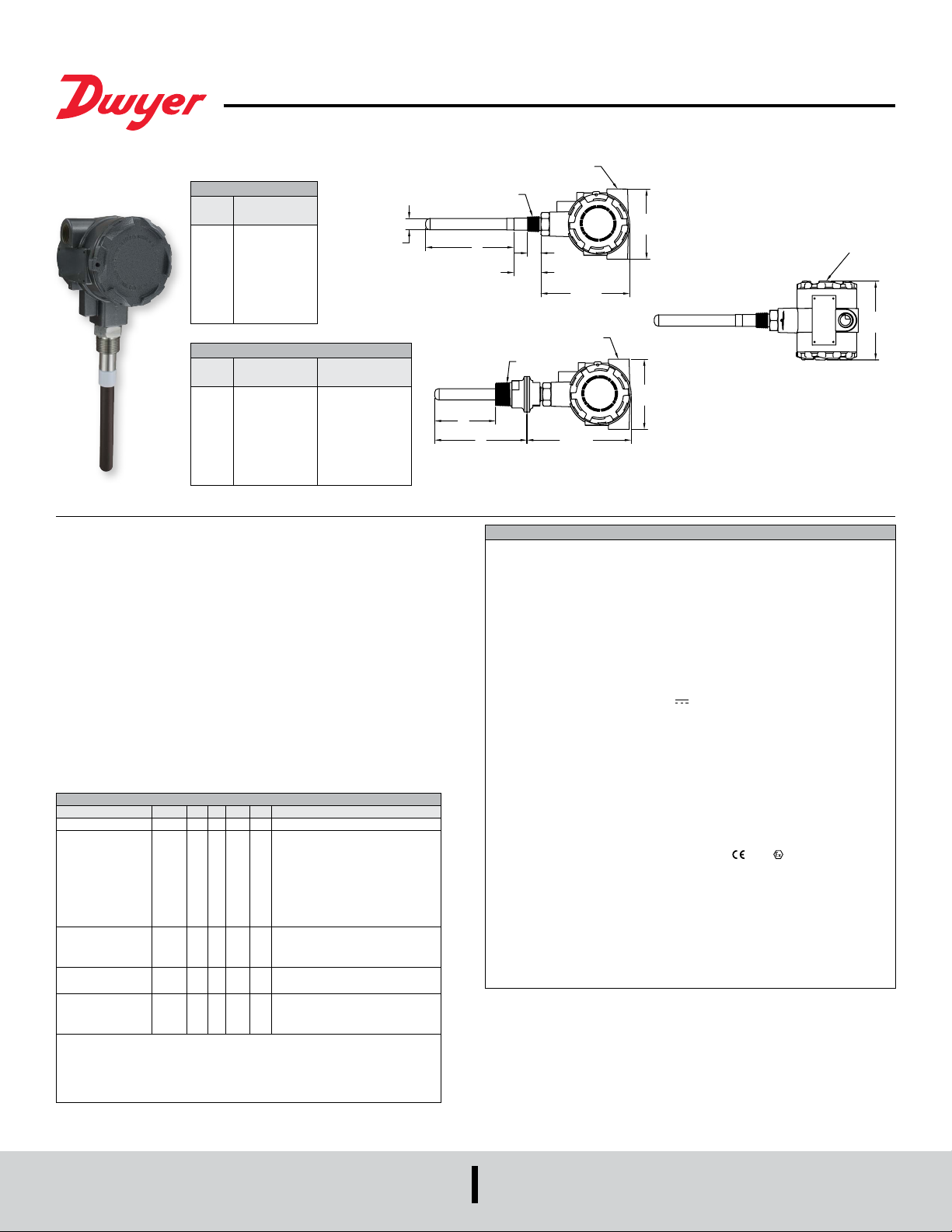

THREADED MOUNT

Probe

LengthAin [mm]

3˝

3 [76.20]

5˝

5 [127.00]

10˝

10 [254.00]

15˝

15 [381.00]

20˝

20 [508.00]

30˝

30 [762.00]

36˝

36 [914.40]

1.5˝ TRI-CLAMP MOUNT

Probe

LengthAin [mm]

3˝

3-1/2 [88.90]

5˝

5-1/2 [139.70]

10˝

10-1/2 [266.70]

15˝

15-1/2 [393.70]

20˝

20-1/2 [520.70]

30˝

30-1/2 [744.70]

36˝

36-1/2 [927.10]

03

05

10

15

20

30

36

A

B

C

3˝ probe length

5˝ probe length

10˝ probe length

15˝ probe length

20˝ probe length

30˝ probe length

36˝ probe length

3/4˝ male NPT

1.5˝ tri-clamp kit with 1˝ male NPT

3/4˝ male BSPT

ATEX and IECEx (IS)

U2

UL (IS)*

Female M20 electrical entries

(female 1/2˝ NPT standard)

B

in [mm]

1-25/32 [45.24]

3-25/32 [96.04]

8-25/32 [223.04]

13-25/32 [350.04]

18-25/32 [477.04]

28-25/32 [731.04]

34-25/32 [883.44]

3/4˝ NPT or 3/4˝ BSPT

5/8

“A”

3/4˝ Male NPT OR 3/4˝ Male BSPT Mount

2X 1/2˝ NPT OR M20 ELECTRICAL ENTRY

“B”

“A”

1.5˝ Tri-Clamp Option Mount

SPECIFICATIONS

Service: Air and compatible gases, any type of particulate conductive or nonconductive.

Wetted Materials: 316L SS, silicone, and PTFE.

Enclosure: Powder coated aluminum.

Accuracy: ±5% of reading.

Particulate Size: 0.3 microns and higher.

Detection Range: 5 to 5000 pA (6 selectable range options).

Temperature Limits: Ambient: -40 to 145°F (-40 to 63°C); Process: -40 to 248°F

(-40 to 120°C).

Pressure Limit: 30 psi (2 bar).

Output Signal: 4 to 20 mA.

Power Requirements: 12 to 28 VDC ( ).

Electrical Connection: Two 1/2˝ female NPT electrical entries or two M20 electrical

entries (A2 sufx only).

Terminal Block: Removable (16 to 20 AWG wire).

Process Connection: See model chart. BSPT process connections are not UL

listed.

Probe Lengths: See model chart.

Enclosure Rating: UL Type 4 (IP66) ATEX/IECEx IP65.

Mounting Orientation: Any.

Averaging Time: 1 to 360 s (10 selectable options).

Weight: Varies with length of probe and type of mount.

Agency Approvals: CE, cULus; ATEX Compliant: 0518 II 1 G Ex ia IIB T4 GA

(-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

(-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

16ATEX1768 X. ATEX Standards: EN 60079-0:2012/A11:2013; EN 60079-11:2012.

IECEx Certied: Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Ex ia IIIC T120°C Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Certicate of Conformity: IECEx UL 16.013X. IECEx Standards: IEC 60079-0: 2011;

IEC 60079-11: 2011. UL Listed Intrinsically Safe for Class I, Groups C and D; Class

II, Groups E, F and G; Class III; Class I Zone 0 AEx ia IIB T4 Ga; Class I Zone 0 Ex

ia IIB T4 Ga.

1-1/2

[38.10]

1˝ NPT

3/4

[19.05]

4-15/16

[125.41]

5-13/16

3-29/32

[99.22]

3-29/32

[99.22]

Process ≤ 120°C) / II 1 D Ex ia IIIC T120°C Da

Process ≤ 120°C). Type Certicate No.: DEMKO

ALLOW 1-1/4˝ [32]

FOR COVER REMOVA

BOTH SIDES

Process ≤ 120°C).

Process ≤ 120°C) /

[11

4-3/8

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

OPERATING PRINCIPLE

Technology

The PMT2 utilizes a highly reliable DC coupled electrostatic induction sensing

technology. The sensor probe is mounted in an airow stream such as a pipe, duct

or stack. The inductive effect takes place when particulate passes near the probe

transferring a charge from the particulate to the probe. A microprocessor lters and

processes the signal into a output that is linear to the mass concentration of particulate.

The PTFE coated probe ensures reliable operation with all types of particulate including

moist powders and highly conductive dusts. The PTFE coated probe eliminates the

need for an air purge and keeps maintenance to a minimum.

Particulate Monitoring

The PMT2 is specically designed to continuously monitor the particulate levels in air

ow from stacks or other emission points being passed through a lter within an air

ltration system. The transmitter should be installed in the exhaust ductwork and can

be used in conjunction with various types of bag, ceramic, cartridge or cyclone lters.

When the PMT2 is rst installed a baseline reading must be measured and noted. This

baseline reading is application dependent and should be measured independently for

each installation. From this baseline the operator will monitor output signal from the

PMT2. The increase in mA output indicates a rising level of particulate in the air stream

which indicates that lters are either wearing out or broken.

The PMT2 is designed to give a proportional output based on the particulate levels in

a duct or pipe, it is not designed to output a signal based on the particulate volumetric

ow. Different types of particulate carry different charges, meaning that two particulates

owing at the same volumetric ow rate could have different output response. The

PMT2 is designed to nd a baseline under ideal operating conditions and allow an

operator to watch the output signal for increases that would signify the bags or lters

are starting to wear or break. The six sensitivity ranges allow the PMT2 to monitor

particulates with low charge properties or high charge properties. As a reference, Table

1 lists particulate charge properties and the suggested range.

INSTALLATION

Unpacking

Remove the PMT2 from the shipping carton and inspect for damage. If damage is

found, notify the carrier immediately.

Location

The following factors should be considered when determining the installation location

for the PMT2:

• Make sure the transmitter is rated for the area classication it will be mounted in.

• Mount the transmitter in a location that will not exceed the temperature and pressure

ratings listed in the specications. The process pressure should not exceed 30 psi (2

bar).

• Make sure the 4 to 20 mA signal wires are not sharing the same conduit with high

voltage power wires.

• Make sure the location the transmitter is mounted in meets the NEMA or IP rating

for the enclosure.

• Locate the transmitter in a location were it can be accessed in case service is

required.

The PMT2 should be mounted in a grounded metal stack, pipe or duct. It should not

be mounted in berglass or plastic stacks, pipes or ducts. The sensing probe should

reach 1/2 to 2/3 the way across the stack, pipe or duct to ensure accurate readings.

For the most stable and accurate readings it is recommended to mount the PMT2 in

a location where the air ow is as laminar as possible. Avoid mounting the transmitter

close to blowers and dampers that cause turbulence. It is ideal to mount the PMT2 in

an area with two upstream duct diameters and one down stream duct diameter that

are free of turbulent causing objects. The sensing probe is coated in a non-stick PTFE

preventing material from coating the probe reducing the need for cleaning or an air

purge.

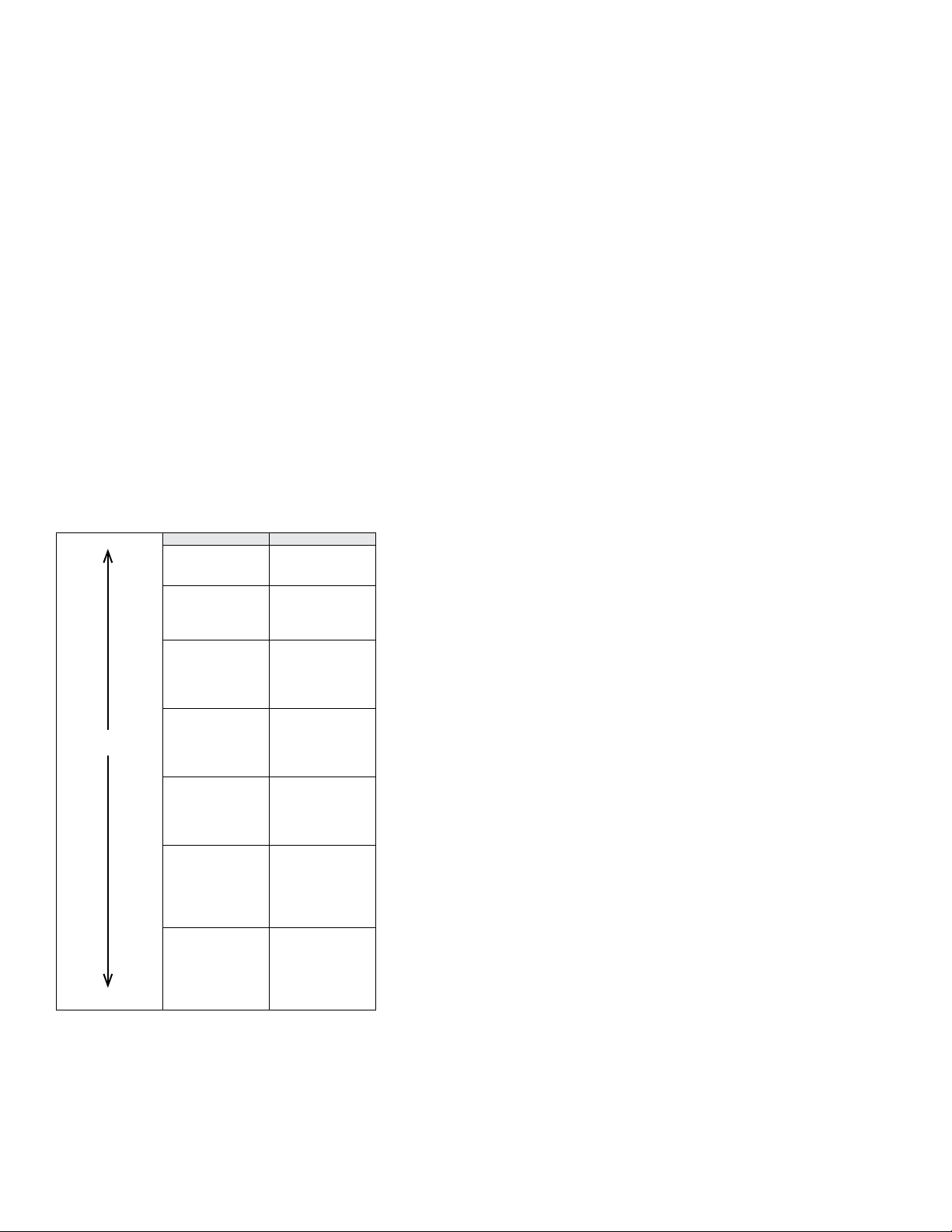

Neutral

Particulate Suggested Range

Human Hands

Asbestos

Rabbit Fur

Acetate

Glass

Mica

Human Hair

Nylon

PositiveNegative

Wood

Fur

Lead

Silk

Aluminum

Paper

Cotton

Steel

Wood

Mylar™

Nickel/Copper

Silver/Brass

Gold/Platinum

Sulfur

Acetate Rayon

Polyester

Styrene (Styrofoam)

Acrylic

Saran™

Polyurethane

Polyethylene

Polypropylene

Vinyl (PVC)

Silicon

PTFE

Silicone Rubber

Table 1: Suggested Ranges

5 to 5000 pA

5 to 1000 pA

5 to 500 pA

5 to 100 pA

5 to 500 pA

5 to 1000 pA

5 to 5000 pA

WIRING

(IF USED)

REMOTE ZERO

NOTICE

• Always install or service this device with the power off and where

required install a disconnect lockout

• Use 16 to 20 AWG copper wire only for line and load connections. Installation must

be made in accordance with local codes and regulations such as the National Electric

Code

• Degree of protection TYPE 4 (IP66) is maintained when suitable glands/plugs are

used in conjunction with UL Listed models

WARNING

HAZARDOUS LOCATIONS

To prevent ignition of hazardous locations the following cau-

tions should be taken:

• Keep device covers tightly closed in operation

• De-energize supply circuit before opening device covers

• Replace device covers before energizing the electrical circuits

• Device is not eld repairable and should be returned to Dwyer Instruments if repair

is needed

WARNING

INTRINSIC SAFETY SPECIFIC CONDITIONS OF USE

To maintain Intrinsic Safety the following cautions should be

taken:

• 4-20 mA signal and remote zero must be treated as separate circuits

• Enclosure parts are constructed of aluminum. Enclosure must be protected from

ignition hazard due to impact or friction

• All openings to enclosure must be sealed using suitable glands and/or plug main-

taining a minimum IP rating of IP66 for UL Listed models and IP65 for ATEX/IECEx

compliant models

• Substitution of parts may impair Intrinsic Safety.

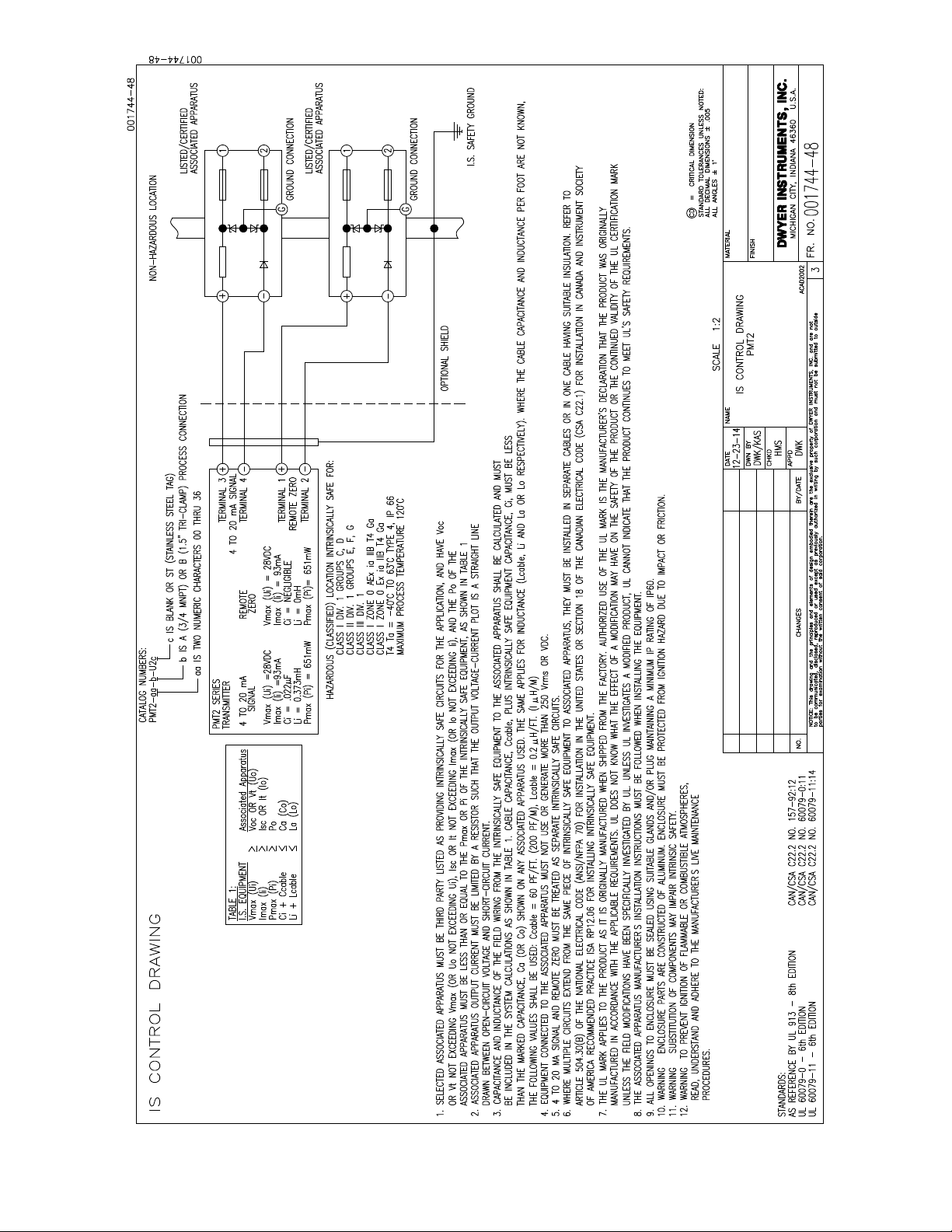

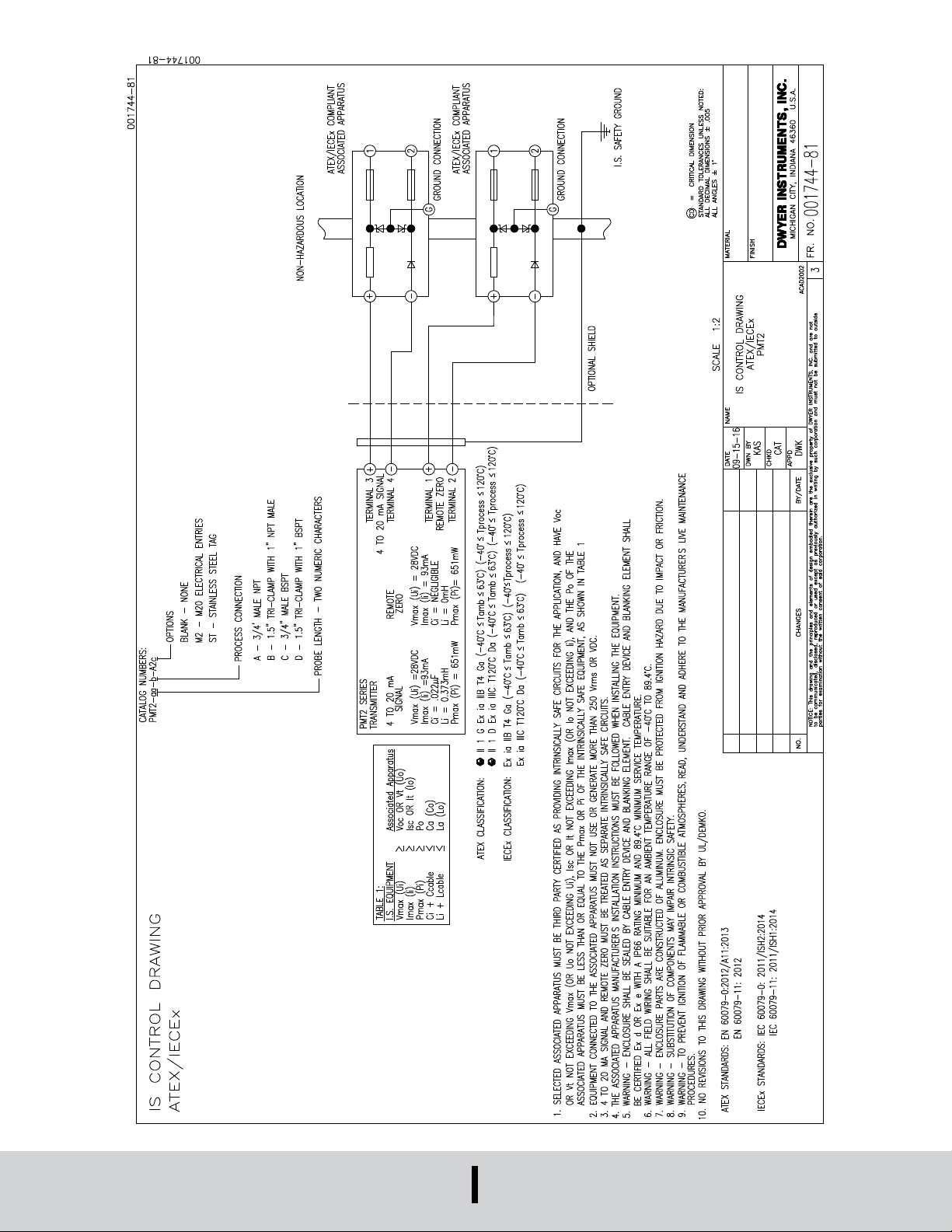

CONTROL DRAWING UL LISTED INTRINSIC SAFETY (SUFFIX U2):

UL Listed Intrinsically Safe for use in Class I Div. 1 Groups C and D; Class II Div. 1

Groups E, F and G; Class III Div. 1; Class I Zone 0 AEx ia IIB T4 Ga; Class I Zone 0 Ex

ia IIB T4 Ga; T4@63°C when installed in accordance with Control Drawing 001744-48

on page 6 of this document.

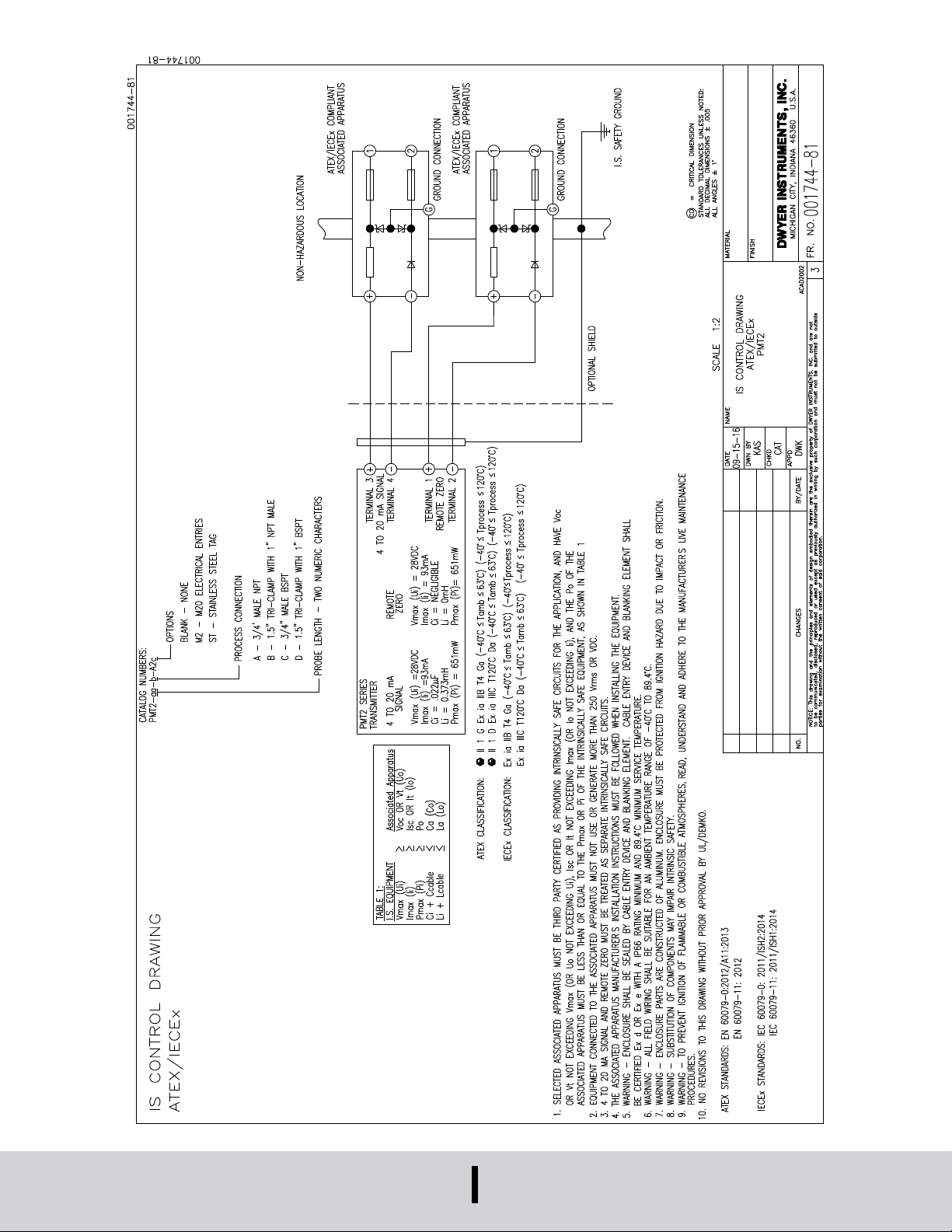

ATEX COMPLIANT (SUFFIX A2)

II 1 G Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

IIIC T120°C Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Process ≤ 120°C) / II 1 D Ex ia

Process ≤ 120°C) when installed in

accordance with Control Drawing 001744-81 on page 7 of this document.

POWER SUPPLY REQUIREMENTS

The maximum DC power supply is 28 VDC. The minimum required DC power supply

is based upon the following:

1. Minimum DC voltage requirement of the Model PMT2.

2. Total load resistance.

3. Total leadwire resistance.

4. Zener barrier voltage drop (Model PMT2-XX-X-X2 only).

The formula for calculating the DC Power Supply is:

VDC = VPMT2 + VLOAD + VLEADWIRE + VBARRIER

Where VPMT2 = 9.5 V

VLOAD = Total load resistance X 20 mA

VLEADWIRE = Total leadwire resistance X 20 mA

VBARRIER = 8.1 V (Typical zener barrier voltage drop for this application)

Example 1: Calculate minimum DC power supply for intrinsically safe models

Step 1 VPMT2 = 9.5 V

Step 2 Calculate VLOAD. Using the industry standard 250 Ω conversion

resistor, VLOAD = 250 X 20 mA = 5 V.

Step 3 Calculate VLEADWIRE. For this example assume a leadwire

resistance of 10 Ω, VLEADWIRE = 10 X 20 mA = 0.2 V

Step 4 VBARRIER = 8.1 V

Step 5 VDC = VPMT2 + VLOAD + VLEADWIRE + VBARRIER = 9.5 + 5 +

0.2 + 8.1 = 22.8 V

CONTROLS

WARNING

LIVE MAINTENANCE PROCEDURE

Live maintenance of Zero, Averaging Time, Range and Test

controls cannot be performed when a ammable or combustible atmosphere is

present.

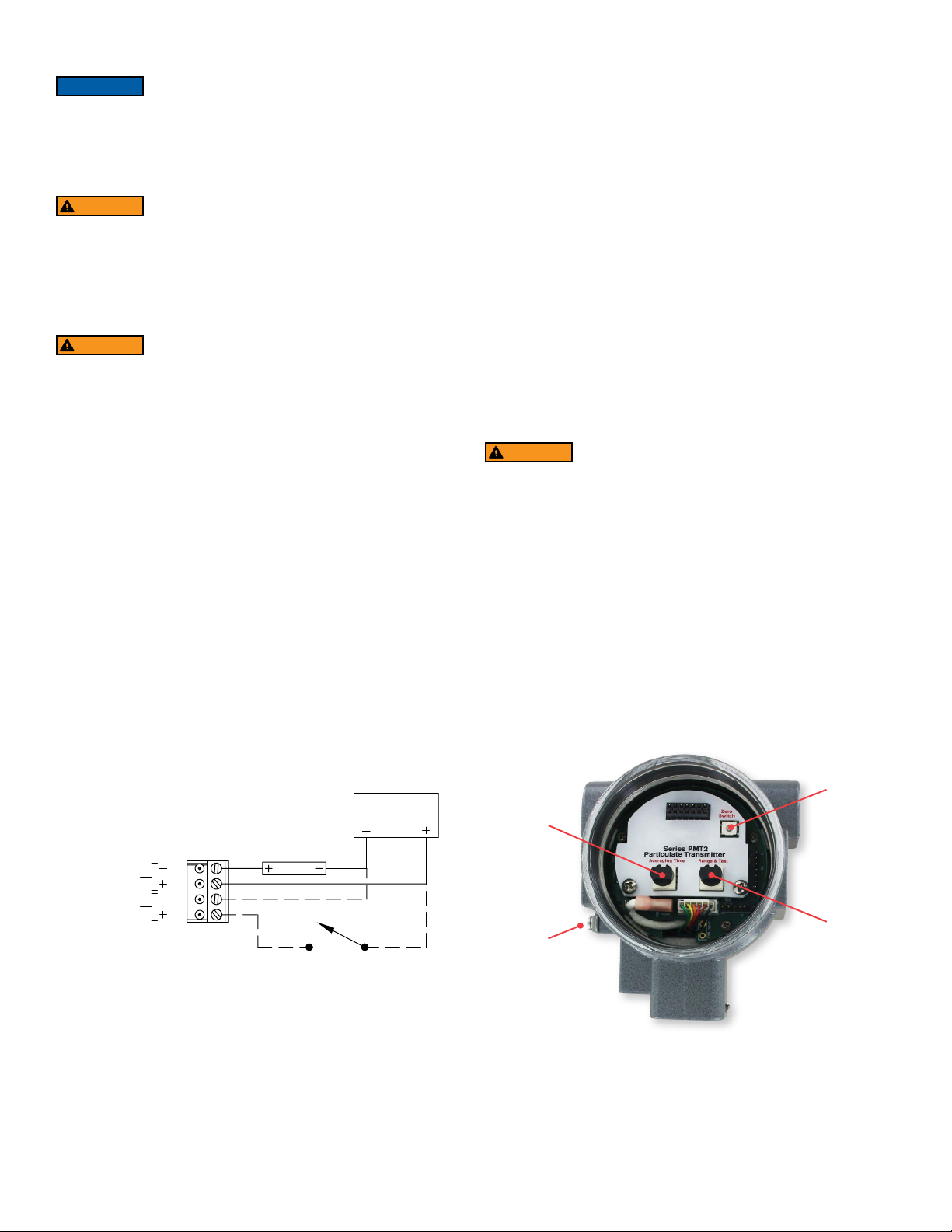

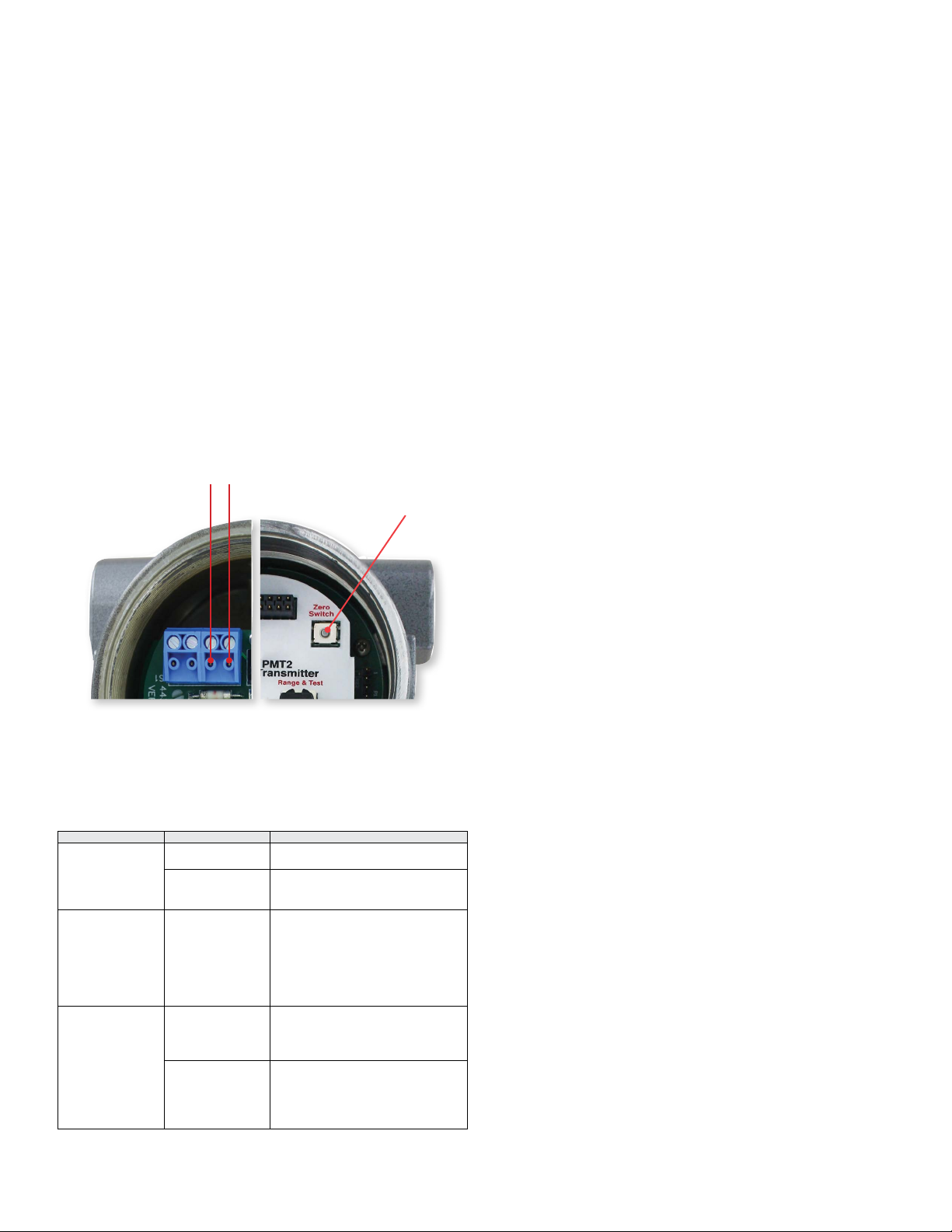

Zero Switch (see Figure 2)

Press and hold the switch for 3 seconds and the PMT2 will digitally re-zero. It is

recommended to re-zero after a lter failure or lter changes. Re-zeroing should only

be done when there is no air ow in the duct.

Averaging Time Selection Switch

The PMT2 will average the output for the selected amount of time. This will dampen

output spikes caused during normal lter cleaning cycles.

IECEx COMPLIANT (SUFFIX A2)

Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Process ≤ 120°C) when installed in accordance

Process ≤ 120°C) / Ex ia IIIC T120°C

with Control Drawing 001744-81 on page 7 of this document.

INTRINSIC SAFETY INPUT PARAMETERS:

4-20 mA Signal, Vmax (Ui) = 28 V; Imax (li) = 93 mA; Ci = .022 μF; Li = 0.373 mH;

Pmax (Pi) = 651 mW

Remote Zero, Vmax (Ui) = 28 V; Imax (li) = 93 mA; Ci = Negligible; Li = 0 mH; Pmax

(Pi) = 651 mW

POWER

SUPPLY

RECEIVER

4 to 20mA

4

3

2

1

REMOTE ZERO SWITCH

Figure 1: General Installation Wiring (Non-IS)

Range and Test Selection Switch

There are 6 sensitivity ranges that can be selected based on the material the PMT2

will be sensing (see Table 1). There is also an option to output a 4 mA or 20 mA signal,

these options can assist in the installation of the transmitter or trouble shooting.

Zero Switch

Averaging

Time

Range &

Grounding

Screw

Tes t

Figure 2

SET UP

1000 pA

Spike Alarm

TIME

Mounting

Make sure the PMT2 is securely mounted to the stack, pipe or duct to prevent vibration

during operation. Make sure the transmitter is grounded properly.

Control Signal Set Up

Check the power supply wiring to make sure the polarity is correct before powering

the PMT2. Turn the power on to the transmitter and turn the Range and Test selector

switch to 4 mA (position 2). The PMT should output 4 mA, check the output with a

multi-meter or at the device (PLC, Display, etc.) receiving the output signal. Once it is

veried the 4 mA signal is being received, switch the Range and Test selector switch to

20 mA (position 1) and repeat the process. If the output is 0 mA, make sure the power

supply is on and check for loose wires.

Range and Test Selection

When selecting one of the 6 available ranges, the baseline and maximum peak signals

that take place during lter cleaning must be taken into account. The selected ranges

should have enough resolution to monitor the baseline and capture the maximum

peaks during a cleaning cycle. The four linear ranges output 4 mA at 5 pA and 20 mA

at maximum range. The two logarithmic ranges have ner resolution at the low end of

the ranges and less at the high end.

Switch Position Range Output

1 Test 20 mA

2 Test 4 mA

3 5 to 100 pA 5 pA = 4 mA

4 5 to 500 pA 5 pA = 4 mA

5 5 to 1000 pA 5 pA = 4 mA

6 5 to 5000 pA 5 pA = 4 mA

7 Log 5 to 500 pA 5 pA = 4 mA

8 Log 5 to 5000 pA 5 pA = 4 mA

Note: Position 9 and 0 are unused.

Table 2: Range and Test Switch

25 pA = 8 mA

50 pA = 12 mA

75 pA = 16 mA

100 pA = 20 mA

125 pA = 8 mA

250 pA = 12 mA

375 pA = 16 mA

500 pA = 20 mA

250 pA = 8 mA

500 pA = 12 mA

750 pA = 16 mA

1000 pA = 20 mA

1250 pA = 8 mA

250 pA = 12 mA

3750 pA = 16 mA

5000 pA = 20 mA

16 pA = 8 mA

50 pA = 12 mA

158 pA = 16 mA

500 pA = 20 mA

28 pA = 8 mA

158 pA = 12 mA

890 pA - 16 mA

5000 pA = 20 mA

LOGARITHMIC RANGE

The logarithmic ranges offer a prolonged low-end of the scale while the high-end of the

range is compressed. This offers better resolution for the baseline monitoring and still

allows the operator to see the particulate spikes during cleaning cycles. Logarithmic

ranges are recommended for lter bags since they have a greater tendency for

particulate spikes during cleaning cycles.

LOGARITHMIC RANGE EQUATIONS

(M-4)

pA = 10 x R + 0.699

(

16

pA = Measured (pA) Picoamps

M = Measured (mA) Milliamps from the PMT2

R = 2 (for Logarithmic Range 5 to 500 pA)

R = 3 (for Logarithmic Range 5 to 5000 pA)

Example 1: Logarithmic Range 5 to 500 pA with current output of 12 mA:

(12-4)

pA = 10 x 2 + 0.699

(

16

pA = 50

Example 2: Logarithmic Range 5 to 5000 pA with current output of 14 mA:

(14-4)

pA = 10 x 3 + 0.699

(

16

pA = 375

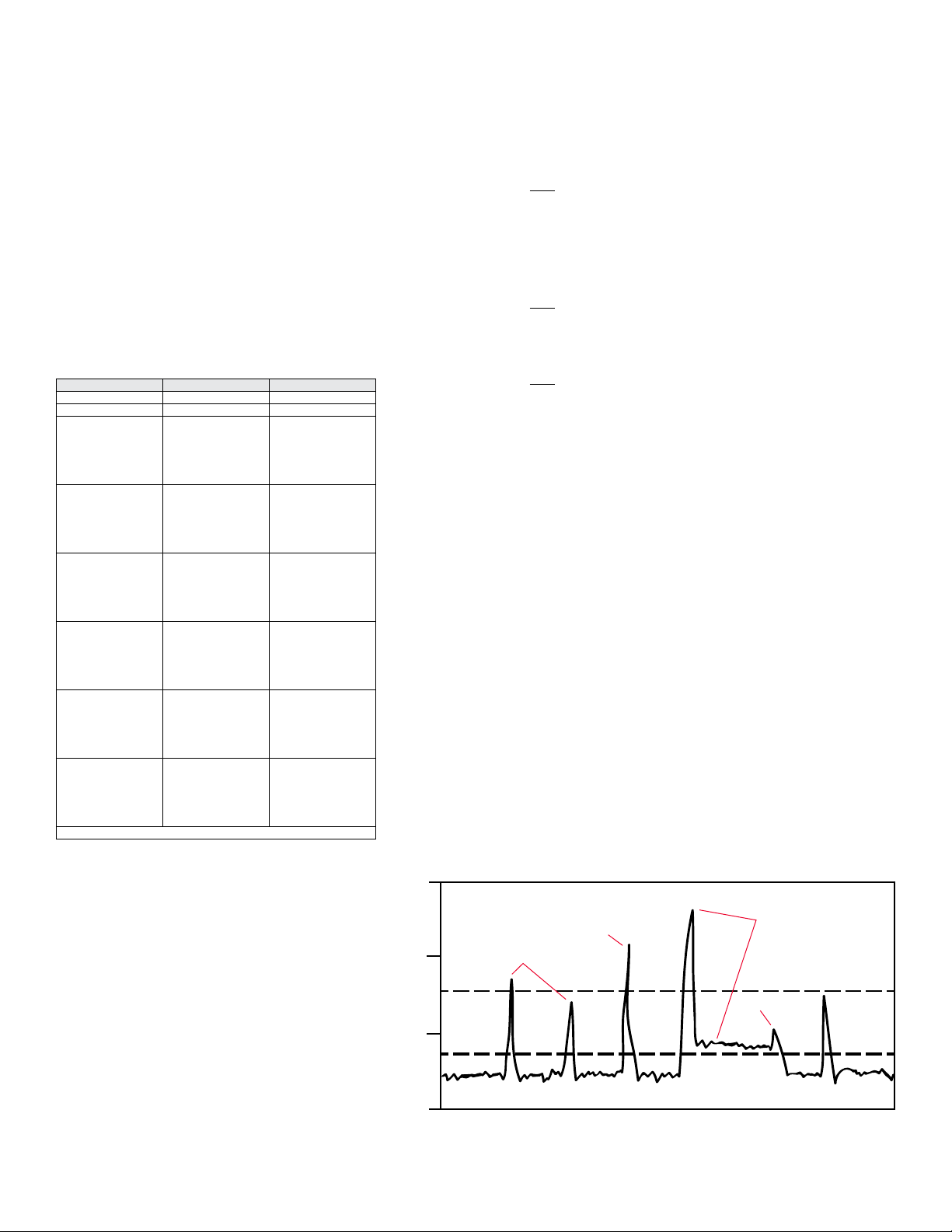

SETTING EMISSION LEVEL ALARMS

The PMT2 will provide a 4 to 20 mA signal based on the range selected at set up.

Alarms can be programmed in the PLC or control system based on the 4 to 20 mA

signal from the particulate transmitter.

It is suggested to set two alarm set points. One alarm set point to monitor the emission

spikes and the second alarm to detect an increase in the baseline.

The alarm monitoring the emission spikes should be set to identify changes in the

spikes caused by the cleaning cycles. As lters become worn, the spike’s height and

duration will increase. The emission spike frequency will also increase because the

lters will require more frequent cleaning as they wear out. If there is a continuous

output above the emission spike alarm, it is more than likely a lter has torn and should

be changed right away.

The baseline alarm should detect an increase in the baseline reading. The type of

dust collector and facility regulations will dictate where the baseline alarm has to be

set. Typically the baseline alarm should be set 4 to 5 times over the initial baseline

reading measurement when lters are rst installed. So, if the baseline is 10 pA the

base line alarm should be set between 40 pA and 50 pA. It is recommended to set a

time delay in the PLC or control panel alarm to prevent false alarms during cleaning

cycles. When the output signal from the PMT2 is continuously above baseline alarm

it is time to replace the lters. If the emission spikes have increased yet the baseline

remains unchanged, it’s an early indication that the lters are starting to wear out and

will need to be changed soon.

)

)

)

750 pA

Emission

500 pA

Baseline

Alarm

5 pA

Spikes caused

by cleaning

Increased spike

because of

filter wear

Figure 3: Typical Filter Emissions

Increased spike and

baseline because

of filter wear

Replaced

filters

AVERAGING SELECTION

The PMT2 offers a digital averaging function because of the irregular ow of particulates

and the spikes during cleaning cycles. There are ten options for averaging ranging

from 1 to 360 seconds. The digital averaging takes a running average of the readings

for the selected amount of time. This will dampen output spikes from particulate

uctuations that could trip alarm settings. It is important to select an averaging setting

that will allow the operator to see the cleaning cycles. It is recommended to monitor the

baseline trend and peak to peak trend between cleaning cycles.

ZERO CALIBRATION

Even though the PMT2 will come zeroed from the factory it is recommended to zero

the transmitter after installation to ensure the best accuracy. When zeroing the PMT2,

make sure the dust collector is shut down and there is no air ow in the duct, stack or

pipe the transmitter is monitoring. It is recommended to re-zero the PMT2 once every

12 months for optimal performance. Please check your local laws and regulations as

clean air standards may require zero calibration on a certain time schedule based

on application. There are two ways the PMT2 can be zeroed. The rst method is

with the zero button on the front of the transmitter. Press and hold the button for 3

seconds and the transmitter will begin zeroing. The second method is the remote zero.

Supply DC voltage as shown in Figure 4 across the zero terminals on the back of

the transmitter for at least 3 seconds for the transmitter to start zeroing. While the

transmitter is zeroing, the PMT2 will output about 3.5 mA. The zero function will take

approximately 3 minutes. When zeroing is complete the output will return to a normal

output signal and the transmitter is ready for operation.

Remote Zero

10 to 28 V

- +

Zero Switch

MAINTENANCE/REPAIR

Upon nal installation of the Series PMT2, no routine maintenance is required. The

Series PMT2 is not eld serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

Note: Do not zero the PMT2 while the dust collector is in operation.

Figure 4: Remote Zero and Zero Switch

Symptom Potential Source Corrective Action

High Output Loop Wiring Check for dirty or defective terminals,

Power Supply Check the output voltage of the power

Erratic Output Loop Wiring Check the output voltage of the power

Low or No Output Zeroing The PMT2 will output about 3.5 mA

Loop Wiring Check for intermittent shorts, open

Table 3: Troubleshooting

interconnecting pins or receptacles.

supply at the transmitter terminals. It

should be 9.5 to 28 VDC.

supply at the transmitter terminals. It

should be 9.5 to 28 VDC.

Check for intermittent shorts, open

circuits and multiple grounds.

Check the polarity at the signal

terminals.

while zeroing. Wait approximately 3

minutes and the 4 to 20 mA signal

should return to normal.

circuits and multiple grounds.

Check the polarity at the signal

terminals.

Check the loop impedance.

’

’

–––

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Partikeltransmitter Serie PMT2

2X 1/2˝(12,7 mm) NPT ODER M20

[15.88]

AUF BEIDEN SEITEN

[147.64]

®

Technische Daten – Installations- und Betriebsanleitung

Merkblatt PC-PMT2

GEWINDEMONTAGE

Sonde

LängeAin [mm]

3˝

3 [76.20]

5˝

5 [127.00]

10˝

10 [254.00]

15˝

15 [381.00]

20˝

20 [508.00]

30˝

30 [762.00]

36˝

36 [914.40]

MONTAGE TRI-CLAMP 1.5˝ (38 mm)

Sonde

LängeAin [mm]

3˝

3-1/2 [88.90]

5˝

5-1/2 [139.70]

10˝

10-1/2 [266.70]

15˝

15-1/2 [393.70]

20˝

20-1/2 [520.70]

30˝

30-1/2 [744.70]

36˝

36-1/2 [927.10]

Der Partikeltransmitter der SERIE PMT2 dient der Messung des Partikelausstoßes

von Entstaubern. Mittels einer direkt gekoppelten elektrostatischen

Induktionssensortechnologie überwacht der Transmitter einen pA-Strom, der entsteht,

wenn sich ein Partikel entlang der Sonde bewegt; das Signal beträgt je nach Stärke des

Partikels zwischen 4 und 20 mA. Der PMT2 bietet 6 Empndlichkeitsstufen, so dass der

Benutzer diejenige auswählen kann, die am besten zu seiner Anwendung passt. Auch

der Auswahlschalter für Messbereich und Tests kann auf ein Ausgabesignal von 4 mA

oder 20 mA eingestellt werden, wenn dies bei der Einrichtung oder Fehlerbehebung

hilfreich ist. Bei Bedarf lässt sich zur Dämpfung des Signals die Zeiteinstellung mitteln.

MERKMALE / VORZÜGE

• simple 2-Drahtmontage für SPS und Steuertafeln

• haftabweisende Sonde mit PTFE-Beschichtung gegen Falschmessungen an

feuchtem und leitfähigem Staub, Kondensat und Staubansammlungen

• durch Nullkalibrierung aus der Ferne verringert sich Wartungszeit

TABELLE

Beispiel PMT2 -05 -A -U2 PMT2-05-A-U2

Serie PMT2 Partikeltransmitter

Sondenlänge 03

Prozessanschluss A

Gehäuse A2U2ATEX und IECEx (IS)

Optionen STM2Kennzeichnung Edelstahl

*Optionen ohne ATEX- oder IECEx-Schutz

Achtung: Geräte ohne A2-Sufx sind nicht nach 2014/34/EC (ATEX) zertiziert.

Diese Geräte sind für den Einsatz in explosionsgefährdeten Räumen nicht

geeignet. Sie sind nur nach CE getestet.

05

10

15

20

30

36

B

C

B

in [mm]

1-25/32 [45.24]

3-25/32 [96.04]

8-25/32 [223.04]

13-25/32 [350.04]

18-25/32 [477.04]

28-25/32 [731.04]

34-25/32 [883.44]

Sondenlänge 3˝ (76.20 mm)

Sondenlänge 5˝ (127 mm)

Sondenlänge 10˝ (254 mm)

Sondenlänge 15˝ (381 mm)

Sondenlänge 20˝ (508 mm)

Sondenlänge 30˝ (762 mm)

Sondenlänge 36˝ (914 mm)

Außengewinde 3/4˝ (19 mm)

1.5˝ (38 mm)-Tri-clamp-Bausatz mit 1˝

(25 mm)-NPT-Außengewinde

3/4˝ (19 mm) BSPT-Gewinde

UL (IS)*

Sockel M20 elektrische Eingänge

(Sockel 1/2˝ (12.7 mm) NPT-

Standard)

5/8

Montage NPT-Außengewinde 3/4˝ (19 mm) ODER

ELECTRISCHER EINGANG

3/4˝ (19 mm) NPT oder

3/4˝ (19 mm) BSPT

“A”

3/4˝ (19 mm) Montage BSPT-Außengewinde

2X 1/2˝(12,7 mm) NPT ODER M20

ELECTRISCHER EINGANG

“B”

Montageoption Tri-Clamp 1.5˝ (38 mm)

3-29/32

[99.22]

3/4

[19.05]

1-1/2

[38.10]

1˝ (25 mm) NPT

“A”

TECHNISCHE DATEN

Wartung: Luft und kompatible Gase, alle Arten von Partikel leitend oder nicht

leitend.

Mediumberührende Teile: 316L SS, Silikon und PTFE.

Gehäuse: pulverbeschichtetes Aluminium.

Genauigkeit: ±5 % des Messwerts.

Partikelgröße: 0,3 Mikrometer und mehr.

Messbereich: 5 bis 5000 pA (6 auswählbare Messbereichsoptionen).

Temperaturbereich: Umgebungstemp.: -40 to 145 °F (-40 bis 63 °C);

Prozesstemp.: -40 bis 120 °F (-40 bis 248 °C).

Druckbereich: 30 bar (2 psi).

Signalausgabe: 4 bis 20 mA.

Leistungsbedarf: 12 bis 28 V Gleichstrom ( ).

Elektrischer Anschluss: Zwei 1/2˝ NPT-Außengewinde für elektrische Eingänge

oder zwei M20 elektrische Eingänge (A2 nur Sufx).

Klemmleiste: abnehmbar (Draht 16 bis 20 AWG).

Prozessanschluss: Siehe Tabelle. BSPT-Prozessanschlüsse sind nicht ULgelisted.

Sondenlängen: Siehe Tabelle.

Gehäuse: UL-Typ 4 (IP66) ATEX/IECEx IP65.

Montagerichtung: alle.

Mittelungszeit: 1 bis 360 s (10 auswählbare Optionen).

Gewicht: je nach Probenlänge und Art der Befestigung.

Zulassungen: CE, cULus; ATEX zertiziert: 0518 II 1 G Ex ia IIB T4 GA (-40°C

≤ Tamb ≤ 63°C) (-40°C ≤ T

(-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

16ATEX1768 X. ATEX-Standards: EN 60079-0:2012/A11:2013; EN 60079-11:2012.

IECEx Zertiziert: Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

/ Ex ia IIIC T120°C Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Konformitätszertikat: IECEx UL 16.013X. IECEx-Standards: IEC 60079-0: 2011;

IEC 60079-11: 2011. UL als eigensicher Klasse I, Gruppe C und D eingestuft;

Klasse II, Gruppe E, F und G; Klasse III; Klasse I Zone 0 AEx ia IIB T4 Ga; Klasse I

Zone 0 Ex ia IIB T4 Ga.

4-15/16

[125.41]

5-13/16

3-29/32

[99.22]

Prozess ≤ 120°C) / II 1 D Ex ia IIIC T120°C Da

Process ≤ 120°C). Zertikat Nr.: DEMKO

SPIELRAUM 1-1/4˝ (32 mm) [32]

FÜR ENTFERNUNG DER

ABDECKUNGEN

Prozess ≤ 120°C).

Prozess ≤ 120°C)

4-3/8

[111.13]

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, USA

Tel.: +1 - 219/879-8000

Fax: +1 - 219/872-9057

www.dwyer-inst.com

E-Mail: info@dwyermail.com

FUNKTIONSPRINZIP

Technologie

Der PMT2 verwendet eine höchst verlässliche direkt gekoppelte elektrostatische

Induktionssensortechnologie. Dabei wird die Sensorsonde in einem Luftstrom montiert

wie beispielsweise einer Leitung, einem Rohr oder Schacht. Der induktive Effekt tritt ein,

wenn sich ein Partikel an einer Sonde entlang bewegt, so dass die Ladung vom Partikel

auf die Sonde übertragen wird. Dabei ltert ein Mikroprozessor das Signal und wandelt es

in ein Ausgabesignal um, das sich linear zur Massenkonzentration des Partikels verhält.

Die beschichtete PTFE-Sonde gewährleistet bei allen Partikeln einen verlässlichen

Betrieb, einschließlich Feuchtpulver und hochleitfähiger Stäube. Dank der

beschichteten PTFE-Sonde wird keine Sperrluft benötigt und die Wartung auf ein

Mindestmaß beschränkt.

Partikelüberwachung

Der PMT2 ist speziell zur durchgängigen Überwachung des Partikelgehalts in

Luftströmen aus Schächten und anderen Ausstoßstellen ausgelegt, die durch einen Filter

in einer Luftlteranlage geleitet werden. Der Transmitter sollte im Abluftkanal montiert

werden und kann in Verbindung mit verschiedenen Arten von Beutel-, Keramik-, Kerzenoder Zyklonltern verwendet werden. Bei der Erstmontage des PMT2 eine Messung der

Grundlinie vornehmen und den Wert festhalten. Dieser Messwert richtet sich nach der

Anwendung und muss bei jeder Installation einzeln ermittelt werden. Auf der Grundlage

dieses Werts überwacht der Bediener das Ausgabesignal des PMT2. Ein Anstieg beim

mA-Wert des Ausgangssignals deutet auf einen erhöhten Partikelgehalt im Luftstrom

hin, weil die Filter entweder abgenutzt oder defekt sind.

Der PMT2 ist für ein proportionales Ausgabesignal auf der Grundlage des Partikelpegels

in Rohren und Leitungen ausgelegt, nicht jedoch für ein Ausgabesignal auf der Grundlage

des Partikelvolumenstroms. Verschiedene Partikelarten transportieren unterschiedliche

Ladungen, so dass zwei Partikel, die sich mit derselben Durchussgeschwindigkeit

bewegen, zwei verschiedene Ausgabesignale erzeugen können. Der PMT2 wurde

dazu entwickelt, unter idealen Betriebsbedingungen eine Grundlinie zu nden und

dem Bediener die Möglichkeit zu geben, das Ausgangssignal auf einen Anstieg zu

kontrollieren, die darauf hinweist, dass die Beutel oder Filter sich allmählich abnutzen

oder Schäden aufweisen. Durch die sechs Empndlicheitsstufen lassen sich mit dem

PMT2 sowohl Partikel mit niedriger als auch mit hoher Ladung überwachen. Zur

Orientierung sind in Tabelle 1 die Ladungseigenschaften und die empfohlenen Stufen

aufgeführt.

MONTAGE

Auspacken

Den PMT2 aus dem Versandkarton nehmen und auf Schäden untersuchen. Bei

eventuellen Schäden den Spediteur umgehend in Kenntnis setzen.

Montagestelle

Bei der Auswahl der Stelle, an der der PMT2 installiert werden soll, sind folgende

Punkte zu beachten:

• Darauf achten, dass der Transmitter für die Umgebung eingestuft ist, in der er

montiert werden soll.

• Den Transmitter an einer Stelle montieren, an der die in den technischen Daten

aufgeführten Temperatur- und Druckwerte nicht überschritten werden. Der

Prozessdruck darf 2 Bar (30 psi) nicht überschreiten.

• Darauf achten, dass die Signalkabel für 4 bis 20 mA nicht durch die gleiche Leitung

verlaufen wie die Starkstromkabel.

• Darauf achten, dass die Stelle, an der der Transmitter angebracht wird, den NEMAoder IP-Betriebswert für das Gehäuse erfüllt.

• Den Transmitter an einer Stelle anbringen, wo er im Wartungsfall erreichbar ist.

Der PMT2 sollte in einem geerdeten Metallschacht, -rohr oder einer geerdeten

Metallleitung montiert werden. Nicht an Schächten, Rohren oder Leitungen aus

Glasfaser oder Kunststoff anbringen. Zur Gewährleistung einer genauen Messung

muss die Sonde 1/2 bis 2/3 über den Schacht, das Rohr oder die Leitung reichen.

Am stabilsten und genausten sind die Messwerte, wenn der PMT2 an einer Stelle

montiert wird, an der der Luftstrom möglichst laminar ist. Den Transmitter möglichst

nicht in der Nähe von Ventilatoren und Luftklappen montieren, die Turbulenzen

verursachen. Idealerweise sollte der PMT2 in einem Bereich mit zwei vorgelagerten

Rohrdurchmessern und einem nachgelagerten Rohrdurchmesser montiert werden,

die frei von Turbulenzen hervorrufenden Gegenständen sind. Die Sensorsonde ist mit

einem haftabweisenden PTFE beschichtet, so dass kein Material an der Sonde haften

bleibt, wodurch sich der Reinigungs- und Luftspülaufwand verringert.

neutral

Partikel Empfohlene Stufe

Menschenhände

Asbest

Kaninchenfell

Azetat

Glas

Glimmer

Menschenhaar

Nylon

positivnegativ

Holz

Fell

Blei

Seide

Aluminium

Papier

Baumwolle

Stahl

Holz

Mylar™

Nickel / Kupfer

Silber / Messing

Gold / Platin

Schwefel

Azetatseide

Polyester

Styren (Styropor)

Acryl

Saran™

Polyurethan

Polyethylen

Polypropylen

Vinyl (PVC)

Silikon

PTFE

Silikonkautschuk

Tabelle 1: empfohlene Stufen

5 bis 5000 pA

5 bis 1000 pA

5 bis 500 pA

5 bis 100 pA

5 bis 500 pA

5 bis 1000 pA

5 bis 5000 pA

VERKABELUNG

E

NULLABGLEICH

AUS DER FERN

ACHTUNG

• Bei Montage und Wartung des Geräts die Netzspannung

stets ausschalten und bei Bedarf den Sperrschalter betätigen

• Bei Leitungs- und Lastanschlüssen nur Draht mit 16 bis 20 AWG verwenden. Bei

der Montage die vor Ort geltenden Vorschriften und Gesetze wie den National Electric

Code beachten.

• Schutzstufe TYPE 4 (IP66) ist gewährleistet, wenn passende Anschlüsse und

Stecker gemeinsam mit UL-gelisteten Modellen verwendet werden.

WARNHINWEIS

GEFAHRENSTELLEN

Damit sich Gefahrenstellen nicht entzünden, sind

folgende Vorkehrungen zu treffen:

• Geräteabdeckungen während des Betriebs fest geschlossen halten.

• Vor dem Öffnen der Geräteabdeckung die Stromversorgung ausschalten.

• Vor dem erneuten Einschalten der Stromversorgung die Geräteabdeckungen wieder

aufsetzen.

• Das Gerät lässt sich nicht vor Ort reparieren und muss deshalb im Reparaturfall an

Dwyer Instruments geschickt werden.

WARNHINWEIS

SPEZIFISCHE NUTZUNGSBEDINGUNGEN BEZÜGLICH

EIGENSICHERHEIT

Zur Aufrechterhaltung der Eigensicherheit sind folgende

Vorsichtsmaßnahmen zu ergreifen:

• Signal von 4-20 mA und der Nullabgleich aus der Fernen müssen als zwei getrennte

Schaltkreise behandelt werden.

• Die Bauteile des Gehäuses bestehen aus Aluminum. Das Gehäuse muss vor

Brandgefahr durch Stoßeinwirkung oder Reibung geschützt werden.

• Alle Gehäuseöffnungen müssen mit passenden Anschlüssen und Steckern

abgedichtet sein, die mindestens der IP-Schutzklasse IP66 für UL-gelistete Modelle

und IP65 für ATEX/IECEz zertizierte Modelle entsprechen.

• Durch den Austausch von Bauteilen wird die Eigensicherheit gefährdet.

STEUERPLAN UL-GELISTETE EIGENSICHERHEIT (ENDUNG U2):

UL als eigensicher eingestuft für Gebrauch in Klasse I Unterklasse 1 Gruppe C und D; Klasse

II Unterklasse 1 Gruppe E, F und G; Klasse III Unterklasse. 1; Klasse I Zone 0 AEx ia IIB T4

Ga; Klasse I Zone 0 Ex ia IIB T4 Ga; T4@63°C, sofern Installation in Übereinstimmung mit

Steuerplan 001744-48 auf Seite 6 des vorliegenden Dokuments erfolgt ist.

ATEX ZERIFIZIERT (SUFFIX A2)

II 1 G Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

IIIC T120°C Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Process ≤ 120°C) / II 1 D Ex ia

Process ≤ 120°C), sofern Installation in

Übereinstimmung mit Steuerplan 001744-81 auf Seite 7 dieses Dokuments erfolgt ist.

IECEx ZERIFIZIERT (SUFFIX A2)

Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

T120°C Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Process ≤ 120°C) / Ex ia IIIC

Process ≤ 120°C), sofern Installation in

Übereinstimmung mit Steuerplan 001744-81 auf Seite 7 dieses Dokuments erfolgt ist.

EINGABEPARAMETER EIGENSICHERHEIT:

Signal 4-20 mA, Vmax (Ui) = 28 V; Imax (li) = 93 mA; Ci = .022 μF; Li = 0.373 mH;

Pmax (Pi) = 651 mW

Nullabgleich aus der Ferne, Vmax (Ui) = 28 V; Imax (li) = 93 mA; Ci = vernachlässigbar;

Li = 0 mH; Pmax (Pi) = 651 mW

LEISTUNGSBEDARF

Die maximale Netzspannung beträgt 28 V Gleichstrom. Die erforderliche

Gleichstromversorgung basiert auf folgenden Werten:

1. Minimale Gleichspannung für Modell PMT2.

2. Gesamtlastwiderstand.

3. Gesamtwiderstand der Anschlussleitung.

4. Spannungsabfall Zener-Schranke (nur Modell PMT2-XX-X-X2).

Die Formel zur Berechnung der Gleichstromversorgung lautet:

V (Gleichstrom) = VPMT2 + VLOAD + VLEADWIRE + VBARRIER

wobei VPMT2 = 9,5 V

VLOAD = Gesamtlastwiderstand X 20 mA

VLEADWIRE = Gesamtwiderstand der Anschlussleitung X 20 mA

VBARRIER = 8.1 V (bei dieser Anwendung typischer Spannungsabfall bei Zener-

Schranke)

Beispiel 1: Minimale Gleichstromversorgung für eigensichere Modelle

berechnen

Schritt 1 VPMT2 = 9,5 V

Schritt 2 VLOAD berechnen. Dabei Umrechnungswiderstand der Branchennorm

von 250 Ω, VLOAD = 250 X 20 mA = 5 V verwenden.

Schritt 3 VLEADWIRE berechnen. Für dieses Beispiel ausgehen von einem

Gesamtwiderstand der Anschlussleitung von 10 Ω, VLEADWIRE = 10 X

20 mA = 0.2 V

Schritt 4 VBARRIER = 8.1 V

Schritt 5 VDC = VPMT2 + VLOAD + VLEADWIRE + VBARRIER = 9.5 + 5 + 0.2 +

8.1 = 22.8 V

STEUERELEMENTE

WARNHINWEIS

WARTUNG BEI LAUFENDEM BETRIEB

Bei Vorliegen einer entzündlichen oder ammbaren Atmosphäre

dürfen keine Wartungsarbeiten an Nullabgleich, Mittelungszeit,

Stufen und Teststeuerungen bei laufendem Betrieb vorgenommen werden.

Nullschalter (siehe Abbildung 2)

Den Schalter 3 lang gedrückt halten, so dass sich der PMT2 einen digitalen Nullabgleich

durchführt. Nach einem Funktionsausfall oder Austausch des Filters empehlt sich ein

erneuter Nullabgleich. Einen erneuten Nullabgleich nur dann durchführen, wenn keine

Luft durch die Leitung strömt.

Auswahlschalter Mittelungszeit

Der PMT2 mittelt das Ausgangssignal über den angegebenen Zeitraum. So werden

Spitzen ausgeglichen, die beim normalen Filterreinigungszyklus auftreten.

Auswahlschalter Stufen und Test

Je nach aufzuspürendem Material stehen bei der Messung mit dem 6 PMT2

Empndlichkeitsstufen zur Auswahl (siehe Tabelle 1). Ferner gibt es die Option eines

Ausgabesignals von 4 mA oder 20 mA, welche bei der Montage des Transmitters und

bei der Fehlerbehebung hilfreich sein können.

RECEIVER

SCHALTER FÜR NULLABGLEICH AUS DER FERN

(WENN VERWENDET)

4 bis 20 mA.

4

3

2

1

E

Abbildung 1: allgemeine Montageverkabelung (nicht IS)

NETZVERSORGUNG

Mittelungszeit

Erdungsschraube

Abbildung 2

Nullschalter

Stufen und

Tes ts

ENRICHTUNG

1000 pA

Emissionsspitzenalar

Montage

Damit es während des Betriebs nicht zu Vibrationen kommt, darauf achten, dass der

PMT2 fest am Schacht, Rohr oder an der Leitung angebracht ist. Dafür sorgen, dass

der Transmitter korrekt geerdet ist.

Einrichtung des Steuersignals

Verkabelung der Stromversorgung auf korrekte Polarität kontrollieren, bevor Sie die

Stromzufuhr zum PMT2 einschalten. Die Stromzufuhr zum Transmitter einschalten

und den Auswahlschalter für Stufen und Tests auf 4 mA (Position 2) stellen. Das

Ausgabesignal des PMT beträgt normalerweise 4 mA; das Ausgabesignal mit

Mehrfachmessgerät oder an dem Gerät kontrollieren (SPS, Anzeige usw.), das das

Ausgabesignal empfängt. Sobal der Empfang des Signals von 4 mA bestätigt ist,

den Auswahlschalter für die Stufen und Tests auf 20 mA (Position 1) stellen und den

Vorgang wiederholen. Bei einem Signal von 0 mA kontrollieren, ob die Stromversorgung

eingschaltet ist und eventuell Drähte locker sitzen.

LOGARITHMISCHE STUFE

Bei den logarithmischen Stufen ist das untere Ende des Skala verlängert und das

obere Ende komprimiert. So hat der Bediener die Möglichkeit, die Grundlinie

in einer besseren Auösung zu überwachen und gleichzeitig die Spitzen beim

Reinigungszyklus im Auge zu behalten. Die logarithmischen Stufen empfehlen sich

bei Filterbeuteln, da diese eine größere Wahrscheinlichkeit von Partikelspitzen bei der

Reingung aufweisen.

BERECHNUNGEN LOGARITHMISCHE STUFE

(M-4)

pA = 10 x R + 0,699

(

16

pA = gemessene Pikoampere (pA)

M = am PMT2 gemessene Milliampere (mA)

R = 2 (für logarithmische Stufe 5 bis 500 pA)

R = 3 (für logarithmische Stufe 5 bis 5000 pA)

)

Auswahl von Stufen und Tests

Bei Auswahl einer der 6 verfügbaren Stufen müssen die Grundlinie und die maximalen

Spitzensignale beachtet werden, die während der Filterreinigung auftreten. Die

ausgewählte Stufe muss eine ausreichende Auösung aufweisen, um die Grundlinie zu

überwachen und die maximale Spitze bei einem Reinigungszyklus zu erfassen. Die vier

linearen Stufen entsprechen einem Ausgangssignal von 4 mA bei 5 pA und 20 mA auf

der Höchststufe. Die zwei logarithmischen Stufen verfügen über eine feinere Auösung

am niedrigeren Ende der Stufe und weniger am höheren Ende.

Schalterposition Stufe Signalausgabe

1 Test 20 mA

2 Test 4 mA

3 5 bis 100 pA 5 pA = 4 mA

4 5 bis 500 pA 5 pA = 4 mA

5 5 bis 1000 pA 5 pA = 4 mA

6 5 bis 5000 pA 5 pA = 4 mA

7 Log 5 bis 500 pA 5 pA = 4 mA

8 Log 5 bis 5000 pA 5 pA = 4 mA

Hinweis: Position 9 und 0 sind ungenutzt.

Tabelle 2: Auswahlschalter Stufen und Test

25 pA = 8 mA

50 pA = 12 mA

75 pA = 16 mA

100 pA = 20 mA

125 pA = 8 mA

250 pA = 12 mA

375 pA = 16 mA

500 pA = 20 mA

250 pA = 8 mA

500 pA = 12 mA

750 pA = 16 mA

1000 pA = 20 mA

1250 pA = 8 mA

250 pA = 12 mA

3750 pA = 16 mA

5000 pA = 20 mA

16 pA = 8 mA

50 pA = 12 mA

158 pA = 16 mA

500 pA = 20 mA

28 pA = 8 mA

158 pA = 12 mA

890 pA = 16 mA

5000 pA = 20 mA

750 pA

Beispiel 1: Logarithmischer Bereich von 5 bis 500 pA bei Ausgangsstrom von 12 mA:

(12-4)

pA = 10 x 2 + 0,699

(

16

pA = 50

Beispiel 2: Logarithmischer Bereich von 5 bis 5000 pA bei Ausgangsstrom von 14 mA:

(14-4)

pA = 10 x 3 + 0,699

(

16

pA = 375

EINSTELLUNG DER EMISSIONSPEGELALARME

Der PMT2 stellt ein Signal zwischen 4 und 20 mA bereit, je nachdem, welche

Stufe bei der Einrichtung ausgewählt wurde. Alarme können in einer SPS oder

Steuerungsanlage auf der Grundlage des Signals von 4 bis 20 mA aus dem

Partikeltransmitter programmiert werden.

Es empehlt sich, zwei Alarmsollwerte einzustellen. Dabei überwacht ein Sollwert die

Emissionsspitzen und der zweite den Anstieg der Grundlinie.

Der Alarm zur Überwachung der Emissionsspitzen sollte so eingestellt sein, dass er

Änderungen bei den Spitzen erfasst, die durch die Reinigungszyklen entstehen. Bei

Abnutzung der Filter nehmen Höhe und Dauer der Spitzen zu. Auch die Häugkeit der

Emissionsspitzen wird größer, da die Filter bei Abnutzung häuger gereinigt werden

müssen. Liegt die Signalausgabe durchgehend oberhalb des Emissionsspitzenalarms,

ist der Filter höchstwahrscheinlich defekt und sollte umgehend ausgetauscht werden.

Der Grundlinienalarm misst wahrscheinlich einen Anstieg des Grundlinienwerts. Wo

der Grundlinienalarm eingestellt wird, richtet sich nach der Art des Staublters und

nach den Vorschriften der Einrichtung. Normalerweise wird bei der Erstinstallation

der Filter der Grundlinienalarm beim 4- bis 5-Fachen des zuerst gemessenen

Grundlinienwerts eingestellt. Beträgt also die Grundlinie 10 pA, ist der Grundlinienalarm

auf 40 pA bis 50 pA einzustellen. Damit während der Reinigungszyklen kein falscher

Alarm ausgelöst wird, empehlt es sich, in der SPS oder der Steuerstafel eine

Zeitverzögerung einzustellen. Wenn das Ausgangssignal des PMT2 durchgängig über

dem Grundlinienalarm liegt, ist es Zeit für einen Filterwechsel. Eine Zunahme der

Emissionsspitzen bei gleichzeitig unveränderter Grundlinie deutet darauf hin, dass die

Filter sich allmählich abnutzen und bald ausgewechselt werden müssen.

Spannungsspitze

durch Reinigung

)

)

höhere Spannungsspitze

durch Filterabnutzung

höhere Spannungsspitze

und Grundlinie durch

Filterabnutzung

500 pA

Grundlinienalarm

5 pA

m

Filteraustausch

ZEITVERLAUF

Abbildung 3: Typische Filteremissionen

MITTELUNGSAUSWAHL

Aufgrund des unregelmäßigen Partikelstroms und der Spitzen während der

Reinigungszyklen bietet der PMT2 eine digitale Mittelungsfunktion. Zur Mittelung stehen

zehn Optionen zwischen 1 und 360 Sekunden bereit. Mit der digitalen Mittelungsfunktion

wird über den angegebenen Zeitraum der laufende Durchschnitt der Messwerte ermittelt.

So werden Spitzen ausgeglichen, die infolge von Partikelschwankungen auftreten und

den Alarm auslösen können. Dabei ist es wichtig, die Mittelung so einzustellen, dass der

Bediener die Reinigungszyklen sehen kann. Zwischen den Reinigungszyklen empehlt es

sich, die Bewegung der Grundlinie und die Tendenz zwischen den Spitzen zu überwachen.

NULLKALIBRIERUNG

Zwar wird der PMT2 kalibriert geliefert; dennoch empehlt es sich, nach der Montage

einen Nullabgleich vorzunehmen, um eine optimale Genauigkeit zu gewährleisten.

Beim Nullabgleich des PMT2 sicherstellen, dass der Staublter ausgeschaltet ist und

keine Luft durch die zu überwachende Leitung, das Rohr oder den Schacht strömt.

Zwecks optimaler Leistung den PMT2 einmal alle 12 erneut kalibrieren. Bitte die vor Ort

geltenden Gesetze und Vorschriften beachten, da je nach Anwendung möglicherweise

Nullkalibrierungen nach einem bestimmten Zeitplan erfolgen müssen. Der Nullabgleich

am PMT2 kann auf zwei Arten vorgenommen werden. Die erste Möglichkeit ist der

Nullschalter vorn am Transmitter. Dazu den Schalter 3 lang gedrückt halten, so dass der

Transmitter einen Nullabgleich durchführt. Die zweite Methode ist der Nullabgleich aus

der Ferne. Wie in Abbildung 4 die Nullklemmleisten auf der Rückseite des Transmitters

mindestens 3 Sekunden mit Gleichstrom versorgen, so dass der Transmitter mit dem

Nullabgleich beginnt. Während des Nullabgleichs gibt der PMT2 ein Signal von circa

3,5 mA aus. Der Nullabgleich dauert circa 3 Minuten. Nach Abschluss des Nullabgleichs

normalisiert sich das Ausgangssignal, und der Transmitter ist einsatzbereit.

Nullabgleich aus der Ferne

10 bis 28 V

WARTUNG / REPARATUR

Im Anschluss an die Montage der Serie PMT2 ist keine Routinewartung erforderlich.

Die Serie PMT2 lässt sich nicht vor Ort warten und muss deshalb im Reparaturfall

eingeschickt werden. Keine Reparatur vor Ort vornehmen, da dadurch die

Gewährleistung aufgehoben wird.

GEWÄHRLEISTUNG / EINSENDUNG

Siehe „Allgemeine Vertriebsbedingungen“ in unserem Katalog und auf der Website.

Bevor Sie das Produkt zur Reparatur einschicken, holen Sie sich bitte beim

Kundendienst eine Warenrücksendenummer. Fügen Sie außerdem eine kurze

Erläuterung des Problems sowie zusätzliche Anmerkungen bei.

- +

Anmerkung: Keinen Nullabgleich des PMT2 durchführen, wenn der Staublter in

Abbildung 4: Nullabgleich aus der Ferne und Nullschalter

Symptom Mögliche Ursache Korrekturmaßnahme

Hohes Signal Verkabelung Anschlussklemmen, Verbindungsstifte

Netzversorgung Die Ausgangsspannung der

Unregelmäßiges

Signalausgabe

Geringes oder kein

Ausgabesignal

Verkabelung Die Ausgangsspannung der

Nullstellung Während des Nullabgleichs gibt der

Verkabelung Auf zwischenzeitliche Kurzschlüsse,

Betrieb ist.

und Steckdosen auf Schmutz und

Defekte kontrollieren.

Stromversorgung an den Klemmleisten

des Transmitters kontrollieren.

Sie muss zwischen 9,5 und 28 V

(Gleichstrom) betragen.

Stromversorgung an den Klemmleisten

des Transmitters kontrollieren.

Sie muss zwischen 9,5 und 28 V

(Gleichstrom) betragen.

Auf zwischenzeitliche Kurzschlüsse,

offene Schaltkreise und

Mehrfacherdung untersuchen.

Polarität der Signalanschlussklemmen

prüfen.

PMT2 ein Signal von circa 3,5 mA aus.

Circa 3 Minuten warten, bis das Signal

wieder in ein normales Signal ausgibt,

d.h. zwischen 4 und 20 mA.

offene Schaltkreise und

Mehrfacherdung untersuchen.

Polarität der Signalanschlussklemmen

prüfen.

Schleifenwiderstand kontrollieren.

Tabelle 3: Fehlerbehebung

Nullschalter

’

’

–––

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, USA

Tel.: +1 - 219/879-8000

Fax: +1 - 219/872-9057

www.dwyer-inst.com

E-Mail: info@dwyermail.com

Sonde-émetteur à particules série PMT2

2X ENTRÉE ÉLECTRIQUE 1/2 po (12,7 mm)

[15.88]

DU COUVERCLE

®

Spécications - Installation et mode d'emploi

Bulletin PC-PMT2

La sonde-émetteur à particules SÉRIE PMT2 est prévu pour mesurer les taux

d'émission de particules à la sortie des ltres à poussière. La sonde-émetteur utilise

une technologie de détection à induction électrostatique couplée en CC pour mesurer

un courant en pA généré lorsque les particules passent à proximité de la sonde ; un

signal entre 4 et 20 mA varie selon le taux de particules. Le PMT2 propose 6 plages

de sensibilité pour permettre à l'utilisateur de choisir la plage qui correspond le mieux

à son utilisation. Le sélecteur de plage et de test peut également être positionné pour

envoyer un signal de 4 mA ou 20 mA pour aider au paramétrage ou à la recherche

de panne. Le paramétrage du calcul de temps moyen peut être utilisé pour lisser le

signal si nécessaire.

FONCTIONNALITÉS/AVANTAGES

• Installation simple à 2 câbles pour le PLC et les panneaux de contrôle.

• Une sonde recouverte de PTFE antiadhésif pour éviter les lectures faussées à cause

de l'humidité et des poussières conductrices, la condensation et l'accumulation de

poussière,

• La réinitialisation à distance permet de réduire le temps de maintenance

TABLEAU DU MODÈLE

Exemple PMT2 -05 -A -U2 PMT2-05-A-U2

Séries PMT2 Émetteur-sonde à particules

Longueur de sonde 03

Processus de

raccordement

Indice de protection

du boîtier

Options STM2Etiquette en acier inoxydable

* Options qui ne sont pas homologuées ATEX ou IECEx.

Attention : Les unités qui ne comportent pas le marquage A2 ne satisfont pas aux

exigences de la Directive 2014/34/EC (ATEX). Ces unités ne sont pas conçues

pour une utilisation en atmosphère potentiellement dangereuses au sein de l'Union

Européenne. Ces unités peuvent être estampillées CE pour d'autres Directives de

l'Union Européenne.

BAGUE DE

RACCORDEMENT FILETÉE

Sonde

LongueurApo [mm]

3 po

5 po

10 po

15 po

20 po

30 po

36 po

BAGUE DE RACCORDEMENT À TROIS

BROCHES 1,5 po (38 mm)

Sonde

LongueurApo [mm]

3 po

5 po

10 po

15 po

20 po

30 po

36 po

05

10

15

20

30

36

A

B

C

A2

U2

3 [76.20]

5 [127.00]

10 [254.00]

15 [381.00]

20 [508.00]

30 [762.00]

36 [914.40]

B

3-1/2 [88.90]

5-1/2 [139.70]

10-1/2 [266.70]

15-1/2 [393.70]

20-1/2 [520.70]

30-1/2 [744.70]

36-1/2 [927.10]

3 po (76.20 mm) longueur de sonde

5 po (127 mm) longueur de sonde

10 po (254 mm) longueur de sonde

15 po (381 mm) longueur de sonde

20 po (508 mm) longueur de sonde

30 po (762 mm) longueur de sonde

36 po (914 mm) longueur de sonde

Raccord mâle NPT 3/4 po (19 mm)

Kit trois broches 1,5 po (38 mm) avec

raccord mâle NPT 1 po (25 mm)

Raccord mâle NPT 3/4 po (19 mm)

ATEX et IECEx (IS)

UL (IS)*

Entrées électriques femelles M20

(femelle 1/2 po (12,7 mm) NPT standard)

po [mm]

1-25/32 [45.24]

3-25/32 [96.04]

8-25/32 [223.04]

13-25/32 [350.04]

18-25/32 [477.04]

28-25/32 [731.04]

34-25/32 [883.44]

NPT OU M20

NPT 3/4 po (19 mm) ou

BSPT 3/4 po (19 mm)

5/8

Bague de raccordement mâle NPT 3/4 po

2X ENTRÉE ÉLECTRIQUE 1/2 po (12,7 mm)

NPT OU M20

“A”

(19 mm) ou mâle BSPT 3/4 po (19 mm)

“B”

“A”

Bague de raccordement à trois broches

1,5 po (38 mm)

SPÉCIFICATIONS

Service : Air et gaz compatibles, tout type de particules conductrices ou nonconductrices.

Matériaux mouillés : 316L SS, silicone, et PTFE.

Boîtier : Aluminium recouvert d'une couche conductrice.

Précision : ±5% du résultat.

Taille des particules : 0,3 microns et plus.

Plage de détection : 5 à 5000 pA (6 options de plage possibles).

Limites de température : ambiante : -40 à 145°F (-40 à 63°C) ; en fonction : -40 à

248°F (-40 à 120°C).

Limite de pression : 2 psi (30 bar).

SIgnal en sortie : 4 à 20 mA.

Puissance électrique nécessaire : 12 à 28 VCC ( ).

Raccordement électrique : Deux entrés électriques femelles 1/2 po (12,7 mm)

NPT ou deux entrées électriques M20 (marquage A2 uniquement).

Bornier : Amovible (câble de 16 à 20 AWG).

Processus de raccordement : Voir le tableau du modèle. Les processus de

raccordement BSPT ne sont pas enregistrés UL.

Longueurs de sonde : Voir le tableau du modèle.

Indice de protection du boîtier : UL Type 4 (IP66) ATEX/IECEx IP65.

Orientation de montage : Indifférente.

Durée moyenne : 1 à 360 s (10 options possibles).

Poids : Variable selon la longueur de la sonde et le type de raccord.

Homologations : CE, cULus; conforme ATEX: 0518 II 1 G Ex ia IIB T4 GA

(-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

(-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

16ATEX1768 X. Normes ATEX : EN 60079-0:2012/A11:2013; EN 60079-11:2012.

Certié IECEx : Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Ex ia IIIC T120°C Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Certicat de conformité : IECEx UL 16.013X. Normes IECEx : IEC 60079-0: 2011;

IEC 60079-11: 2011. Enregistré UL comme intrinsèquement sûr pour la classe I,

groupes C et D ; la classe II, groupes E, F et G ; la classe III ; la classe I zone 0

AEx ia IIB T4 Ga ; la classe I zone 0 Ex ia IIB T4 Ga.

[19.05]

1-1/2

[38.10]

1 po (25 mm)

NPT

3/4

5-13/16

[147.64]

4-15/16

[125.41]

3-29/32

[99.22]

3-29/32

[99.22]

Process ≤ 120°C) / II 1 D Ex ia IIIC T120°C Da

Process ≤ 120°C). Certicat n° : DEMKO

PRÉVOIR 1-1/4 po (32 mm) [32]

POUR LE RETRAIT

DES DEUX CÔTÉS

Process ≤ 120°C).

Process ≤ 120°C) /

4-3/8

[111.13]

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, États-Unis.

Téléphone : +1 219/879-8000

Fax : +1 219/872-9057

www.dwyer-inst.com

courriel : info@dwyermail.com

PRINCIPE DE FONCTIONNEMENT

Technologie

Le PMT2 utilise une technologie de détection à induction électrostatique couplée

en CC extrêmement able. La sonde de détection est installée sur un passage d'air

comme un tuyau, une conduite ou cheminée. L'effet d'induction se produit lorsque des

particules passent à proximité de la sonde transférant une charge de la particule à la

sonde. Un microprocesseur ltre et traite le signal pour renvoyer un résultat linéaire de

la concentration globale en particules.

La sonde recouverte de PTFE garanti un fonctionnement able avec tous les types de

particules y compris les poudres humides et les poussières hautement conductrices. La sonde

recouverte de PTFE élimine la nécessité de purge d'air et permet une maintenance minimum.

Surveillance des particules

Le PMT2 est spécialement conçu pour surveiller les niveaux de particules en continu

dans le ux d'air des cheminées ou autres points d'émission après le passage à travers

le ltre d'un système de ltration de l'air. L'émetteur doit être installé dans le conduit

d'évacuation et peut être utilisé conjointement avec différent types de ltres à sac,

céramique, à cartouche ou cyclonique. Lors de la première installation du PMT2 une

mesure du niveau de référence moyen doit être effectuée et enregistrée. Cette mesure

du niveau de référence dépend de l'utilisation et doit être mesurée indépendamment

pour chaque installation. L'opérateur surveillera le signal en sortie du PMT2 par rapport

à ce niveau de référence. L'élévation du signal en mA indique un niveau de particules

en augmentation dans le ux d'air qui signie que les ltres sont soit usagés soit brisés.

Le PMT2 est prévu pour donner un signal proportionnel basé sur le niveau de particules

dans une conduite ou un tuyau, it n'est pas prévu pour sortir un signal basé sur le ux

volumétrique de particules. Les différents types de particules transportent différentes

charges, ce qui signie que deux particules transportées au même débit volumétrique

pourraient donner lieu à un signal différent. Le PMT2 est prévu pour identier un niveau

de référence dans les conditions de fonctionnement idéales et permettre à l'opérateur

de surveiller les hausses du signal en sortie qui signieraient que les sacs ou les ltres

commencent à se dégrader ou à se briser. Les six plages de sensibilité permettent au PMT2

de surveiller aussi bien des particules à charge basse que des particules à charge haute.

Á titre de référence, le tableau 1 liste les charges des particules et les plages suggérées.

INSTALLATION

Déballage

Retirer le PMT2 de son carton de transport et vérier l'absence de dommage. En cas

de dommage, informez immédiatement le transporteur.

Emplacement

Les facteurs suivant doivent être pris en compte pour déterminer l'emplacement de

l'installation du PMT2 :

• Vérier que l'émetteur est adapté pour la classication de la zone où il sera installé.

• Installer l'émetteur à un emplacement qui ne dépassera pas les niveaux de

température et de pression gurant dans les caractéristiques. La pression en

fonctionnement ne doit pas dépasser 30 psi (2 bar)

• Vérier que les câbles de 4 à 20 mA ne sont pas installés dans la même gaine que

les câbles haute tension.

• Vérier que l'emplacement où l'émetteur est installé est conforme aux niveaux

NEMA et IP pour le boîtier.

• Installer l'émetteur à un endroit où il peut être facilement accessible si un entretien

est nécessaire

Le PMT2 doit être monté dans une cheminée , un tuyau ou une conduite métallique

stabilisé. Il ne doit pas être monté sur des cheminées, tuyaux ou conduites en

plastique ou en bre de verre. La sonde de détection doit se situer entre 1/2 et 2/3

de la longueur de la cheminée, tuyau ou conduite pour assurer des résultats précis.

Pour les résultats les plus ables possibles il est recommandé d'installer le PMT2

dans un endroit où le ux d'air est aussi laminaire que possible. Eviter de monter

l'émetteur à proximité de souferies et de régulateurs qui causent des turbulences.

Idéalement, monter le PMT2 dans une zone avec deux diamètres de conduite de ux

montant et un diamètre de conduite de ux descendant, libres de tout objet pouvant

causer des turbulences. La sonde de détection est en PTFE antiadhésif pour éviter

que des matières ne recouvrent la sonde, réduisant la nécessité de nettoyage ou de

purge d'air.

Neutre

Particules Plage suggérée

Mains humaines

Amiante

Fourrure de lapin

Acétate

Verre

Mica

Poils humains

Nylon

PositifNégatif

Bois

Fourrure

Plomb

Soie

Aluminium

Papier

Coton

Acier

Bois

Mylar™

Nickel/cuivre

Argent/laiton

Or/platine

Souffre

Acétate de cellulose

Polyester

Styrène (mousse de

polystyrène)

Acrylique

Saran™

Polyuréthane

Polyéthylène

Polypropylène

Vinyle (PVC)

Silicone

PTFE

Gomme de silicone

Tableau 1 : plages suggérées

5 à 5000 pA

5 à 1000 pA

5 à 500 pA

5 à 100 pA

5 à 500 pA

5 à 1000 pA

5 à 5000 pA

CÂBLAGE

ANCE

RÉINITIALISA

À DIST

AVIS

• Toujours installer ou entretenir le dispositif en position hors

tension et installer un verrou de déconnection si nécessaire

• Utiliser uniquement des câbles en cuivre de 16 à 20 AWG pour les connections de

ligne et de charge. L'installation doit être effectuée en conformité avec les codes et les

règlementations locales tels que le Code Électrique National

• Le degré de protection TYPE 4 (IP66) est maintenu lorsque les prises/écrous

adaptés sont utilisés avec les modèles enregistrés UL.

AVERTISSEMENT

EMPLACEMENTS Á RISQUE

Les précautions suivantes doivent être prises pour

éviter l'embrasement d'emplacements à risque :

• Toujours laisser le couvercle du dispositif solidement fermé pendant le fonctionnement

• Mettre le circuit hors tension avant d'ouvrir le couvercle du dispositif

• Replacer le couvercle du dispositif avant de remettre le circuit électrique sous tension

• Le dispositif ne peux pas être réparé par l'utilisateur et doit être renvoyé à Dwyer

Instruments si une réparation est nécessaire

AVERTISSEMENT

CONDITION D'UTILISATION SPÉCIFIQUES À LA

SÉCURITÉ INTRINSÈQUE

Les précautions suivantes doivent être prises an de

préserver la sécurité intrinsèque :

• le signal de 4 à 20 mA et la réinitialisation à distance doivent être traités comme des

circuits séparés.

• Les éléments du boîtier sont en aluminium. Le boîtier doit être protégé contre le

risque d'incendie lié aux chocs ou aux frottements.

• Toutes les ouvertures du boîtier doivent être xées avec les écrous et/ou les prises

adaptés pour maintenir un niveau d'IP de IP66 pour les modèles homologèés UL et de

IP65 les modèles conformes ATEX/IECEz

• Le remplacement de pièces peut nuire à la sécurité intrinsèque.

SCHÉMA DE CONTRÔLE DE SÉCURITÉ INTRINSÈQUE ENREGISTRÉ UL

(SUFFIXE U2) :

Enregistré UL comme intrinsèquement sûrs pour l'utilisation en classe I div. 1 groupes

C et D ; classe II div. 1 groupes E, F et G ; classe III div. 1 ; classe I zone 0 AEx ia IIB

T4 Ga ; classe I zone 0 Ex ia IIB T4 Ga ; T4@63°C si installé en conformité avec le

schéma de contrôle 001744-48 de la page 6 du présent document.

CONFORME ATEX (MARQUAGE A2)

II 1 G Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

ia IIIC T120°C Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Process ≤ 120°C) / II 1 D Ex

Process ≤ 120°C) si installé en

conformité avec le schéma de contrôle 001744-81 de la page 7 du présent document.

CONFORME IECEx (MARQUAGE A2)

Ex ia IIB T4 Ga (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Da (-40°C ≤ Tamb ≤ 63°C) (-40°C ≤ T

Process ≤ 120°C) si installé en conformité avec le

Process ≤ 120°C) / Ex ia IIIC T120°C

schéma de contrôle 001744-81 de la page 7 du présent document.

PARAMÈTRES ENTRANTS DE SÉCURITÉ INTRINSÈQUE :

Signal de 4-20 mA, Vmax (Ui) = 28 V ; Imax (li) = 93 mA ; Ci = .022 μF ; Li = 0.373 mH ;

Pmax (Pi) = 651 mW

Réinitialisation à distance, Vmax (Ui) = 28 V ; Imax (li) = 93 mA ; Ci = négligeable ;

Li = 0 mH ; Pmax (Pi) = 651 mW

ALIMENTATION

RÉCEPTEUR

(LE CAS ÉCHÉANT)

4 à 20 mA

TION

ANCE

4

3

2

1

COMMUTATEUR DE RÉINITIALISATION À DIST

ALIMENTATION ÉLECTRIQUE REQUISE

La tension d'alimentation CC maximale est de 28 V. La tension d'alimentation CC

minimale nécessaire est basée sur les indications suivantes :

1. Tension minimum CC pour le modèle PMT2.

2. Résistance totale de charge.

3. Résistance totale du câble en plomb.

4. Baisse de tension de la barrière Zener (Modèle PMT2-XX-X-X2 uniquement).

La formule pour calculer la tension d'alimentation CC est :

VCC = VPMT2 + VLOAD + VLEADWIRE + VBARRIER

Où VPMT2 = 9,5 V

VLOAD = résistance totale de charge X 20 mA

VLEADWIRE = résistance totale du câble en plomb X 20 mA

VBARRIER = 8,1 V (baisse de tension classique de la barrière Zener pour ce type

d'utilisation)

Exemple 1 : Calcul de la tension minimum d'alimentation CC pour les modèles

intrinsèquement sûrs

Étape 1 VPMT2 = 9,5 V

Étape 2 Calcul du VLOAD. En utilisant les résistances de conversion standard de

l'industrie 250 Ω, VLOAD = 250 X 20 mA = 5

Étape 3 calcul du VLEADWIRE. Cet exemple part du principe que la résistance

des câbles en plomb dest de 10 Ω, VLEADWIRE = 10 X 20 mA = 0.2 V

Étape 4 VBARRIER = 8,1 V

Étape 5 VDC = VPMT2 + VLOAD + VLEADWIRE + VBARRIER = 9.5 + 5 + 0.2 +

8.1 = 22.8 V

CONTRÔLES

AVERTISSEMENT

PROCÉDURE DE MAINTENANCE EN

FONCTIONNEMENT

La maintenance en fonctionnement pour la réinitialisation,

la moyenne de durée, le contrôle des plages et des tests ne peuvent pas être

effectués en atmosphère inammable ou combustible.

Commutateur de réinitialisation (voir gure 2)

Maintenir le commutateur enfoncé pendant 3 secondes et le PMT2 se réinitialisera

numériquement. Il est recommandé de réinitialisation après un problème ou un

remplacement de ltre. La réinitialisation doit uniquement être effectuée lorsqu'il n'y a

pas de ux d'air dans la conduite.

Commutateur de sélection de durée moyenne

Le PMT2 fait la moyenne des niveaux en sortie sur la durée sélectionnée. Cela aura

pour effet de lisser les crêtes du signal apparues pendant les cycles normaux de

nettoyage des ltres.

Commutateur de sélection des plages et de test

Il y a 6 plages de sensibilité qui peuvent être choisies selon les matériaux que le PMT2

va détecter (voir tableau 1). Il existe également une option pour sortir un signal à 4 mA

ou 20 mA ; ces options peuvent aider lors de l'installation de l'émetteur ou pour la

détection de panne.

Commutateur

de

réinitialisation

Durée

moyenne

Plage et test

Vis de terre

Figure 1 : câblage général pour l'installation (non IS)

Figure 2

PARAMÉTRAGE

1000 pA

Alarme de pi

Installation

Vérier que le PMT2 est solidement xé sur la cheminée, le tuyau ou la conduite pour éviter

les vibrations durant le fonctionnement. Vérier que l'émetteur est correctement fermé.

Paramétrage du signal de contrôle

Vérier le câblage de l'alimentation électrique pour s'assurer que la polarité est

correcte avant de mettre le PMT2 sous tension. Mettre l'émetteur sous tension et

tourner le sélecteur de plage et de test vers 4 mA (position 2). Le PMT doit envoyer

4 mA, vérier la sortie avec un multimètre ou sur le dispositif qui reçoit le signal (PLC,

écran, etc.). Une fois la réception du signal de 4 mA vériée, basculer le sélecteur de

plage et de test sur 20 mA (position 1) et répéter le processus. Si la sortie est 0 mA,

vérier que le système est sous tension et vérier s'il y a des câbles débranchés.

Sélection de plage et test

Lors de la sélection de l'une des 6 plages disponibles, le niveau de référence et les

crêtes de signal maximales qui apparaissent lors du nettoyage des ltres doivent être

pris en compte. Les plages sélectionnées doivent avoir une résolution sufsante pour

surveiller le niveau de référence et capter les crêtes maximales pendant un cycle

de nettoyage. Les quatre plages linéaires envoient 4 mA à 5 pA et 20 mA à la plage

maximale. Les deux plages logarithmiques ont une résolution plus ne à l'extrémité

basse de la plage et moins ne à l'extrémité haute.

Position du commutateur Plage Sortie

1 Test 20 mA

2 Test 4 mA

3 5 à 100 pA 5 pA = 4 mA

4 5 à 500 pA 5 pA = 4 mA

5 5 à 1000 pA 5 pA = 4 mA

6 5 à 5000 pA 5 pA = 4 mA

7 Log 5 à 500 pA 5 pA = 4 mA

8 Log 5 à 5000 pA 5 pA = 4 mA

Remarque : les positions 9 et 0 ne sont pas utilisées.

Tableau 2 : commutateur de plage et de test

25 pA = 8 mA

50 pA = 12 mA

75 pA = 16 mA

100 pA = 20 mA

125 pA = 8 mA

250 pA = 12 mA

375 pA = 16 mA

500 pA = 20 mA

250 pA = 8 mA

500 pA = 12 mA

750 pA = 16 mA

1000 pA = 20 mA

1250 pA = 8 mA

250 pA = 12 mA

3750 pA = 16 mA

5000 pA = 20 mA

16 pA = 8 mA

50 pA = 12 mA

158 pA = 16 mA

500 pA = 20 mA

28 pA = 8 mA

158 pA = 12 mA

890 pA = 16 mA

5000 pA = 20 mA

PLAGES LOGARITHMIQUES

Les plages logarithmiques permettent de prolonger l'extrémité basse de l'échelle alors

que l'extrémité haute est compressée. Ceci offre une meilleure résolution pour la

surveillance du niveau de référence et permet tout de même à l'opérateur de voir les

crêtes de particules pendant les cycles de nettoyage. Les plages logarithmiques sont

recommandées pour les ltres à sac qui n'ont pas une grande tendance à générer des

crêtes de particules pendant les cycles de nettoyage.

ÉQUATIONS DES PLAGES LOGARITHMIQUES

(M-4)

pA = 10 x R + 0,699

(

16

pA = (pA) Pico ampères mesurés

M = (mA) Milliampères mesurés depuis le PMT2

R = 2 (pour la plage logarithmique de 5 à 500 pA)

R = 3 (pour la plage logarithmique de 5 à 5000 pA)

Exemple 1 : Plage logarithmique de 5 à 500 pA avec une sortie actuelle à 12 mA :

(12-4)

pA = 10 x 2 + 0,699p

(

16

pA = 50

Exemple 2 : Plage logarithmique de 5 à 5000 pA avec une sortie actuelle à 14 mA :

(14-4)

pA = 10 x 3 + 0,699pA

(

16

pA = 375

PARAMÉTRER LES ALERTES DE NIVEAU D'ÉMISSION

Le PMT2 fournira un signal de 4 à 20 mA selon la plage choisie lors du paramétrage.

Des alertes peuvent être programmées dans le PLC ou le système de contrôle sur

la base d'un signal de 4 à 20 mA en provenance de la sonde-émetteur à particules.

Il est recommandé de paramétrer deux points d'alerte. Un point d'alerte pour surveiller

les pics d'émission et le second pour détecter une augmentation par rapport au niveau

de référence.

L'alerte de surveillance des pics d'émission doit être paramétrée pour identier les

changements dans les crêtes dues aux cycles de nettoyage. Lorsque les ltres

commencent à s'user, la hauteur des crêtes et leur durée augmente. La fréquence

des pics d'émission augmentera également puisque les ltres auront besoin d'un

nettoyage plus fréquent au fur et à mesure de leur usure. En cas de signal continu au-

dessus du seuil d'alerte de pic d'émission, il est plus que probable qu'un ltre se soit

déchiré et doive être remplacé immédiatement.

L'alarme du niveau de référence doit détecter une augmentation dans la mesure

du niveau de référence. Le type de collecteur de poussière et la règlementation

des locaux dicteront à quel niveau positionner l'alerte du niveau de référence.

Typiquement, l'alerte de niveau de référence doit être positionnée 4 à 5 fois au-dessus

de la première mesure du niveau de référence lors de l'installation des ltres. Donc si

le niveau de référence est 10 pA, l'alerte de niveau de référence doit être positionnée

entre 40 pA et 50 pA. Il est recommandé de paramétrer un délai dans le PLC ou le

panneau de contrôle pour éviter les fausses alertes pendant les cycles de nettoyage.

Lorsque le signal en sortie du PMT2 est continuellement au-dessus du niveau d'alerte

de référence, il est temps de remplacer les ltres. Si les pics d'émission ont augmenté

alors que le niveau de référence reste inchangé, il s'agit d'une indication précoce que

les ltres commencent à s'user et qu'ils devront être changés dans peu de temps.

)

)

)

750 pA

d'émission

500 pA

Alarme de

niveau bas

5 pA

Pics plus fréquents

liés à l'usure du filtre

Pics liés au

nettoyage

c

HORAIRE

Figure 3 : émissions typiques de ltres

Pics et niveaux bas plus

fréquents liés à l'usure du filtre

Filtres remplacés

SÉLECTION DE CALCUL DE MOYENNE

Le PMT2 dispose d'une fonction numérique de calcul de moyenne du fait du ux

irrégulier de particules et des crêtes durant les cycles de nettoyage. Il y a dix options

pour le calcul de moyenne allant de 1 à 360 secondes. Le calcul numérique de

moyenne prend la moyenne glissante des lectures pour la durée sélectionnée. Cela

va lisser les crêtes du signal liées aux uctuations de particules qui pourraient fausser

le paramétrage des alertes. Il est important de sélectionner des paramètres de calcul

de moyenne qui permettront à l'opérateur de visualiser les cycles de nettoyage. Il est

recommandé de surveiller le niveau de référence et la tendance de crête à crête entre

les cycles de nettoyage.

RÉGLAGE DU ZÉRO

Même si le PMT2 est initialisé en usine, il est recommandé de réinitialiser l'émetteur

après l'installation pour assurer la meilleure précision possible. Lors de la réinitialisation

du PMT2, vérier que le collecteur de poussière est fermé et qu'il n'y a pas de ux d'air

dans la conduite, la cheminée ou le tuyau que l'émetteur surveille. Il est recommandé

de réinitialiser PMT2 une fois tous les 12 mois pour des performances optimales. Merci

de vérier la règlementation locale et les lois en vigueur ; en effet, les normes sur la

propreté de l'air peuvent imposer une réinitialisation selon un calendrier donné en

fonction de l'utilisation. Il y a deux façons de réinitialiser le PMT2. La première méthode

consiste à utiliser le commutateur de réinitialisation à l'avant de l'émetteur. Maintenir le

commutateur enfoncé pendant 3 secondes et l'émetteur commencera sa réinitialisation.

La seconde méthode consiste à utiliser la réinitialisation à distance. Envoyer la tension

CC comme indiqué sur la gure 4 dans la borne de réinitialisation située à l'arrière

de l'émetteur pendant au moins 3 secondes pour que l'émetteur commence sa

réinitialisation. Pendant que l'émetteur se réinitialise, le PMT2 enverra environ 3,5 mA.

La fonction de réinitialisation dure environ 3 minutes. Lorsque la réinitialisation est

terminée, le signal redevient normal et l'émetteur est prêt à fonctionner.

Réinitialisation à distance

10 à 28 V

- +

Commutateur de réinitialisation

MAINTANCE/REPARATION

Après l'installation nale du PMT2 Série, aucune maintenance de routine n'est